fuse chart OPEL GT-R 1973 Service Manual

[x] Cancel search | Manufacturer: OPEL, Model Year: 1973, Model line: GT-R, Model: OPEL GT-R 1973Pages: 625, PDF Size: 17.22 MB

Page 75 of 625

lG- 54 1973 OPEL SERVICE’ MANtiAL/SIGNAL SYSTEMSCdNTENTS

9Subject

DESCRIPTION AND OPERAT!ON:

Directional Signal Lever

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Horn. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .HazardWarning

Flasher. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .BrakeSystemWarningLight

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .DIAGNOSIS:

SignalSystem,.......................

i . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .MAINTENANCE AND ADJUS,TMENTS:

MAJOR REPAIR:

Directional Signal Switch

:. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

HornRemoval. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .Removing Horn Contact

. . . . :.............................................

SPECIFICATIONS:

FuseChart. . . . . . I . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .Page No.

1 G-54

1 G-54

1 G-55

lG-55 _1 G-55

1 G-55

16-551 G-55

1 G-56

DESCRIPTION AND OPERATION

DIRECTIONAL SIGNAL LEVERThe direction signal switch lever is a multi- purpose

lever controlling direction signals, passing signal,

and high and low beams. See Figure

lG-1.301Gl

Figure lG-1 Directional Signal Position for Headlamp

OperationThe direction signal lever is provided with a

two-step mechanism for operation of headlight high and

low beams, and passing signal (not in New Jersey).

With headlights off, moving the lever repeatedly to-

wards steering wheel flashes headlights as a passing

signal. With headlights on, moving the lever repeat-

edly towards steering wheel up to first stop also

flashes passing signal regardless whether or not the

direcl:ion signals are switched on. When the lever is

moved up to the second stop, the headlights are

changed from high to low beam

dr vice versa. On all

Rallye cars, when switching from low to high beam

position, with the fog lamp instrument panel switch

“ON” and ignition switch in “RUN” position, the

fog lights are automatically

switChed off. Direction

signals work in the normal manner; pushing the lever

up for right turn signal and pulling the lever down

for left turn signal.

The horn button is located in the center part of the

steering wheel. The horn is actuated by pushing

down on the ends of both spokes on Opel 1900 andManta’s or on the center horn button on the Rallye.

The button is provided with a spring-loaded plunger.See Figure

lG-2.

Page 549 of 625

98.40 1973 OPEL SERVICE MANUAL

2. Interconnect manifold and gage set (J-5725-01),

gage charging lines (J-5418) and gage adapters

(J-5420) to air conditioning system as shown in Figure

9B-40.3. Place transmission in “Park” for automatics and

in neutral for manuals. Apply hand brake.

4. Turn blower switch to the “Hi” position.

5. Turn temperature switch to “Max” position.

6. Run engine at 2000 RPM for ten (10) minutes with

car doors and windows closed and the hood up. Place

a high volume industrial type fan in front of radiator

if head pressure should exceed 250 psi and also at

high ambients to bring the pressures to within the

limits specified in the Functional Charts in Division

V.In the case of the Opel 1900 and the Manta, a ther-

mometer should be placed in a position to read the

temperature of the air discharging from the right-

hand A/C outlet. In case of the GT, a thermometer

should be placed in a position to read the tempera-

ture of the air discharging from the left-rear A/C

outlet.

HEATER-AIR CONDITIONER REFRIGERANT

CIRCUIT TROUBLE DIAGNOSIS GUIDE

Insufficient Cooling (Check Air Flow)

Normal Air Flow (Inspect system for visual defects.

Run functional tests.)

Discharge Air

- Normal Temp Check for air leaks

through dash, car body, windows, or from heater or

ventilators.

Discharge Air

- High Temp Check sight glass for

foaming and compressor clutch for engagement.

No Compressor Clutch Engagement Check connec-

tions at clutch switch, harness connectors, and check

clutch switch.

No Foaming Compare evaporator pressure to that

on functional test table.

Foaming System is probably low on refrigerant.

Check for leaks, repair, evacuate, and charge. If

foaming still occurs, check for restriction in refriger-

ant lines between condenser and receiver dehydrator.

Evaporator Pressure Normal Compare head pres-

sure to pressure on functional test table.

Evaporator Pressure Low Ice may be forming on

evaporator. Low volume of air discharging at A/C

outlet after system has been running above idle con-dition

,for approximately 15-30 min.utes. Discharging

air gradually elevating in temperature. Check expan-

sion valve. If valve isn’t permitting flow of liquid,

this will be indicated by a warm pipe out of the

evaporator. This may be caused by: 1) Clogged or

Plugged inlet screen in the expansion valve; 2)

Broken capillary line; or 3) Discharged temperature

bulb. If the valve is okay, the pipe out of the evapora-

tor will be cold.

Evaporator Pressure High Check the expansion

valve to determine if themobulb is making good con-

tact and is properly insulated. Operate engine at 2000

RPM with maximum air conditioning setting. If

evaporator pressure remains high, feel suction line.

If line feels frosty or extremely

(cold with relative

high ambient conditions, then partially cover the

condenser to obtain head pressures from 265 psi to

280 psi maximum. If evaporator pressure rises above

30 psi, change the expansion valve.

Also, check if compressor may be the cause due to

some internal or external mechanical trouble which

prevents reduction of pressure. Check for external

troubles, slipping belt, bad clutch and/or pulley, or

improper clutch engagement, before investigating

the compressor internally.

Head Pressure High Check for the following: Con-

denser air flow low, air in system, excessive refriger-

ant in system, restriction in condenser.Head.PressureLowRestriction in flow of refrigerant

to evaporator, or expansion valve plugged or defec-

tive.

Low Air Flow (Check blower operation and

evaporator. Check operation of controls.)

Ice BIocking Evaporator Run functional test. If

evaporator pressure is low, ice may form on evapora-

tor and reduce air flow.

Evaporator Pressure Low Ice may be forming on

evaporator. Low volume of air discharging at A/C

outlet after system has been running above idle con-

dition for approximately 15-30 minutes. Discharging

air gradually elevating in temperature. Check expan-

sion valve. If valve isn’t permitting flow of liquid,

this will be indicated by a warm pipe out of the

evaporator. This may be caused by: 1) Clogged or

plugged inlet screen in the expansion valve; 2)

Broken capillary line, or 3) Discharged temperature

bulb. If the valve is okay, the pipe out of the evapora-

tor will be cold.BlowerNot OperatingCheck for the following: Fuse

blown, blower switch defective, wire broken or loose

connection, poor ground connection, or blower mo-

tor defective.

Page 599 of 625

AIR CONDITIONER SYSTEM -OPEL 1900 - MANTA9B- 91FAN DOES NOT RUN Correct electrical fault.

FAN RUNS

- Check air velocity.

NOT OK Clean evaporator inlets.

Clean evaporator core.

Clean evaporator outlets.

OK Check refrigeration (refer to Refrigeration

Diagnosis Guide).

MAINTENANCE AND ADJUSTMENTS

ADJUSTMENT OF THERMOSTATIC SWITCHThe system makes use of a thermostatic switch with

a self-supporting air sensing capillary. This capillary

controls the switch by sensing the temperature of the

air leaving the evaporator fins.

Checking for Proper Operation

I. Install the gauge set and set up the vehicle as

described under FUNCTIONAL TESTING SYS-

TEM iti Refrigerant Components Section.

2. Movement of the temperature control knob

should result in a definite change in suction pressure

and cycling of the compressor clutch.

3. If compressor continues to operate regardless of

the knob adjustment, it indicates that the switch

points are fused, which will lead to evaporator

freeze- up. The switch should be replaced.

Adjusting Switch

If, after ihe foregoing checks, the switch seems to be

operating correctly, adjust for proper setting if neces-

sary, as

~follows:1. Set up car as described in FUNCTIONAL

TESTING SYSTEM in Refrigerant Components

Section.2. The suction side of the system, read on the low

pressure gauge, should pull down to the pressure

shown in the chart in SPECIFICATIONS in Refrig-

erant Components Section.

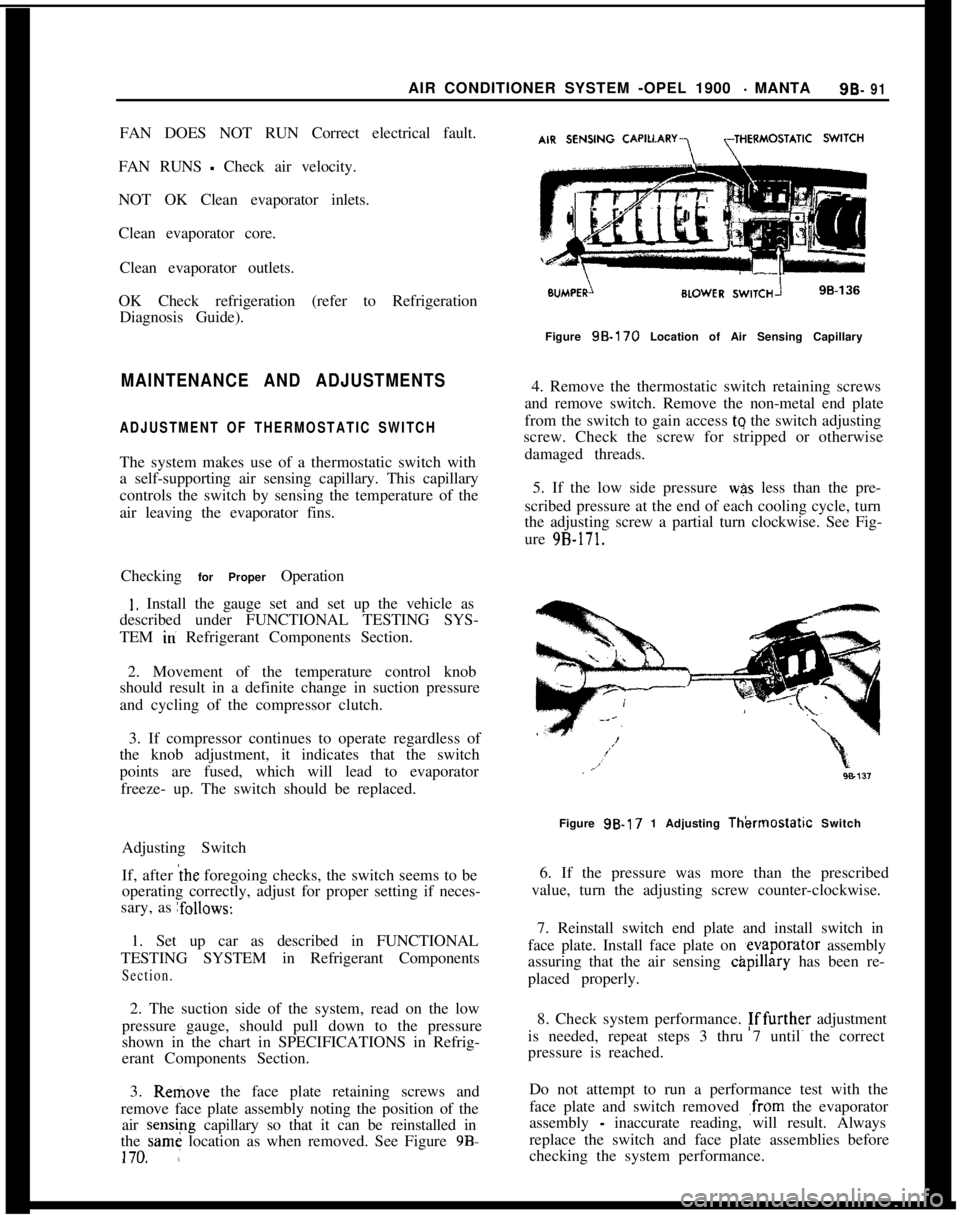

3. Remove the face plate retaining screws and

remove face plate assembly noting the position of the

air sensipg capillary so that it can be reinstalled in

the same location as when removed. See Figure 98.170. ,:Figure

98.170 Location of Air Sensing Capillary

4. Remove the thermostatic switch retaining screws

and remove switch. Remove the non-metal end plate

from the switch to gain access tq the switch adjusting

screw. Check the screw for stripped or otherwise

damaged threads.

5. If the low side pressure

was less than the pre-

scribed pressure at the end of each cooling cycle, turn

the adjusting screw a partial turn clockwise. See Fig-

ure

9B-171.Figure 9B-17 1 Adjusting

Thkmosfatic Switch

6. If the pressure was more than the prescribed

value, turn the adjusting screw counter-clockwise.

7. Reinstall switch end plate and install switch in

face plate. Install face plate on ,evaporator assembly

assuring that the air sensing

c&pillary has been re-

placed properly.

8. Check system performance. Fffurther adjustment

is needed, repeat steps 3 thru 7 until the correct

pressure is reached.

Do not attempt to run a performance test with the

face plate and switch removed

,from the evaporator

assembly

- inaccurate reading, will result. Always

replace the switch and face plate assemblies before

checking the system performance.

Page 606 of 625

98.98 1973 OPEL SERVICE MANUALDIAGNOSISTROUBLE DIAGNOSIS GUIDE

Insufficient Cooling

CHECK AIR FLOW

FAN DOES NOT RUN

- Correct electrical fault.

FAN RUNS

- Check air velocity.

NOT OK

- Clean evaporator inlets.

Clean evaporator core.

Clean evaporator outlets.

OK

- Check refrigeration (refer to Refrigeration

Diagnosis Guide).

MAINTENANCE AND ADJUSTMENTS

ADJUSTMENT OF THERMOSTATIC SWITCHThe system makes use of a thermostatic switch with

a self-supporting air sensing capillary. This capillary

controls the switch by sensing the temperature of the

air leaving the evaporator tins.

Checking for Proper Operation

1. Install the gauge set, and set up the vehicle as

described under FUNCTIONAL TESTING SYS-

TEM in Refrigerant Components Section.

2. Movement of the temperature control knob

should result in a definite change in suction pressure

and cycling of the compressor clutch.

3. If compressor continues to operate regardless of

the knob adjustment it indicates that the switch

points are fused, which will lead to evaporator

freeze-up. The switch should be replaced.

Adjusting Switch

If after the foregoing checks, the switch seems to be

operating correctly, adjust for proper setting if neces-

sary, as follows:

1. Set up car as described in FUNCTIONAL

TESTING SYSTEM in Refrigerant Components

Section.

2. The suction side of the system, read on the lowpressure gauge, should pull down to the pressure

shown in the chart in SPECIFICATIONS in Refrig-

erant Components Section.

3. Remove the duct assembly mtaining screws and

remove the duct assembly noting the position of the

air sensing capillary so that it can be reinstalled in

the same location as when removed. See Figure 9B-

190.Figure 98.190 Duct Assembly and Retaining Screws

Figure 9B-13 1 Duct Assembly

4. Remove the thermostatic switch retaining screws

and remove switch. Remove the non-metal end plate

from the switch to gain access to the switch adjusting

screw. Check the screw for stripped or otherwise

damaged threads.

Page 622 of 625

Subject

Page NumbelSubjectPage Number4.Speed Manual I..

Clutch

Detent Cable Adjustment

:Differential

Directional Signal Switch

Repair Opel 1900 & Manta

Repair GT

:Disassembly of

4.Speed Manual Transmission

DistributorFunction of Valves and Hydraulic Control Units

Opel

3.Speed Automatic.................

74-21

Fuse Chart..............................lG-56

Fusible Link.............................

lA-8Specifications.

Point Replacement..

..,78-127A-

17c-9148-73E-393E-4878.23

1C-26

1 c-20

GEGas Tank See Fuel Tank

General Specifications

Engine...............................6A-28

Opel 3.Speed Automatic

.................7C-134

Transmission, Manual.,

..................78-33

Clutch...............................7A-7

Body................................ZA-4

Governor Drive Gear

Opel

3.Speed Automatic.................7C-103

Grille

Opel 1900 & Manta.....................8A-7

GT..................................8A-6 Electrically Heated Rear Window

Engine

General Description

Cooling System

Lubrication System

Trouble Diagnosis

Exhaust Manifold

Exhaust System

Removal and Installation

External Oil Leaks,

Opel 3 Speed Automatic

FFast Idle Adjustment

..................

Filter-Engine Oil

......................

Fluid Checking Procedure Transmission

Opel 3Speed Automatic.............

Frame-Opel 1900 & Manta.............

Frame

GT-Opel......................

SWVOOpel Xipeed Automatic...........

Front Suspension

Opel1900&Manta.................

GT..............................

Front Wheel Alignment................

Front Wheel Bearing Adjustment

All Series.........................

Fuel Gauge

Trouble Diagnosis

Opell$OO&Manta...............

GT............................

Fuel Pump Operation..................

Fuel System

Fuel Tank (Opel 1900 & Manta)

.......

Fuel Lines (Opel 1900 & Manta)

.......

Fuel Tank

(GT)....................

Fuel Gauge Tank Unit

(GT)...........

Fuel Lines

(GT)....................

Fuel Tank Removal and Installation....

Cleaning Tank.....................

lH-576A-268-326A-46A-66A-126D-427C-816E-51

oc-77C~Bl2B-826-77c-1003A-23A-23C-223A-4

HHazard Warning Flasher

....................lG-55

Headlamp Aiming

.........................1 F-46

Headlamp Switch

Opel 190.0 & Manta

.....................1 F-46

Headlamp Mechanism GT

..................8A-2

Heater System Opel 1900 &Manta

Trouble Diagnosis

......................9A-11

Description and Operation

................9A-10

Adjustments and Minor Service............9A-12

Removal and Installation

.................9A-12

Specifications..........................$A-16

Heater System GT

Trouble Diagnosis

......................9A-4

Description and Operation

................9A-2

Adjustments and Minor Service

............9A-4

Removal and Installation.................9A-5

Specifications..........................$A-9Horn

Operation.............................lG-54

Hydraulic Operation

Opel

3.Speed Automatic.................7C-64

IIdentification Number Vehicle...............

OA-1ldle.Adjustment

..........................6E-51

Inflation Pressures, Tires.

...................36-62

Ignition Coil

Specifications.

.........................

lC-26Identification, Engine

......................

OA-1Ignition System

Timing...............................

lC-20Instrument Panel Parts Removal