change time OPEL GT-R 1973 Service Manual

[x] Cancel search | Manufacturer: OPEL, Model Year: 1973, Model line: GT-R, Model: OPEL GT-R 1973Pages: 625, PDF Size: 17.22 MB

Page 4 of 625

1973

GTOPEL1900

MANTA

CHASSISSERVICE

MANUAL

This manual contains service informationfor the 1973 Opel 1900, Manta and GT

models. Refer to the introduction for

adescription of the arrangement of this

manual for locating desired information

easily.All

infotmation, illustrations and specifi-cations contained in this manual are basedon the latest product information aveil-able at the time of publication approval.

Therefore, the right is reserved to make

changes at any time without notice.TABLE OF CONTENTS

SUBJECT

I I

1ELECTRICAL

I I2FRAME AND BUMPERS

I I3SUSPENSION AND STEERING

I I4REAR AXLE

I I5BRAKES

I I

6ENGINE

I I7TRANSMISSION

I I

8CHASSIS SHEET METAL

I I

9ACCESSORIES

Page 16 of 625

LUBRICATION AND MAINTENANCE OC-7SERVICESLUBE AND GENERAL MAINTENANCE

Vehicle operation under conditions such as heavy

dust, continuous short trips, use of other than un-

leaded or low lead fuels or pulling trailers, is not

considered normal use and therefore more frequent

maintenance will be required. Such additional

maintenance requirements are included where appli-

cable.

Engine OilChange each 4 months or

3,COO miles, whichever

occurs first, or each 2 months or

3,ooO miles when

the vehicle is operated under the following condi-

tions: (a) driving in dusty conditions, (b) trailer pull-

ing, (c) extensive idling or (d) short-trip operation at

freezing temperatures (with engine not thoroughly

warmed-up).Engine oils have a definite effect on ease of starting,

oil economy, combustion chamber deposits and en-

gine wear. It is recommended that a” oil which,

according to the label on the can is; (1) intended for

service SE and (2) passes car makers’ tests be used.

Oils confotming to these types contain detergent ad-

ditives. -

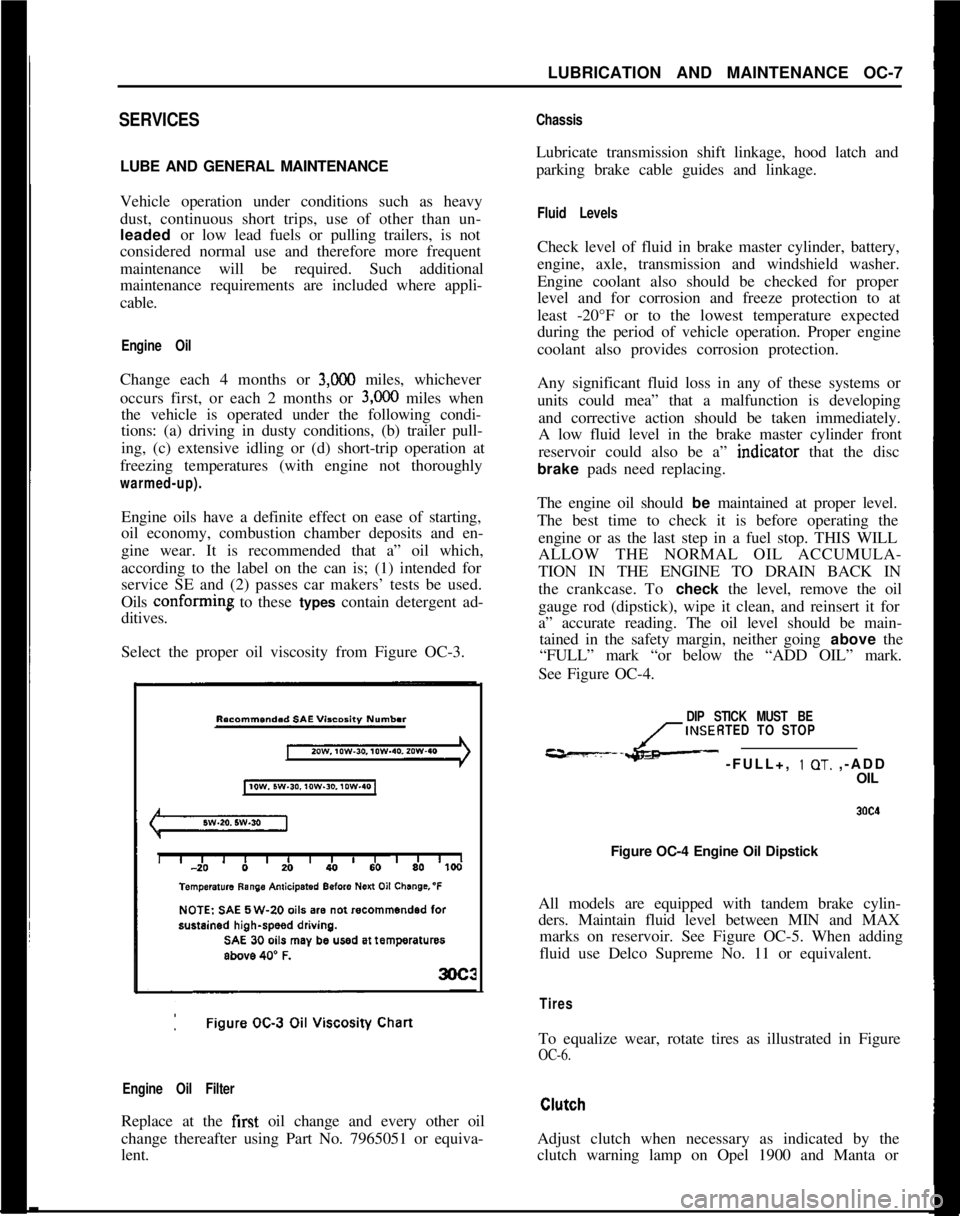

Select the proper oil viscosity from Figure OC-3.

Engine Oil FilterReplace at the first oil change and every other oil

change thereafter using Part No. 7965051 or equiva-

lent.

ChassisLubricate transmission shift linkage, hood latch and

parking brake cable guides and linkage.

Fluid LevelsCheck level of fluid in brake master cylinder, battery,

engine, axle, transmission and windshield washer.

Engine coolant also should be checked for proper

level and for corrosion and freeze protection to at

least -20°F or to the lowest temperature expected

during the period of vehicle operation. Proper engine

coolant also provides corrosion protection.

Any significant fluid loss in any of these systems or

units could mea” that a malfunction is developing

and corrective action should be taken immediately.

A low fluid level in the brake master cylinder front

reservoir could also be a” indtcator that the disc

brake pads need replacing.

The engine oil should be maintained at proper level.

The best time to check it is before operating the

engine or as the last step in a fuel stop. THIS WILL

ALLOW THE NORMAL OIL ACCUMULA-

TION IN THE ENGINE TO DRAIN BACK IN

the crankcase. To check the level, remove the oil

gauge rod (dipstick), wipe it clean, and reinsert it for

a” accurate reading. The oil level should be main-

tained in the safety margin, neither going above the

“FULL” mark “or below the “ADD OIL” mark.

See Figure OC-4.

DIP STICK MUST BE

INSERTED TO STOP

---L- -FULL+, 1 OT. ,-ADD

OIL

Figure OC-4 Engine Oil Dipstick

All models are equipped with tandem brake cylin-

ders. Maintain fluid level between MIN and MAX

marks on reservoir. See Figure OC-5. When adding

fluid use Delco Supreme No. 11 or equivalent.

TiresTo equalize wear, rotate tires as illustrated in Figure

OC-6.Adjust clutch when necessary as indicated by the

clutch warning lamp on Opel 1900 and Manta or

Page 19 of 625

CC-10 1973 OPEL SERVICE MANUAL

wiper blades. Check amount and direction of fluid

sprayed by washers during use.,

E. Defrosters - Check performance by moving con-

trols to “DEF” and noting

am$nmt of air directed

against the windshield.

I

F. Wheel Alignment and

Balabce - In addition to

abnormal tire wear, the need fbr wheel alignment

service may be indicated by a pull to the right or

!eftwhen driving on a straight and level road. The need

for wheel balancing is usually

iddicated by a vibra-

tion of the steering wheel or

se;+ tihile driving at

normal highway speeds.I

IG. Brakes

- Be alert to illumiriation of the brake

warning light or changes in braking action,

SUCK as

repeated pulling to one side, unusual sounds when

braking or increased brake pedal travel. Any of thesecould indicate the need for

brakk system inspection

and/or service.

H. Parking Brake and Transmission “PARK”

Mechanism

- Check parking brake holding ability by

parking on a fairly steep hill and restraining the vehi-

cle with the parking brake only.

eon cars with auto-

matic transmissions, check the holding ability of the

“PARK” mechanism by releasing all brakes after

the transmission selector lever hak been placed in the“P” position.

I. Glass

- Check for broken, scrritched, dirty or da-

maged glass on vehicle that

coulld obscure vision’or

become an injury hazard.

J. Lights and Buzzers

- Check all instrument panel

illuminating and warning lights,’ seat belt reminder

light and buzzer, ignition key

b&er, interior lights,

license plate lights, side marker! lights, headlamps,

parking lamps, tail lamps, brake lights, turn signals,

backup lamps, and hazard warding flashers. Have

someone observe operation of

&ach exterior light

while you activate the controls: The operation of

instrument panel warning lights is covered in the

“Starting and Operating“ section of your

Own&%

Manual.K. Transmission Shift Indicator

‘- Check to be sure

automatic transmission shift

indiCator accurately i”-

dicates the shift position selected.

I

CAUTION: Before making thk check below,I

be sure to have a clear dist&e ahead and:

behind the car, set the parking brake and

firmly apply the foot brake.

Do not depress

accelerator pedal. Be prepared to

turn off ’

ignition switch

immediat+y if engine

should start.L. Starter Safety Switch (Automatic Transmissibn

Cars)

- Check starter safety switch by placing the

transmission in each of the driving gears while

at-tempting to start the engine. The starter should oper-ate only in the Park (“P”) or Neutral (“N”)

positions.

M. Horn

- Blow the horn occasionally to be sure thatit works. (Ignition switch must be in the “ON” posi-

tion.)

N. Seat Back Latches

- Check to see that seat back

latches are holding by pulling forward on the top of

each folding seat back.

0. Rearview Mirrors and Sun Visors

- Check that

friction joints are properly adjusted so mirrors and

sun visors stay in the selected position.

P. Door Latches

- Check for positive closing, latch-

ing and locking.

Q. Hood Latches - Check to make sure hood closesfirmly by pressing on the hood at the latching point

after each closing. Check also for broken, damaged

or missing parts which might prevent secure latch-

ing.R. Fluid Leaks

- Check for fuel, water, oil or other

fluid leaks by observing the ground beneath the vehi-cle after it has been parked for a while. If gasoline

fumes or fluid are noticed at any time, the cause

should be determined and corrected without delay

because of the possibility of fire.

S. Exhaust System

- Be alert to any change in the

sound of the exhaust system or a smell of fumes

which may indicate a leak.

Head Restraints

- Check that no head restraint

components are missing, damaged or loose. (Does

not apply to GT Models).

Disc BrakesCheck brake pads and condition of rotors while

wheels are removed during tire rotation. (Note belowregarding more frequent checks also applies to disc

brakes.)

Parking and Drum BrakesCheck drum

brake linings and other internal brake

components at each wheel (drums, wheel cylinders,

etc.). Parking brake adjustment also should be

checked whenever drum brake linings are checked.

NOTE: More frequent checks should be

made if driving conditions a.nd habits result

in frequent brake application. When brakes

require relining, it is recommended thatyou use those genuine General Motors

parts specified for your car,and Delco fluid

as required.

Page 41 of 625

I

ilC- 201973 OPEL SERVICE MANUAL

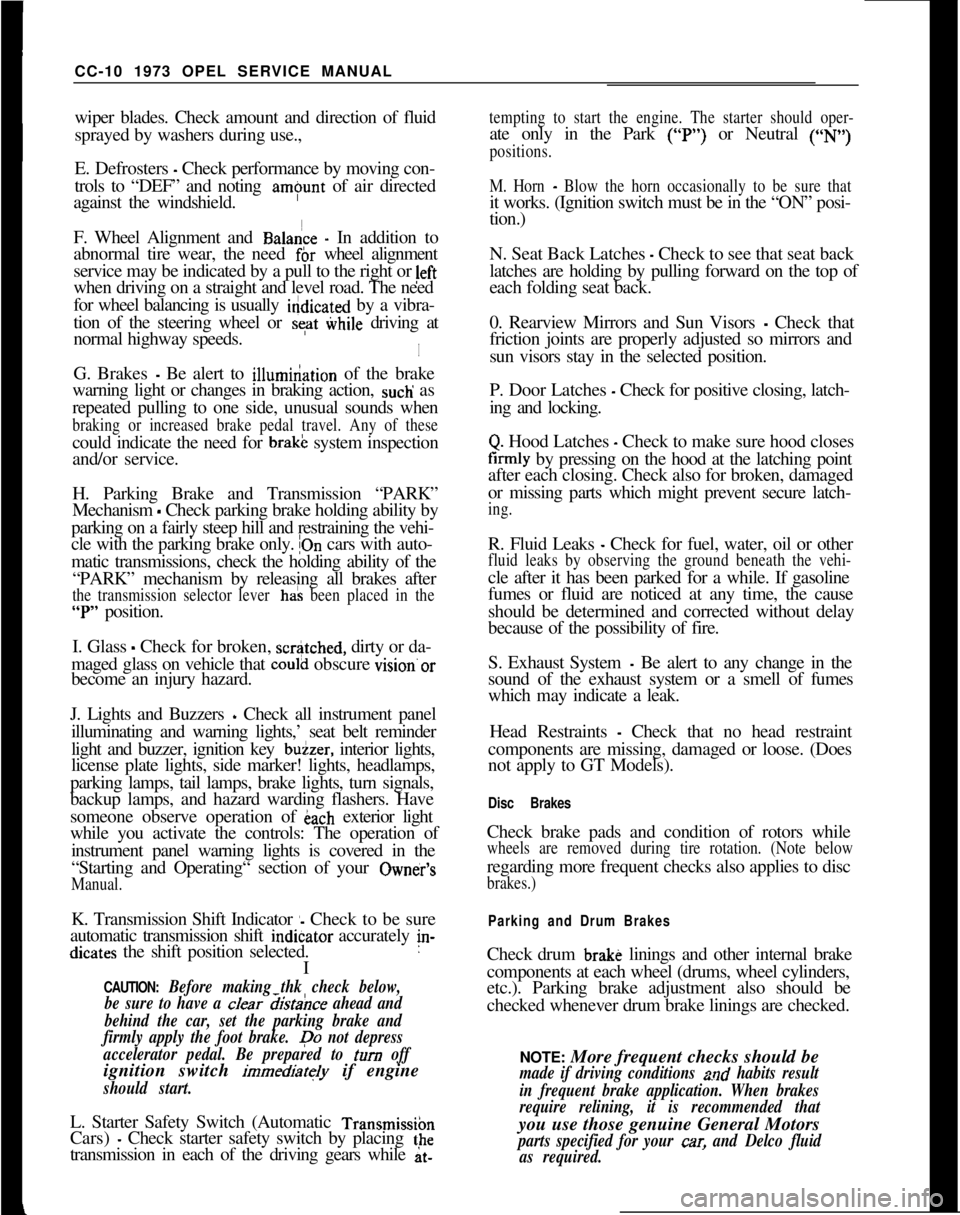

There is also a plastic hood slipped over the distrivu-tar cap with an outlet for the ignition cables as an

added protection against moisture from the outside.

See Figure lC-2.

Figure lC-2 Ignition Distributor With Hood Installed

MAINTENANCE AND ADJUSTMENTS

CONTACT POINT REPLACEMENT

Removing Contact Points1. Remove contact support lock

,screw and remqve

contact point support. If condenser is to be replaced,

it will be necessary to replace condenser and

1eads;asan assembly.

Installing Contact Points1. Lightly lubricate distributor cam with high tein-perature cam and ball bearing lubricant. Excessive

lubricant will throw off into contact points.

:

,

2. Position support on breaker plate and install lock

screw leaving slightly loose for later adjustment..

3. Plug breaker arm wire in.

4. Adjust breaker point gap to ,016”.

/

DWELL ANGLE ADJUSTMENT

1. Connect dwell meter.

2. Remove distributor cap. Remove rotor. Loosen

breaker point set screw approximately

l/8 turn.

3. Insert screwdriver in notch of stationary breaker

point. Observe dwell meter while cranking engine.

Twist screwdriver as required to obtain a reading of

50 degrees plus or minus 3 degrees.4. Tighten breaker point set screw, then recheck

dwell.

5. Install rotor and cap.~Start engine and recheck

dwell. It is important that dwell be rechecked, as

instal~lation of rotor and cap will sometimes change

the dwell angle.

IGNITION TIMING ADJUSTMENT

Preliminary Timing (Engine Won’t Run)To time the ignition on any engine which will run,

use subparagraph b only. However, if the timing of

an engine is completely off, the following procedure

must first be used to get the engine to run.

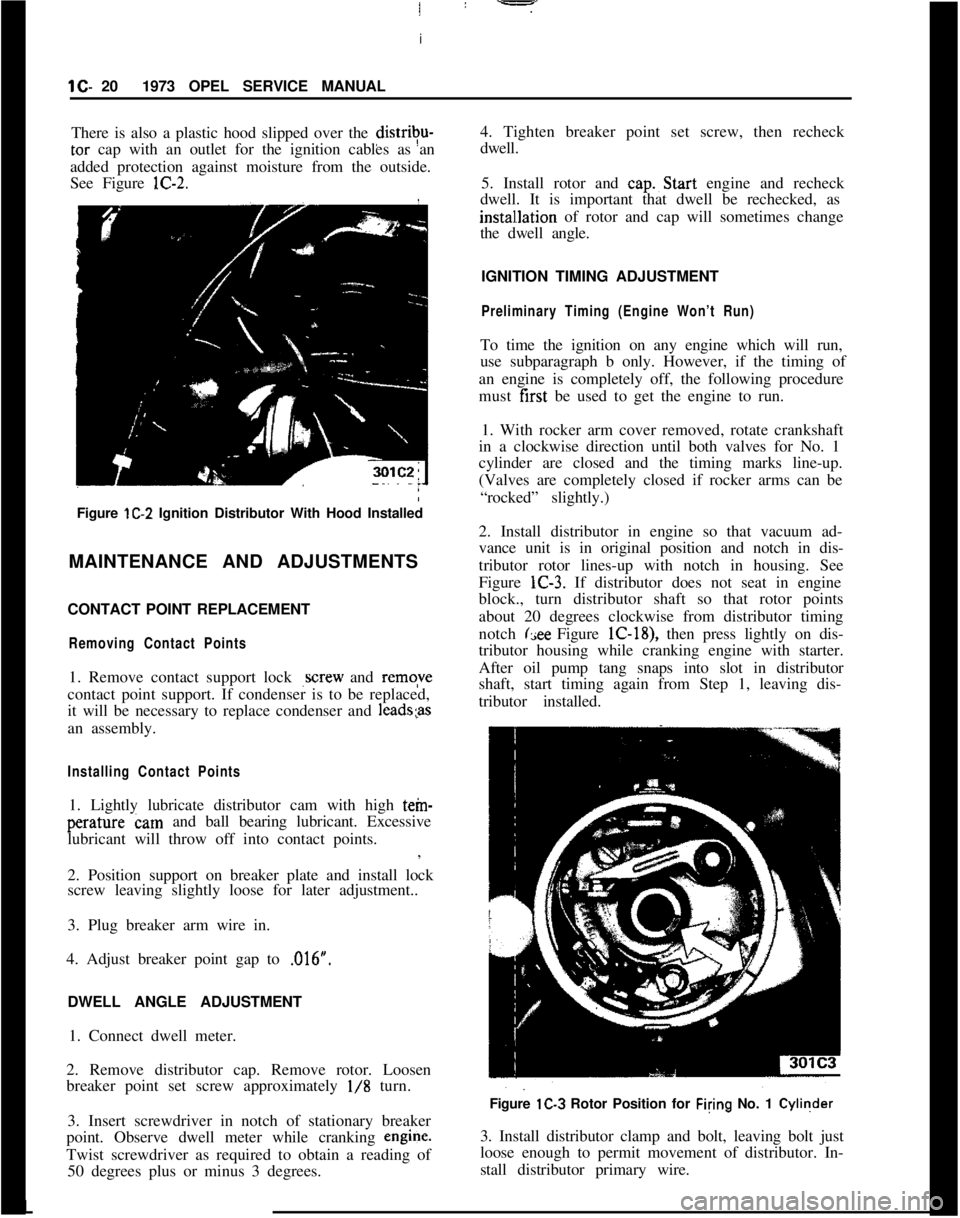

1. With rocker arm cover removed, rotate crankshaft

in a clockwise direction until both valves for No. 1

cylinder are closed and the timing marks line-up.

(Valves are completely closed if rocker arms can be

“rocked” slightly.)

2. Install distributor in engine so that vacuum ad-

vance unit is in original position and notch in dis-

tributor rotor lines-up with notch in housing. See

Figure lC-3. If distributor does not seat in engine

block., turn distributor shaft so that rotor points

about 20 degrees clockwise from distributor timing

notch

(see Figure lC-18), then press lightly on dis-

tributor housing while cranking engine with starter.

After oil pump tang snaps into slot in distributor

shaft, start timing again from Step 1, leaving dis-

tributor installed.

Figure lC-3 Rotor Position for Filing No. 1 Cyliqder

3. Install distributor clamp and bolt, leaving bolt just

loose enough to permit movement of distributor. In-

stall distributor primary wire.L

Page 67 of 625

1F. 46 1973 OPEL SERVICE MANUAL

’

/

Headlight High-Low Beam Control and Passing:

SignalI

When the headlights have been switched on, high

and low beam selection is made by raising the direc-

tional signal lever toward steering wheel. Each

ti&the lever is raised, beam position, will change.

When the headlights are not on, a flashing headlight

signal may be given by raising and lotiering the di-

rectional signal lever. With the headlights on and

inlow beam position, raising and lowering the direc-

tional signal lever will also cause the headlights to

flash.

Fog Light SwitchAll Rallye models are equipped with two white f?g

lights mounted below the front bumper.

The fog light toggle switch is located on the

insty-ment cluster to the left of the temperature and

fuelgauge cluster.

/

The fog lights can be turned off at any time by the

toggle switch, but can only be tyrned on when: :

1. The ignition switch on or the

?gine running.!

2. The fog light toggle switch lower half is pushed

in.3. The parking lights and/or low beam headlights

are

OKThe fog lights are automatically turned off if the

ignition switch is on and the headlights are switched

to high beam position.

Courtesy LightThe courtesy light illuminates the interior of the Car

when any door is opened. The courtesy light can also

be turned on with all doors closed by tilting the l&s.

GT Headlamp MechanismThe concealed headlamps are moved mechanically.

Pushing actuating lever on left side of console opens

headlamps and pulling lever closes headlamps. Two

(2) meshing gear segments convert the movement, of

the lever to a rotation of 180 degrees. The pivots of

the headlamps lie below the centerline so that with

headlamps in closed position, the headlamp housing

is flush with front sheet metal. Refer to Group 110,

Section “F”, for service procedures on the GT head-

lamp mechanism.

A white indicator lamp in the instrument panel lights

if the headlamps are not completely opened lorclosed The switches of the headlamp electrical sys-

tem are located behind the left headlamp operating,

mechanism.

MAINTENANCE AND ADJUSTMENTSHEADLAMP AIMING

The headlamps must be properly aimed in order to

obtain maximum road illumination and safety that

has been built into the headlighting equipment. With

the Guide T-3 type sealed beam units, proper aiming

is even more important because the increased range

and power of this lamp make even slight variations

from recommended aiming hazardous to approach-

ing motorists. The headlamps must be checked for

proper aim whenever a sealed beam unit is replaced

and after an adjustment or repairs of the front end

sheet metal assembly.

Regardless of method used for checking headlamp

aim, car must be at normal weight, that is, with gas,

oil, water, and spare tire. Tires must be uniformly

inflated to specified pressure. If car will regularly

carry an unusual load in rear compartment, or a

trailer, these loads should be on car when headlamps

are checked. Some States have special requirements

for headlamp aiming adjustment, and these require-

ments should be known and observed.

Horizontal and vertical aiming of each seal beam

unit is provided by two adjusting screws which move

the mounting ring in the body against the tension of

the coil spring. There is no adjustment for focus,

since the sealed beam unit is set for proper focus

during manufacturing assembly.

MAJOR REPAIRHEADLIGHT SWITCH

- OPEL 1900. MANTA

Removal1. Remove instrument cluster cover panel. See Sec-

tion H.

2. Compress retaining springs and pull switch out.

See Figure 1 F-

1.3. Pull multiple socket off switch.

Installation

1: Plug multiple socket in switch and push switch in

panel until clips lock in place.

2. Replace instrument cover and secure with two (2)

screws.

Page 125 of 625

I2A- 21973 OPEL SERVICE MANUAL

GENERAL INFORlVlATION

CONTENTS

SubjectPage No.

DESCRIPTION AND OPERATION: (Not Applicable)

DIAGNOSIS: (Not Applicable)

MAINTENANCE AND ADJUSTMENTS:

PaintMaintenance. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2A-2

ChromeMaintenance

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2A-2

StainRemoval

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2A-2

MAJOR REPAIR: (Not Applicable)

SPECIFICATIONS:

Bolt

TorqueSpecifications. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2A-4

Special Body Tools

. . . . , . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2A-5

MAINTENANCE AND ADJUSTMENTSPAINT MAINTENANCE

To remove heavy concentrations of road dirt and

grime, it is recommended that the car be washed

using an automotive shampoo or mild soap, and cold

to lukewarm water. Use of harsh soaps or detergents

is not advised. In areas where salt is used on the

roads during the winter months, more frequentwashing is recommended.

Use of cleaners and polishes are required if no high

luster is obtainable by waxing. To protect the paint

finish, sparingly apply several coats of wax. Each

coat should be thoroughly rubbed to remove any

surplus wax.

Once the car is properly waxed, road dirt may easily

be removed by use of cold to lukewarm water and a

sponge. Dry by use of a chamois.

CHROME MAINTENANCE

Chrome parts should be washed with water and a

mild detergent. If rust or salt corrosion should ap-

pear, they may be removed with Buick Rust Eraser

or equivalent. Do not use scouring powders or stiff

brushes.STAIN REMOVAL

Before attempting to remove spots or stains from

upholstery fabrics, determine as accurately as possi-

ble: (1) Nature and age of the spot or stain. (2) The

affect of stain removing agents on the color, struc-

ture and general appearance of the fabric.

For best results, stains should be removed from

upholstery as soon as possible after they have been

made. If they are allowed to stand for some time,

they often become set, and removal becomes more

diffxult and frequently impossible.

There are three basic types of acceptable’ cleaners

available to car owners: (1) Volatile cleaners, (2) Syn-

thetic detergents, (3) Neutral soap (non-alkaline).

The volatile cleaners are recommended since they

have great solvent powers for grease, oils and general

road grime. Synthetic detergents generally loosen

stains satisfactorily, however, the use of improper

type detergents (containing bleach) involves risk of

damage to the color or finish of fabrics.

Precautions For Cleaning FabricsDo not use laundry soap or detergents containing

bleaches. The use of these agents tends to weaken

fabric and to change its color. Do

not use too much

cleaning fluid. Some interior trim assemblies are pad-

Page 151 of 625

2F-281973 OPEL SERVICE MANUAL

guides to height adjustment rings, loosen second

screw (see Figure 2F-6), and swing guides away from

guide rail.

NOTE: When swinging front guides inboard, be

careful not to change position of height adjustment

rings. It is suggested that the position of the height

adjustment rings be marked with a pencil prior to

loosening of front guide attaching screws.

5. Retighten remaining screw holding front guide in

position to prevent height adjustment rings from

turning.

6. Turn lifter guide tension springs 90 degrees in-

board and pull lifters out of sun roof panel brackets

(see Figure

2F-7).Figure

ZF-7 Pulling Rear Lifter Guide out of Sun RoofPanel BracketNOTE: Do not loosen lifter pin nut as this will

change height adjustment on rear of sun roof.

7. Lift out sun roof panel.

Installation of Sun Roof Panel1. Install sun roof panel onto guide rails and locate

panel evenly in stin roof opening.

2. Reposition front guides in original position on

guide rails. Be sure that they squarely contact guide

rails and are not cocked.

NOTE: To achieve proper clearance of front guides

to guide rail, the guides should lightly touch edge ofdshould have a clearance of no

3. Reconnect

riar lifter guides onto sun roof panel

brackets and reposition tension spring as shown in

Figure

2F-3.4. Crank sun roof fully closed and check that the rear

lifters are at approximately 90 degrees with respect

to guide rails and contact guide stops (see Figure

2F-3). If adjustment is required remove crank handle

and cable crank (see Figure 2F-4) and physically

reposition lifters to position described above. Rotate

cable crank to its fully clockwise limit and reinstall.

5. Pull sun roof frame forward and reattach to sun

roof panel.

6. Open and close sun roof several times and recheck

for smoothness of operation.

Removal of Sunlpoof Frame1. Remove sun roof panel.

2. Crank rear lifter guides to furthermost rear posi-

tion.

3. Remove screws securing upper corner plates in

position and lift out upper corner plates (see Figure

2F-8).Figure 2F-&Removing Upper Corner Plates

4. Remove scretii securing left und

r@t guide rai1%lift up front ends

of- guide rails and msert wedge

under forward g&de rail ends. Slide out sun roof

frame.

Page 227 of 625

36. 601973 OPEL SERVICE MANUAL

severe or careless driver. Rapid acceleration and de-celeration, severe application of brakes, taking turns

at excessive speed, high-speed driving, and striking

curbs or other obstructions which lead to misalign-

ment are driving habits which will shorten the life of

any tire.hiaintenance of proper inflation pressure and peri-

odic interchanging of tires to equalize wear are

within the control of the driver. Underinflation

raises the internal temperature of a tire greatly due

to the continual friction caused by the flexing of the

side walls. Tire squealing on turns is an indication of

underinflation or excessive speed on the turns. A

combination of underinflation, high road tempera-

tures, and high-speed driving will quickly ruin the

best tire made.

High speed on straight highways or expressways nor-

mally causes more rapid wear on the rear than on thefront tires, although cupping of front tires can result

if the tires are not periodically switched from wheel

to wheel. Driving turns and curves at too high a rate

of speed causes the front tires to wear much faster

than the rear tires.

An inspection of the tires, together with information

as to locality in which the car has been operated willusually indicate whether abnormal wear is due to the

operating conditions described above or to mechani-cal faults which should be corrected.

The various types of

abnormal tire wear and their

causes are described in the following paragraphs.

Shoulder or Underinflation Tread WearWhen a tire is underinflated, the side walls and

shoulders of the tread carry the load, while the centerof tread folds in or compresses due to the low inter-

nal air pressure. This action causes the shoulders to

take all of the driving and braking load, resulting in

much faster wear of shoulders than of the center of

tread. See Figure 3G-7. For maximum results in han-dling, riding and tire life, tire inflation pressures

should never be allowed to go below the specified

minimum pressure.

Continuous high-speed driving on curves, right and

left, may produce tread wear very similar to underin-flation wear and might very easily be mistaken for

such. Side thrust when rounding turns causes wear

on the sides of tire tread. In making a turn to the left,especially at high speeds, the outside shoulder of the

right tire and the inside shoulder of the left tire take

the side thrust and naturally receive the most wear.

The only possible correction is to advise slower

speeds on curves. Do not increase tire inflation pres-

sures beyond specified limits, as this will cause centeror over-inflation wear. See paragraph below.

Canter or Overinflation Tread Wear

Excessive wheel camber, either positive or negative,causes the tire to run at such an angle to the road

surface that one side of the tread wears much more

than the other. See Figure

3G-7.When tire inflation pressures are maintained within

the specified limits, the tire will make a full contact

across the entire width of tread, thereby distributing

the wear evenly over the total surface of the tread

area.

Cross or Toe Tread WearWhen the front wheels have an excessive amount of

either toe-in or toe-out, the tires are actually draggedsideways when they travel straight down the road

and cross wear or scraping action takes place rapidly

wearing away the tread of tires. This cross wear con-dition will usually produce a tapered or feathered

edge on the ribs of the tire tread. See Figure

3G-7.In most cases, this can be detected by rubbing the

hand across the tire tread.

If the tapered or feathered edges are on the inner

sides of the ribs on one of both sides, it indicates thatone or both tires have excessive toe-in, while the

same condition in the outer sides of ribs indicates

excessive toe-out. Usually, excessive toe-in causes

excessive tire wear on the outer edge of the right

front tire and toe-out causes tire wear on the inner

edge of the left front tire. See Section 3C for toe-in

correction.Cornering wear caused by high-speed driving on

curves (see following paragraph) sometimes has the

appearance of toe wear. Care must be used to distin-guish between these two types of wear so that the

proper corrective measures will be used.

Side or Camber WearExcessive wheel camber, either positive or negative,

causes the tire to run at such an angle to the road

surface that one side of the tread wears much more

than the other. See Figure

3G-7.The amount or angle of the camber wear will be

governed by the amount of positive or negative cam-ber. Tire tread wear very similar in appearance to

camber wear may be caused by driving on turns at

excessive speeds. This “cornering” tread wear (see

paragraph below) cannot be corrected by change of

camber angle.

Adjustments for specified camber are covered in Sec-

tion 3C.

Page 228 of 625

WHEELS AND TIRES3G- 61Cornering Tread WearThe modern independently-sprung automobile al-

lows the driver to negotiate turns at a high rate of

speed with a greater feeling of safety. This fact is

responsible for a comparatively new type of tread

wear that can easily be mistaken for toe or camber

wear.When a car is making a turn, the tires are supposed

to be rolling in a circle. When the turn is made at

high speed, however, centrifugal force acting on the

car causes the tires to be distorted sideways and to

slip or skid on the road surface. This produces a

diagonal cross type of wear, which in severe cases

will result in a fine or sharp edge on each rib of the

tire treads.

Cornering wear can be distinguished from toe or

camber wear by the rounding of the outside shoulder

of the tire and by the roughening of tread surface in

this section denoting severe abrasion. See Figure

3G-7.No alignment or tire pressure cahnge can be made

that will relieve cornering wear. Only the driver can

effect a cure and that is by slowing down on curves.

Heel and Toe Tread WearHeel and toe wear is a saw-tooth effect with one end

of each tread block worn more than the other.

The end which wears is the one that first grips the

road when the brakes are applied. High-speed driv-

ing and excessive “se of the brakes will cause this

type of irregular tire wear. This type of wear will

occur on any type of block tread design. See Figure3G-7.

Heel and toe wear is not so prevalent on the rear tires

because of the propelling action which creates a

counteracting force which wears the opposite end of

the tread block. These two stresses on the rear tires

wear the tread blocks in opposite directions and re-

sult in more even wear while on the front tires, the

braking stress is the only one which is effective. This

may be counteracted by interchanging tires.

A small amount of irregular wear, slightly

saw-toothed in appearance, at the outer segments of tires

is a normal condition and is due to the difference in

circumference between the center and the outer

edges of the tire tread. This saw-toothed appearance,

however, will be exaggerated by underinflation, im-

proper toe-in, or both.Cupped or Scalloped Type Tire Wear

Cupping or scalloping is associated with wear on acar driven mostly at highway speeds without recom-

mended tire rotation. Factors which promote cup-

ping include underinflation, incorrect toe-in setting

or camber setting, and steady highway speeds on

smooth, paved surfaces as opposed to gravel or

rough asphalt.

The following recommendations suggest action that

may be taken to help prevent cupping.

1. Rotate tires as recommended in Figure

3G-6.2. Frequently inspect front tires for irregular wear

due to underinflation, improper toe-in setting, or

camber setting. Regardless of the original cause of

cupped tread wear on either front tire, no alignment

or balance job, however perfect, can prevent future

excessive wear of the spots. Once a front tire acquires

flat or cupped spots, additional wear will continue at

a rapid rate. At the time of correction, however, the

cupped tire should be interchanged with a rear tire

on which the tread runs true. The cupped tire will,

to a certain degree, true itself on a rear wheel.

Although not normally the cause of cupping, the

following factors can contribute to the problem.

Looseness of parts in the suspension system, such as

worn steering knuckle ball joints, loose wheel bear-

ings, inoperative shock absorbers, and any excessive

looseness throughout the steering system all tend to

allow the front wheels to kick around and, if any of

the wheel alignment factors are incorrect, irregular

spotty tire tread wear of one type or another may

result.

Wobble or runout of a tire, either front or rear, due

to bent wheel or to tire being improperly mounted

will cause uneven wear.

MAINTENANCE AND ADJUSTMENTSDEMOUNTING AND MOUNTING

TUBELESS TIRESDue to “se of symmetrical rims, tires must be

mounted over the narrow rim shoulder i.e., over out-

side rim flange.

When demounting a tubeless tire “se care to avoid

damaging the rim-seal ridges on tire beads DO NOT

USE TIRE IRONS TO FORCE BEADS A WA Y

FROM WHEEL RIM FLANGES.

When tire is removed, inspect it carefully to deter-

mine whether loss of air was caused by puncture or

by improper

tit of beads against rim flanges. If im-

proper fit is indicated, check wheel as follows: Do

not reuse dented rims.

Page 264 of 625

POWER BRAKE BOOSTER AND MASTER CYLINDER5A- 5ConditionGrabby Brakes (Apparent

Off-and On Condition)

Possible Cause1. Broken or damaged

hydraulic brake lines.Correction1. Inspect and replace, as

“CXXSSary.2. Insufficient fluid in

master cylinder.

3. Defective master cylinder

seals.4. Cracked master cylinder

casting.2. Fill reservoirs with approved

brake fluid check for leaks.

3. Repair or replace, asnecessary.4. Replace

5. Leaks at front disc brake

calipers or rear wheel

cylinders

in pipes or connections.5. Inspect and repair, as

necessary.Brakes Fail to Release6. Air in hydraulic system.

1. Blocked passage in power

piston.

2. Air valve sticking shut.6. Bleed system.

1. Inspect and repair or replace,

as necessary.

2. Check for proper lubrication of

air valve “0” ring.

3. Broken piston return spring

3. Replace

master cylinder.

4. Tight pedal linkage.5. Repair or replace, as

necessary.

MAINTENANCE AND ADJUSTMENTS

CHECKING BRAKE BOOSTER OPERATIONThe operation of the brake booster can be checked by

simple means and without any special devices.

1. With engine off, first clear the booster of any

vacuum by depressing brake pedal several times.

2. Then depress brake pedal and start engine. If the

vacuum system is working correctly, the brake pedal,

kept under even foot pressure, moves farther down-

wards due to the additional pressure developed by

the booster. Should the brake pedal not move farther

downwards, the vacuum system is deficient. In this

case check the vacuum hose to booster, to vacuum

control valve and to engine intake manifold connec-

tions.3. If the vacuum system operates properly, the defect

is in the brake booster itself. A dirty filter impairs oreven prevents air from entering into the booster and

thereby the formation of a difference in pressure in

the vacuum cylinder.

Repairs cannot be carried out on the brake booster.

If no deficiency can be found in the vacuum system

or filter, the brake booster has to be replaced.

Under normal operating conditions the brake

booster requires no service. However, under adverse

conditions such as frequent driving on sandy or

dusty roads, the filter and sound deadener should be

replaced occasionally. To do so, the brake booster

must be removed but it isn’t necessary to detach the

master cylinder.

BRAKE BOOSTER FILTER SERVICEUnder normal operating conditions the filter need

not be exchanged for a new one.

Under adverse operating conditions

- frequent driv-