checking oil OPEL GT-R 1973 Service Manual

[x] Cancel search | Manufacturer: OPEL, Model Year: 1973, Model line: GT-R, Model: OPEL GT-R 1973Pages: 625, PDF Size: 17.22 MB

Page 20 of 625

LUBRICATION AND MAINTENANCE OC-11

Throttle Linkage

Check for damaged or missing parts, interference or

binding. Any deficiencies should be corrected with-

out delay.

Headlights

Check for proper aim. Correct as necessary. More

frequent checks should be made if oncoming motor-

ists signal when you are already using your low

beams, or if illumination of the area ‘ahead seems

inadequate.

Underbody

In geographic areas using a heavy concentration of

road salt or other corrosive materials for snow re-

moval or road dust control, flush and inspect the

complete under side of the car at least once each

year, preferably after a winter’s exposure. Particular

attention should be given to cleaning out underbody

members where dirt and other foreign materials may

have collected.

EMISSION CONTROL MAINTENANCE

Thermostatically Controlled Air Cleaner

Inspect installation to make certain that all hoses and

ducts are connected and correctly installed. Also,

check valve for proper operation.

Carburetor Choke

Check choke mechanism for free operation. A bind-

ing condition may have developed from petroleum

gum formation on the choke shaft or from overtight-

ening of air cleaner clamp. Also check electric choke

terminal connections and fuse.

Timing, Dwell and Distributor

Adjust timing and dwell accurately as outlined under

Tune-Up in Group 6 at the first 4 months or 6,ooOmiles of operation, then at 12 month or

12,OQO mile

intervals. Adjustments must be made with test equip-

ment known to be accurate.

Replace distributor points every 12 months or 12,000

miles and carefully clean and inspect the complete

distributor cap to prevent misfiring and deteriora-

tion.

Carburetor and Idle

SpeedTorque carburetor attaching bolts and/or nuts to 12

ft.lbs. to compensate for compression of gasket atiirst 4 months or 6,000 miles of vehicle operation.Adjust idle speed to specifications with known accu-

rate equipment.

Proper functioning of the carburetor is particularly

essential to control of emissions. Correct mixtures

for emission compliance and idle quality have been

preset by Opel. Plastic idle mixture limiters have

been installed on the idle mixture screw, idle air

screw, and throttle stop screw to preclude unauthor-

ized adjustment. The plastic caps on the idle mixture

screw and the idle adjustment screw must be

removed to perform an idle speed adjustment. The

plastic cap on the throttle stop screw is not to be

removed unless some major carburetor repair or re-

placement which affects the throttle stop screw ad-

justment has been necessary.

Carburetor Fuel Inlet Filter

Replace filter at 12 month or

12,OCO mile intervals

or more often if clogged.

Spark Plugs

Replace at

6,ooO mile intervals when operating with

leaded fuels or at 12,000 mile intervals when using

unleaded fuels. Use of leaded fuels results in lead

deposits on spark plugs and can cause misfiring at

mileages less than

12,OilO miles. Where misfiring oc-

curs prior to

6,ooO miles, spark plugs in good condi-

tion can often be cleaned, tested and reinstalled in an

engine with acceptable results.

Spark Plug Wires

Inspect spark plug wires for evidence of checking or

cracking of exterior insulation and tight fit in the

distributor cap and at the spark plugs. Exterior of

wires should be cleaned, any evidence of corrosion

on ends removed and wire replace if deteriorated.

Positive Crankcase Ventilation System

The PCV metered orifice should be cleaned at 12,000

mile intervals under normal use, and at 6,000 mile

intervals when the vehicle is used under the follow-

ing conditions: driving in dusty conditions, extensive

idling, trailer pulling and short trip operation at

freezing temperatures (engine not thoroughly

warmed-up).

Evaporation Control System

Check all fuel and vapor lines and hoses for proper

connections and correct routing as well as condition.

Remove canister and check for cracks or damage.

Replace damaged or deteriorated parts as necessary.

Replace filter in open end of canister at 24month/24,000 mile intervals.

Page 31 of 625

1 B- 101973 OPEL SERVICE #MANUAL

STARTlhG SYSTEM

/

ALL

MODEILS

CONTENTS

Subject

DESCRIPTION AND OPERATION:

Starting SystemDescription

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . \

. . . . . .

DIAGNOSIS:

Starting System Diagnosis,

. . . . . . . . . . . . . . . . . , . . . . . . . . . . . . . . . . . . \

. . . . . . . .

MAINTENANCE AND ADJUSTMENTS:Starting System

Checks. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . \

. . . . . . . . . . . . . .

MAJOR REPAIR:

Removal. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . \

. . . . . . . . . . . . . . . . . ., . . . . . . . . . . . . . . . . . . . . . . . . . .

Disassembly. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . a.... . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .\

CleaningandInspecting Parts. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . \

. .

Replacing Field Coils. . . . . . . . . . . , . . . . . . . . . . . . . . . . . . . . . . . . \

. . . . . . . . . . . . . . . . . . . .

Checking and Replacing Brushes. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Replacing Bushings. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . , . . . . \

. . . . . . . . . . . . . . . . . . . . . .

Assembly. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . \

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . \

. . . . . .

Installation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . \

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . \

. . . .

SPECIFICATIONS:

Starter Specifications

. . . . , . , . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Page No.

lB-10

16-10

18-12

18-13

18-13

18-14

18-14

16-15

18-16

lB-16

18-17

18-17

DESCRIPTION AND OPERATION

STARTING SYSTEM DESCRlPTlqN

The new Delco Remy starter for 1973 is a brush-

type series wound electric motor equipped with an

overrunning clutch and operated by a

soienoid. The

field frame is enclosed by the commutator end frame

and the drive housing and carries the pole shoes and

the

field coils. The armature has a spline on the drive

end which carries the over-running clutch and pinion

assembly. The armature shaft is supported in

sin-

tered bronze bushings in the commtitator end frame

and the drive end housing. These bushings are

packed with lubricant during initial assembly

and

TROUBLE DIAGNOSIS ’

STARTING SYSTEM DIAGNOSIS/

require no additional lubrication between overhaul

periods.

As the starter is operated by turning the ignition

switch on the instrument panel, the shift lever is

moved against spring tension. By means of the guide

ring, the shift lever moves the pinion into mesh with

the flywheel ring gear.

After the pinion meshes with the flywheel ring gear

teeth, the solenoid contact disc closes the circuit and

the engine is cranked. When the engine starts, the

speed of the rotating flywheel causes the pinion to

over-run the clutch and armature. The pinion con-

tinues to be engaged as long as the shift lever is kept

in the cranking position.

In case of cranking motor breakdown, it should be kept in mind that the

relevant cause(s) for the trouble may not only lie in the cranking mot\

or itself

Page 35 of 625

lB- 14 1973 OPEL SERVICE MANUAL !

6. Remove shift lever shaft and: lift armature aid

shift lever assembly.

7. Drive back retaining ring on armature shaft. See

Figure

lB-5.

8. Take the lock ring, retaining ring, and

over&-

ning clutch and pinion off armature shaft. Cheqk

groove in shaft for burrs and remove with a soft tile.

Cleaning and Inspecting Parts

1. Clean and check all parts. Replace defective parts.

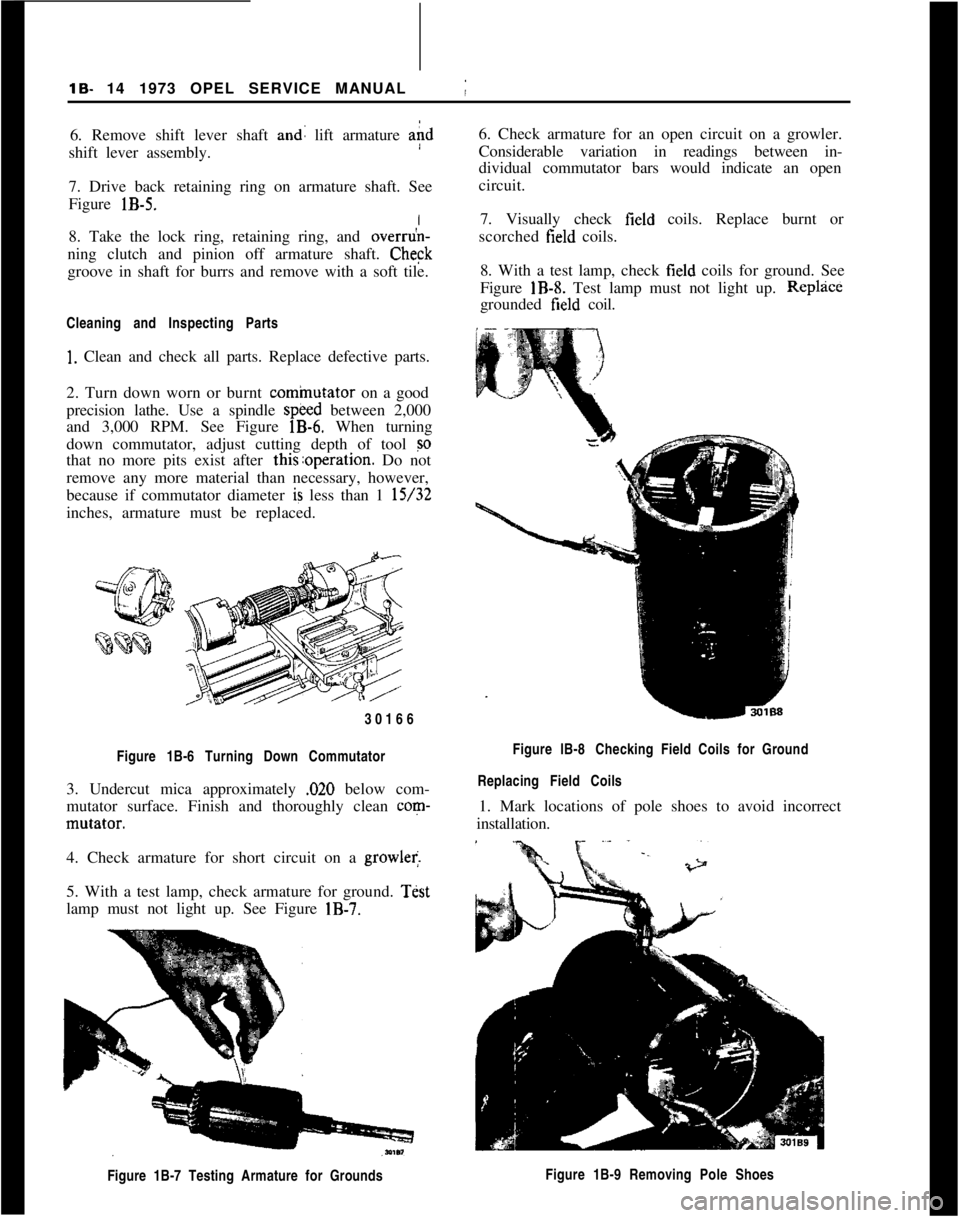

2. Turn down worn or burnt

cominutator on a good

precision lathe. Use a spindle

speed between 2,000

and 3,000 RPM. See Figure

lB-6. When turning

down commutator, adjust cutting depth of tool

so

that no more pits exist after this:operation. Do not

remove any more material than necessary, however,

because if commutator diameter

is less than 1 15/32

inches, armature must be replaced.

30166

Figure 1B-6 Turning Down Commutator

3. Undercut mica approximately ,020 below com-

mutator surface. Finish and thoroughly clean

corn-

mutator.

I

4. Check armature for short circuit on a

growler.

5. With a test lamp, check armature for ground.

Test

lamp must not light up. See Figure

IB-7.

Figure 1B-7 Testing Armature for Grounds

j

6. Check armature for an open circuit on a growler.

Considerable variation in readings between in-

dividual commutator bars would indicate an open

circuit.

7. Visually check

field coils. Replace burnt or

scorched

field coils.

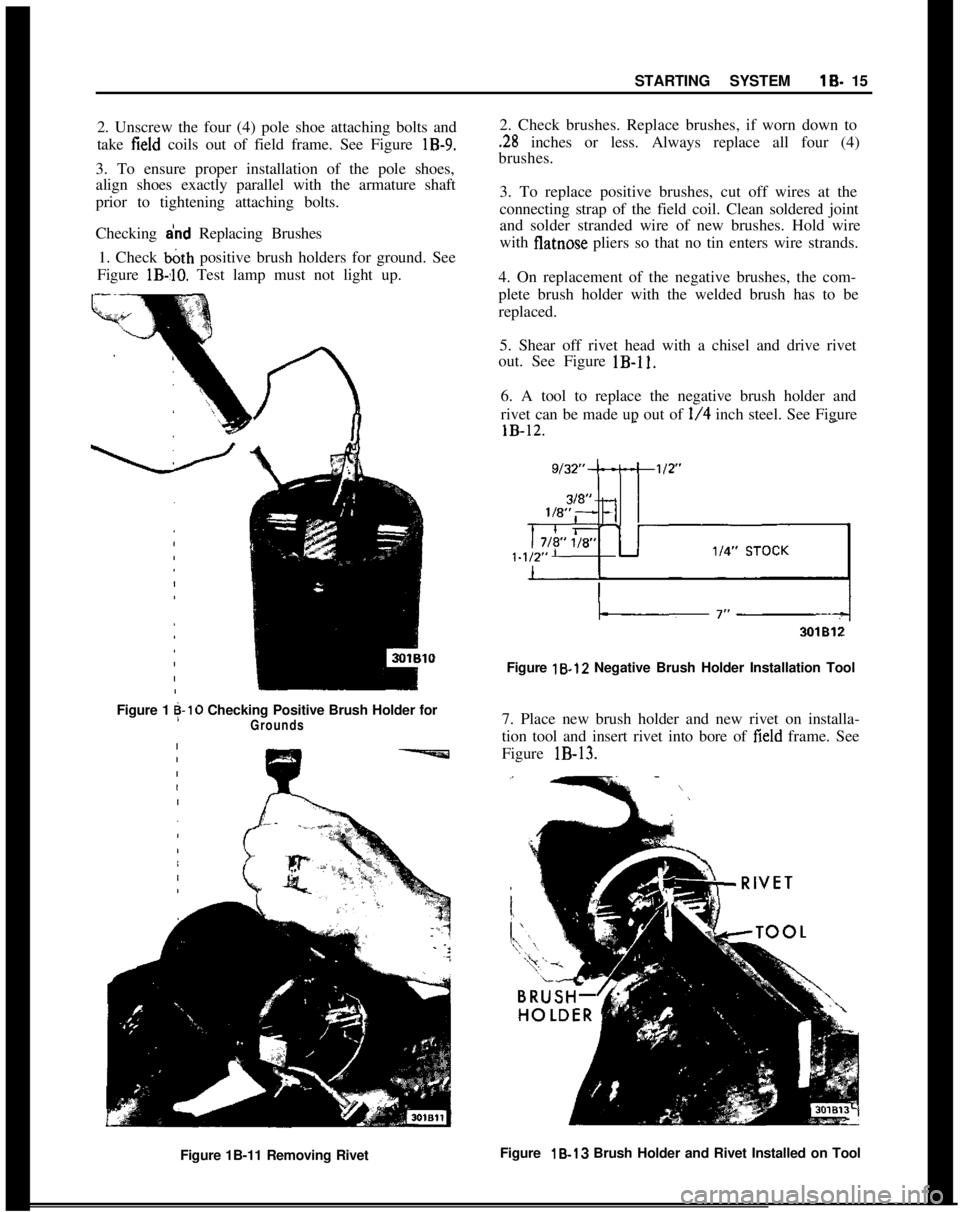

8. With a test lamp, check

field coils for ground. See

Figure

IB-8. Test lamp must not light up. Replzice

grounded field coil.

Figure lB-8 Checking Field Coils for Ground

Replacing Field Coils

1. Mark locations of pole shoes to avoid incorrect

installation.

Figure 1B-9 Removing Pole Shoes

Page 36 of 625

STARTING SYSTEMlS- 15

2. Unscrew the four (4) pole shoe attaching bolts and

take

field coils out of field frame. See Figure lB-9.

3. To ensure proper installation of the pole shoes,

align shoes exactly parallel with the armature shaft

prior to tightening attaching bolts.

Checking

a’nd Replacing Brushes

1. Check

b&h positive brush holders for ground. See

Figure

lB-,lO. Test lamp must not light up.

Figure 1g-10 Checking Positive Brush Holder forGrounds

2. Check brushes. Replace brushes, if worn down to

.28 inches or less. Always replace all four (4)

brushes.

3. To replace positive brushes, cut off wires at the

connecting strap of the field coil. Clean soldered joint

and solder stranded wire of new brushes. Hold wire

with

flatnose pliers so that no tin enters wire strands.

4. On replacement of the negative brushes, the com-

plete brush holder with the welded brush has to be

replaced. 5. Shear off rivet head with a chisel and drive rivet

out. See Figure

lB-11.

6. A tool to replace the negative brush holder and

rivet can be made up out of

l/4 inch steel. See Figure

Figure 18.12 Negative Brush Holder Installation Tool

7. Place new brush holder and new rivet on installa-

tion tool and insert rivet into bore of

field frame. See

Figure

lB-13.

Figure 1B-11 Removing Rivet Figure 18-13

Brush Holder and Rivet Installed on Tool

Page 42 of 625

IGNITION SYSTEMlC-214. Rota&distributor counterclockwise slightly until

contact pbints just start to open. This must be done

very carefully or engine will not start.

5. Install distributor cap. Make sure spark plug wires

are correctly installed in distributor cap, through clip

and on spark plugs.

Finish TimingIContact boint gap

(.016” at widest gap) or dwell 50

degrees plus or minus 3 degrees should always be

checked before adjusting ignition timing.

1. Connekt timing light to No. 1 spark plug.

2. Disconnect and plug vacuum advance unit and

retard u$it hoses.

3. Connect a tachometer from distributor side of coil

to

groun$l.4. Start dngine. Set idle speed to 900 RPM.

5. Rotate distributor as necessary to align timing

marks. T;ming mark is a steel ball embedded in the

flywheel and a pointer in a window in the right fly-

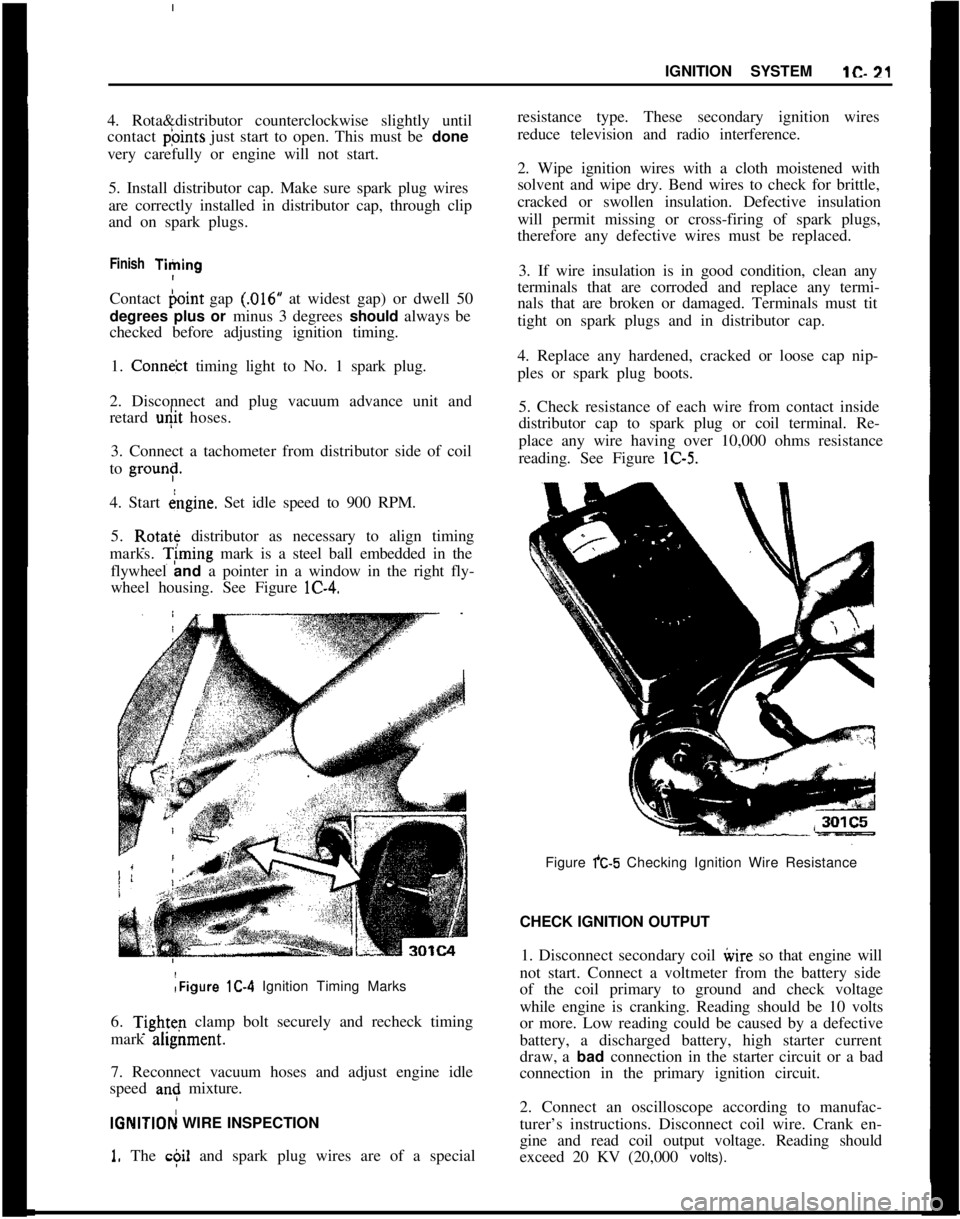

wheel housing. See Figure lC-4.:Figure lC-4 Ignition Timing Marks

6.

Tightq clamp bolt securely and recheck timing

mark ahgnment.

7. Reconnect vacuum hoses and adjust engine idle

speed

an: mixture.

IGNlTlOFj WIRE INSPECTION

1. The c$il and spark plug wires are of a specialresistance type. These secondary ignition wires

reduce television and radio interference.

2. Wipe ignition wires with a cloth moistened with

solvent and wipe dry. Bend wires to check for brittle,

cracked or swollen insulation. Defective insulation

will permit missing or cross-firing of spark plugs,

therefore any defective wires must be replaced.

3. If wire insulation is in good condition, clean any

terminals that are corroded and replace any termi-

nals that are broken or damaged. Terminals must tit

tight on spark plugs and in distributor cap.

4. Replace any hardened, cracked or loose cap nip-

ples or spark plug boots.

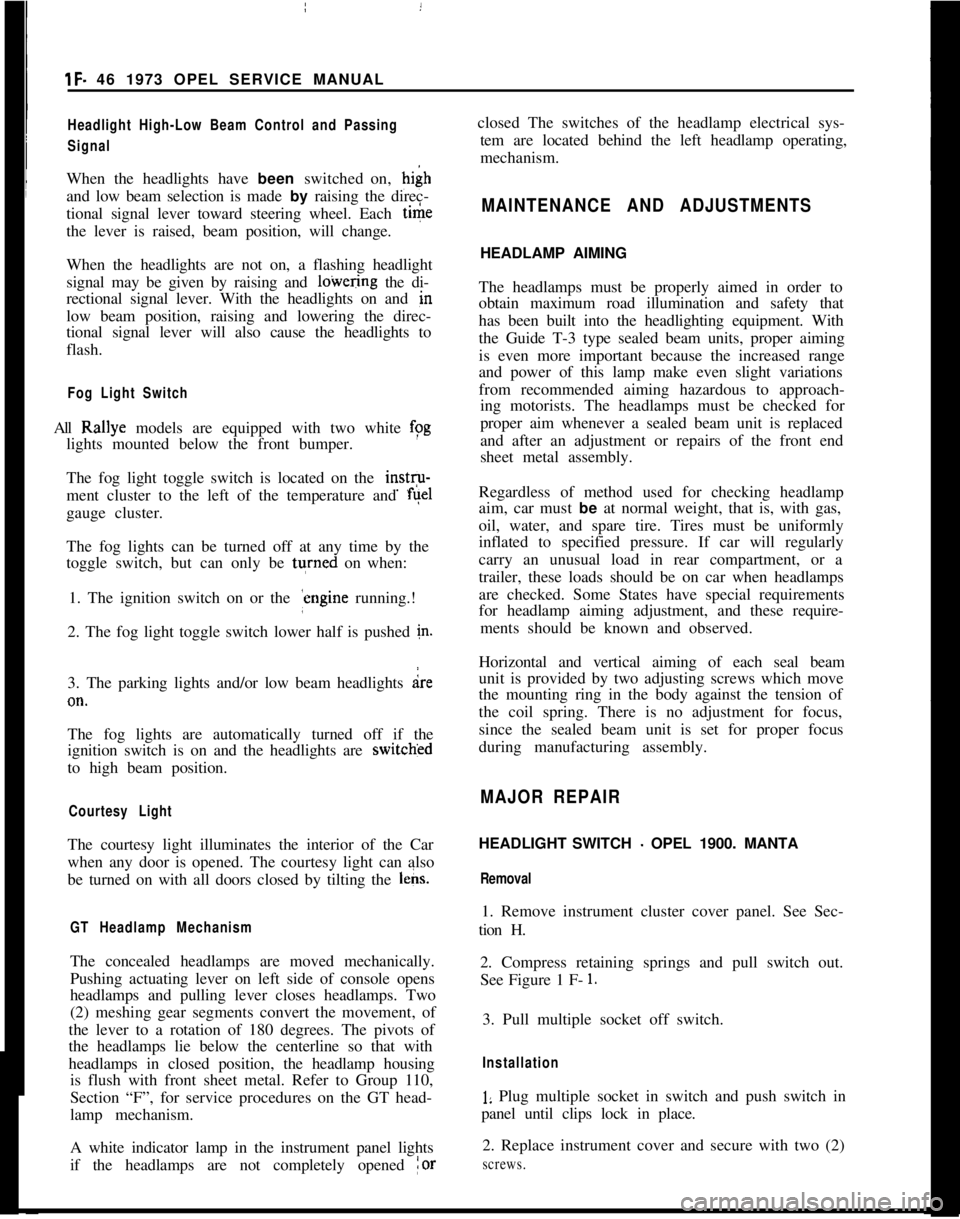

5. Check resistance of each wire from contact inside

distributor cap to spark plug or coil terminal. Re-

place any wire having over 10,000 ohms resistance

reading. See Figure lC-5.

Figure fC-5 Checking Ignition Wire Resistance

CHECK IGNITION OUTPUT

1. Disconnect secondary coil ivire so that engine will

not start. Connect a voltmeter from the battery side

of the coil primary to ground and check voltage

while engine is cranking. Reading should be 10 volts

or more. Low reading could be caused by a defective

battery, a discharged battery, high starter current

draw, a bad connection in the starter circuit or a bad

connection in the primary ignition circuit.

2. Connect an oscilloscope according to manufac-

turer’s instructions. Disconnect coil wire. Crank en-

gine and read coil output voltage. Reading should

exceed 20 KV (20,000 volts).

Page 67 of 625

1F. 46 1973 OPEL SERVICE MANUAL

’

/

Headlight High-Low Beam Control and Passing:

SignalI

When the headlights have been switched on, high

and low beam selection is made by raising the direc-

tional signal lever toward steering wheel. Each

ti&the lever is raised, beam position, will change.

When the headlights are not on, a flashing headlight

signal may be given by raising and lotiering the di-

rectional signal lever. With the headlights on and

inlow beam position, raising and lowering the direc-

tional signal lever will also cause the headlights to

flash.

Fog Light SwitchAll Rallye models are equipped with two white f?g

lights mounted below the front bumper.

The fog light toggle switch is located on the

insty-ment cluster to the left of the temperature and

fuelgauge cluster.

/

The fog lights can be turned off at any time by the

toggle switch, but can only be tyrned on when: :

1. The ignition switch on or the

?gine running.!

2. The fog light toggle switch lower half is pushed

in.3. The parking lights and/or low beam headlights

are

OKThe fog lights are automatically turned off if the

ignition switch is on and the headlights are switched

to high beam position.

Courtesy LightThe courtesy light illuminates the interior of the Car

when any door is opened. The courtesy light can also

be turned on with all doors closed by tilting the l&s.

GT Headlamp MechanismThe concealed headlamps are moved mechanically.

Pushing actuating lever on left side of console opens

headlamps and pulling lever closes headlamps. Two

(2) meshing gear segments convert the movement, of

the lever to a rotation of 180 degrees. The pivots of

the headlamps lie below the centerline so that with

headlamps in closed position, the headlamp housing

is flush with front sheet metal. Refer to Group 110,

Section “F”, for service procedures on the GT head-

lamp mechanism.

A white indicator lamp in the instrument panel lights

if the headlamps are not completely opened lorclosed The switches of the headlamp electrical sys-

tem are located behind the left headlamp operating,

mechanism.

MAINTENANCE AND ADJUSTMENTSHEADLAMP AIMING

The headlamps must be properly aimed in order to

obtain maximum road illumination and safety that

has been built into the headlighting equipment. With

the Guide T-3 type sealed beam units, proper aiming

is even more important because the increased range

and power of this lamp make even slight variations

from recommended aiming hazardous to approach-

ing motorists. The headlamps must be checked for

proper aim whenever a sealed beam unit is replaced

and after an adjustment or repairs of the front end

sheet metal assembly.

Regardless of method used for checking headlamp

aim, car must be at normal weight, that is, with gas,

oil, water, and spare tire. Tires must be uniformly

inflated to specified pressure. If car will regularly

carry an unusual load in rear compartment, or a

trailer, these loads should be on car when headlamps

are checked. Some States have special requirements

for headlamp aiming adjustment, and these require-

ments should be known and observed.

Horizontal and vertical aiming of each seal beam

unit is provided by two adjusting screws which move

the mounting ring in the body against the tension of

the coil spring. There is no adjustment for focus,

since the sealed beam unit is set for proper focus

during manufacturing assembly.

MAJOR REPAIRHEADLIGHT SWITCH

- OPEL 1900. MANTA

Removal1. Remove instrument cluster cover panel. See Sec-

tion H.

2. Compress retaining springs and pull switch out.

See Figure 1 F-

1.3. Pull multiple socket off switch.

Installation

1: Plug multiple socket in switch and push switch in

panel until clips lock in place.

2. Replace instrument cover and secure with two (2)

screws.

Page 253 of 625

48. 221973 OPEL SERVICE MANUAL

9. Position

case assembly and outer races in the car-

rier. Use a soft-faced hammer to drive the case into

the carrier until the side bearing outer races bottom

in their bores.

10. Install side bearing caps in their original location

and torque the bolts to 33

lb.ft.IN. LB. TORQUL

11. Rotate case assembly several times to seat the

bearings. Check backlash and preload using a torque

wrench on a ring gear attaching bolt. See Figure 4B-

35. Torque required to turn case should be 20 to 30

Ib.in. for new bearings or 10 to 20 lb.in., for used

bearings. If torque is not correct, it will be necessary

to r&him the side bearings.

12. Insta!l torque tube assembly.

13. Install axle shafts.Figure 48.35 Checking Side Bearing

Preload

SPECIFICATIONS

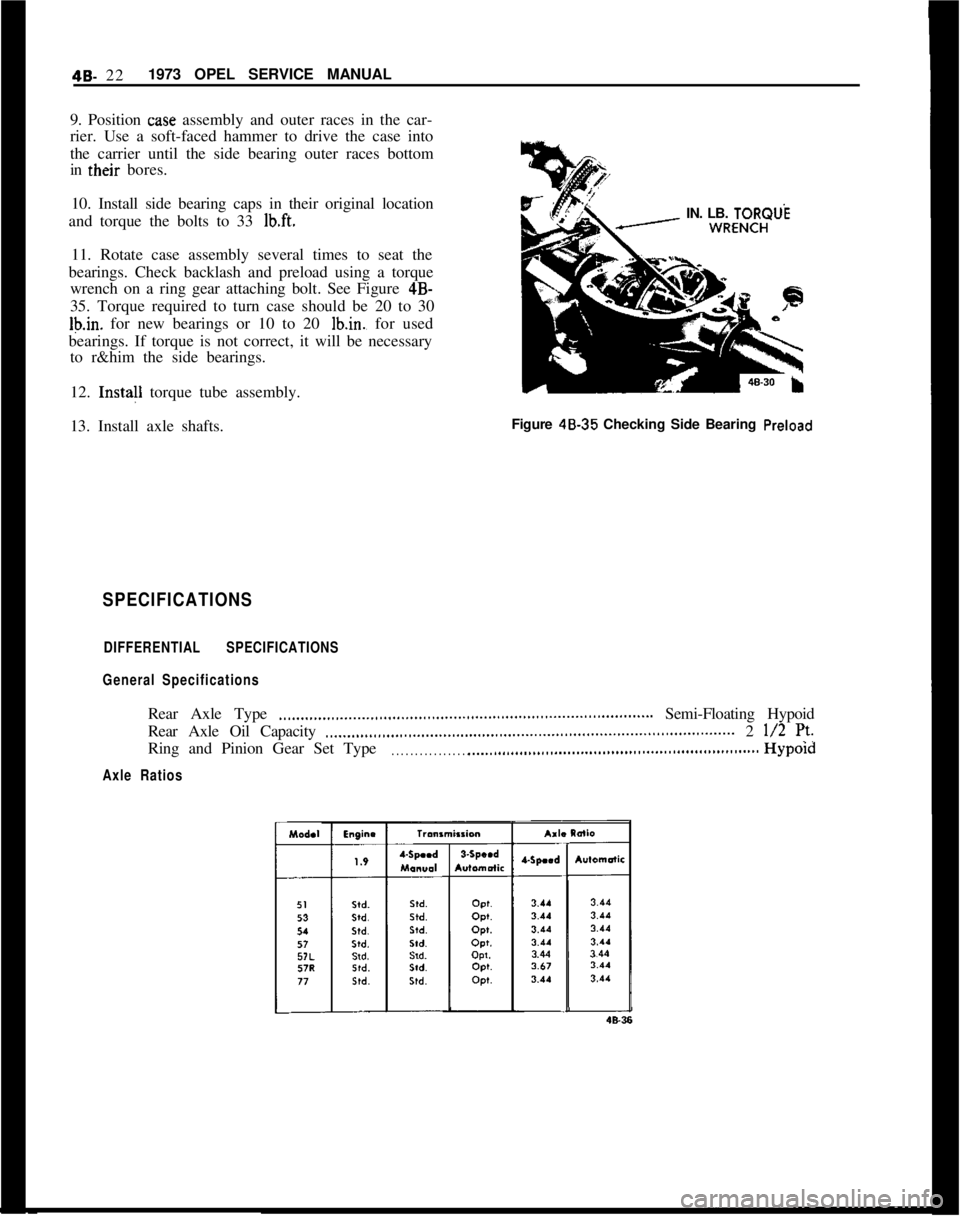

DIFFERENTIAL SPECIFICATIONS

General SpecificationsRear Axle Type

.,,...,,,...,,_...._..,,...,,,...,,,....,,.,...,,.,,...,,..,,,........................ Semi-Floating Hypoid

Rear Axle Oil Capacity

..____,,...,,,...,.,..,............,,..,,..,,................................................. 2 l/2 7’.Ring and Pinion Gear Set Type

. . . . . . . . . . . . . . . . . .._................................................................Hypold

Axle Ratios

Page 274 of 625

DISC BRAKES5B- 15

ConditionPossible Cause

2. Binding brake pedal

mechanism.Correction

2. Check and lubricate, ifnecessary.3. Corroded caliper

assembly.3. Clean and lubricate.

MAINTENANCE AND ADJUSTMENTSDISC BRAKE MAINTENANCE

Checking Brake Fluid Level

The brake fluid level in the brake fluid container

must be checked during predelivery inspection, then

every 3,000 miles during inspection and preventive

maintenance servicing.

The brake fluid level must not be higher than the

inscription “MAX” and must be at least up to

“MIN”. Replenish brake fluid, if necessary.

Because of the relatively large brake caliper bore

cross section and the self-adjustment of the disc

brakes, resulting in a greater piston travel to compen-

sate for friction pad wear, the brake fluid level drops

faster than in fluid containers for drum brakes with

their smaller wheel brake cylinders. For this reason

pay special attention to the fluid level in the brake

fluid container.

Drop of brake fluid level can be due to friction pad

wear and may not be due to leakage in the braking

system.On loss of brake fluid due to leakage, the brake sys-

tem must be checked thoroughly.

Friction Pad Adjustment

Friction pad adjustment is not necessary on the front

wheel disc brakes as this is done automatically by the

pistons in the brake calipers.

Lubricating Front Wheel Bearings

When removing one or both brake discs, check lu-

brication of front wheel bearings and the cavity of

the wheel hub and replenish if necessary (see operat-

ion

“Removing and Reinstalling Brake Disc”).

When carrying out other work on disc brakes which

does not necessitate the removal and installation of

the brake disc, lubricating wheel bearings is not

necessary.Checking Disc Brake Friction Pads for Wear

Whenever a disc brake equipped car is in for periodic

service, while the car is raised, the friction pads in

both brake calipers should be checked for wear by

making a simple measurement. Worn or oily friction

pads must be replaced.

Measure friction pad wear as follows:

1. Remove friction pads.

2. Using a one-inch micrometer, measure the thick-

ness of the pad and friction plate. See Figure

5B-23.Figure 58-23 Checking Brake Friction Pad Thickness

3. If any one of the four measurements is less than

-.280, replace all four friction pads. (Partial replace-

ment of friction pads would cause unequal braking.)

Removal and Installation of Friction Pads

1. Raise car and remove front wheels.

2. Drive dowel pins out of brake calipers toward

center of car. See Figure

5B-24. Dowel pins must be

driven inward because they are secured by enlarge

fluted inner ends.

3. Remove friction pads from brake calipers. See

Figure

5B-25.

Page 307 of 625

6A- 161973 OPEL SERVICE MANUALInspection of Connecting Rod Bearings and

Crankshaft JournalsRemove oil pan.

After removal of oil pan, disconnect two connecting

rods at a time from crankshaft and inspect the bear-

ings and crankpin journals. While,tuming crankshaft

it is necessary to

t&porarily reconnect the rods to

crankshaft to avoid possibility of damaging the jour-

nals through contact with loose rods.

If connecting rod bearings are chipped or scored they

should be replaced. If bearings

are in good physical

condition check for proper clearance on crankpins as

described under, checking clear$nce and selecting

replacement connecting rod beartngs.

If crankpin journals are scored or ridged, the crank-

shaft must be replaced, or reground for undersize

bearings, to insure satisfactory life of connecting rod

bearings. Slight roughness may be polished out withfine grit polishing cloth thoroughly wetted with en-

gine oil. Burrs may be honed off with a fine oil stone.

Use an outside micrometer to check crankpins for

out- of-round. If crankpins are mpre than

,002” out-

of- round, satisfactory life of new ,bearings cannot be

expected.

Checking Clearance and Selecting Replacement

Connecting Rod BearingsService bearings are furnished in standard size and

several undersizes. The clearance of connecting rod

(and crankshaft) bearings may be checked by use of

Plastigage, Type PG-1 (green), or equivalent, which

is soluble in oil.

1. Remove connecting rod cap with bearing shell.

Wipe off oil from bearing and crankpin journal, also

blow oil out of hole in crankshaft.

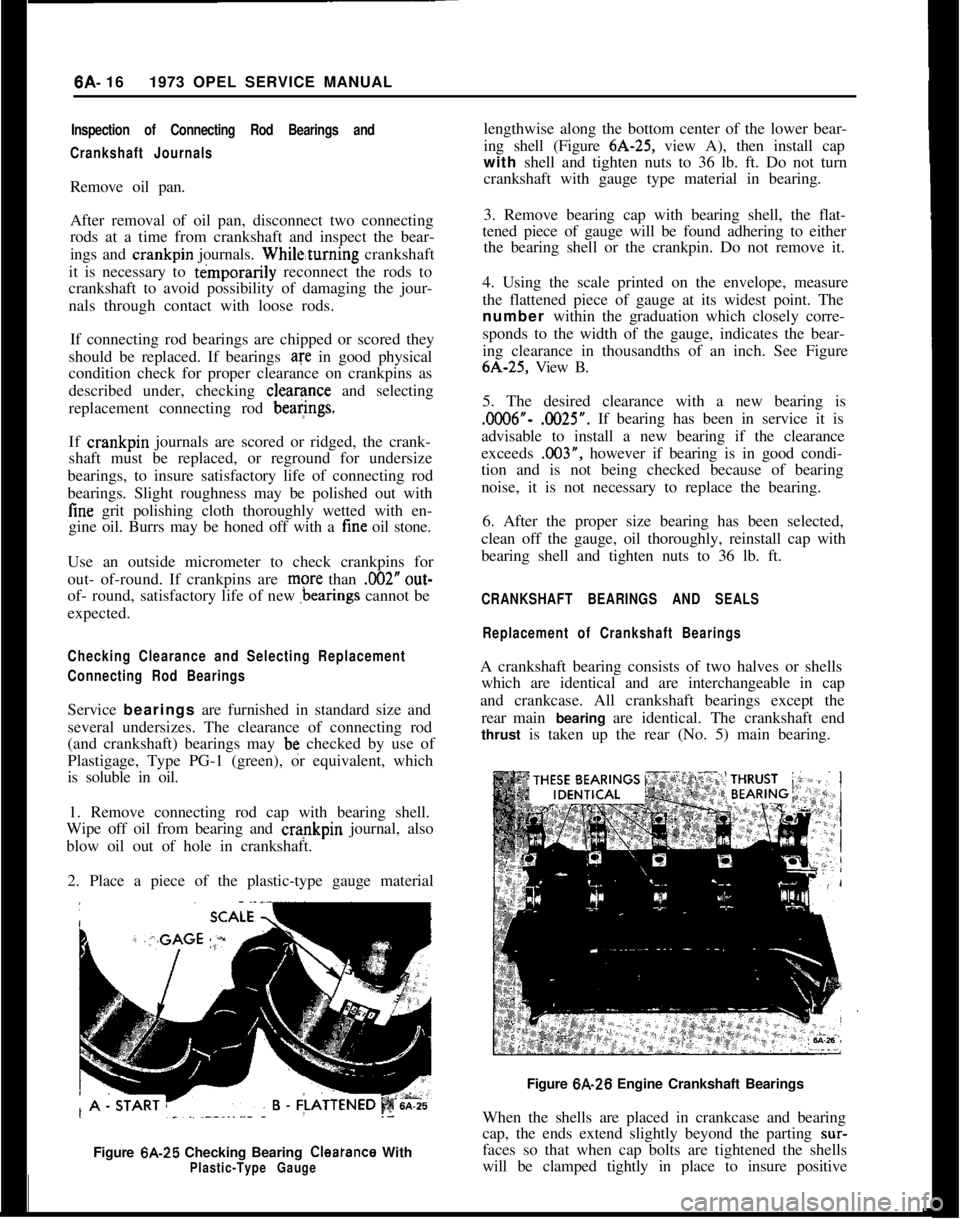

2. Place a piece of the plastic-type gauge material

Figure 6A-25 Checking Bearing

Cleatance WithPlastic-Type Gaugelengthwise along the bottom center of the lower bear-

ing shell (Figure 6A-25, view A), then install cap

with shell and tighten nuts to 36 lb. ft. Do not turn

crankshaft with gauge type material in bearing.

3. Remove bearing cap with bearing shell, the flat-

tened piece of gauge will be found adhering to either

the bearing shell or the crankpin. Do not remove it.

4. Using the scale printed on the envelope, measure

the flattened piece of gauge at its widest point. The

number within the graduation which closely corre-

sponds to the width of the gauge, indicates the bear-

ing clearance in thousandths of an inch. See Figure6A-25, View B.

5. The desired clearance with a new bearing is.0006”- .0025”. If bearing has been in service it is

advisable to install a new bearing if the clearance

exceeds .003”, however if bearing is in good condi-

tion and is not being checked because of bearing

noise, it is not necessary to replace the bearing.

6. After the proper size bearing has been selected,

clean off the gauge, oil thoroughly, reinstall cap with

bearing shell and tighten nuts to 36 lb. ft.

CRANKSHAFT BEARINGS AND SEALS

Replacement of Crankshaft BearingsA crankshaft bearing consists of two halves or shells

which are identical and are interchangeable in cap

and crankcase. All crankshaft bearings except the

rear main bearing are identical. The crankshaft end

thrust is taken up the rear (No. 5) main bearing.

Figure 6A-26 Engine Crankshaft Bearings

When the shells are placed in crankcase and bearing

cap, the ends extend slightly beyond the parting

sur-faces so that when cap bolts are tightened the shells

will be clamped tightly in place to insure positive

Page 308 of 625

ENGINE MECHANICAL AND MOUNTS6A- 17

seating and to prevent turning.The ends of she//s

must never be tiled flush with parting surface of

crankcase or bearing cap.Crankshaft bearings are the precision type which do

not require reaming to size. Shims are not provided

for adjustment since worn bearings are readily re-

placed with new bearings of proper size. Bearings for

service replacement are furnished in standard size

and undersizes. Under no circumstances should

crankshaft bearing caps be tiIed to adjust for wear in

old bearing.After removal of oil pan, pipe and screen assembly,

perform the following removal, inspection and in-

stallation operations on each crankshaft bearing in

turn so that the crankshaft will be well supported by

the other bearings.

If crankshaft has been removed to check straightness

the following procedure is suggested. Rest crank-

shaft on “V-blocks” at number one and number live

main bearing journals. Check indicator runout at

No. 3 main bearing journal. Total indicator reading

should not exceed

.C012”.1. Since any service condition which affects the

crankshaft bearings may also affect the connecting

rod bearings, it is advisable to inspect connecting rod

bearings

first. If crankpins are worn to the extent

that crankshaft should be replaced or reground, re-

placement of crankshaft bearings only will not be

satisfactory.

If replacement of cylinder block or crankshaft is re-

quired, always check main bearing clearance with

plastic-type gauge to obtain specified limits.

2. Remove one bearing cap, then clean and inspect

lower bearing shell and the crankshaft journal. If

journal surface is scored or ridged, the crankshaft

must be replaced or reground to insure satisfactory

operation with new bearings. Slight roughness may

be polished out with tine grit polishing cloth

thoroughly wetted with engine oil, and burrs may be

honed off with a tine stone.

3. If condition of lower bearing shell and crankshaft

journal is satisfactory, check the bearing clearance

with a plastic-type gauge.

4. When checking a crankshaft bearing with plastic-

type gauging material, turn crankshaft so that oil

hole is up to avoid dripping of oil on the gauge

material. Place paper shims in lower halves of adja-

cent bearings and tighten cap bolts to take the weight

of crankshaft

off the lower shell of beating being

checked.5. If bearing clearance exceeds

.C03”, it is advisable

to install a new bearing; however, if bearing is in

good condition and is not being checked because ofbearing noise, it is not necessary to replace the bear-

ing.6. Loosen all crankshaft bearing cap bolts

l/2 turn,

and remove cap of bearing to be replaced.

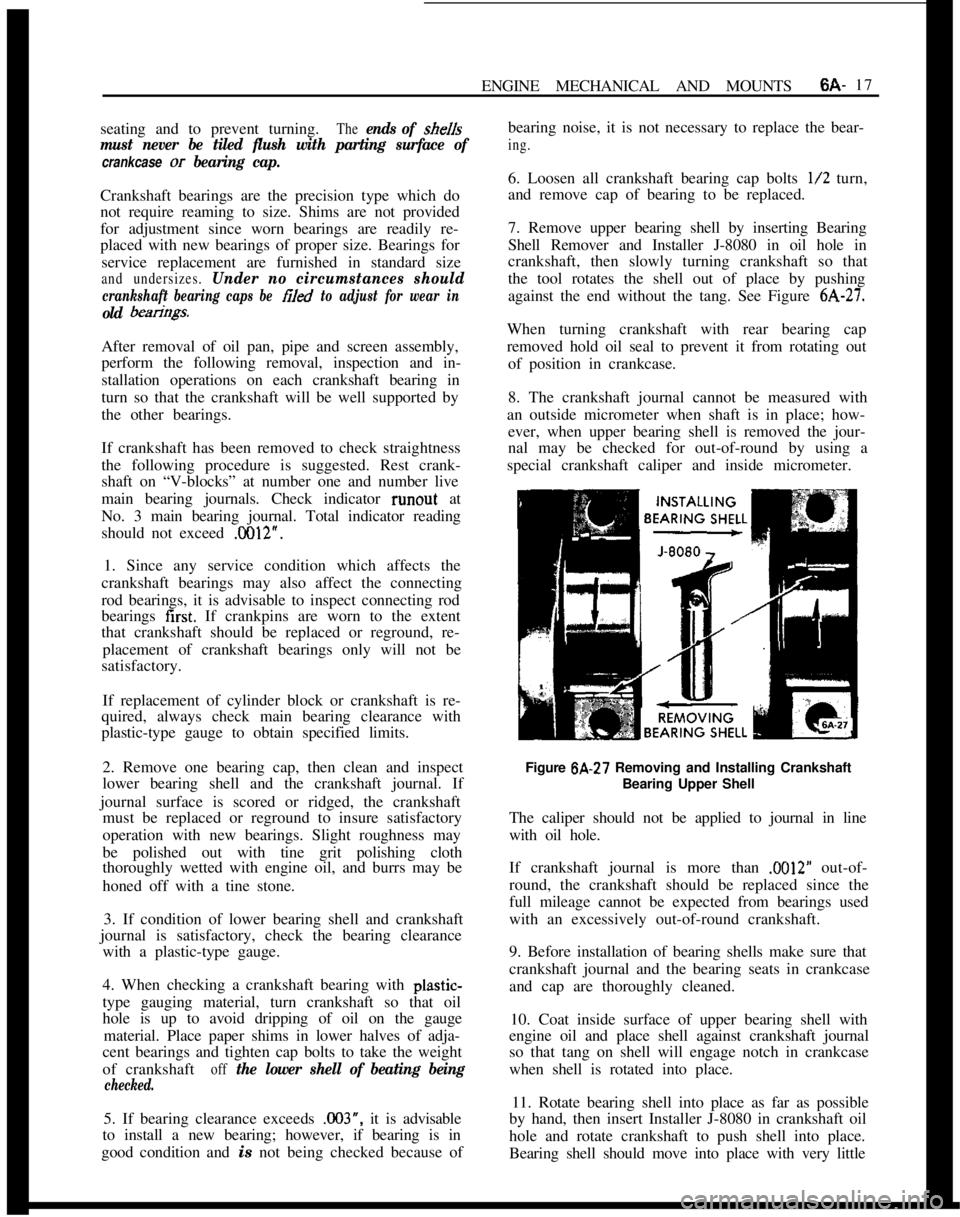

7. Remove upper bearing shell by inserting Bearing

Shell Remover and Installer J-8080 in oil hole in

crankshaft, then slowly turning crankshaft so that

the tool rotates the shell out of place by pushing

against the end without the tang. See Figure

6A-27.When turning crankshaft with rear bearing cap

removed hold oil seal to prevent it from rotating out

of position in crankcase.

8. The crankshaft journal cannot be measured with

an outside micrometer when shaft is in place; how-

ever, when upper bearing shell is removed the jour-

nal may be checked for out-of-round by using a

special crankshaft caliper and inside micrometer.

Figure 6A-27 Removing and Installing Crankshaft

Bearing Upper Shell

The caliper should not be applied to journal in line

with oil hole.

If crankshaft journal is more than

.M)12” out-of-

round, the crankshaft should be replaced since the

full mileage cannot be expected from bearings used

with an excessively out-of-round crankshaft.

9. Before installation of bearing shells make sure that

crankshaft journal and the bearing seats in crankcase

and cap are thoroughly cleaned.

10. Coat inside surface of upper bearing shell with

engine oil and place shell against crankshaft journal

so that tang on shell will engage notch in crankcase

when shell is rotated into place.

11. Rotate bearing shell into place as far as possible

by hand, then insert Installer J-8080 in crankshaft oil

hole and rotate crankshaft to push shell into place.

Bearing shell should move into place with very little