window OPEL GT-R 1973 Service Manual

[x] Cancel search | Manufacturer: OPEL, Model Year: 1973, Model line: GT-R, Model: OPEL GT-R 1973Pages: 625, PDF Size: 17.22 MB

Page 5 of 625

The 1973 Opel Chassis Service MayI has been completely revised with respect to layout, format and information content

in a” attempt

to provide you “The Technician” with a tiore logical and usable publication. An example of the new grouping

layout 6 exhibited on the preceding

page. Each wow is rubdivided as follows:

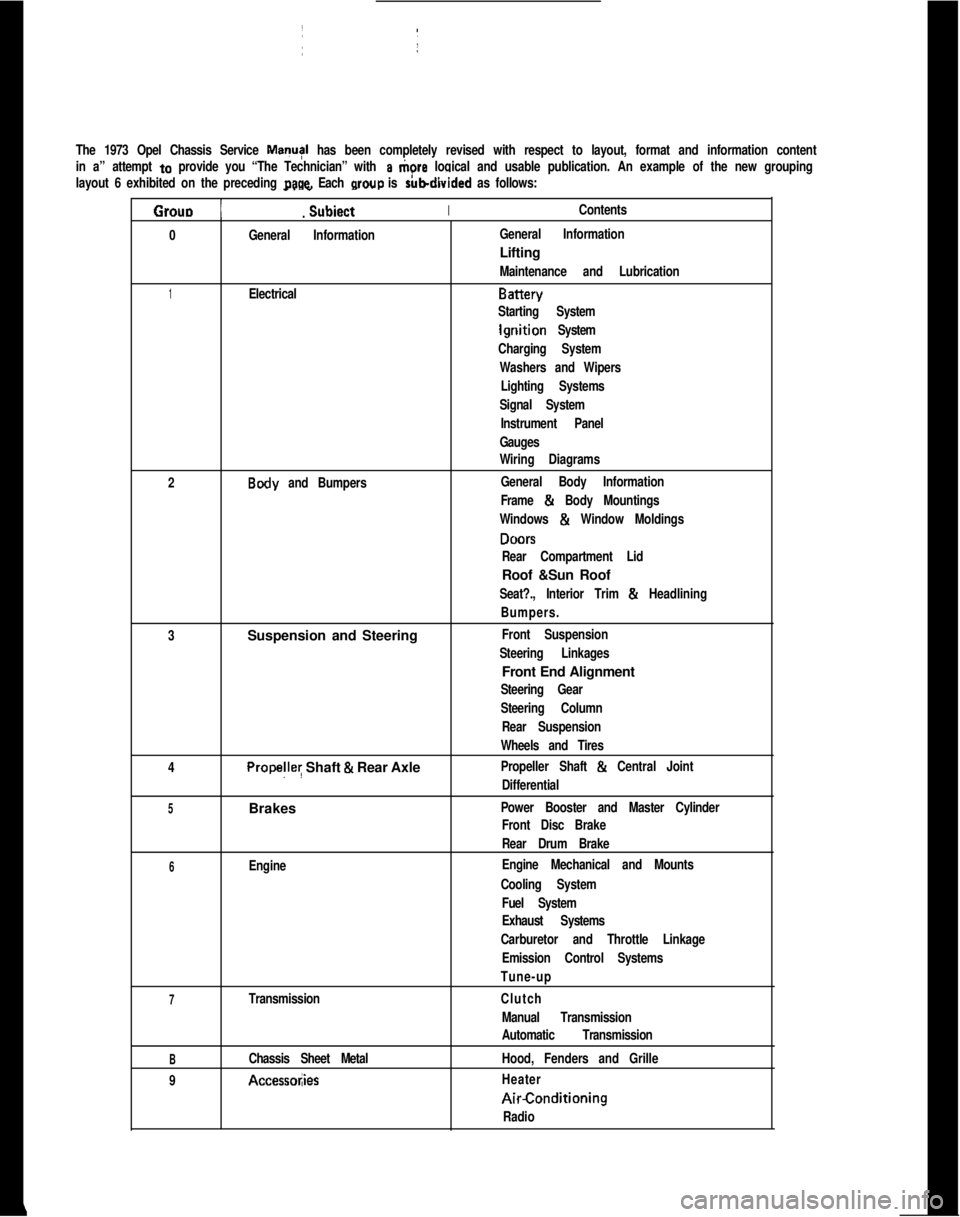

Grouo 1

_. _

Subiect IIContents.

0

General InformationIGeneral InformationLifting

Maintenance and Lubrication

1ElectricalBattery

Starting System

lgriition System

Charging System

Washers and Wipers

Lighting Systems

Signal SystemI

Instrument Panel

Gauges

Wiring Diagrams

2

Body and Bumpers:General Body InformationI

Frame & Body Mountings

Windows

& Window Moldings

DONS

Rear Compartment LidRoof &Sun Roof

Seat?., Interior Trim & Headlining

Bumpers.

3Suspension and Steering

Front Suspension

Steering Linkages1Front End Alignment

Steering Gear

Steering Column

Rear Suspension

Wheels and Tires

4

Propelley Shaft & Rear AxlePropeller Shaft & Central Joint

Differential

5Brakes ~Power Booster and Master Cylinder

Front Disc BrakeI

Rear Drum Brake

6EngineEngine Mechanical and Mounts

Cooling System

Fuel System

Exhaust Systems

Carburetor and Throttle Linkage

Emission Control Systems

Tune-up

7TransmissionClutch

Manual Transmission

Automatic Transmission

BChassis Sheet MetalHood, Fenders and Grille

9

Accessol;iesHeaterAirConditioning

Radio

Page 42 of 625

IGNITION SYSTEMlC-214. Rota&distributor counterclockwise slightly until

contact pbints just start to open. This must be done

very carefully or engine will not start.

5. Install distributor cap. Make sure spark plug wires

are correctly installed in distributor cap, through clip

and on spark plugs.

Finish TimingIContact boint gap

(.016” at widest gap) or dwell 50

degrees plus or minus 3 degrees should always be

checked before adjusting ignition timing.

1. Connekt timing light to No. 1 spark plug.

2. Disconnect and plug vacuum advance unit and

retard u$it hoses.

3. Connect a tachometer from distributor side of coil

to

groun$l.4. Start dngine. Set idle speed to 900 RPM.

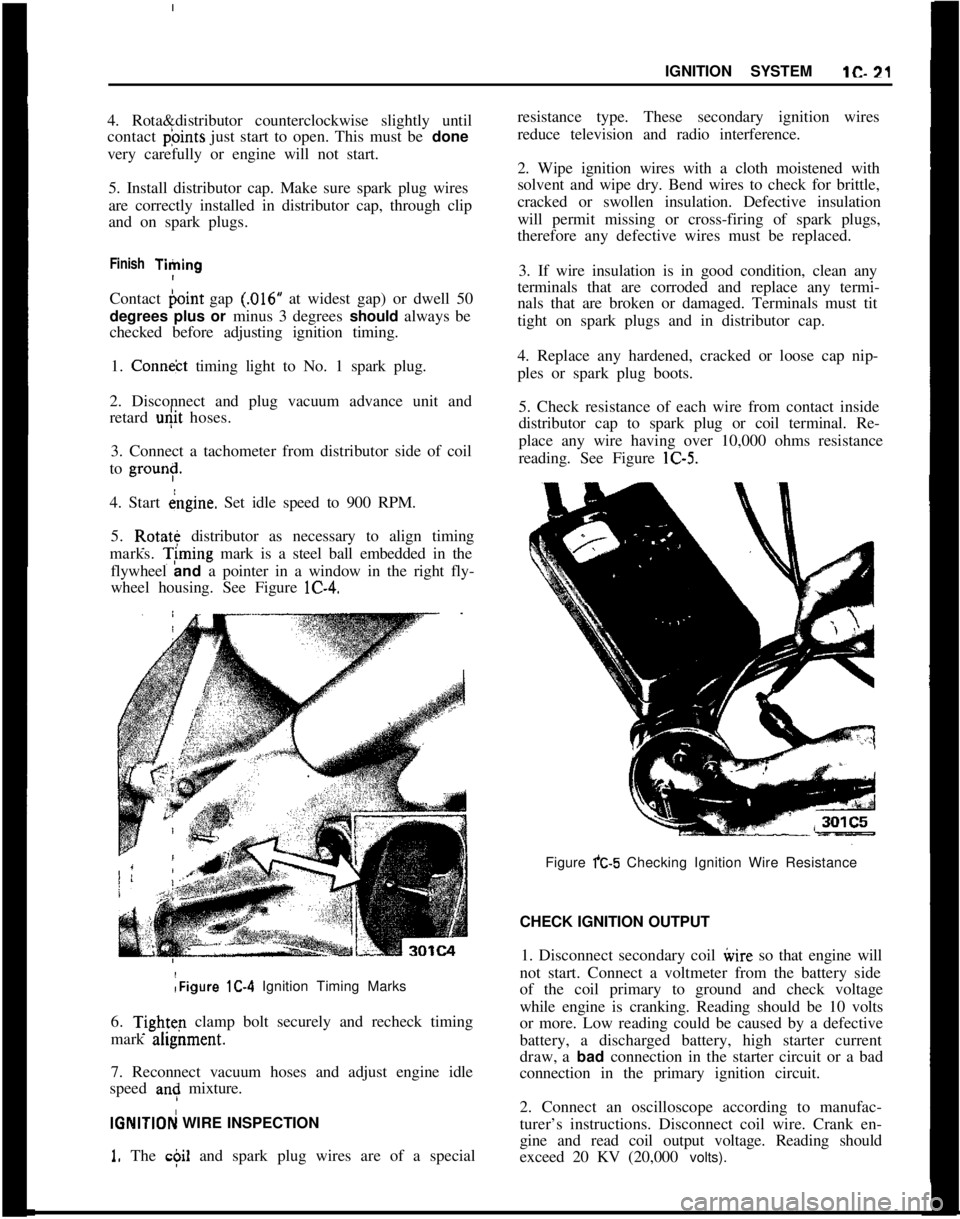

5. Rotate distributor as necessary to align timing

marks. T;ming mark is a steel ball embedded in the

flywheel and a pointer in a window in the right fly-

wheel housing. See Figure lC-4.:Figure lC-4 Ignition Timing Marks

6.

Tightq clamp bolt securely and recheck timing

mark ahgnment.

7. Reconnect vacuum hoses and adjust engine idle

speed

an: mixture.

IGNlTlOFj WIRE INSPECTION

1. The c$il and spark plug wires are of a specialresistance type. These secondary ignition wires

reduce television and radio interference.

2. Wipe ignition wires with a cloth moistened with

solvent and wipe dry. Bend wires to check for brittle,

cracked or swollen insulation. Defective insulation

will permit missing or cross-firing of spark plugs,

therefore any defective wires must be replaced.

3. If wire insulation is in good condition, clean any

terminals that are corroded and replace any termi-

nals that are broken or damaged. Terminals must tit

tight on spark plugs and in distributor cap.

4. Replace any hardened, cracked or loose cap nip-

ples or spark plug boots.

5. Check resistance of each wire from contact inside

distributor cap to spark plug or coil terminal. Re-

place any wire having over 10,000 ohms resistance

reading. See Figure lC-5.

Figure fC-5 Checking Ignition Wire Resistance

CHECK IGNITION OUTPUT

1. Disconnect secondary coil ivire so that engine will

not start. Connect a voltmeter from the battery side

of the coil primary to ground and check voltage

while engine is cranking. Reading should be 10 volts

or more. Low reading could be caused by a defective

battery, a discharged battery, high starter current

draw, a bad connection in the starter circuit or a bad

connection in the primary ignition circuit.

2. Connect an oscilloscope according to manufac-

turer’s instructions. Disconnect coil wire. Crank en-

gine and read coil output voltage. Reading should

exceed 20 KV (20,000 volts).

Page 66 of 625

LIGHTING SYSTEMSlF-45LIGHTING SYSTEMS

CONTENTS

Subject

DESCRIPTION AND OPERATION:

LightingSystems................................................................

DIAGNOSIS:MAINTENANCT AND ADJUSTMENTS:

Headlamp Aiming..............................................................

MAJOR REPAIR:

Opel 1900

- Manta

HeadlightSwitch............................................................

Fog Lamp or Heated Rear Window Switch

..........

SealBeam........................................................................

Tail Lamps........................................................................

LicensePlateLamp........................................................

FrontSideMarker..........................................................

Rear Side Marker..........................................................

Courtesy Light................................................................

DoorJamSwitch............................................................

GT

Front Turn Signal..........................................................

SealBeam........................................................................

Tail Lamps........................................................................

Side Marker......................................................................

LicensePlateLamp........................................................

Backup Lamp

..................................................................

InteriorLight....................................................................

Headlamp Switch..........................................................

DoorJamSwitch............................................................

SPECIFICATIONS:

Page No.

1 F-45

1 F-46

1 F-46

1 F-47

1 F-47

1 F-40

1 F-49

1 F-49

1 F-50

1 F-50

1 F-50lF-51lF-51lF-51

1 F-52

1 F-52

1 F-53

1 F-53

1 F-53

1 F-53

DESCRIPTION AND OPERATION

DESCRIPTION OF LIGHTING SYSTEMThe

three-baition light switch on Opel 1900 and

Manta corjtrols the headlights, taillights, parking

lights, side marker lights, instrument panel lights,

and the lic&se plate light.

When the

Qght switch knob is pulled out to the first

stop, the .pxking lights, side marker lights, the Ii-

cerise plate light, and the instrument panel lights will

light.

Pulling the knob out all the way turns the headlights

on.The instrument panel lights come on when the head-

light switch is pulled out to the first stop or pulled

out ‘all the way. The instrument panel lights are

turned off by turning the switch knob counterclock-

wise past the first detent.

Page 78 of 625

,I

IINSTRUMENT PANEL

lH- 57

/

/SubjectPage No. INSTRUMENT PANEL

CONTENTS

DESCRIPTION AND OPERATION:

Instrument Panel

- Opel 1900 - Manta. . . . . . . . . . . . . . . . . . . . . .Instrument

Panel-GT. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .DIAGNOSIS:

MAINTENANCE AND ADJUSTMENTS:

MAJOR REPAIR:

Instrument Cluster Housing

- Opel 1900 - Manta . .

Windshield Wiper Switch

. , . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .InstrumentCluster

Bulbs. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .InstrumentCluster

Housing-GT. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .Combined Switch Assemblies

. . . . . , . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .CigarLighter

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . , . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .SPECIFICATIONS: (Not Applicable)

I H-57

1H-58

1H-59

1H-61

lH-61

1H-61

1H-63

1H-64

DESCF(lPTlON AND OPERATION2. The fog light toggle switch lower half is pushed in.INSTRUFENT PANEL (OPEL 1900. MANTA)

Headligl$ Switch

3. The parking lights and/or low beam headlights are

on.The thr& position light switch controls the head-

lights, @lights, parking lights, side marker lights,

license

plate light and instrument panel lights and is

located

4t the lower left on the instrument panel.

With thk switch knob pulled outward to the first

stop,

thi parking lights, side marker lights, license

plate

ligiit and instrument panel lights will light. Theinstrumdnt panel lights can be turned off by turning

the

lightSwitch knob counterclockwise past the first

detent. IThe fog lights are automatically turned off if the

ignition switch is on and the headlights are on high

beam.

Windshield Wiper Switch

The windshield wiper switch is located on the instru-ment panel to the right of the headlight switch.

By pull&g the lightswitch knob out all the way, the

headlights will also be turned on.

IBy pushing the lower half of this switch in to the first

stop, the wipers will operate at slow speed. By push-ing in to the second stop, the wipers will operate at

fast speed.

Fog

Ligh) Switch (Rallye)The fog

iight toggle switch is located in the instru-

ment cluster to the left of the temperature and fuel

gauge

cl+ster. The fog lights can be turned off at any

time by

t,he toggle switch, but can only be turned on

when: ,

Electrically Heated Rear Window Switch (If

Equipped)The heated rear

wind&v switch is located in the

instrument panel to the right of the clock opening.

1. The ignition switch is on or the engine running.

ITo operate (only possible with the engine running),

push in on the lower half of the switch. When the

rear window is being heated, the switch will

belighted.

Page 79 of 625

1 H- 581973 OPEL SERVICE MANUAL

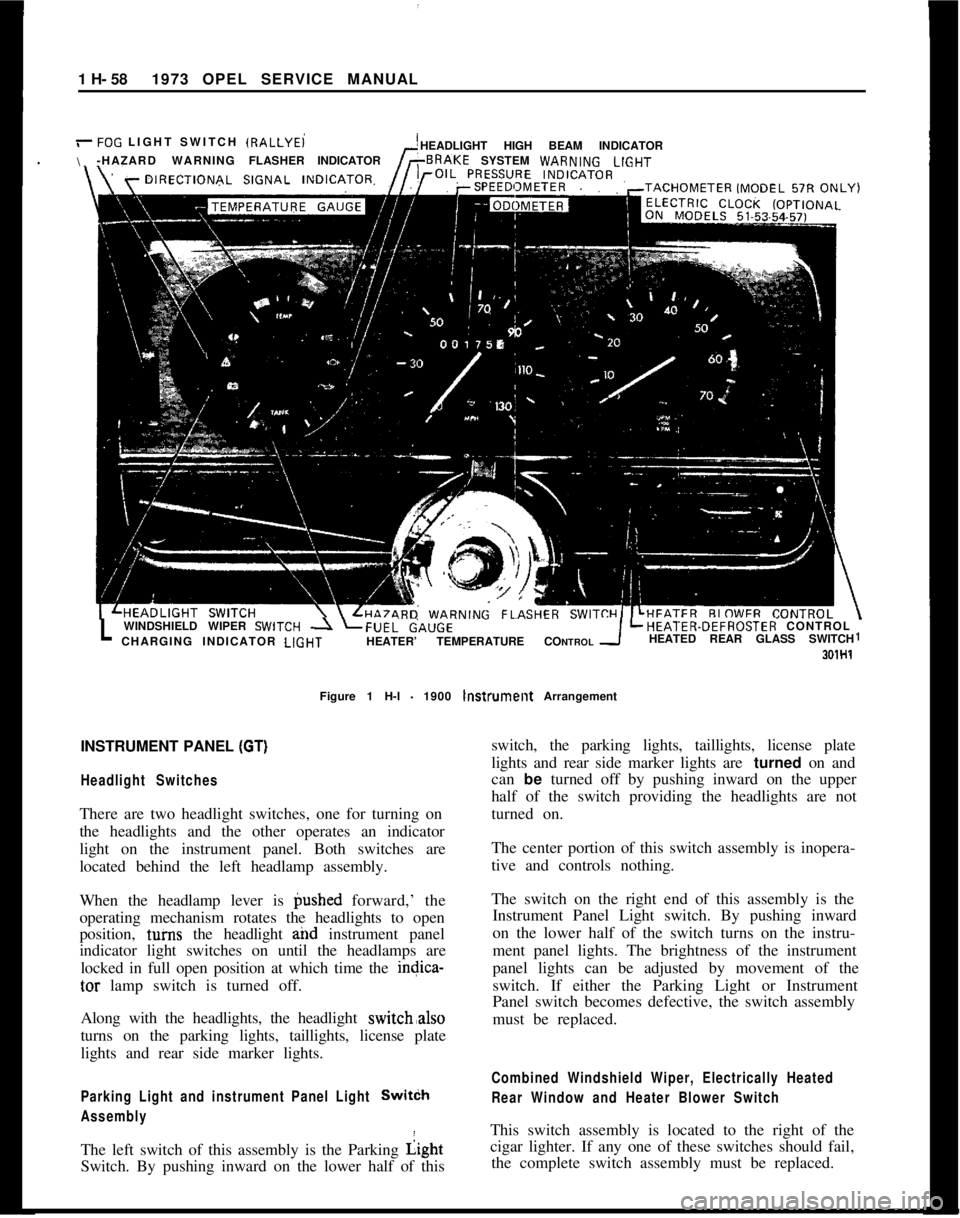

/-FOG LIGHT SWITCH IRALLYEi

\HEADLIGHT HIGH BEAM INDICATOR

-HAZARD WARNINGFLASHERINDICATORSYSTEM WARN,NGLlGHT

LWINDSHIELD WIPER SWlTCH -1 LFUEL&,UGELHEATER-DEFROSTER CONTROL

CHARGING INDICATOR LlGHTHEATER’ TEMPERATURE CONTROLHEATED REAR GLASS SWITCH1

301H1Figure 1 H-l

- 1900 lnstrumellt Arrangement

INSTRUMENT PANEL

(GT)I

Headlight SwitchesThere are two headlight switches, one for turning on

the headlights and the other operates an indicator

light on the instrument panel. Both switches are

located behind the left headlamp assembly.

When the headlamp lever is @shed forward,’ the

operating mechanism rotates the headlights to open

position, tuins the headlight and instrument panel

indicator light switches on until the headlamps are

locked in full open position at which time the indica-

tar lamp switch is turned off.

Along with the headlights, the headlight switch,also

turns on the parking lights, taillights, license plate

lights and rear side marker lights.

Parking Light and instrument Panel Light SwitCh

AssemblyThe left switch of this assembly is the Parking Light

Switch. By pushing inward on the lower half of thisswitch, the parking lights, taillights, license plate

lights and rear side marker lights are turned on and

can be turned off by pushing inward on the upper

half of the switch providing the headlights are not

turned on.

The center portion of this switch assembly is inopera-

tive and controls nothing.

The switch on the right end of this assembly is the

Instrument Panel Light switch. By pushing inward

on the lower half of the switch turns on the instru-

ment panel lights. The brightness of the instrument

panel lights can be adjusted by movement of the

switch. If either the Parking Light or Instrument

Panel switch becomes defective, the switch assembly

must be replaced.

Combined Windshield Wiper, Electrically Heated

Rear Window and Heater Blower SwitchThis switch assembly is located to the right of the

cigar lighter. If any one of these switches should fail,

the complete switch assembly must be replaced.

Page 80 of 625

/

I

IINSTRUMENT PANELlH- 59

Figure 1 H-2

- GT Instrument and Switch Arrangement

The Wihdshield Wipers have two-speed operation.

By pushing the lower half of the switch inward to the

first stop, the wipers will operate at half speed and

by deprbssing to the second stop will provide full

speed oieration. When the switch is returned to the

off posit/on, the wiper blades automatically return to

their park position.

I

The El

this optlpn. The engine must be running before

suffi-cient current can be generated to energize this circuit

even th6ugh the switch is depressed to the “ON”

position! When the window is being heated, a warm-

ing light’on the instrument panel will glow. This light

is locate? below the left ventilation inlet.

The

Heiter Blower Switch is a three position switch.

By depressing the lower half of the switch to the first

stop,

th& blower will operate at low speed. Whendepressdd to the second stop, the blower will operate

at high ipeed.

Four Way Hezrerd Warning Flasher SwitchThe

hazard warning flasher switch is located below

the heater controls in the center console. By

depress-ing the lower half of the switch, all four turn- signal

lamps flash at the same time. Although this system

makes use of the regulat turn signal system, it has a

separate feed wire to the switch which allows for its

operation even with the ignition switch and doors

locked. No vehicle should be driven with this system

in operation because of its universal meaning “This

Vehicle Is Not Moving”. To turn the system off,

simply depress the upper half of the switch.

MAJOR REPAIR

Removal of Instrument Cluster Housing Assembly.Opel 1900 Manta

Before starting any instrument panel repair, always

disconnect battery ground cable first.

I

Page 81 of 625

/

I1 H- 601973 OPEL SEW& MANUAL

1. Remove headlight switch button by depressing

retaining clip on shaft and pulling back on switch

knob. See Figure lH-3.

Figure 1 H-5

- Removing Cluster Screws

Figure lH-3

- Removing Headlight Switch Knob,

2. Remove two (2) plugs on cluster panel. See FigurelH-4.301H6

-Figure 1 H-4 Removing Plugs

3. Remove two (2) sheet metal screws behind plugs

on cluster. See Figure lH-5.

4. Pull off heater control knobs toward front.

j5. On top, carefully pull instrument ‘trim plate

:to-wards steering wheel and remove plate.

6. Remove two screws for lower housing

attach&t.See Figure lH-6.Figure 1 H-6 Lower Housing Attaching Screws

7. Disconnect speed0 cable at cluster by turning cou-

pling counterclockwise.

8. If equipped, pull heated rear window or fog lamp

switch out of instrument housing and disconnect

wires from switches.

9. Pull cluster right and left sides partially out and

disconnect wires on back of cluster. See Figure lH-7.

Installation

1.

P&e instrument cluster in position and connect

wires on back of cluster.

2. Pull fog light or heated back glass switch wires

into opening, if equipped, and connect wires and

replace switch.

3. Connect two screws on lower housing attachment.

Page 124 of 625

GROUP 2

[I

L

RnnVI----.

anlnIT\..YI-

BUMPERSII-

L

L

Section

2A

2B

2C

2D

2E

2F

2G 2H

Title

General Information Frame and Body Mountings

. . . . . . . . . . . . . . . . . . . .

Windows and Window

Moldings

Doors

_................................

Rear Compartment Lid

Roof and Sun Roof

Seats, Interior Trim and Headlining

Bumpers

. . . . . . . . . . . . . . . . . . . . . . . . . . .

Page No.

2A- 2

2B- 6

2c- 9

2D-13

2E-22

2F-24

26-33

2H-38

Page 132 of 625

WINDOWS AND WINDOW MOLDINGS2c-9WINDOWS AND WINDOW MOLDINGS

CONTENTS

Subject

DESCRIPTION AND OPERATION: (Not Applicable)

DIAGNOSIS: (Not Applicable)

MAINTENANCE AND ADJUSTMENTS: (Not

Applicable)

MAJOR REPAIR:

Removal and Installation

Windshield

RevealMolding. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .Windshield

andBackWindow. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

DoorWindow. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .Rear Quarter Window Molding

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .Rear Quarter Window

-1900 -Manta. . . . . . . . . . . . . . . . . .RearQuarterWindow

-GT. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

RearQuarterWindowLock. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .SPECIFICATIONS: (Not Applicable)Page No.

2c- 9

2c-10

2c-11

2c-11

2c-12

2c-12

2c-12

MAJOR REPAIR

REMOVAL AND INSTALLATION OF WINDSHIELD3. With Tools J-2 1828 and J-2 1549, insert new reveal

REVEAL MOLDINGmolding and install escutcheon.

1. Remove reveal molding escutcheon. Starting at

one end, pull molding out of rubber channel. See

Figure

2C-2.Figure ZC-2 Removing Reveal Molding

Figure ZC-3 Pushing Windshield Out 2. Prior to installation, place molding in water and

heat up to approximately 113

- 122 degrees F.

Page 133 of 625

2c-101973 OPEL SERVICE MANUAL

REMOVAL AND INSTALLATION OF WINDSHIELD

OR BACK WINDOW-WINDSHIELD SHOWN

1. Flap back windshield wiper arms,

2. Beginning at one end, pull molding out of rubber

channel.

3. Beginning at one corner, push out windshield

together with rubber channel. See Figure 2C-3.4. Place new windshield on glass holding fixture and

tit new rubber channel. See Figure

2C-4.5. Insert a thick string into large sealing lip of rubber

channel so that both ends are crossed at bottom cen-

ter of windshield. See Figure

2C-5.6. With a sealer gun, coat outside of pinchweld flange

with sealing compound. See Figure

2C-6./’

Figure

2C-4 Fitting Rubber Channel on Windshield

Figure

2C-5 String Inserted Into Rubber ChannelFigure 2C-6 Applying Sealer on Pinchweld Flange

7. Place windshield in body opening and, with in-

serted string, pull rubber channel lip over pinchweld

flange, always tapping windshield from outside with

a striking pad. See Figure

2C-7.Figure

2C-7 Pulling Rubber Channel Lip Over

Pinchweld Flange