ECU OPEL MERIVA 2017 Owner's Manual

[x] Cancel search | Manufacturer: OPEL, Model Year: 2017, Model line: MERIVA, Model: OPEL MERIVA 2017Pages: 251, PDF Size: 8.14 MB

Page 150 of 251

![OPEL MERIVA 2017 Owners Manual 148Driving and operatingManual mode

Move selector lever out of position D

towards the left and then forwards or backwards.

<:shift to a higher gear]:shift to a lower gear

If a higher gear is selected OPEL MERIVA 2017 Owners Manual 148Driving and operatingManual mode

Move selector lever out of position D

towards the left and then forwards or backwards.

<:shift to a higher gear]:shift to a lower gear

If a higher gear is selected](/img/37/58232/w960_58232-149.png)

148Driving and operatingManual mode

Move selector lever out of position D

towards the left and then forwards or backwards.

<:shift to a higher gear]:shift to a lower gear

If a higher gear is selected when

vehicle speed is too low, or a lower

gear when vehicle speed is too high,

the shift is not executed. This can

cause a message in the Driver

Information Centre.

In manual mode, no automatic

shifting to a higher gear takes place

at high engine revolutions.

Electronic driving

programmes

● Following a cold start, the operating temperature

programme increases engine

speed to quickly bring the

catalytic converter to the required

temperature.

● The automatic neutral shift function automatically shifts to

idling when the vehicle is stopped with a forward gear engaged and

the brake pedal is pressed.

● Special programmes automatically adapt the shiftingpoints when driving up inclines or

down hills.

Kickdown If the accelerator pedal is pressed

down completely in automatic mode,

the transmission shifts to a lower gear

depending on engine speed.Fault

In the event of a fault, g illuminates.

Additionally a code number or a

vehicle message is displayed in the

Driver Information Centre. Vehicle

messages 3 106.

The transmission no longer shifts automatically. Continued travel is

possible with manual shifting.

Only the highest gear is available.

Depending on the fault, second gear

may also be available in manual

mode. Shift only when vehicle is at a

standstill.

Have the cause of the fault remedied

by a workshop.

Interruption of power supply

In the event of an interruption of

power supply, the selector lever

cannot be moved out of the P

position. The ignition key cannot be

removed from the ignition switch.

If the vehicle battery is discharged,

start the vehicle using jump leads

3 213.

Page 170 of 251

168Driving and operatingRear axle load

When the trailer is coupled and the

towing vehicle fully loaded, the

permissible rear axle load (see

identification plate or vehicle

documents) may be exceeded by

80 kg (vehicles with LPG system:

110 kg), the gross vehicle weight rating may be exceeded by 70 kg

(vehicles with LPG system: 95 kg). If

the permissible rear axle load is

exceeded, a maximum speed of

100 km/h applies.

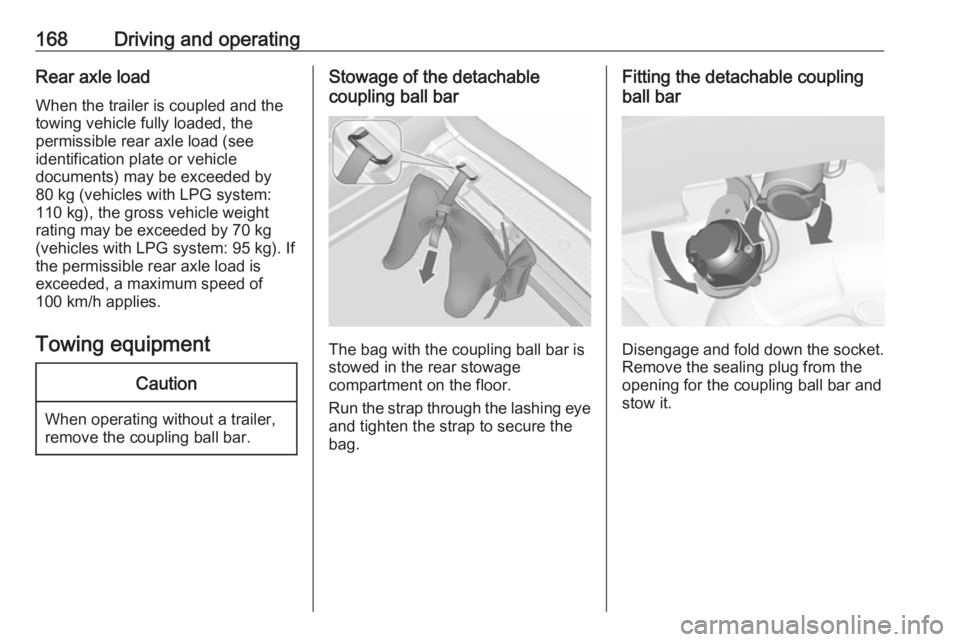

Towing equipmentCaution

When operating without a trailer,

remove the coupling ball bar.

Stowage of the detachable

coupling ball bar

The bag with the coupling ball bar is

stowed in the rear stowage

compartment on the floor.

Run the strap through the lashing eye and tighten the strap to secure the

bag.

Fitting the detachable coupling

ball bar

Disengage and fold down the socket. Remove the sealing plug from the

opening for the coupling ball bar and

stow it.

Page 176 of 251

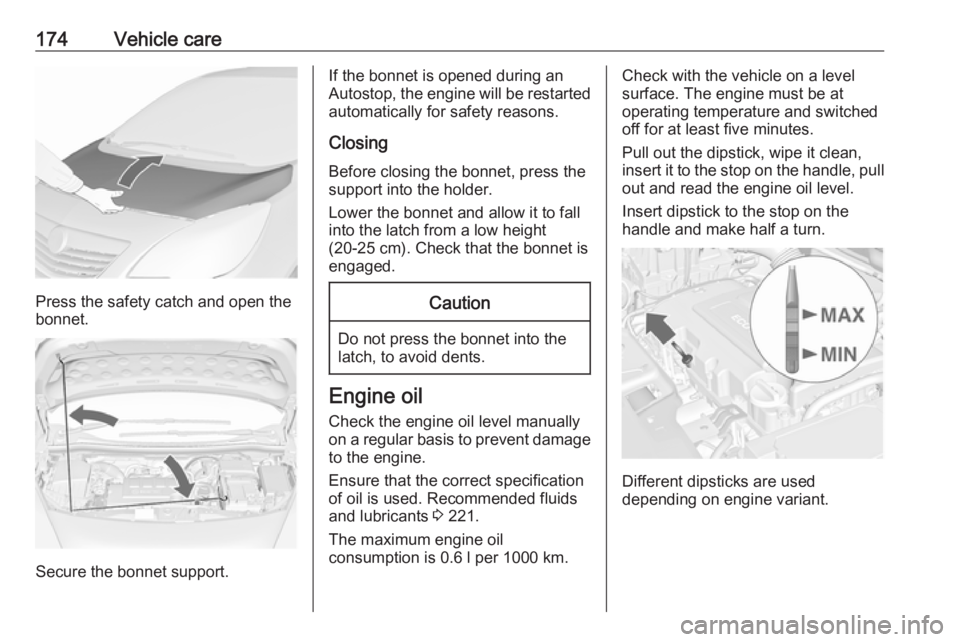

174Vehicle care

Press the safety catch and open the

bonnet.

Secure the bonnet support.

If the bonnet is opened during an

Autostop, the engine will be restarted automatically for safety reasons.

Closing

Before closing the bonnet, press the

support into the holder.

Lower the bonnet and allow it to fall

into the latch from a low height

(20-25 cm). Check that the bonnet is engaged.Caution

Do not press the bonnet into the

latch, to avoid dents.

Engine oil

Check the engine oil level manually

on a regular basis to prevent damage

to the engine.

Ensure that the correct specification

of oil is used. Recommended fluids

and lubricants 3 221.

The maximum engine oil

consumption is 0.6 l per 1000 km.

Check with the vehicle on a level

surface. The engine must be at

operating temperature and switched

off for at least five minutes.

Pull out the dipstick, wipe it clean,

insert it to the stop on the handle, pull

out and read the engine oil level.

Insert dipstick to the stop on the

handle and make half a turn.

Different dipsticks are used

depending on engine variant.

Page 185 of 251

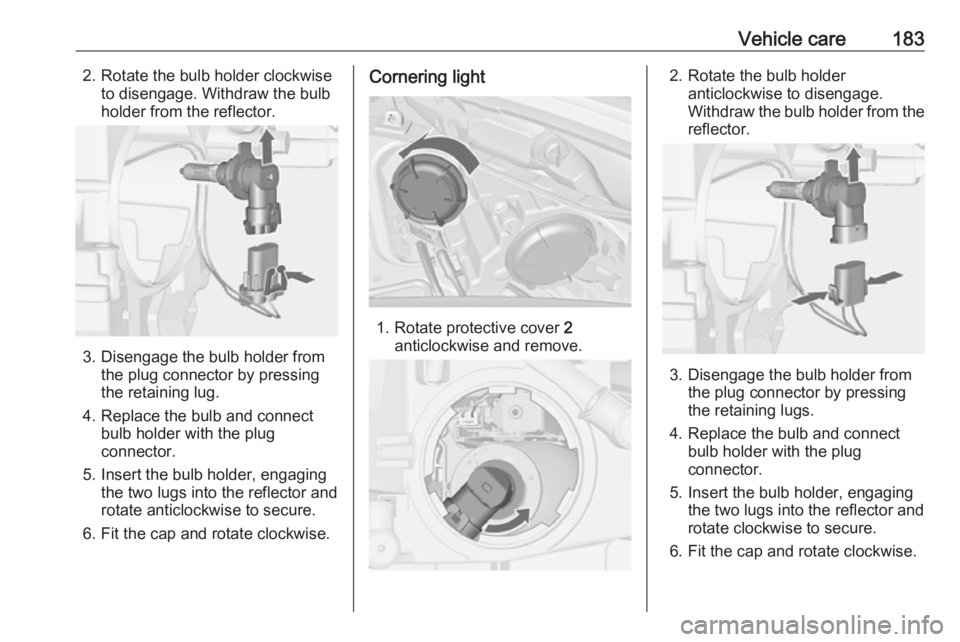

Vehicle care1832. Rotate the bulb holder clockwiseto disengage. Withdraw the bulb

holder from the reflector.

3. Disengage the bulb holder from the plug connector by pressing

the retaining lug.

4. Replace the bulb and connect bulb holder with the plug

connector.

5. Insert the bulb holder, engaging the two lugs into the reflector and

rotate anticlockwise to secure.

6. Fit the cap and rotate clockwise.

Cornering light

1. Rotate protective cover 2

anticlockwise and remove.

2. Rotate the bulb holder anticlockwise to disengage.

Withdraw the bulb holder from the

reflector.

3. Disengage the bulb holder from the plug connector by pressing

the retaining lugs.

4. Replace the bulb and connect bulb holder with the plug

connector.

5. Insert the bulb holder, engaging the two lugs into the reflector and

rotate clockwise to secure.

6. Fit the cap and rotate clockwise.

Page 187 of 251

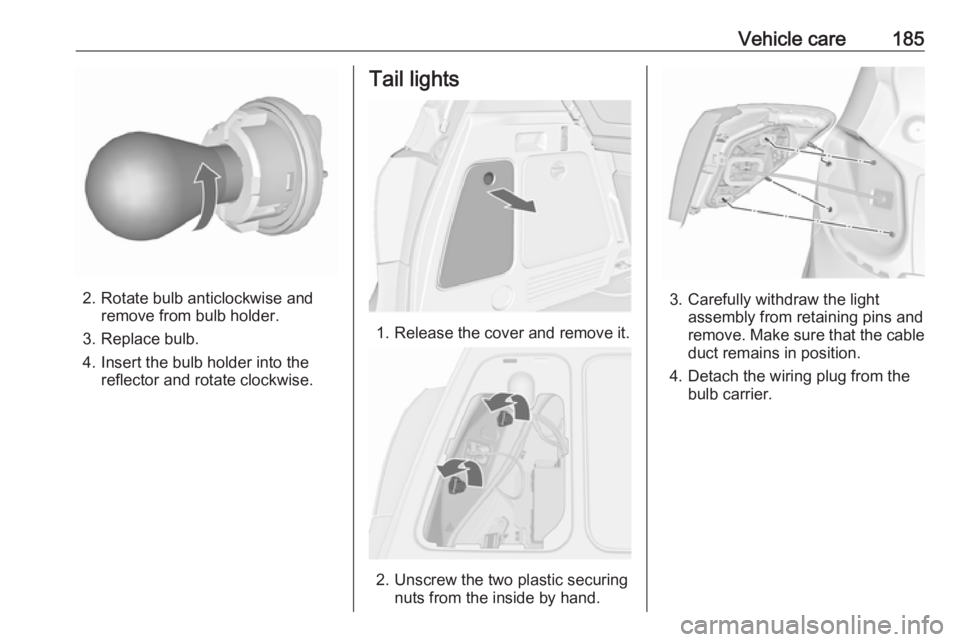

Vehicle care185

2. Rotate bulb anticlockwise andremove from bulb holder.

3. Replace bulb.

4. Insert the bulb holder into the reflector and rotate clockwise.

Tail lights

1. Release the cover and remove it.

2. Unscrew the two plastic securing nuts from the inside by hand.

3. Carefully withdraw the lightassembly from retaining pins and

remove. Make sure that the cable duct remains in position.

4. Detach the wiring plug from the bulb carrier.

Page 188 of 251

186Vehicle care

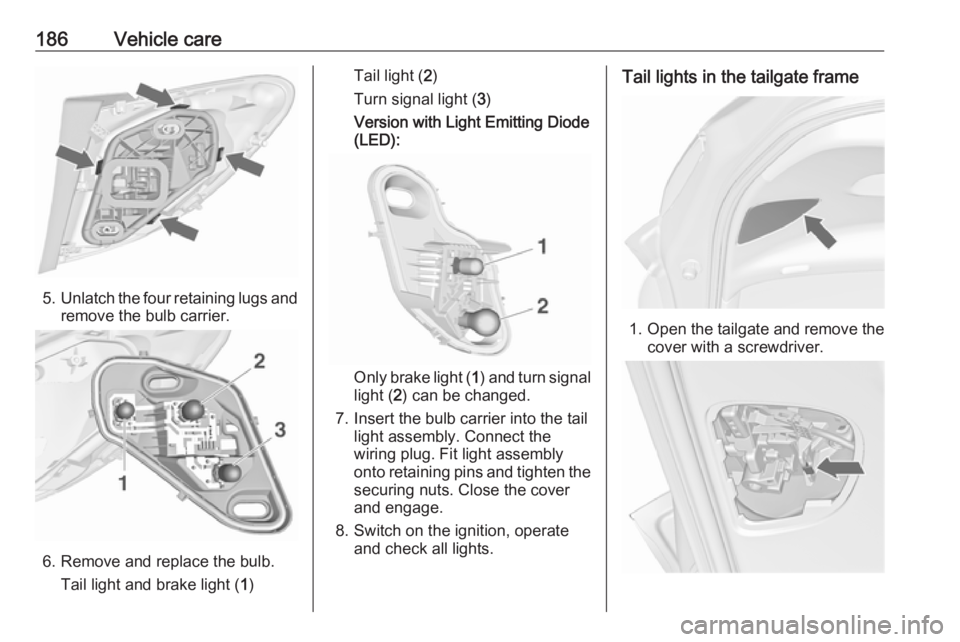

5.Unlatch the four retaining lugs and

remove the bulb carrier.

6. Remove and replace the bulb.

Tail light and brake light ( 1)

Tail light ( 2)

Turn signal light ( 3)

Version with Light Emitting Diode (LED):

Only brake light ( 1) and turn signal

light ( 2) can be changed.

7. Insert the bulb carrier into the tail light assembly. Connect the

wiring plug. Fit light assembly

onto retaining pins and tighten the securing nuts. Close the cover

and engage.

8. Switch on the ignition, operate and check all lights.

Tail lights in the tailgate frame

1. Open the tailgate and remove the

cover with a screwdriver.

Page 210 of 251

208Vehicle careMake the following preparations and

observe the following information:

● Park the vehicle on a level, firm and non-skid surface. The front

wheels must be in the straight- ahead position.

● Apply the parking brake and engage first gear, reverse gear or

P .

● Remove the spare wheel 3 210.

● Never change more than one wheel at once.

● Use the jack only to change wheels in case of puncture, not

for seasonal winter or summer

tyre change.

● The jack is maintenance-free.

● If the ground on which the vehicle

is standing is soft, a solid board

(max. 1 cm thick) should be

placed under the jack.

● Take heavy objects out of the vehicle before jacking up.

● No people or animals may be in the vehicle when it is jacked-up.

● Never crawl under a jacked-up vehicle.●Do not start the vehicle when it is

raised on the jack.

● Before screwing in the wheel bolts, clean them and lightly coat

the taper of each wheel bolt with

commercially available grease.9 Warning

Do not grease the thread of the

wheel bolt.

1. Pull off the wheel cover.

For wheel covers with visible

wheel bolts: The cover can remain

on the wheel. Do not remove the

retaining rings on the wheel bolts.

Alloy wheels: Disengage wheel

bolt caps with a screwdriver and

remove. To protect the wheel,

place a soft cloth between the

screwdriver and the alloy wheel.

2. Variant 1:

Install the wheel wrench ensuring

that it locates securely and loosen

each wheel bolt by half a turn.

Variant 2:

Page 211 of 251

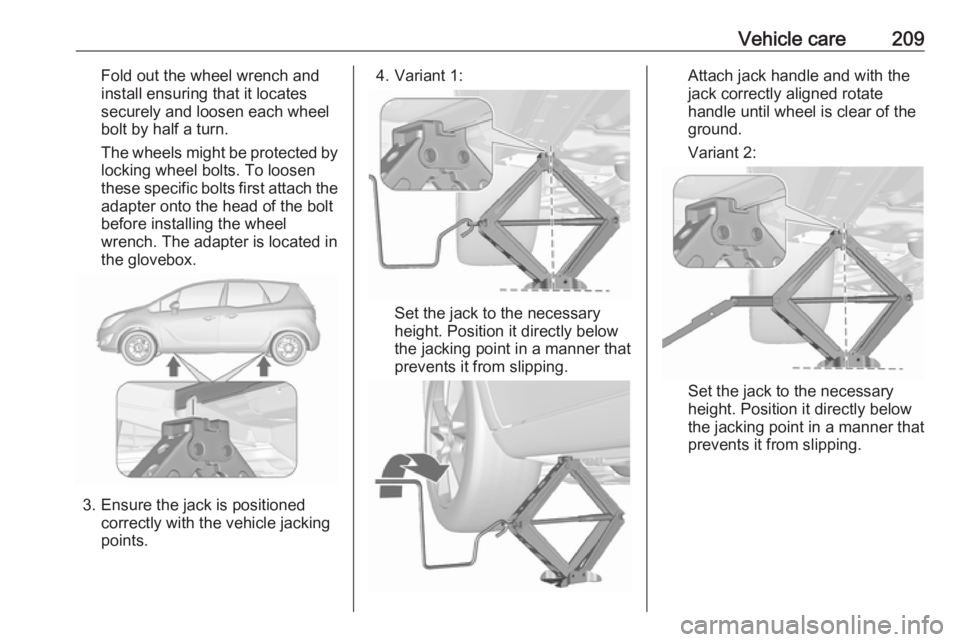

Vehicle care209Fold out the wheel wrench and

install ensuring that it locates

securely and loosen each wheel

bolt by half a turn.

The wheels might be protected by locking wheel bolts. To loosen

these specific bolts first attach the

adapter onto the head of the bolt

before installing the wheel

wrench. The adapter is located in

the glovebox.

3. Ensure the jack is positioned correctly with the vehicle jacking

points.

4. Variant 1:

Set the jack to the necessary

height. Position it directly below

the jacking point in a manner that

prevents it from slipping.

Attach jack handle and with the

jack correctly aligned rotate handle until wheel is clear of theground.

Variant 2:

Set the jack to the necessary

height. Position it directly below

the jacking point in a manner that

prevents it from slipping.

Page 212 of 251

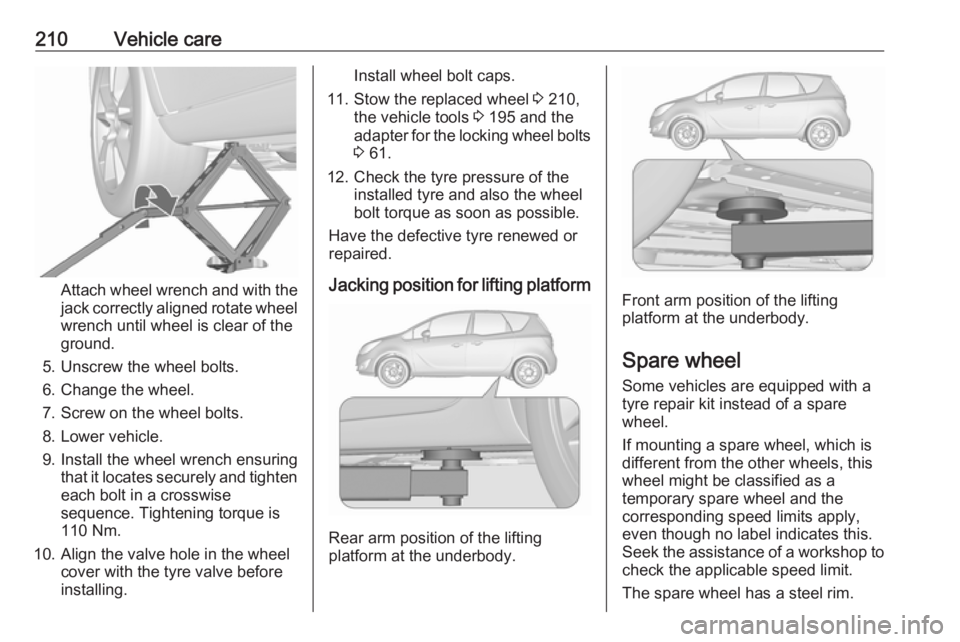

210Vehicle care

Attach wheel wrench and with the

jack correctly aligned rotate wheel wrench until wheel is clear of the

ground.

5. Unscrew the wheel bolts. 6. Change the wheel.

7. Screw on the wheel bolts.

8. Lower vehicle.

9. Install the wheel wrench ensuring that it locates securely and tighten

each bolt in a crosswise

sequence. Tightening torque is

110 Nm.

10. Align the valve hole in the wheel cover with the tyre valve before

installing.

Install wheel bolt caps.

11. Stow the replaced wheel 3 210,

the vehicle tools 3 195 and the

adapter for the locking wheel bolts 3 61.

12. Check the tyre pressure of the installed tyre and also the wheel

bolt torque as soon as possible.

Have the defective tyre renewed or repaired.

Jacking position for lifting platform

Rear arm position of the lifting

platform at the underbody.

Front arm position of the lifting

platform at the underbody.

Spare wheel Some vehicles are equipped with a

tyre repair kit instead of a spare

wheel.

If mounting a spare wheel, which is

different from the other wheels, this

wheel might be classified as a

temporary spare wheel and the

corresponding speed limits apply,

even though no label indicates this.

Seek the assistance of a workshop to

check the applicable speed limit.

The spare wheel has a steel rim.

Page 213 of 251

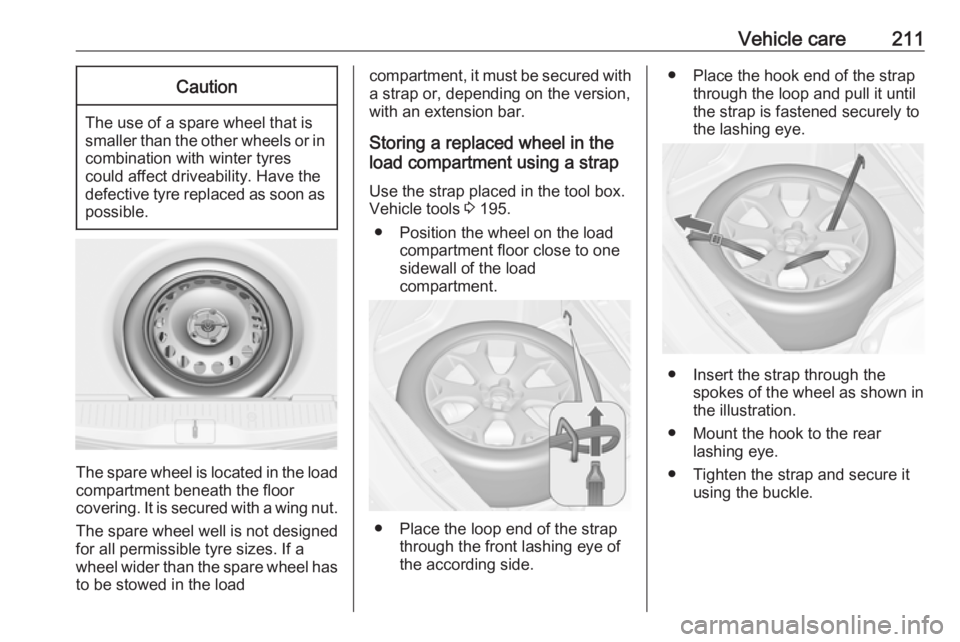

Vehicle care211Caution

The use of a spare wheel that issmaller than the other wheels or in combination with winter tyres

could affect driveability. Have the defective tyre replaced as soon as

possible.

The spare wheel is located in the load

compartment beneath the floor

covering. It is secured with a wing nut.

The spare wheel well is not designed for all permissible tyre sizes. If a

wheel wider than the spare wheel has

to be stowed in the load

compartment, it must be secured with a strap or, depending on the version,

with an extension bar.

Storing a replaced wheel in the

load compartment using a strap

Use the strap placed in the tool box.

Vehicle tools 3 195.

● Position the wheel on the load compartment floor close to one

sidewall of the load

compartment.

● Place the loop end of the strap through the front lashing eye of

the according side.

● Place the hook end of the strap through the loop and pull it until

the strap is fastened securely to

the lashing eye.

● Insert the strap through the spokes of the wheel as shown in

the illustration.

● Mount the hook to the rear lashing eye.

● Tighten the strap and secure it using the buckle.