remove seats OPEL GT-R 1973 Service Manual

[x] Cancel search | Manufacturer: OPEL, Model Year: 1973, Model line: GT-R, Model: OPEL GT-R 1973Pages: 625, PDF Size: 17.22 MB

Page 18 of 625

LUBRICATION AND MAINTENANCE OC-9

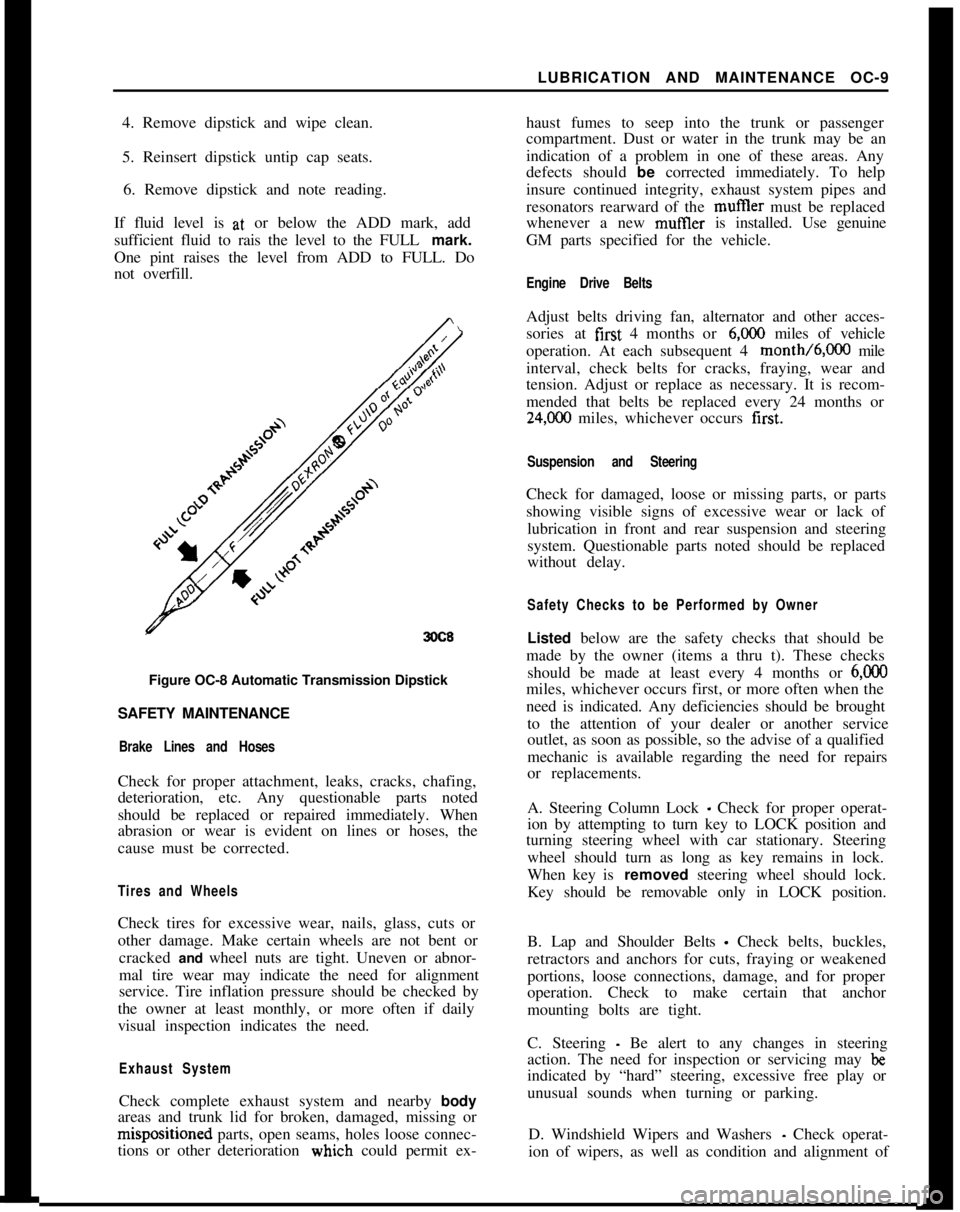

4. Remove dipstick and wipe clean.

5. Reinsert dipstick untip cap seats.

6. Remove dipstick and note reading.

If fluid level is at, or below the ADD mark, add

sufficient fluid to rais the level to the FULL mark.

One pint raises the level from ADD to FULL. Do

not overfill.

3OC8Figure OC-8 Automatic Transmission Dipstick

SAFETY MAINTENANCE

Brake Lines and HosesCheck for proper attachment, leaks, cracks, chafing,

deterioration, etc. Any questionable parts noted

should be replaced or repaired immediately. When

abrasion or wear is evident on lines or hoses, the

cause must be corrected.

Tires and WheelsCheck tires for excessive wear, nails, glass, cuts or

other damage. Make certain wheels are not bent or

cracked and wheel nuts are tight. Uneven or abnor-

mal tire wear may indicate the need for alignment

service. Tire inflation pressure should be checked by

the owner at least monthly, or more often if daily

visual inspection indicates the need.

Exhaust SystemCheck complete exhaust system and nearby body

areas and trunk lid for broken, damaged, missing orm&positioned parts, open seams, holes loose connec-

tions or other deterioration wiuch could permit ex-haust fumes to seep into the trunk or passenger

compartment. Dust or water in the trunk may be an

indication of a problem in one of these areas. Any

defects should be corrected immediately. To help

insure continued integrity, exhaust system pipes and

resonators rearward of the muftler must be replaced

whenever a new mufIler is installed. Use genuine

GM parts specified for the vehicle.

Engine Drive BeltsAdjust belts driving fan, alternator and other acces-

sories at first 4 months or

6,ooO miles of vehicle

operation. At each subsequent 4 month/6,000 mile

interval, check belts for cracks, fraying, wear and

tension. Adjust or replace as necessary. It is recom-

mended that belts be replaced every 24 months or

24,C00 miles, whichever occurs first.

Suspension and SteeringCheck for damaged, loose or missing parts, or parts

showing visible signs of excessive wear or lack of

lubrication in front and rear suspension and steering

system. Questionable parts noted should be replaced

without delay.

Safety Checks to be Performed by OwnerListed below are the safety checks that should be

made by the owner (items a thru t). These checks

should be made at least every 4 months or

6,ooOmiles, whichever occurs first, or more often when the

need is indicated. Any deficiencies should be brought

to the attention of your dealer or another service

outlet, as soon as possible, so the advise of a qualified

mechanic is available regarding the need for repairs

or replacements.

A. Steering Column Lock

_ Check for proper operat-

ion by attempting to turn key to LOCK position and

turning steering wheel with car stationary. Steering

wheel should turn as long as key remains in lock.

When key is removed steering wheel should lock.

Key should be removable only in LOCK position.

B. Lap and Shoulder Belts

- Check belts, buckles,

retractors and anchors for cuts, fraying or weakened

portions, loose connections, damage, and for proper

operation. Check to make certain that anchor

mounting bolts are tight.

C. Steering

- Be alert to any changes in steering

action. The need for inspection or servicing may

beindicated by “hard” steering, excessive free play or

unusual sounds when turning or parking.

D. Windshield Wipers and Washers

- Check operat-

ion of wipers, as well as condition and alignment of

Page 158 of 625

SEATS, INTERIOR TRIM AND HEADLININGZG-35

2. Push off side panel trim pad. Trim pad is held in

position by a retaining button.

REMOVAL AND INSTALLATIONOF HEADLINING

Removal

1. Disconnect battery.

2. Lift out rear seat cushion (sedans only).

3. From trunk area, loosen tabs holding cardboard

against rear seat cross brace and lift out cardboard

(sedans only).

4. Pry up two tabs holding lower portion of rear seat

back in position, swing back of seat forward and lift

out (sedans only).

5. From trunk area pry out parcel shelf plastic retain-

ers and lift out parcel shelf (sedans only).

6. Remove rear-view mirror, sun visors, interior

lamp, assist straps and coat hooks. Remove front and

rear windows on all but Wagon Models. On Wagons,

remove the front window and the quarter windows.

7. Work door opening pinchweld finishing strip

away from pinchweld as far as necessary to expose

edge of headlining.

8. Start at: left or right windshield pillar and pry

headlining loose.

9. Roll back headlining to expose metal tabs securing

headlining listing wire to roof and unhook headhn-

ing front listing wire from metal tabs using a blunt

edge tool.

10. Pull loose the edges of headlining cemented to

door openings, rear quarter window openings, rear

quarter pillar and from under rear window rubber

channel. On rear quarter pillars, slightly bend down

cardboard of rear quarter trim pad to facilitate re-

moval. During removal, special care should be taken

not to tear headlining at seams.

11. After edges of headlining have been pulled loose,

tilt remaining listing wires with headlining forward

or rearward and pull listing wires free from side roof

rails. Lift out headlining and listing wires.

Installation1. Check secureness of noise insulation pad on inside

of roof panel and recement as necessary using asphalt

cement. If headlining is to be replaced, insert listing

wires into headlining according to their markings.

Progressing from the front listing wire to the rear

wire, the left ends of the wires are color coded as

follows:1st listing wire

- No marking, wire is thinner than

other wires

2nd listing wire

- Red

3rd listing wire

- Blue

4th listing wire

_ Green

5th listing wire

- Brown

6th listing wire

- White

2. Install 1st listing wire ends into retainer slots in-

side roof rails and hook listing wire into six metal

tabs above windshield. Lightly bend tabs with a ham-

mer as shown in Figure

2G-8.

HEAOLlN’lNdA-----

26-8Figure

2G-8 Headlining With 1st Listing Wire Hooked

Onto Metal Tabs

LISTINGWIRE

SECTIOND-D

4 26-9Figure 2G-9 2nd and 5th Listing Wire Attachment

Page 160 of 625

SEATS, INTERIOR TRIM AND HEADLINING20.378. If wagon, install front window and quarter win-

dows. It other than wagon, install front and rear

windows.9. Install coat hooks, assist straps, interior lamp, sun

visors, and rear view mirror.

10. Install parcel shelf and plastic retainers (sedans

only).

11. Install rear seat back into position and bend over

tabs holding lower portion of seat back (sedans only).

12. In trunk area instail cardboard against rear seat,

cross brace, and bend over tabs (sedans only).

13. Install rear seat cushion (sedans only).

14. Connect battery.REMOVAL AND INSTALLATION OF REAR SIDE

PANEL TRIM PAD

1, Unscrew shield on lock pillar. See Figure 2G- 11.

2. Pull off sealing strip on lock pillar and rear quarter

window. See Figure 2G- 12.

3. Remove ash tray.

4. Remove rear seat and push retaining button out of

trim pad. See Figure

2G-13.5. Pull out trim pad towards the front.

6. Prior to installation, press together sealing strip

ends to obtain a tight seat.

Page 218 of 625

REAR SUSPENSION3F- 51

REAR SUSPENSION

CONTENTS

Subject

DESCRIPTION AND OPERATION:

Description and Operation of Rear Suspension. . . . . .DIAGNOSIS: (Not Applicable)

MAINTENANCE AND ADJUSTMENTS: (Not

Applicable)

MAJOR REPAIR:

Rear Shock Absorber Removal and Replacement . .

Rear

SpringRemovalandInstallation. . . . . . . . . . . . . . . . . . . . . . . .LowerControlArmReplacement

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .Stabilizer

RodReplacement. . . . . . . . . . . ~ . . . . . . . . . . . . . . . . . . . . . ..-....Track Rod Replacement

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .SPECIFICATIONS:

Rear

SuspensionSpecifications. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .Page No.3F-5

13F-513F-523F-533F-533F-533F-53

DESCRIPTION AND OPERATIONDESCRIPTION AND OPERATION OF REAR

SUSPENSIONAll Opels utilize the three link rear suspension ar-

rangement. This rear suspension consists of coil

springs, track rod, shock absorbers and lower control

arms.The coil springs set between two seats which arc

situated ahead of the rear axle housing.

The track rod is utilized on all models to control the

lateral stability of the rear axle assembly. It is of

tubular design. A stabilizer rod is used on all Wagons

as well as Fast Backs and Sedans. The GT is not

equipped with a stabilizer rod.

The lower control arms are of tubular design and

function as two links of the three link suspension

system. They are attached to the underbody through

brackets welded to the side rails and to the rear axle

assembly through the front portion of the spring seat

bracket. The lower control arms control the fore and

aft movement of the rear axle assembly.

The third link in this suspension system is the torque

tube which is connected to the differential carrier

and also to the underbody through rubber bushings

in the central joint support bracket.The torque tube in conjunction with the lower con-

trol arms absorb all acceleration and braking torque.

MAJOR REPAIR

REAR SHOCK ABSORBER REMOVALAND INSTALLATION

RemovalNOTE: The trim panel under the spare tire must be

removed on the GT to gain access to attaching nuts.

1. Remove upper attaching nut, retainer and rubber

grommet.

2. Remove lower attaching nut and rubber grommet

retainer, compress shock absorber and remove from

lower mounting pin.

Installation1. Replace upper and lower rubber grommets, if

necessary, before installing shock absorber.

2. Extend shock absorber and position in car. Attach

at lower end first, torque nut to 15 lb.ft. on the GT,

and torque to 47 lb.ft. on the Opel 1900

- Manta.

Page 219 of 625

3F. 521973 OPEL SERVICE MANUAL

3. Install rubber grommet, retainer and self-locking

nut at top of shock absorber. Torque to 10 lb. ft.

Always use new self-locking nuts.

REAR SPRING REMOVAL AND INSTALLATION

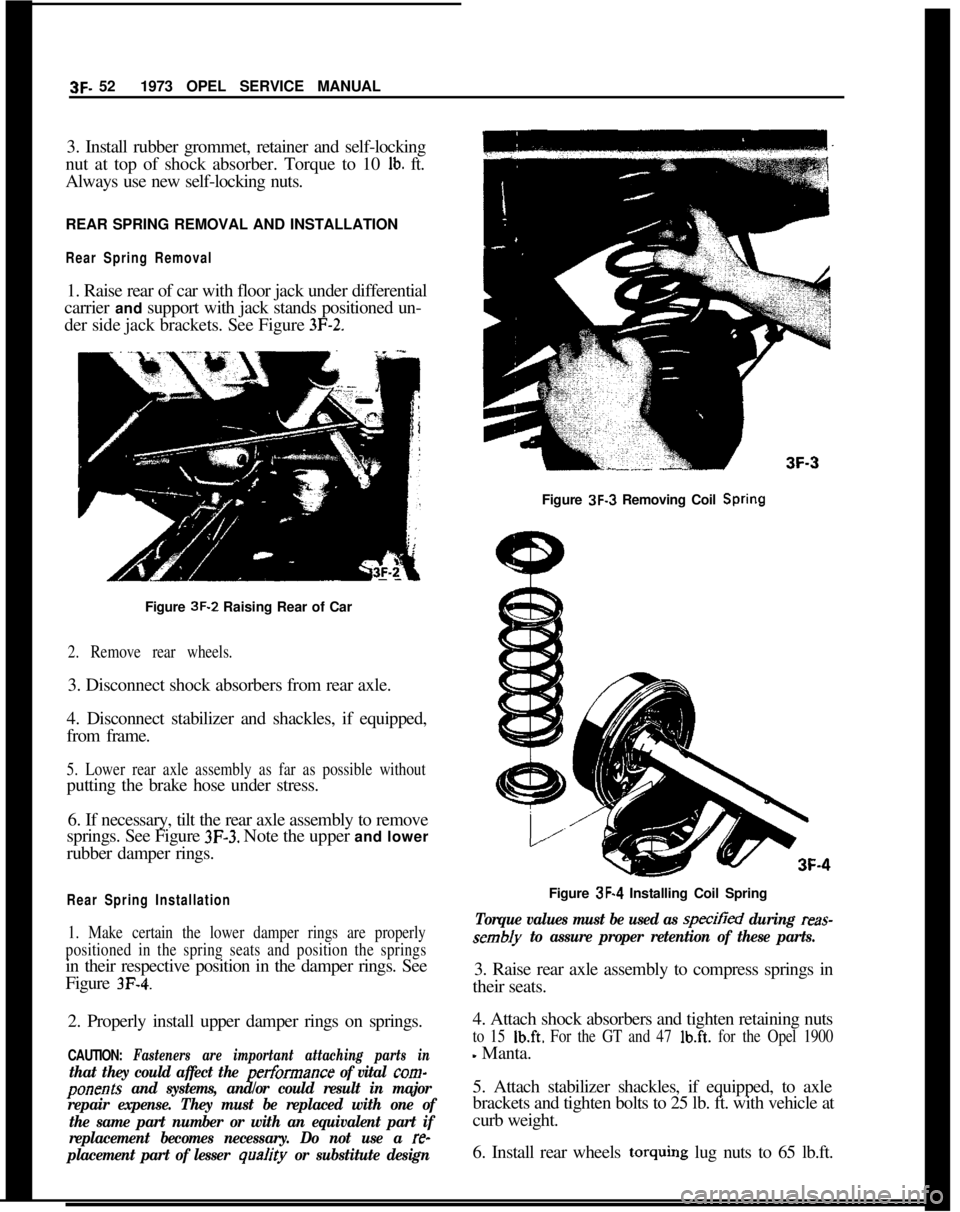

Rear Spring Removal1. Raise rear of car with floor jack under differential

carrier and support with jack stands positioned un-

der side jack brackets. See Figure

3F-2.Figure 3F-3 Removing Coil

SpringFigure 3F-2 Raising Rear of Car

2. Remove rear wheels.3. Disconnect shock absorbers from rear axle.

4. Disconnect stabilizer and shackles, if equipped,

from frame.

5. Lower rear axle assembly as far as possible withoutputting the brake hose under stress.

6. If necessary, tilt the rear axle assembly to remove

springs. See Figure

3F-3. Note the upper and lower

rubber damper rings.

Rear Spring Installation

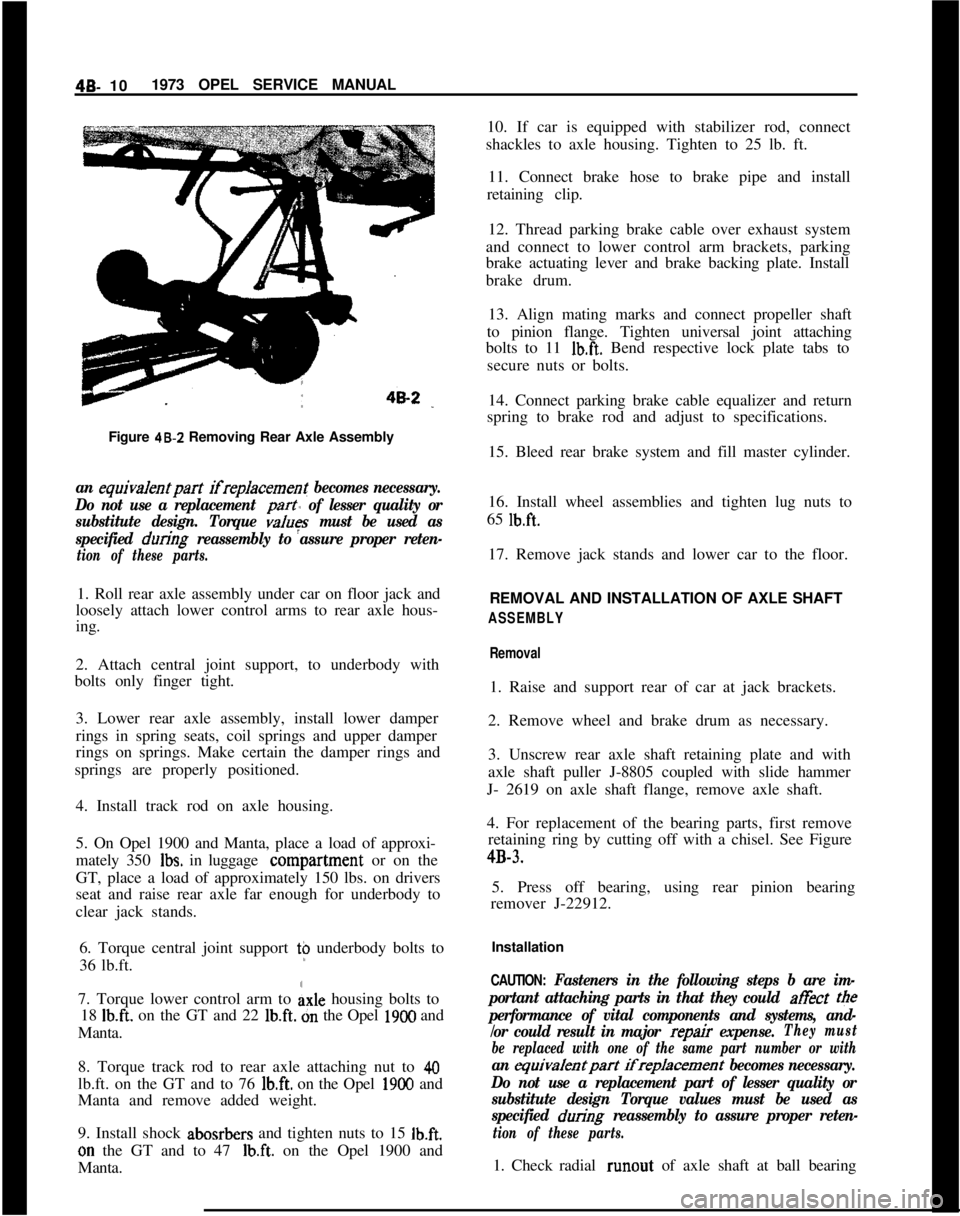

1. Make certain the lower damper rings are properly

positioned in the spring seats and position the springsin their respective position in the damper rings. See

Figure

3F-4.2. Properly install upper damper rings on springs.

CAUTION: Fasteners are important attaching parts in

that they could affect the performance of vital corn-

ponents and systems, and/or could result in major

repair expense. They must be replaced with one of

the same part number or with an equivalent part if

replacement becomes necessary. Do not use a

re-

placement part of lesser

qua/ity or substitute designFigure 3F-4 Installing Coil Spring

Torque values must be used as specitied during reas-

sembly to assure proper retention of these parts.3. Raise rear axle assembly to compress springs in

their seats.

4. Attach shock absorbers and tighten retaining nuts

to 15 Ib.ft. For the GT and 47 lb.ft. for the Opel 1900

- Manta.

5. Attach stabilizer shackles, if equipped, to axle

brackets and tighten bolts to 25 lb. ft. with vehicle at

curb weight.

6. Install rear wheels torquing lug nuts to 65 lb.ft.

Page 241 of 625

4B- 101973 OPEL SERVICE MANUAL

Figure 48-Z Removing Rear Axle Assemblyan equiva/entpart ifreplacement becomes necessary.

Do not use a replacement

part of lesser quality or

substitute design. Torque

values must be used as

specified

during reassembly to assure proper reten-

tion of these parts.1. Roll rear axle assembly under car on floor jack and

loosely attach lower control arms to rear axle hous-

ing.

2. Attach central joint support, to underbody with

bolts only finger tight.

3. Lower rear axle assembly, install lower damper

rings in spring seats, coil springs and upper damper

rings on springs. Make certain the damper rings and

springs are properly positioned.

4. Install track rod on axle housing.

5. On Opel 1900 and Manta, place a load of approxi-

mately 350

Ibs. in luggage conipartment or on the

GT, place a load of approximately 150 lbs. on drivers

seat and raise rear axle far enough for underbody to

clear jack stands.

6. Torque central joint support t$ underbody bolts to

36 lb.ft.

7. Torque lower control arm to

Axle housing bolts to

18

Ib.ft. on the GT and 22 lb.ft. dn the Opel 1900 and

Manta.

8. Torque track rod to rear axle attaching nut to

40lb.ft. on the GT and to 76

lb.ft. on the Opel 1900 and

Manta and remove added weight.

9. Install shock abosrbers and tighten nuts to 15

Ib.ft.on the GT and to 47

Ib.ft. on the Opel 1900 and

Manta.10. If car is equipped with stabilizer rod, connect

shackles to axle housing. Tighten to 25 lb. ft.

11. Connect brake hose to brake pipe and install

retaining clip.

12. Thread parking brake cable over exhaust system

and connect to lower control arm brackets, parking

brake actuating lever and brake backing plate. Install

brake drum.

13. Align mating marks and connect propeller shaft

to pinion flange. Tighten universal joint attaching

bolts to 11

Ib.ft. Bend respective lock plate tabs to

secure nuts or bolts.

14. Connect parking brake cable equalizer and return

spring to brake rod and adjust to specifications.

15. Bleed rear brake system and fill master cylinder.

16. Install wheel assemblies and tighten lug nuts to

65

lb.ft.17. Remove jack stands and lower car to the floor.

REMOVAL AND INSTALLATION OF AXLE SHAFT

ASSEMBLY

Removal1. Raise and support rear of car at jack brackets.

2. Remove wheel and brake drum as necessary.

3. Unscrew rear axle shaft retaining plate and with

axle shaft puller J-8805 coupled with slide hammer

J- 2619 on axle shaft flange, remove axle shaft.

4. For replacement of the bearing parts, first remove

retaining ring by cutting off with a chisel. See Figure4B-3.

5. Press off bearing, using rear pinion bearing

remover J-22912.

Installation

CAUTION: Fasteners in the following steps b are im-

portant attaching parts in that they could at&t

tee

performance of vital components and systems, and-

/or could result in major

repair expense.They must

be replaced with one of the same part number or with

an equivalentpart ifreplacement becomes necessary.

Do not use a replacement part of lesser quality or

substitute design Torque values must be used as

specified

during reassembly to assure proper reten-

tion of these parts.1. Check radial runout of axle shaft at ball bearing

Page 306 of 625

ENGINE MECHANICAL AND MOUNTS6A- 15New inlet valves must not be refaced or lapped with

grinding compound.The correct angle for the intake

and exhaust valve head is 44 degrees.10. Install cylinder head.

11. Adjust valve clearance. See MAINTENANCE

AND ADJUSTMENTS.

7. Inspect valve guides. Worn or pitted guides can be

reamed to accept valves with oversize stems. Over-

size valves are occasionally used in production.

Oversize valves are marked

’ 1 u “2” or “A” and are

stamped into the valve stem end and also stamped

near spark plug hole. See Figure 6A-22.

Replacing Rocker Arm Studs1. When replacing rocker arm studs become

neces-

sary, remove air cleaner, rocker arm cover and

rocker arm.

8. Reseat valve seats in cylinder head in the following

sequence:

Intake

NOTE:The rocker arm studs are screwed into the

cylinder head. A tapered part of the stem serves to

a void stud loosening.With 45 degrees cutter, remove burnt structure until

a metallic bright seat is obtained. Lightly coat valve

head with red lead, insert it into guide and turn it

under light pressure several times back and forth.

Thereby a contact pattern is obtained and the seat

width can be measured. If valve does not seat per-

fectly all around, lightly recut valve seat to the estab-

lished seat width of

,049” - .059” with 30 degrees

correction cutter.

ExhaustThe directions for reconditioning intake valve seats

apply in principle also to exhaust valve seat recondi-

tioning with the exception that the valve seat width

should be

.063-,073 in. and different cutters are em-

ployed.

NOTE:

: OTse new valve seals whenever

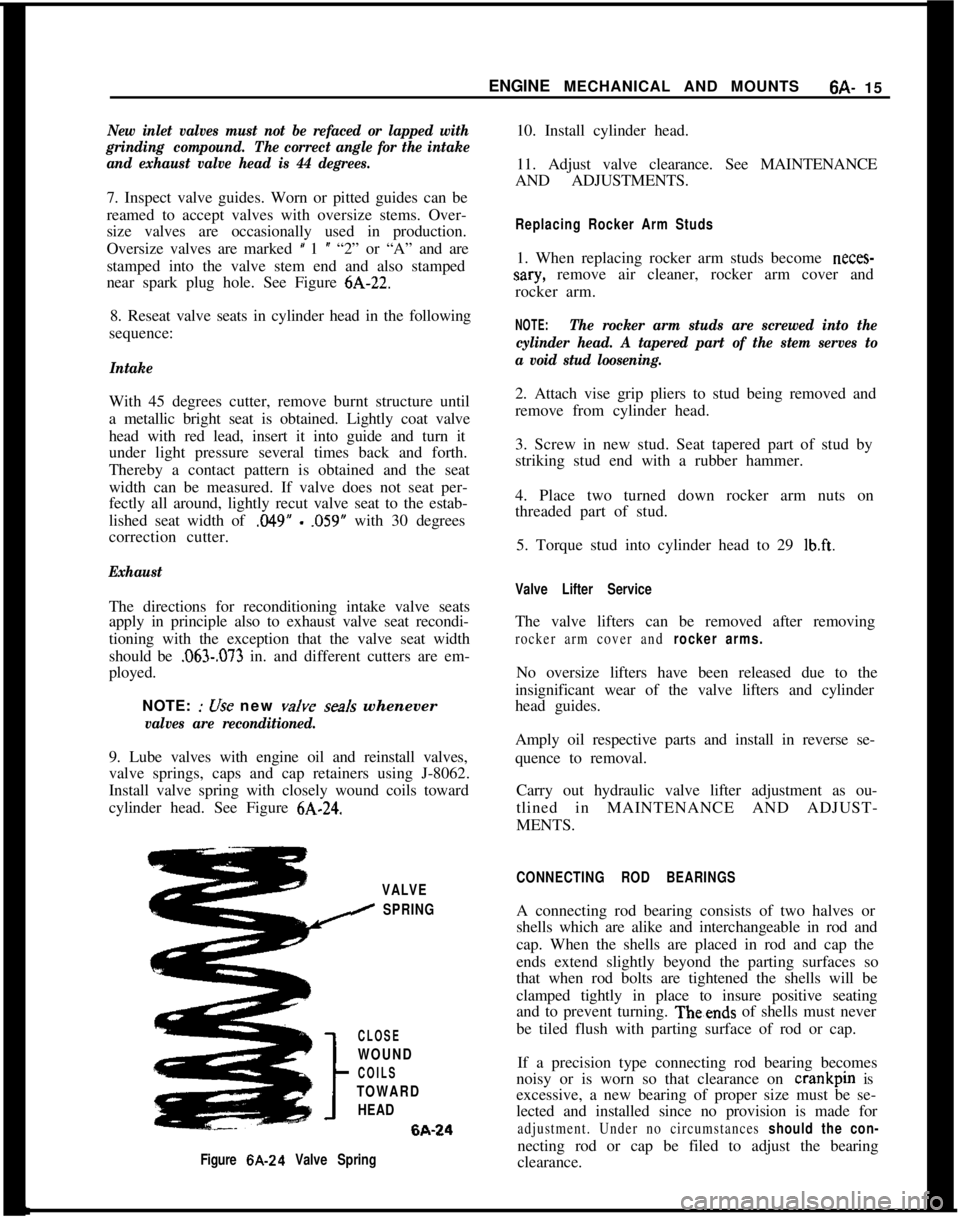

valves are reconditioned.9. Lube valves with engine oil and reinstall valves,

valve springs, caps and cap retainers using J-8062.

Install valve spring with closely wound coils toward

cylinder head. See Figure

6A-24.2. Attach vise grip pliers to stud being removed and

remove from cylinder head.

3. Screw in new stud. Seat tapered part of stud by

striking stud end with a rubber hammer.

4. Place two turned down rocker arm nuts on

threaded part of stud.

5. Torque stud into cylinder head to 29

lb.ft.

Valve Lifter ServiceThe valve lifters can be removed after removing

rocker arm cover and rocker arms.No oversize lifters have been released due to the

insignificant wear of the valve lifters and cylinder

head guides.

Amply oil respective parts and install in reverse se-

quence to removal.

Carry out hydraulic valve lifter adjustment as ou-

tlined in MAINTENANCE AND ADJUST-

MENTS.

VALVE

I SPRING

CLOSE

WOUND

COILS

TOWARD

HEAD6A-24

Figure 6A-24 Valve SpringCONNECTING ROD BEARINGSA connecting rod bearing consists of two halves or

shells which are alike and interchangeable in rod and

cap. When the shells are placed in rod and cap the

ends extend slightly beyond the parting surfaces so

that when rod bolts are tightened the shells will be

clamped tightly in place to insure positive seating

and to prevent turning. Theends of shells must never

be tiled flush with parting surface of rod or cap.

If a precision type connecting rod bearing becomes

noisy or is worn so that clearance on crankpin is

excessive, a new bearing of proper size must be se-

lected and installed since no provision is made for

adjustment. Under no circumstances should the con-necting rod or cap be filed to adjust the bearing

clearance.

Page 308 of 625

ENGINE MECHANICAL AND MOUNTS6A- 17

seating and to prevent turning.The ends of she//s

must never be tiled flush with parting surface of

crankcase or bearing cap.Crankshaft bearings are the precision type which do

not require reaming to size. Shims are not provided

for adjustment since worn bearings are readily re-

placed with new bearings of proper size. Bearings for

service replacement are furnished in standard size

and undersizes. Under no circumstances should

crankshaft bearing caps be tiIed to adjust for wear in

old bearing.After removal of oil pan, pipe and screen assembly,

perform the following removal, inspection and in-

stallation operations on each crankshaft bearing in

turn so that the crankshaft will be well supported by

the other bearings.

If crankshaft has been removed to check straightness

the following procedure is suggested. Rest crank-

shaft on “V-blocks” at number one and number live

main bearing journals. Check indicator runout at

No. 3 main bearing journal. Total indicator reading

should not exceed

.C012”.1. Since any service condition which affects the

crankshaft bearings may also affect the connecting

rod bearings, it is advisable to inspect connecting rod

bearings

first. If crankpins are worn to the extent

that crankshaft should be replaced or reground, re-

placement of crankshaft bearings only will not be

satisfactory.

If replacement of cylinder block or crankshaft is re-

quired, always check main bearing clearance with

plastic-type gauge to obtain specified limits.

2. Remove one bearing cap, then clean and inspect

lower bearing shell and the crankshaft journal. If

journal surface is scored or ridged, the crankshaft

must be replaced or reground to insure satisfactory

operation with new bearings. Slight roughness may

be polished out with tine grit polishing cloth

thoroughly wetted with engine oil, and burrs may be

honed off with a tine stone.

3. If condition of lower bearing shell and crankshaft

journal is satisfactory, check the bearing clearance

with a plastic-type gauge.

4. When checking a crankshaft bearing with plastic-

type gauging material, turn crankshaft so that oil

hole is up to avoid dripping of oil on the gauge

material. Place paper shims in lower halves of adja-

cent bearings and tighten cap bolts to take the weight

of crankshaft

off the lower shell of beating being

checked.5. If bearing clearance exceeds

.C03”, it is advisable

to install a new bearing; however, if bearing is in

good condition and is not being checked because ofbearing noise, it is not necessary to replace the bear-

ing.6. Loosen all crankshaft bearing cap bolts

l/2 turn,

and remove cap of bearing to be replaced.

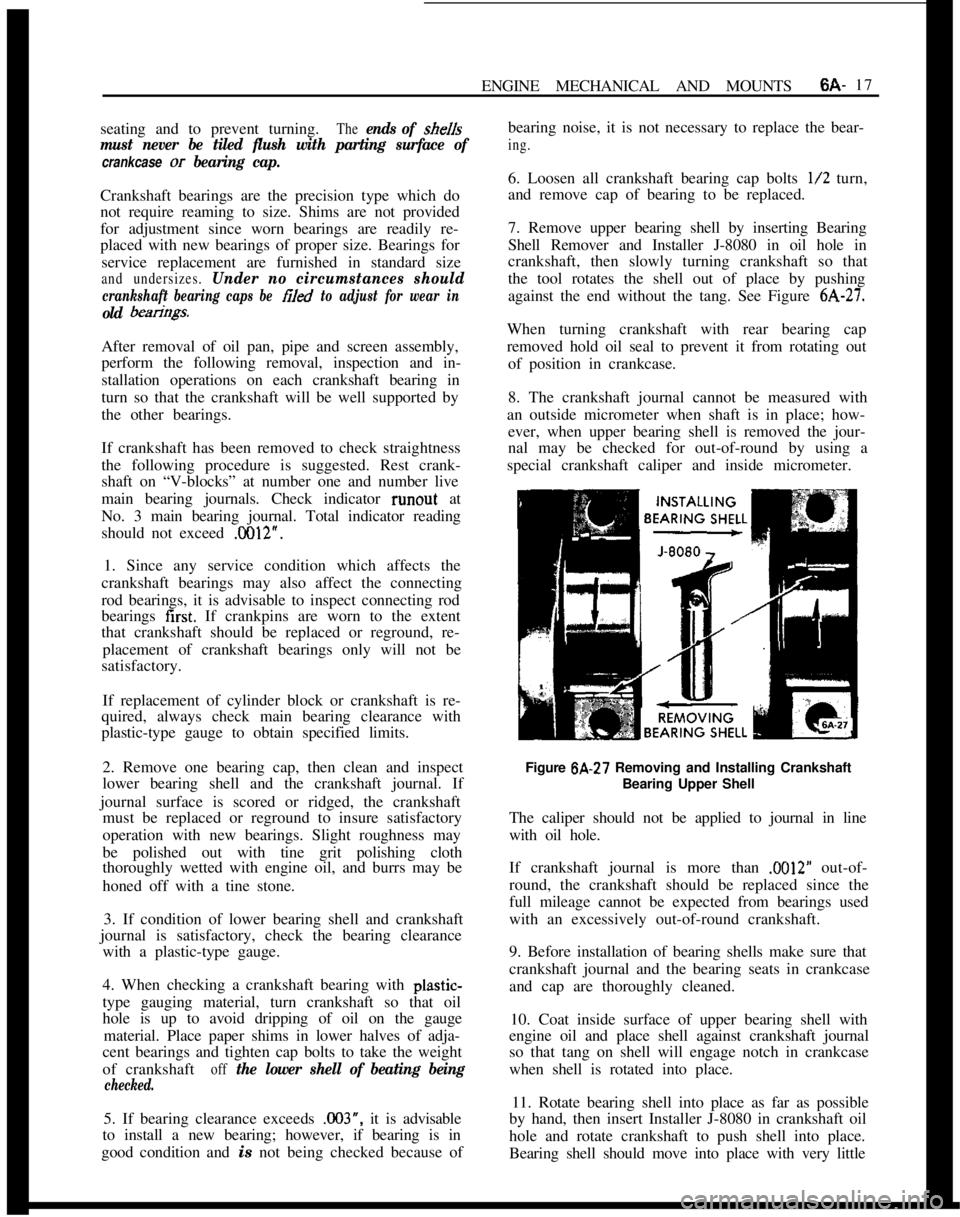

7. Remove upper bearing shell by inserting Bearing

Shell Remover and Installer J-8080 in oil hole in

crankshaft, then slowly turning crankshaft so that

the tool rotates the shell out of place by pushing

against the end without the tang. See Figure

6A-27.When turning crankshaft with rear bearing cap

removed hold oil seal to prevent it from rotating out

of position in crankcase.

8. The crankshaft journal cannot be measured with

an outside micrometer when shaft is in place; how-

ever, when upper bearing shell is removed the jour-

nal may be checked for out-of-round by using a

special crankshaft caliper and inside micrometer.

Figure 6A-27 Removing and Installing Crankshaft

Bearing Upper Shell

The caliper should not be applied to journal in line

with oil hole.

If crankshaft journal is more than

.M)12” out-of-

round, the crankshaft should be replaced since the

full mileage cannot be expected from bearings used

with an excessively out-of-round crankshaft.

9. Before installation of bearing shells make sure that

crankshaft journal and the bearing seats in crankcase

and cap are thoroughly cleaned.

10. Coat inside surface of upper bearing shell with

engine oil and place shell against crankshaft journal

so that tang on shell will engage notch in crankcase

when shell is rotated into place.

11. Rotate bearing shell into place as far as possible

by hand, then insert Installer J-8080 in crankshaft oil

hole and rotate crankshaft to push shell into place.

Bearing shell should move into place with very little

Page 347 of 625

6E- 561973 OPEL SERVICE MANUAL

valve stop screw. Loosen the stop screw until the

valve is completely closed. Turn the screw in l/4turn from closed position, hold, and tighten lock nut.

This is done to insure that the throttle blade will not

stick closed. See Figure

6E-30.PUMPFigure 6E-30 Adjusting Secondary Throttle Valve Gap

24. Install accelerator pump connecting rod in lower

hole of primary throttle shaft lever and cotter pin in

outboard hole at accelerator pump actuating lever

end. Paying attention to proper arrangement of cot-

ter pin and washers. See Figure

6E-2.25. With throttle plate completely closed, there

should be no clearance between the pump levei and

the pump plunger rod.

26. If a clearance is present, loosen 4 accelerator

Figure

6E-31 Accelerator Pump CoverFigure 6C32 Accelerator Pump Cover

pump cover retaining screws and allow the

dia-’phragm spring to push plunger against lever so that

a zero clearance exists. Then retighten the screws.

See Figures

6E-3 1 and 6E-32.27. Insert accelerator pump discharge nozzle so that

the bent tube end points into suction channel of the

primary barrel.

28. Fill the bowl with fuel.

29. With fuel in bowl, slowly open the throttle and

observe the accelerator pump pressure relief valve

exhaust ports and where it seats into the bowl. See

Figure

6E-33. Fuel should not be bleeding back into

the bowl from the exhaust ports or where the relief

valve seats, but a steady stream of fuel should dis-

charge from the discharge nozzle.

30. With fuel in bowl, rapidly open the throttle atid

observe the exhaust ports of the pressure relief valve.

See Figure

6E-33. Fuel should~exhaust’from the ac-

celerator pump pressure relief valve exhaust ports.

3 1. If the pressure relief valve malfunctions, remove

it and replace with a new one.

32. No float adjustment is possible, so check position

of float arm by comparing with a new float of thesame carburetor type. If float arm is bent, replace

float.

Page 474 of 625

AUTOMATIC TRANSMISSION 7C-113

12. Inspect the piston return springs. Evidence of

extreme heat or burning in the area of the clutch may

have caused the springs to take a heat set and would

justify replacement of the springs.

Figure 7C-16313. Inspect second clutch hub bushing for scoring or

wear.14. If necessary, remove second clutch hub bushing

using remover and installer J-23130-6 with driver

handle J-8092. See Figure 7C-164.

P-J-6092

SECOND CLUTCH

DRUM

iJ:23130-6Figure

7C-16415. Clean in solvent to remove any foreign matter.

Install new second clutch hub bushing using tool

J-23 130-6 and driver handle J-8092. Bushing must be

driven in until tool bottoms on bench. See Figure 7C-

164.16. To install second clutch piston into second clutch

drum, use installer tool J-23080 so as not to damage

lip seal. See Figure 7C-165. Use liberal amount of

transmission fluid for ease of installation and to pre-

vent seal damage.

SECOND CLUTCHDRUM

J-23,060Figure

7C-16517. Remove second clutch piston and seal installer

J-23080.18. Install 22 springs and retaining seat on second

clutch piston.

19. Using spring compressor tool J-2590-12 with

adapter J-21420-1 on retaining seat, compress sec-

ond clutch piston return springs. Care should be

taken so that retainer does not catch in snap ring

groove and damage retainer.

20. Install snap ring with snap ring pliers such as

J-

8059.21. Install bronze thrust washer so that the tang seats

in the slot of the second clutch hub. Secure with

petroleum jelly (unmedicated).

22. Inspect condition of composition and steel plates.

Do not diagnose a composition drive plate by co/or.

A. Dry composition plates with compressed air and

inspect the composition surface for:

1. Pitting and flaking

2. Wear

3. Glazing