hood open OPEL GT-R 1973 Service Manual

[x] Cancel search | Manufacturer: OPEL, Model Year: 1973, Model line: GT-R, Model: OPEL GT-R 1973Pages: 625, PDF Size: 17.22 MB

Page 352 of 625

EMISSION CONTROL SYSTEMS6F- 61I

1.HEAT STOVE

2.CONNECTING HOSE.

3.VACUUM DIAPHRAGM

4.VALVE (El-METAL SPRING)

5.VACUUM HOSES

6.AIR CLEANER HOUSING

7.CARBURETOR

BF-2

Figure 6F-2 Heated Air Systemthe lower edge of the stove passes across the manifold

surface, picking up heat. The heated air is drawn out

from the upper end of the manifold, through the

heated air pipe into the snorkel of the air cleaner. See

Figure

6F-2.The temperature control air cleaner is designed to

mix this heated air with cold air from under the hood

so that carburetor inlet air temperature averages

about 115 degrees. This mixing is done by an air door

located in the air cleaner snorkel. Most of the time,

the door will be partially open, as required, to control

the temperature. When the underhood temperature

reaches about 135 degrees, the door will close tight,

not allowing any more warm air from the mainifold

to enter the snorkel of the air cleaner. Obviously, if

underhood temperatures rise above 135 degrees, theair cleaner will no longer be able to control tempera-ture and the inlet air temperature will rise with

un-derhood temperature.

The temperature door is moved by a diaphragm type

vacuum motor. When there is no vacuum present in

the motor, the diaphragm spring forces the door

closed. Whenever the engine is running, the amount

of vacuum present in the vacuum motor depends on

the temperature sensor in the air cleaner which is

located in the vacuum line between the intake mani-

fold and the vacuum motor. In the sensor, a bi-metal

temperature sensing spring starts to open a valve to

bleed more air into the vacuum line whenever the

temperature in the air cleaner rises above about 115

degrees. Whenever the temperature falls below about

115 degrees, the sensing spring starts to close the air

Page 353 of 625

6F. 62 1973 OPEL SERVICE MANUAL

bleed into the vacuum line, allowing more manifold

vacuum to reach the vacuum motor. Whenever there

is nine inches or more of vacuum in the vacuum

motor, the diaphragm spring is compressed, the door

is opened.

When the engine is not running, the diaphragm

spring will always hold the door closed. However,

when the engine is running, the position of the door

depends on the air temperature in the air cleaner.

When starting a cold engine (air cleaner temperature

under 85 degrees), the air door will open immedi-

ately. This is because the air bleed valve in the sensor

is closed so that full manifold vacuum, is applied in

the vacuum motor. As soon as the air cleaner starts

receiving hot air from the heat stove, the sensor will

cause the air door to close partially, mixing cold air

with the hot air as necessary to regulate air cleaner

temperature within 20 degrees of the ideal 115 de-

grees air inlet temperature.

If underhood air temperature rises to 135 degrees,

the air bleed valve in the sensor will be wide open so

that vacuum to the vacuum motor approaches zero.

The diaphragm spring in the vacuum motor will hold

the air door closed tightly. If underhood temperature

rises above 135 degrees, carburetor inlet air tempera-

ture will also rise above 135 degrees.

While air cleaner temperature is being regulated, ac-

celerating the engine hard will cause the vacuum

level in the intake manifold and in the vacuum motor

to drop. Whenever vacuum drops below 5 inches, the

diaphragm spring will close the air

door in order to

get the

maxumum outside air flow required for max-

imum acceleration.

The carburetor is set by the manufacturer for

800-

850 RPM (automatic transmission) or 850-900 RPM

(manual transmission) and 1.5 to 2.5 percent CO.

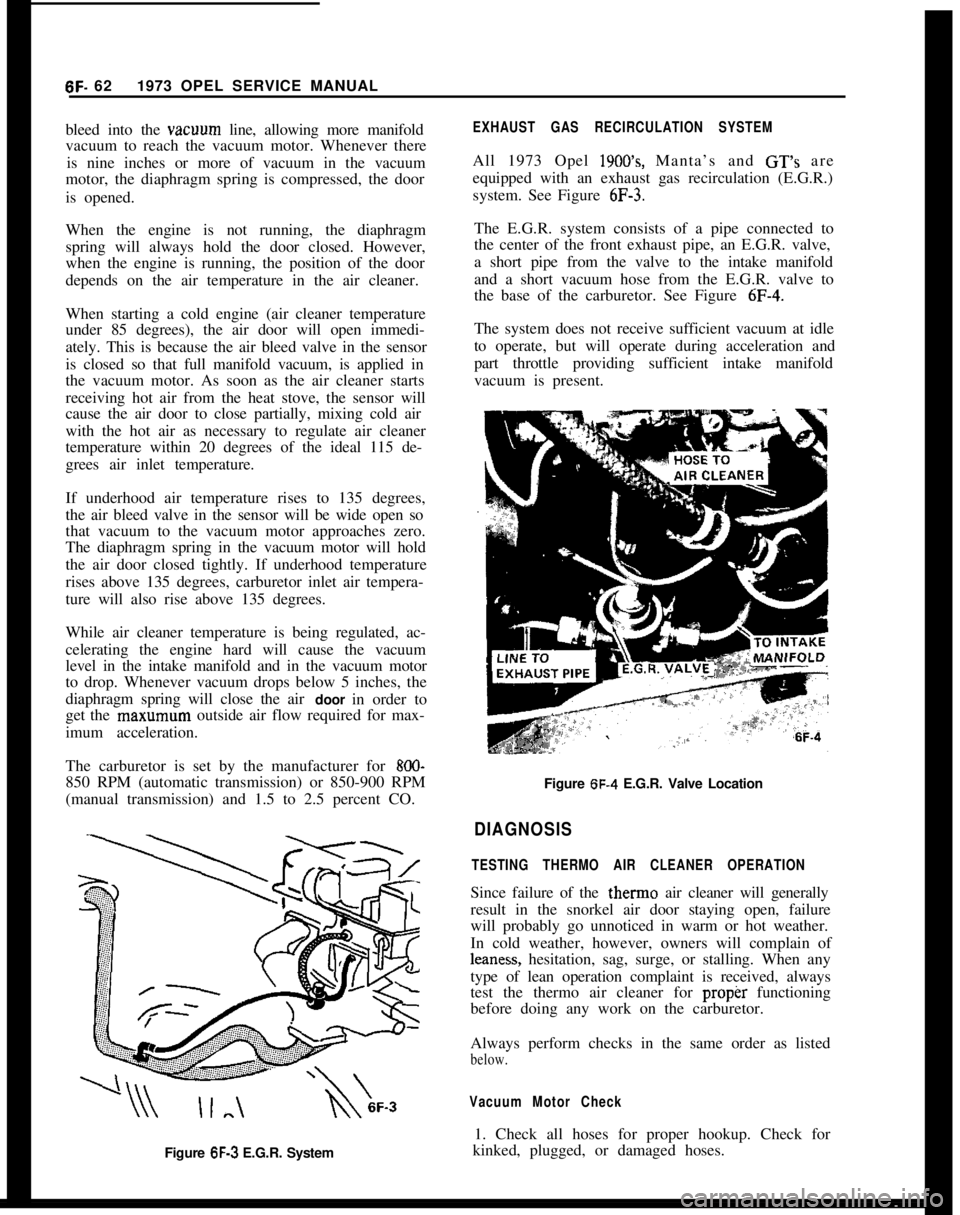

Figure 6F-3 E.G.R. System

EXHAUST GAS RECIRCULATION SYSTEM

All 1973 Opel 1900’s, Manta’s and GT’s are

equipped with an exhaust gas recirculation (E.G.R.)

system. See Figure

6F-3.

The E.G.R. system consists of a pipe connected to

the center of the front exhaust pipe, an E.G.R. valve,

a short pipe from the valve to the intake manifold

and a short vacuum hose from the E.G.R. valve to

the base of the carburetor. See Figure

6F-4.

The system does not receive sufficient vacuum at idle

to operate, but will operate during acceleration and

part throttle providing sufficient intake manifold

vacuum is present.

Figure 6F-4 E.G.R. Valve Location

DIAGNOSIS

TESTING THERMO AIR CLEANER OPERATION

Since failure of the therm0 air cleaner will generally

result in the snorkel air door staying open, failure

will probably go unnoticed in warm or hot weather.

In cold weather, however, owners will complain of

leaness, hesitation, sag, surge, or stalling. When any

type of lean operation complaint is received, always

test the thermo air cleaner for

proper functioning

before doing any work on the carburetor.

Always perform checks in the same order as listed

below.

Vacuum Motor Check

1. Check all hoses for proper hookup. Check for

kinked, plugged, or damaged hoses.

Page 503 of 625

8A-2 1973 OPEL SERVICE MANUAL

HOOD, FENDERS, AND GRILLE

CONTENTS

Subject

DESCRIPTION AND OPERATION:

GTHeadlampOperation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .DIAGNOSIS: (Not Applicable)

MAINTENANCE AND ADJUSTMENTS

GTHeadlampMechanism

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .MAJOR REPAIR:

Removal and Installation

Hood (1900

- Manta). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Fender(1900-Manta). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .Headlamp Covering (1900

- Manta). . . . . . . . . . . . . . . . . . . . . . . .Headlamp Assembly

(GT). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .Headlamp

CableAssembly(GT). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .Grille

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .SPECIFICATIONS: (Not Applicable)

DESCRIPTION AND OPERATION

DESCRIPTION AND OPERATION OF GT

HEADLAMP MECHANISMThe concealed headlamps are moved mechanically.

Pushing actuating lever on left side of console opens

headlamps, pulling lever closes headlamps. Two

meshing gear segments convert the movement of the

lever to a rotation of 180 degrees. The pivots of the

headlamps lie below the centerline so that with head-

lamps in closed position the headlamp housing is

flush with front sheet metal.

A white indicator lamp in the instrument panel lights

if the headlamps are not completely opened and

locked. The switches of the headlamp electrical sys-

tem are located behind the left headlamp operating

mechanism.

MAINTENANCE AND ADJUSTMENTS

ADJUSTMENT OF HEADLAMP MECHANISMBoth headlamp assemblies must operate in unison in

order to lock in either the open or closed position.

Page No.

8A-2

8A-2

8A-3

8A-3

8A-4

8A-4

8A-6

8A-61. Adjust headlamps to be parallel in any position by

changing length of right headlamp operating rod.

For adjustment loosen clamp bolt (A). See Figure

8A-1.Figure

8A-l Headlamp Operation Adjustments

Page 504 of 625

HOOD, FENDERS, AND GRILLE8A- 3

2. Adjust headlamps to lock or unlock simultane-

ously by adjusting lock nut (B). See Figure EA-1.3. Adjust headlamp assembly in opening as follows:

a. To align front of assembly vertically or horizon-

tally, loosen bolts indicated (A) in Figure 8A- 2.

b. To align front of assembly longitudinally, loosen

lock nut (B) in Figure 8A-2 and bolts marked (B) in

Figure

8A-3.c. To align rear of assembly vertically loosen bolts

indicated (A) in Figure

8A-3.MAJOR

REPAIR

REMOVAL AND INSTALLATION OF HOOD1. With a pencil, mark hinge positions on engine

hood. See Figure

SA-4.Figure EA.2 Headlamp Assembly Front Adjustment

LocationFigure

CIA-3 Headlamp Assembly Rear AdjustmentLocationFigure

CIA-4 Marking Hinge Position

2. Unscrew engine hood bolts from hinges. Hood

must be aligned so that the distances to the

adjacent surfaces are almost equal all around.

REMOVAL AND INSTALLATION OF FENDER

(OPEL 1900. MANTA)

1. Remove and install front bumper.

2. Remove and install radiator grille.

3. Remove and install headlamp covering.

4. Remove and install side panel trim pad.

5. Remove and install hood catch.

6. Remove and install rubber bumper (hood rest).

7. If required, remove and install direction signal

lamp.

8, Unscrew attaching bolts at fender circumference

and remove fender. See Figure

8A-5.

Page 517 of 625

9A-8 1973 OPEL SERVICE MANUAL

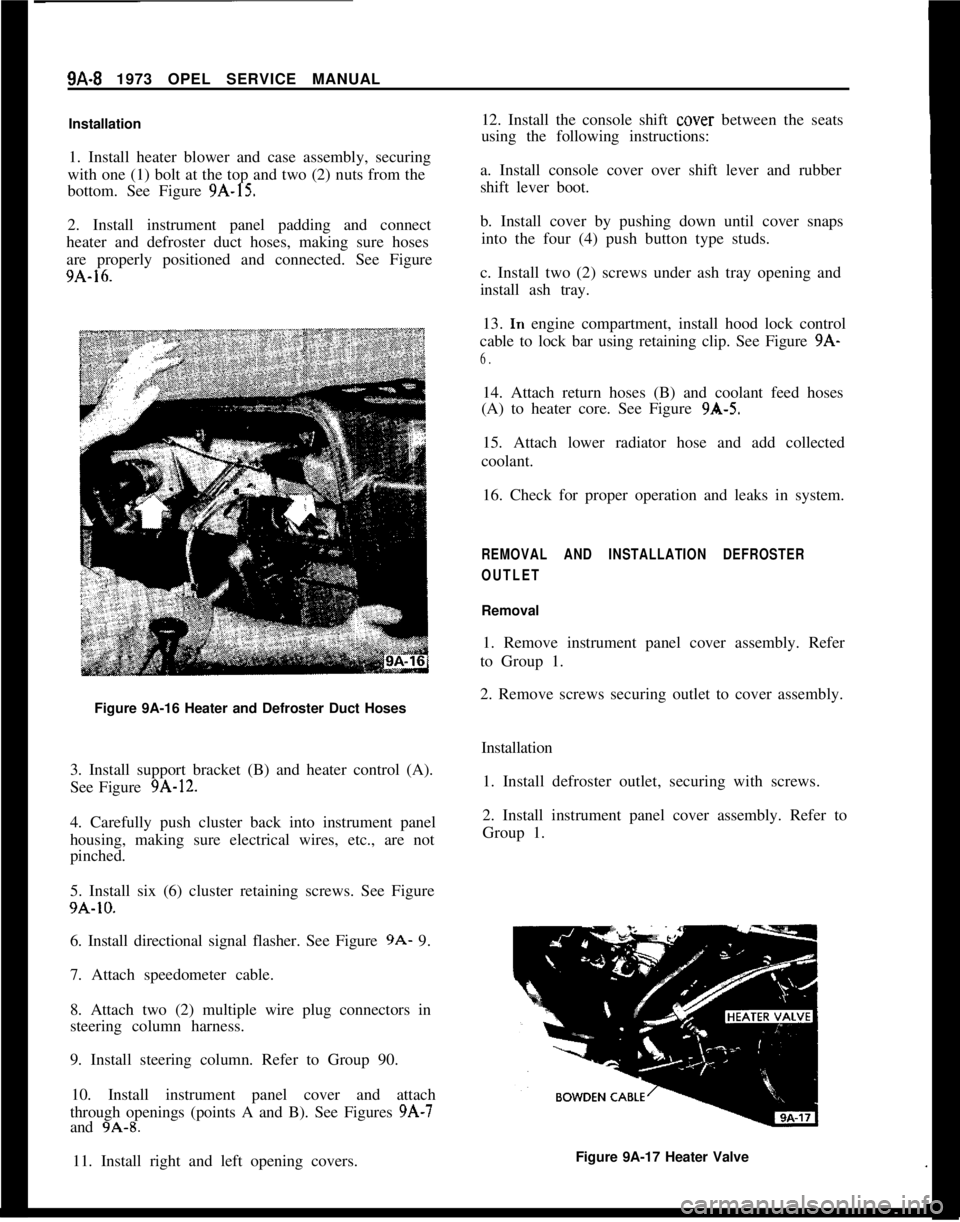

Installation

1. Install heater blower and case assembly, securing

with one (1) bolt at the top and two (2) nuts from the

bottom. See Figure

9A-15.

2. Install instrument panel padding and connect

heater and defroster duct hoses, making sure hoses

are properly positioned and connected. See Figure

9A-16.

Figure 9A-16 Heater and Defroster Duct Hoses

3. Install support bracket (B) and heater control (A).

See Figure

9A-12.

4. Carefully push cluster back into instrument panel

housing, making sure electrical wires, etc., are not

pinched.

5. Install six (6) cluster retaining screws. See Figure

9A-10.

6. Install directional signal flasher. See Figure

9A- 9.

7. Attach speedometer cable.

8. Attach two (2) multiple wire plug connectors in

steering column harness.

9. Install steering column. Refer to Group 90.

10. Install instrument panel cover and attach

through openings (points A and B). See Figures

9A-7

and 9A-8.

11. Install right and left opening covers. 12. Install the console shift

cover

between the seats

using the following instructions:

a. Install console cover over shift lever and rubber

shift lever boot.

b. Install cover by pushing down until cover snaps into the four (4) push button type studs.

c. Install two (2) screws under ash tray opening and

install ash tray. 13.

In engine compartment, install hood lock control

cable to lock bar using retaining clip. See Figure

9A-

6.

14. Attach return hoses (B) and coolant feed hoses

(A) to heater core. See Figure

9A-5.

15. Attach lower radiator hose and add collected

coolant.

16. Check for proper operation and leaks in system.

REMOVAL AND INSTALLATION DEFROSTER

OUTLET

Removal

1. Remove instrument panel cover assembly. Refer

to Group 1.

2. Remove screws securing outlet to cover assembly.

Installation1. Install defroster outlet, securing with screws.

2. Install instrument panel cover assembly. Refer to

Group 1.

Figure 9A-17 Heater Valve

Page 520 of 625

HEATER SYSTEM. OPEL 1900. MANTA9A- 11air is attained, as the water does not cool down in the

second part of the core.

A Water Outlet

B Water Inlet

The center lever actuates the two-stage blower mo-

tor.Lever positions:

Left to Center

- Motor Switched Off

Right of Center

- Lo Blower

Right

- Hi Blower

The lower lever opens and closes the air door which

channels the air flow to either the lower heater out-

lets or to the defroster outlets.

In the left lever position, the air inlet is closed. Up

to the center position, the air is directed

t,o the lower

heater outlets.

When moving the lever from center position towards

the right, the air flow to the lower

heatezr outlets is

reduced and increased to the defroster

csutlets.With the lever in its right position, the air is directed

to the defroster outlets only. For windshield defrost-

ing, all levers have to be moved to the right.

FUNCTION OF THE HEATER AND VENTILATION

SYSTEMThe engine hood is provided with slots in front of the

windshield. The air is directed through the slots into

the heater housing located in the engine compart-

ment, flows into the air distributor housing, and

from there to the lower heater outlets and,/or defros-

ter outlets, depending on the position of the control.

The two-stage blower motor is arranged in the heater

housing above the heater core and actuated by the

center control. The blower motor draws in the air

entering through the slots, blows the air through the

heater core into the air distributor housin:?, and from

there to the lower heater outlets and/or defroster

outlets, depending on the position of the lower con-

trol. See Figure 9A-32.

The heater valve regulates the flow of coolant

through the heater core, thereby varying

t:he temper-

ature of the air flow past the core.

The ventilation of vehicle interior is completed by a

draft-free air circulation pattern. Vent

slots are ar-

ranged below the back window which

are: connected

through channels to the rear quarter

iside panel.

From here, the inside air escapes into

the! open. TheFigure

9A-32 Air Flow

head wind (caused by the car traveling down the

road) promotes this process so that there is always

fresh air in vehicle interior.

On the Model 54 Station Wagon, there will be no air

outlets in the rear. For adequate flow-through type

ventilation, it will be necessary to open a rear win-

dow.Aside from the fresh air admission through the

heater system, two fresh air inlet nozzles are ar-

ranged in the center of the instrument panel. These

nozzles can be turned to direct the air flow in the

desired direction. In addition, rotary flaps allow the

regulation of the entering air or to shut off the air

completely.

These nozzles admit unheated fresh air only and

operate independent of the heater and defroster sys-

tem.

DIAGNOSIS

HEATER SYSTEM TROUBLE DIAGNOSIS

TROUBLETemperature of heated air at outlets too low.

CAUSE AND CORRECTIONCheck radiator cap for proper sealing action. Re-

place, if necessary.

Check for adequate coolant supply. If level is down,

correct cause of coolant loss and refill radiator.

Inspect hose for kinks. Relieve kink or replace hoses.

Check thermostat operation by measuring tempera-

ture of coolant at radiator. Temperature should be

within 5 degrees F. of thermostat rated value (189

degrees F.).

Page 521 of 625

9A-i2 1973 OPEL SERVICE MANUAL

Check that air doors and water temperature control

valve are operating properly.

Check for plugged heater core-backflush heater core

as necessary.TROUBLEInadequate defrosting action.

CAUSE AND CORRECTIONExamine heater-defroster door for proper operation.

Adjust bowden cable so that door is fully closed in

FULL DEFROST position.

Check that air hoses connecting to defroster outlets

are secure.

Check for air leaks around edges of heater air dis-

tributor housing. Seal leaks, as necessary, with bodysea@. Check for body air leaks and seal, as neces-

sary, with body sealer.

TROUBLEBlower inoperative.

CAUSE AND CORRECTIONCheck blower fuse. Replace, if necessary, fuse posi-

tion 4

- amperage 15.

Check wiring for open circuit. Correct, as required.

Inspect for defective component, (i.e., blower switch

or blower motor)

- replace or repair as necessary.

MAINTENANCE AND ADJUSTMENTS

CONTROL CABLE ADJUSTMENTAdjustment of control cables is accomplished by po-

sitioning of the jacket or sheath of the control cable,

as held by the clamps on the control assembly and

heater case or by loosening screws and slidingbowden wire to obtain desired door or water valve

position.

MAJOR REPAIR

REMOVING AND INSTALLING HEATER HOUSING

Removal1. Unscrew hood lock together with ground wire(ground wire only on vehicles with radio interference

suppression). See Figure 9A-33.

Figure 9A-33 Hood Lock Attachments

2. Unscrew heater housing cover.

3. Pull hose of windshield washer system off jet and

take jet out of housing cover.

4. Unscrew bowden control wire from heater valve.

5. Unscrew heater housing from dash panel and pull

it off carefully. See Figure 9A-34.

Figure 9A-34 Heater Housing Attachments

6. Remove water hoses from heater core and pull

heater core out of heater housing. See Figure

9A-35.

Page 522 of 625

Figure SA-35 Heater Core

Installation

1. Apply sealing compound between heater housing

and dash panel.

2. Install heater core into heater housing and attach

water hoses. See Figure 9A-35.

3. Instaii heater housing to dash panel. S,ee Figure9A-44.

4. Install bowden control wire to heater valve.

5. Install windshield washer jet into housing cover

and attach hose.

6. Install heater housing cover, and seal with a seal-

ing compound.

7. Install hood lock, together with

grc’und wire

(ground wire only on vehicles with radio interference

suppression).

REMOVING AND INSTALLING

DEFROSTE+lOUTLETS

Removal

1. Pull out heater switch lever. See Figure 9A- 36.

2. Remove instrument cover.

3. Unscrew bowden control wires from heater valve

and air distributor housing and pull out heater con-

trols.

4. Remove glove compartment.

HEiATER SYSTEM - OPEL 1900 - MANTA9A. 13Figure SA-36 Removing Heater Switch Lever

5. Remove radio.

6. On right side, viewed in driving direction, remove

air distributor housing attaching screws. See Figure9A-37

Figure SA-37 Air Distributor Housing Attaching

SCWWS7. On left side, viewed in driving direction, remove

upper attaching screw through opening for heater

control housing and lower attaching screw below

instrument panel. See Figure 9A-38.

8. Pull air distributor housing off dash panel

Page 591 of 625

r98-82 1973 OPEL SERVICE MANUAL

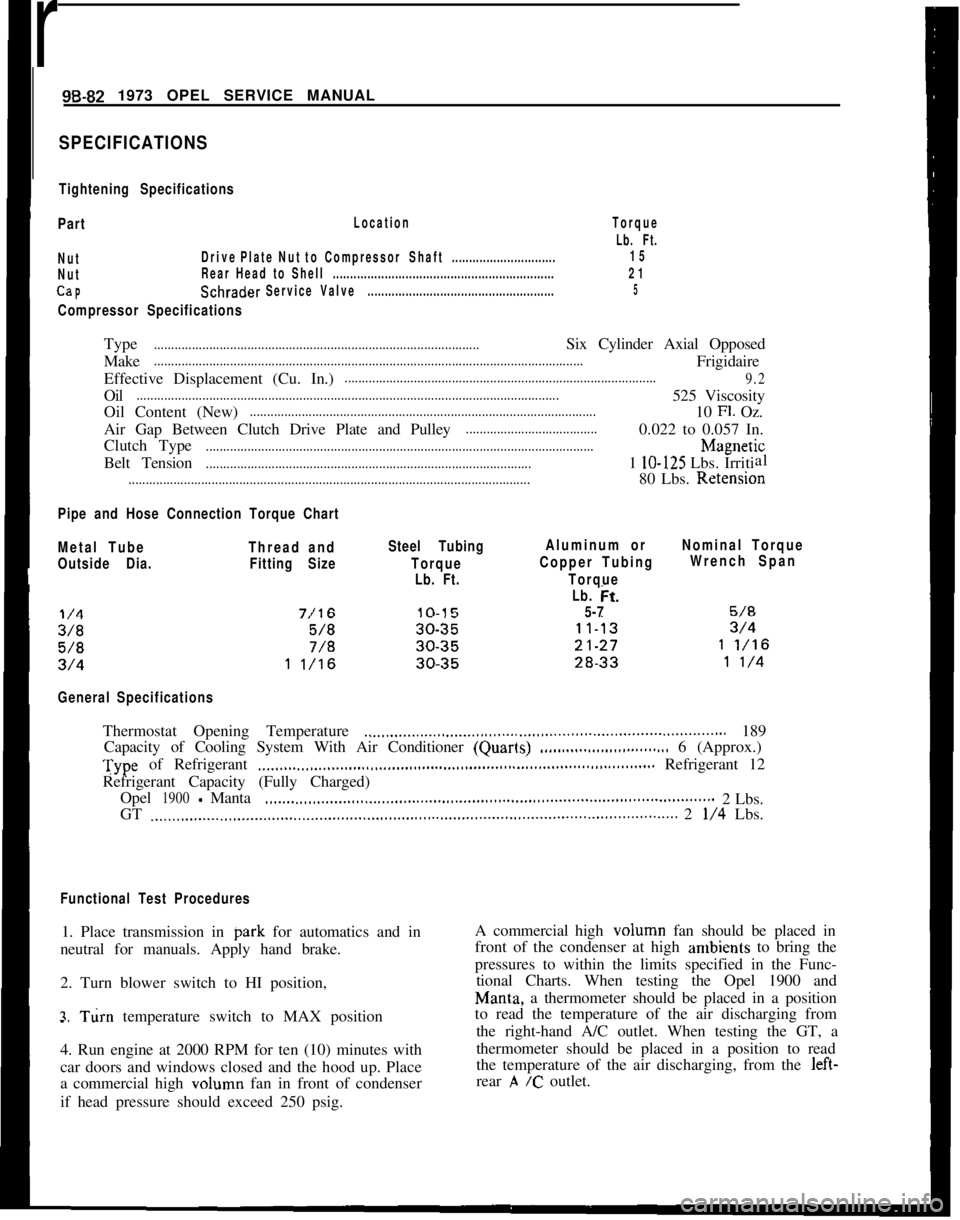

SPECIFICATIONS

Tightening Specifications

Part

Location

NutDrivePlateNut toCompressorShaft..............................

NutRear Head to Shell................................................................

CaPSchraderServiceValve......................................................

Compressor Specifications

Torque

Lb. Ft.

15

21

5Type

..............................................................................................Six Cylinder Axial Opposed

Make

............................................................................................................................Frigidaire

Effective Displacement (Cu. In.)

..........................................................................................

9.2Oil

..........................................................................................................................525 Viscosity

Oil Content (New)

....................................................................................................10 Fl. Oz.

Air Gap Between Clutch Drive Plate and Pulley

......................................0.022 to 0.057 In.

Clutch Type

................................................................................................................h4agnetic

Belt Tension

..............................................................................................1 lo-125 Lbs. Irritial

....................................................................................................................80 Lbs. Retension

Pipe and Hose Connection Torque Chart

Metal TubeThread andSteel TubingAluminum orNominal Torque

I

Outside Dia.Fitting SizeTorqueCopper TubingWrench Span

Lb. Ft.Torque

Lb. tit.

5-7

General SpecificationsThermostat Opening Temperature

.._.....,,,...__....,,.............................................................. 189

Capacity of Cooling System With Air Conditioner (Quarls)

.,,..___....___............... 6 (Approx.)Type of Refrigerant

.___,,,._...,.,,,.__.....,,,.......,,,,.......,,,...................,,,......,,,............ Refrigerant 12

Refrigerant Capacity (Fully Charged)

Opel

1900-Manta,,._....,,,,._...._.,,,,.......,,,........,,............................................................2 Lbs.

GT

,..__..,..,..__..,,,.......,,,,.......,,,........,,,.,......,,,,,......,,.,,........,,.......,,..........,,............... 2 l/4 Lbs.

Functional Test Procedures1. Place transmission in park for automatics and in

neutral for manuals. Apply hand brake.

2. Turn blower switch to HI position,

3. Turn temperature switch to MAX position-.

4. Run engine at 2000 RPM for ten (10) minutes with

car doors and windows closed and the hood up. Place

a commercial high volumn fan in front of condenser

if head pressure should exceed 250 psig.A commercial high volumn fan should be placed in

front of the condenser at high ambients to bring the

pressures to within the limits specified in the Func-

tional Charts. When testing the Opel 1900 and

Man& a thermometer should be placed in a position

to read the temperature of the air discharging from

the right-hand A/C outlet. When testing the GT, a

thermometer should be placed in a position to read

the temperature of the air discharging, from the left-

rear

,A /c outlet.