fuse box OPEL GT-R 1973 Service Manual

[x] Cancel search | Manufacturer: OPEL, Model Year: 1973, Model line: GT-R, Model: OPEL GT-R 1973Pages: 625, PDF Size: 17.22 MB

Page 58 of 625

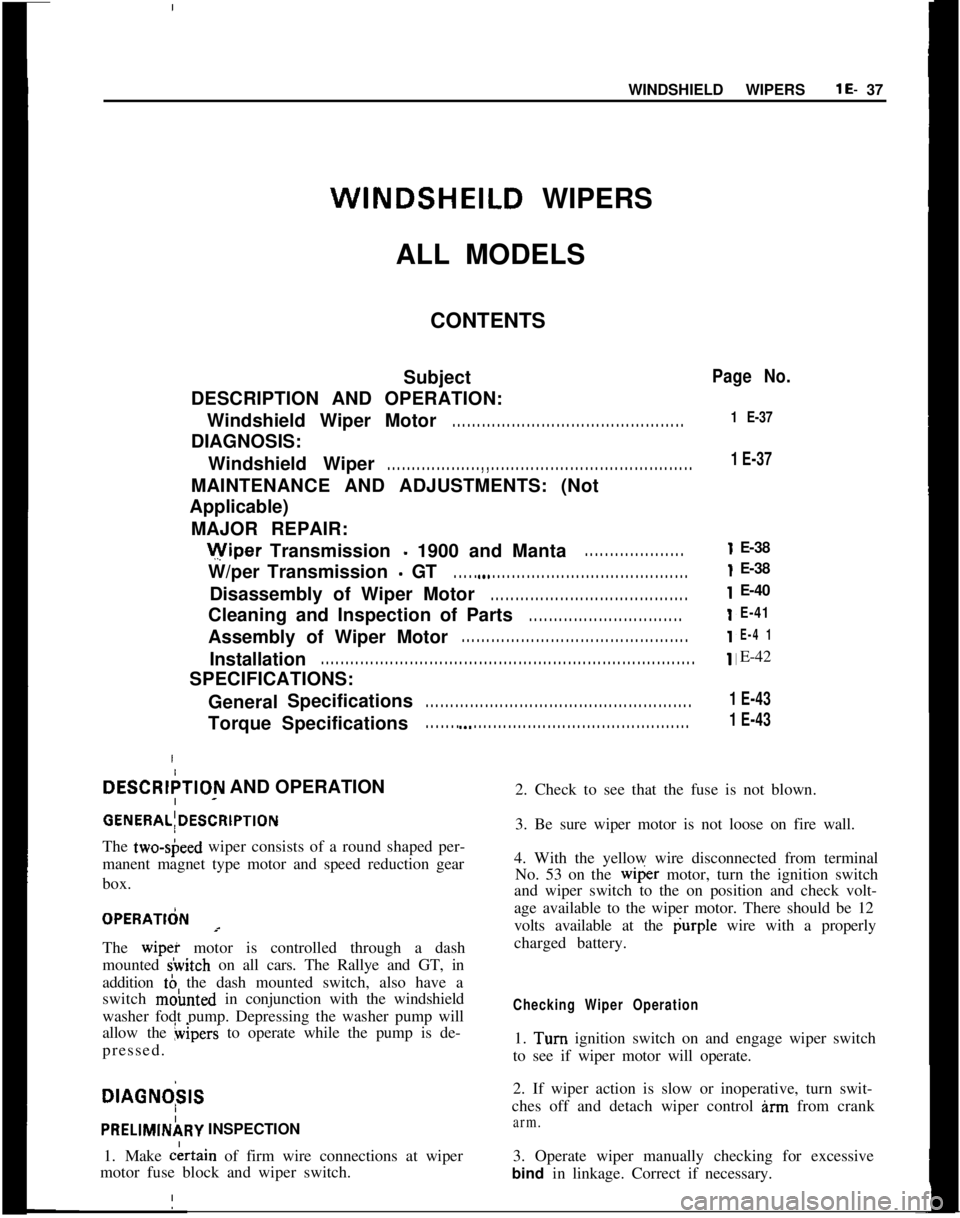

WINDSHIELD WIPERSlE- 37WINDSHEILD WIPERS

ALL MODELS

CONTENTS

Subject

DESCRIPTION AND OPERATION:

Windshield Wiper Motor. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .DIAGNOSIS:

Windshield Wiper

. . . . . . . . . . . . . . . . . . . , , . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .MAINTENANCE AND ADJUSTMENTS: (Not

Applicable)

MAJOR REPAIR:Wiper Transmission

- 1900 and Manta. . . . . . . . . . . . . . . . . . . .W/per Transmission

- GT. . . . . a.* . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .Disassembly of Wiper Motor

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .Cleaning and Inspection of Parts

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .Assembly of Wiper Motor

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .Installation

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .SPECIFICATIONS:

GeneralSpecifications

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .Torque Specifications

. . . . . . . a.. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

DESCRIPTIOfV AND OPERATION

GENERAL;DESCRlPTlDNThe two-sbeed wiper consists of a round shaped per-

manent magnet type motor and speed reduction gear

box. IOPERATldN

=The wipei motor is controlled through a dash

mounted &itch on all cars. The Rallye and GT, in

addition tb the dash mounted switch, also have a

switch moimted in conjunction with the windshield

washer fodt pump. Depressing the washer pump will

allow the bipers to operate while the pump is de-

pressed. i

DIAGNO;SIS

PRELIMINj9RY INSPECTION

1. Make

c&in of firm wire connections at wiper

motor fuse block and wiper switch.

Page No.

1 E-37

1 E-37E-38

E-38

E-40

E-41

E-4 1E-42

1 E-43

1 E-432. Check to see that the fuse is not blown.

3. Be sure wiper motor is not loose on fire wall.

4. With the yellow wire disconnected from terminal

No. 53 on the

wi@er motor, turn the ignition switch

and wiper switch to the on position and check volt-

age available to the wiper motor. There should be 12

volts available at the durple wire with a properly

charged battery.

Checking Wiper Operation1. Turn ignition switch on and engage wiper switch

to see if wiper motor will operate.

2. If wiper action is slow or inoperative, turn swit-

ches off and detach wiper control

inn from crank

arm.3. Operate wiper manually checking for excessive

bind in linkage. Correct if necessary.

Page 527 of 625

98.18 1973 OPEL SERVICE MANUAL

DESCRIPTION AND OPERATION

FUNDAMENTAL PRINCIPLES OF REFRIGERATION

We all know what air conditioning does for us, but

very few understand how or why it works. An air

conditioner is functionally very similar to a refrigera-

tor, so let’s take a look at refrigeration. A refrigerator

is a simple mechanism which, surprisingly enough,

works quite a bit like a tea-kettle boiling on a stove.

That may sound far-fetched, but there is more

similarity between the two than most of us would

suspect. In fact, a modern refrigerator can make ice-

cubes and keep food cool and fresh only because a

liquid called the refrigerant boils inside the freezer.

Of codrse everyone knows a boiling tea-kettle is

“hot” and a refrigerator is “cold”. However, this is

where most of us are apt to get confused. We usually

think of “cold” as a definite, positive condition. Ac-

tually though, there is no such thing as “cold”. The

only way we can define it is in a rather negative sort

of way by saying “cold” is simply the lack of heat

just as darkness is the lack of light. We can:t make

things cold directly. All we can do is remove some

of the heat they contain and they will become cold

as a result. And that is the main job of any ice-box

or refrigerator. Both are simply devices for removing

heat.

All substances contain some heat. Theoretically, the

lowest temperature that any substance could obtain

is 459 degrees Fahrenheit below Zero. This may be

called “Cold”, and anything warmer than this con-

tains heat. Since man has never succeeded in getting

all the heat out of an object, we must think about the

transfer of heat from one object to another when

talking about controlling temperatures.

Figure

96-1 Transfer of Heat

Transfer of HeatThe only thing that will attract heat is a colder ob-ject.

:Like water, which always flows down-hill, heat

always flows down a temperature scale

- from a

warm level down to a colder one. When we hold our

hands out toward the fireplace, heat flows from the

hot fire out to our cold hands (Fig.

9B-1). When we

make a snowball, heat always flows from our warm

hands to the colder snow. In an ice-box, the ice al-

ways is colder than the stored food, so heat naturally

is drawn out of the warm food by the colder ice.

Measurement of HeatEveryone thinks he knows how heat is measured.

Thermometers are used in most: homes. Whenever

we speak of temperature from now on, we will mean

Fahrenheit. They can tell how hot a substance is, but

they can’t tell us everything about heat.

Figure

98-2 Applied Temperature Alone is Not the

Sole Measurement of Heat

When we put a tea-kettle on a stove, we expect it to

get hotter and hotter until it finally boils. All during

the process, we can tell exactly how hot the water is

by means of a thermometer (Fig.

9B-2). However,

our thermometer will show us that the flame is just

as hot when we first put the tea-kettle on the stove

as it is when the water finally boils. Why doesn’t the

water boil immediately then? Also, why does it take

longer to boil a quart of water than a cupful? Obvi-

ously temperature isn’t the only measurement of

heat.

Even though heat is intangible, it can be measured by

quantity as well as intensity. It is recognized that

thermometers indicate only the intensity of heat. The

unit for measuring quantity of heat is specified as

that amount necessary to make 1 pound of water 1

degree warmer (Fig.

9B-3). We call this quantity of

heat a British Thermal Unit. Often it is abbreviated

to Btu.

Perhaps we can get a better idea of these two charac-

Page 561 of 625

96-52 1973 OPEL SERVICE MANUAL

REMOVAL AND INSTALLATION OF EVAPORATOR

AND EXPANSION VALVE. OPEL 1900 - MANTA

Removal

1. Remove negative battery cable from battery.

2. Remove left side of distributor duct, and in line

fuse. See Figure

9B-61.3. Remove glove box. See Figure

9B-62.Figure 96-64 Delay Restrictor

and Check Valve Hose

Assembly Location

5. Disconnect the delay restrictor and check valve

hose assembly from the vacuum cut-off switch and

disconnect the electrical wiring. See Figures 9B-63

and 64.

6. Remove evaporator inlet and outlet pipes re-

tainer and rubber grommet. See Figure

9B-65.Figure

98.62 Glove Box Removed

4. Discharge refrigerant from system. (Refer to

DISCHARGING SYSTEM) and disconnect refrig-

erant hose from evaporator outlet and pipe from

evaporator inlet and tape the open ends of the refrig-

erant lines and evaporator pipes. See Figure

9B-63.Figure

98.65 Inlet and Outlet Pipes retainer and

Rubber Grommet-Opel 1900 - Manta

Figure

98.63 Location of Refrigerant Hoses, Pipes,

Vacuum Cut Off Switch and Evaporator Attaching Bolt

(Left Side) - Opel 1900

- Manta

Page 563 of 625

96-54 1973 OPEL SERVICE MANUAL

valve. The filter screen at the inlet port may be re-

placed. Remove screen by threading a lo-32 NF

screw into old filter screen. With a washer and a nut

on the screw arranged to work as a puller screw, hold

the body of the screw and turn the nut. Insert the

new filter screen into the inlet port and lightly tap

screen only enough to seat.

1. Install expansion valve using new o-rings during

installation. Lubricate o-rings prior to installation

using No. 525 viscosity oil.

2. Install evaporator assembly and case attaching

screws. See Figure 9B-70.3. Install blower motor assembly into case and se-

cure with attaching screws. See Figure

9B-69.4. Install finger guard shields and fan housing case.

See Figure

9B-69.5. Install resistor assembly and electrical connector.

Install blower motor connector. See Figure

9B-69.6. Install assembly into car carefully guiding

evaporator pipes up through cowl opening. See Fig-

ure

9B-71.Figure 93-7 1 Inlet and Outlet Pipes and O-Rings

-Opel 1900 Manta

7. Install two (2) upper attaching evaporator at-

taching nuts. See Figures 9B-66 and

9B-67.8. Install two (2) attaching case mounting bracket

to instrument panel screws. See Figure

9B-67.9. Connect two (2) drain hoses underneath evapora-

tor.10. Install evaporator inlet and outlet pipes retainer

and rubber grommet. See Figure

9B-65.11. Connect vacuum cut-off switch and electrical

wiring, making sure the delay restrictor and checkvalve hoses are installed correctly. See Figures

9B-63and 64.

.gB-72 Delay Restrictor and Check Valve Hose.Assembly

12. Install refrigerant hoses and pipes using new

o-rings on line fittings and evacuate system. Refer to

EVACUATING SYSTEM.

13. While system is being evacuated, install in-line

fuse and left side of distributor duct. See Figure 9B-

61.14. Install glove box.

15. Install negative battery cable and charge system.

Refer to CHARGING SYSTEM.

REMOVAL AND INSTALLATION OF CONDENSER

ASSEMBLY -OPEL 1900. MANTA

Removal

1. Remove negative battery cable from battery.

2. Remove air cleaner.

3. Discharge system. Refer to DISCHARGING

SYSTEM.

4. While system is discharging, remove lower radia-

tor hose from radiator and drain coolant into a suita-

ble container.

5. Remove fan shroud.

6. On vehicles with automatic transmission, un-

screw oil lines from connectors on lower radiator

tank and plug lines. It is essential that no dirt enters

the oil lines. When unscrewing oil lines, hold connec-

tors on lower radiator tank with pliers to avoid leak-

ages. Ensure that no dirt enters oil cooler.

7. Remove upper radiator hose from radiator.

8. Remove lower attaching nut and slide radiator

upward and out of engine compartment.

9. Remove inlet and outlet hoses from condenser

Page 601 of 625

AIR CONDITIONER SYSTEM. OPEL 1900. MANTA9B- 93

2. Remove the left side of distributor duct, and the

in-line fuse. See Figure 9B-174.98.139Figure SB-174 Location of Distributor Duct (Left Side)

Retaining Screws

Figure SB-175 Removing Left Side Distributor Duct

3. Rembve the glove box assembly. See Figure 9B-

176.

4. Discharge refrigerant from system, (refer to DIS-

CHARGING SYSTEM) and disconnect refrigerant

hose from evaporator outlet and pipe from evapora-

tor inlet’and tape the open ends of the refrigerant

lines and evaporator pipes. See Figure

9B-178.5. Disconnect the delay restrictor and check valve

hose assembly from the vacuum cut-off switch and

disconnect the electrical wiring. See Figure

9B-180.6. Rempve evaporator inlet and outlet pipes re-

tainer and rubber grommet. See Figure

9B-178.Figure SB-176 Glove

Bdx Removed

Figure SB-178 Location of Refrigerant Hoses, Pipes,

Vacuum Cut Off Switch and Evaporator Attaching Bolt

(Left Side)

Figure 9B-180 Vacuum Hoses and Wiring

Page 603 of 625

AIR CONDITIONER SYSTEM -OPEL 1900 - MANTA9B- 95

Figure 96.185 Evaporator Inlet and Outlet Pipes andO-Rings

7. Connect the 2 drain hoses underneath evapora-

tor.

8. Install evaporator inlet and outlet pipes retainer

and rubber grommet. See Figure

9B-178.

9. Connect vacuum cut-off switch and electrical

wiring,, making sure the delay restrictor and check

valve hose are installed correctly. See Figure

9B-180.

10. Install refrigerant hoses and pipes using new o-

rings on line fittings and evacuate system. Refer to

EVACUATING SYSTEM.

Il. While system is being evacuated install the in-line

fuse and left side of distributor duct. See Figure

9B-

174.

12. Install the glove box.

Figure 98.186 Delay Restrictor and Check Valve Hose

Assembly

Figure 9B-187 Fuse Block Connections

13. Install negative battery cable and charge the sys-

tem. Refer to CHARGING SYSTEM.