warning OPEL VIVARO 2015 Manual PDF

[x] Cancel search | Manufacturer: OPEL, Model Year: 2015, Model line: VIVARO, Model: OPEL VIVARO 2015Pages: 205, PDF Size: 4.47 MB

Page 158 of 205

156Vehicle care

No.Circuit39Warning chimes40Load compartment power outlet41Driver power window42Rear power outlet43Starting, body control module44Heated seats45Heating, air conditioning46Windscreen wiper47TachographVehicle toolsTools

The jack, wheel wrench, wheel bolt

sleeve, torx key, adapters, wheel

cover hook, towing eye are contained

in a unit, stowed under the driver's

seat.

Slide seat forwards and fold the

backrest forwards 3 45 to access the

tool box. The tool box may be secured

in position with a wing nut.

Wheel changing 3 165, Spare wheel

3 166.

Vehicles with tyre repair kit: The

wheel cover hook and torx key are

stored within the tyre repair kit case,

stowed under the driver's seat.

Tyre repair kit 3 162.

Page 160 of 205

158Vehicle care

Tyre pressures 3 192. Always inflate

tyres to the pressures shown on the

label on the driver's door frame.

The tyre pressure data refers to cold

tyres. It applies to summer and winter tyres.

Always inflate the spare tyre to the

pressure specified for full load.

Incorrect tyre pressures will impair

safety, vehicle handling, comfort and

fuel economy and will increase tyre

wear.

Tyre pressures differ depending on

various options. For the correct tyre

pressure value, follow the procedure

below:

1. Identify the engine identifier code.

Engine data 3 182.

2. Identify the respective tyre.

The tyre pressure tables show all possible tyre combinations 3 192.

For the tyres approved for your

vehicle, refer to the EEC Certificate of

Conformity provided with your vehicle

or other national registration

documents.The driver is responsible for correct

adjustment of tyre pressure.9 Warning

If the pressure is too low, this can

result in considerable tyre warm-

up and internal damage, leading to tread separation and even to tyre

blow-out at high speeds.

Tyre pressure monitoring

system

The Tyre Pressure Monitoring

System (TPMS) uses radio and

sensor technology to check tyre

pressure levels.

Caution

Tyre pressure monitoring system

warns only about low tyre pressure condition and does not replace

regular tyre maintenance by the

driver.

All wheels must be equipped with pressure sensors and the tyres must

have the prescribed pressure.

Note

In countries where the tyre pressure

monitoring system is legally

required, the use of wheels without

pressure sensors will invalidate the

vehicle type approval.

The TPMS sensors monitor the air

pressure in the tyres and transmit tyre pressure readings to a receiver

located in the vehicle.

Tyre pressures in display The current tyre pressures can be

shown in the Driver Information

Centre 3 90.

Page 162 of 205

160Vehicle care

Puncture

A puncture or severely under-inflated

tyre is indicated by illumination of

control indicator w together with C

3 86 and a corresponding message

appears in the Driver Information

Centre. Stop vehicle and switch off

engine.

Tyre pressure 3 192, Tyre repair kit

3 162, Spare wheel 3 166, Wheel

changing 3 165.

Temperature dependency Tyre pressure depends on the

temperature of the tyre. During

driving, tyre temperature and

pressure increase.

The tyre pressure value displayed in

the Driver Information Centre shows

the actual tyre pressure. Therefore it

is important to check tyre pressure

with cold tyres.Relearn function

After changing the wheels, TPMS

needs to recalculate.

With the vehicle stationary, select the tyre pressure menu in the Driver

Information Centre by pressing button

on end of wiper lever. Press and hold button for approx. 3 seconds to

initialise recalculation. A

corresponding message appears in

the Driver Information Centre.

Several minutes of driving may be

required to complete the relearn

process.

If problems occur during the relearn

process, control indicator w remains

illuminated and a warning message is displayed in the Driver Information

Centre.

Driver Information Centre 3 90.

Vehicle messages 3 91.

General information

The use of commercially available

liquid tyre repair kits can impair the

function of the system. Factory-

approved tyre repair kits can be used.

Tyre repair kit 3 162.

External high-power radio equipment

could disrupt the tyre pressure

monitoring system.

Each time the tyres are replaced,

TPMS sensors must be dismounted

and serviced by a workshop.

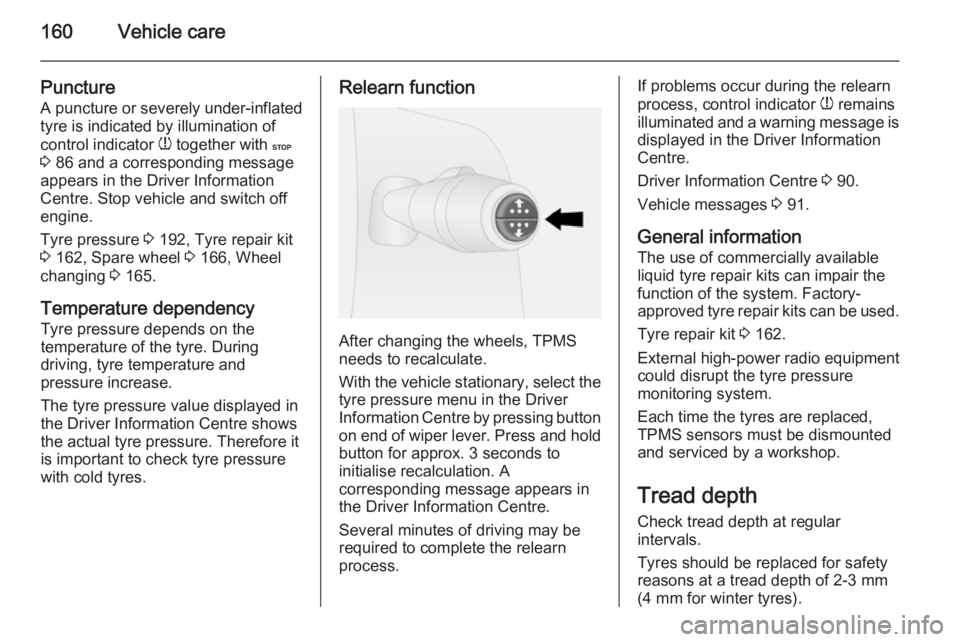

Tread depth

Check tread depth at regular

intervals.

Tyres should be replaced for safety

reasons at a tread depth of 2-3 mm

(4 mm for winter tyres).

Page 163 of 205

Vehicle care161

For safety reasons it is recommended

that the tread depth of the tyres on

one axle should not vary by more than 2 mm.

The legally permissible minimum

tread depth (1.6 mm) has been

reached when the tread has worn

down as far as one of the tread wear

indicators (TWI). Their position is

indicated by markings on the

sidewall.

Tyres age, even if they are not used.

We recommend tyre replacement

every 6 years.

Changing tyre and wheel

size If tyres of a different size than those

fitted at the factory are used, it may be necessary to reprogramme the

speedometer as well as the nominal

tyre pressure and make other vehicle modifications.

After converting to a different tyre

size, have the label with tyre

pressures replaced.9 Warning

Use of unsuitable tyres or wheels

may lead to accidents and will

invalidate the vehicle type

approval.

Wheel covers

Wheel covers and tyres that are

factory approved for the respective

vehicle and comply with all of the

relevant wheel and tyre combination requirements must be used.

If the wheel covers and tyres used are

not factory approved, the tyres must

not have a rim protection ridge.

Wheel covers must not impair brake

cooling.9 Warning

Use of unsuitable tyres or wheel

covers could lead to sudden

pressure loss and thereby

accidents.

Tyre chains

Page 164 of 205

162Vehicle care

Tyre chains are only permitted on thefront wheels.

Always use fine mesh chains that add

no more than 15 mm to the tyre tread

and the inboard sides (including chain

lock).

For tyre size 215/60 R17, consult a

workshop.9 Warning

Damage may lead to tyre blowout.

Wheel covers on steel wheels may

come into contact with parts of the

chains. In such cases, remove the

wheel covers.

Tyre chains may only be used at

speeds up to 50 km/h and, when

travelling on roads that are free of

snow, they may only be used for brief

periods since they are subject to rapid wear on a hard road and may snap.

The use of tyre chains is not permitted on the temporary spare wheel.

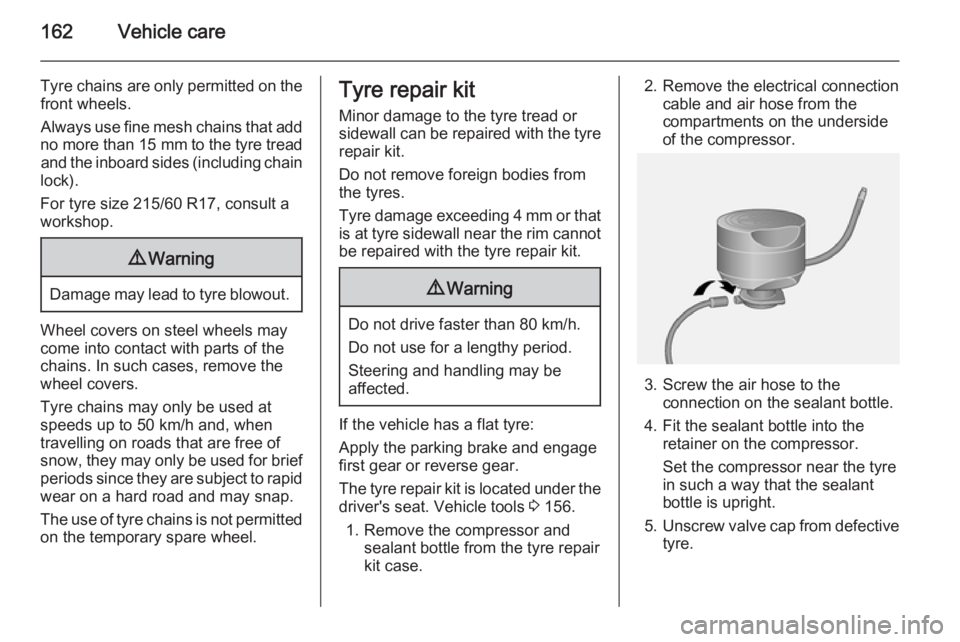

Tyre repair kit

Minor damage to the tyre tread or

sidewall can be repaired with the tyre

repair kit.

Do not remove foreign bodies from

the tyres.

Tyre damage exceeding 4 mm or that

is at tyre sidewall near the rim cannot

be repaired with the tyre repair kit.9 Warning

Do not drive faster than 80 km/h.

Do not use for a lengthy period.

Steering and handling may be

affected.

If the vehicle has a flat tyre:

Apply the parking brake and engage

first gear or reverse gear.

The tyre repair kit is located under the

driver's seat. Vehicle tools 3 156.

1. Remove the compressor and sealant bottle from the tyre repairkit case.

2. Remove the electrical connection cable and air hose from the

compartments on the underside

of the compressor.

3. Screw the air hose to the connection on the sealant bottle.

4. Fit the sealant bottle into the retainer on the compressor.

Set the compressor near the tyre

in such a way that the sealant

bottle is upright.

5. Unscrew valve cap from defective

tyre.

Page 166 of 205

164Vehicle care

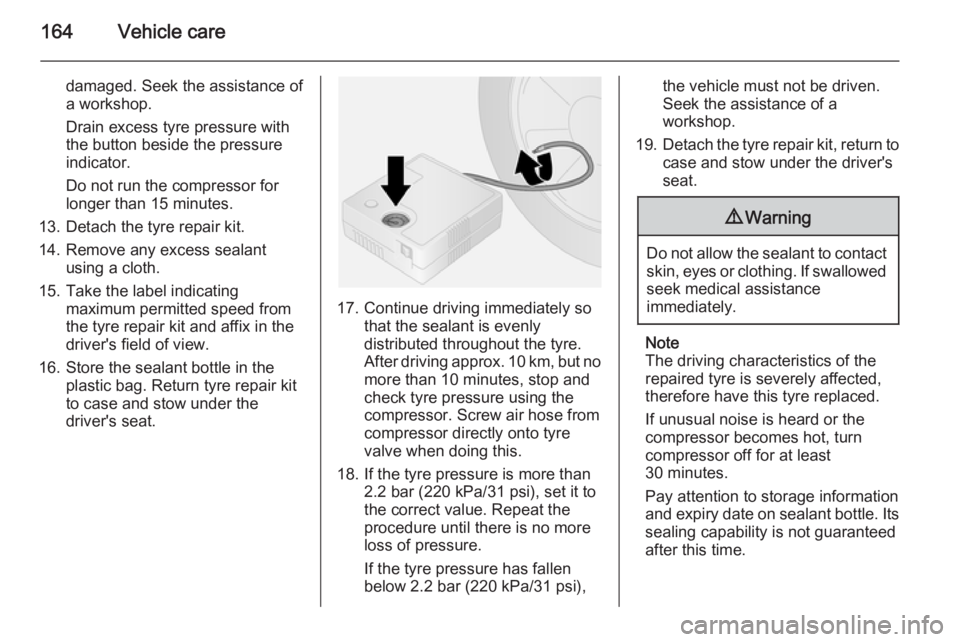

damaged. Seek the assistance of

a workshop.

Drain excess tyre pressure with

the button beside the pressure

indicator.

Do not run the compressor for

longer than 15 minutes.

13. Detach the tyre repair kit.

14. Remove any excess sealant using a cloth.

15. Take the label indicating maximum permitted speed from

the tyre repair kit and affix in the driver's field of view.

16. Store the sealant bottle in the plastic bag. Return tyre repair kitto case and stow under the

driver's seat.

17. Continue driving immediately so that the sealant is evenly

distributed throughout the tyre.

After driving approx. 10 km, but no more than 10 minutes, stop and

check tyre pressure using the

compressor. Screw air hose from

compressor directly onto tyre

valve when doing this.

18. If the tyre pressure is more than 2.2 bar (220 kPa/31 psi), set it to

the correct value. Repeat the

procedure until there is no more

loss of pressure.

If the tyre pressure has fallen

below 2.2 bar (220 kPa/31 psi),

the vehicle must not be driven.

Seek the assistance of a

workshop.

19. Detach the tyre repair kit, return to

case and stow under the driver's

seat.9 Warning

Do not allow the sealant to contact

skin, eyes or clothing. If swallowed seek medical assistance

immediately.

Note

The driving characteristics of the

repaired tyre is severely affected,

therefore have this tyre replaced.

If unusual noise is heard or the

compressor becomes hot, turn

compressor off for at least

30 minutes.

Pay attention to storage information

and expiry date on sealant bottle. Its

sealing capability is not guaranteed

after this time.

Page 169 of 205

Vehicle care167

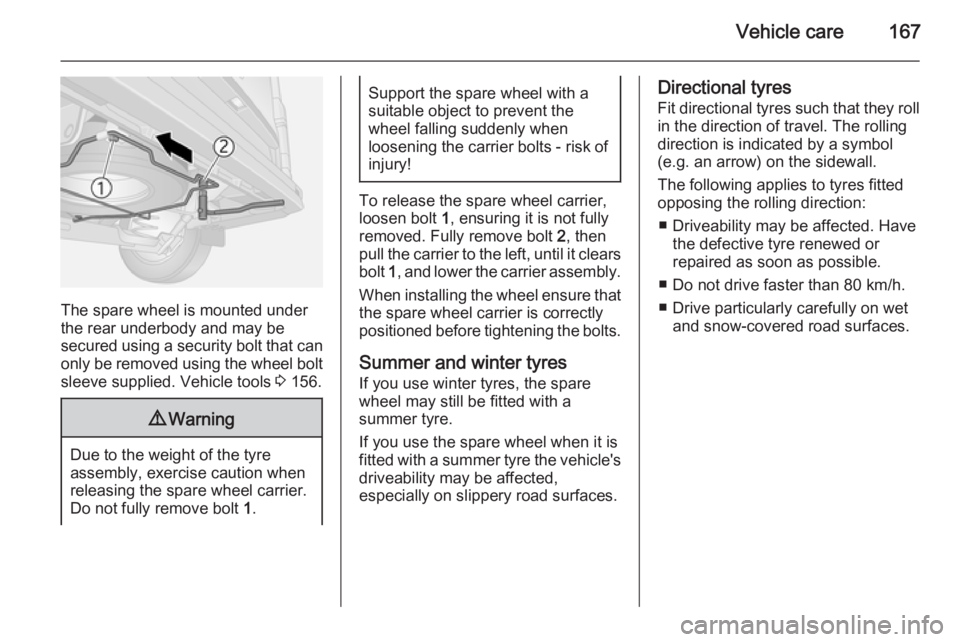

The spare wheel is mounted under

the rear underbody and may be

secured using a security bolt that can

only be removed using the wheel bolt sleeve supplied. Vehicle tools 3 156.

9 Warning

Due to the weight of the tyre

assembly, exercise caution when

releasing the spare wheel carrier.

Do not fully remove bolt 1.

Support the spare wheel with a

suitable object to prevent the

wheel falling suddenly when

loosening the carrier bolts - risk of injury!

To release the spare wheel carrier,loosen bolt 1, ensuring it is not fully

removed. Fully remove bolt 2, then

pull the carrier to the left, until it clears bolt 1, and lower the carrier assembly.

When installing the wheel ensure that

the spare wheel carrier is correctly

positioned before tightening the bolts.

Summer and winter tyres If you use winter tyres, the spare

wheel may still be fitted with a

summer tyre.

If you use the spare wheel when it is

fitted with a summer tyre the vehicle's driveability may be affected,

especially on slippery road surfaces.

Directional tyres

Fit directional tyres such that they roll in the direction of travel. The rolling

direction is indicated by a symbol

(e.g. an arrow) on the sidewall.

The following applies to tyres fitted

opposing the rolling direction:

■ Driveability may be affected. Have the defective tyre renewed or

repaired as soon as possible.

■ Do not drive faster than 80 km/h.

■ Drive particularly carefully on wet and snow-covered road surfaces.

Page 170 of 205

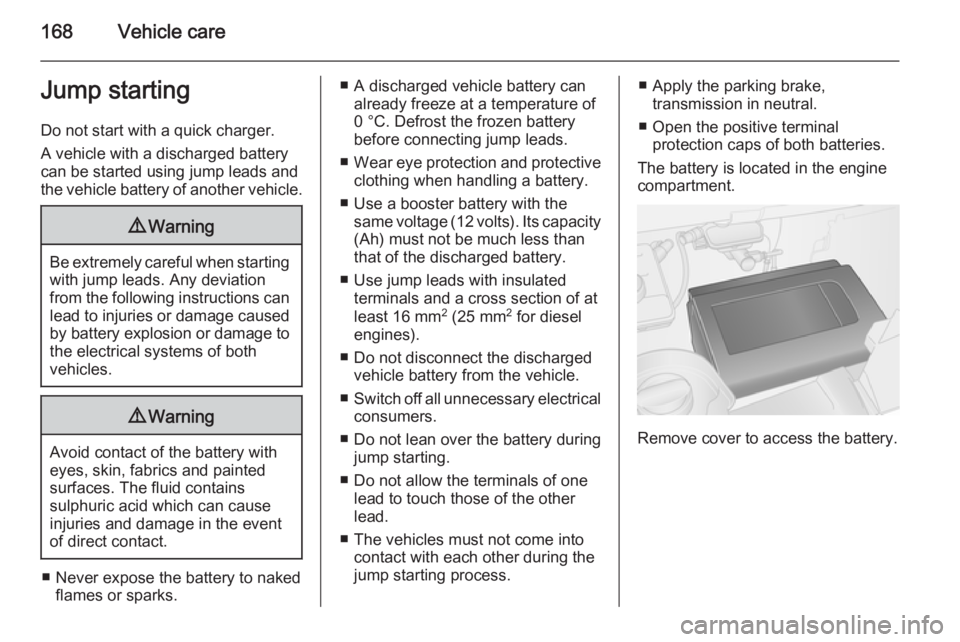

168Vehicle careJump startingDo not start with a quick charger.

A vehicle with a discharged battery

can be started using jump leads and the vehicle battery of another vehicle.9 Warning

Be extremely careful when starting

with jump leads. Any deviation

from the following instructions can

lead to injuries or damage caused

by battery explosion or damage to the electrical systems of both

vehicles.

9 Warning

Avoid contact of the battery with

eyes, skin, fabrics and painted

surfaces. The fluid contains

sulphuric acid which can cause

injuries and damage in the event

of direct contact.

■ Never expose the battery to naked flames or sparks.

■ A discharged vehicle battery canalready freeze at a temperature of

0 °C. Defrost the frozen battery

before connecting jump leads.

■ Wear eye protection and protective

clothing when handling a battery.

■ Use a booster battery with the same voltage (12 volts). Its capacity(Ah) must not be much less than

that of the discharged battery.

■ Use jump leads with insulated terminals and a cross section of at

least 16 mm 2

(25 mm 2

for diesel

engines).

■ Do not disconnect the discharged vehicle battery from the vehicle.

■ Switch off all unnecessary electrical

consumers.

■ Do not lean over the battery during jump starting.

■ Do not allow the terminals of one lead to touch those of the other

lead.

■ The vehicles must not come into contact with each other during thejump starting process.■ Apply the parking brake, transmission in neutral.

■ Open the positive terminal protection caps of both batteries.

The battery is located in the engine

compartment.

Remove cover to access the battery.

Page 178 of 205

176Service and maintenance

service is essential if any warranty or

goodwill claims are to be met, and is

also a benefit when selling the

vehicle.

Service display

The service interval is based on

several parameters depending on

usage.

The service display, located in the

Driver Information Centre, indicates

when the next service is due. Seek

the assistance of a workshop.

Service display 3 82.Recommended fluids,

lubricants and parts

Recommended fluids and

lubricants Only use products that meet the

recommended specifications.

Damage resulting from the use of

products not in line with these

specifications will not be covered by

the warranty.9 Warning

Operating materials are

hazardous and could be

poisonous. Handle with care. Pay

attention to information given on

the containers.

Engine oil

Engine oil is identified by its quality

and its viscosity. Quality is more

important than viscosity when

selecting which engine oil to use. The oil quality ensures e.g. engine

cleanliness, wear protection and oil

aging control, whereas viscosity

grade gives information on the oil's

thickness over a temperature range.

Dexos is the newest engine oil quality

that provides optimum protection for petrol and diesel engines. If it is

unavailable, engine oils of other listed qualities must be used.

Select the appropriate engine oil

based on its quality and on the

minimum ambient temperature

3 181.

Topping up engine oil

Engine oils of different manufacturers

and brands can be mixed as long as

they comply with the required engine

oil quality and viscosity.

Use of engine oil with only

ACEA A1/B1 or only A5/B5 quality is

prohibited, since it can cause long-

term engine damage under certain

operating conditions.

Select the appropriate engine oil

based on its quality and on the

minimum ambient temperature

3 181.

Page 199 of 205

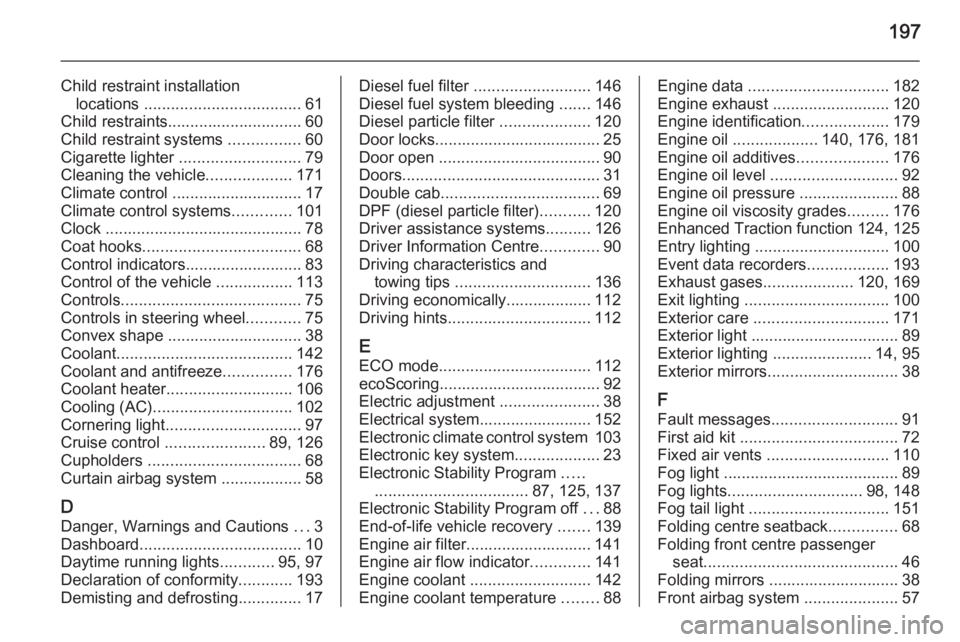

197

Child restraint installationlocations ................................... 61

Child restraints.............................. 60

Child restraint systems ................60

Cigarette lighter ........................... 79

Cleaning the vehicle ...................171

Climate control ............................. 17

Climate control systems .............101

Clock ............................................ 78 Coat hooks ................................... 68

Control indicators.......................... 83

Control of the vehicle .................113

Controls ........................................ 75

Controls in steering wheel ............75

Convex shape .............................. 38

Coolant ....................................... 142

Coolant and antifreeze ...............176

Coolant heater ............................ 106

Cooling (AC) ............................... 102

Cornering light .............................. 97

Cruise control ...................... 89, 126

Cupholders .................................. 68

Curtain airbag system .................. 58

D Danger, Warnings and Cautions ...3

Dashboard .................................... 10

Daytime running lights ............95, 97

Declaration of conformity ............193

Demisting and defrosting ..............17Diesel fuel filter .......................... 146

Diesel fuel system bleeding .......146

Diesel particle filter ....................120

Door locks..................................... 25

Door open .................................... 90

Doors ............................................ 31

Double cab ................................... 69

DPF (diesel particle filter) ...........120

Driver assistance systems ..........126

Driver Information Centre .............90

Driving characteristics and towing tips .............................. 136

Driving economically................... 112

Driving hints ................................ 112

E ECO mode .................................. 112

ecoScoring.................................... 92

Electric adjustment ......................38

Electrical system......................... 152

Electronic climate control system 103

Electronic key system ...................23

Electronic Stability Program .....

.................................. 87, 125, 137

Electronic Stability Program off ...88

End-of-life vehicle recovery .......139

Engine air filter............................ 141

Engine air flow indicator .............141

Engine coolant ........................... 142

Engine coolant temperature ........88Engine data ............................... 182

Engine exhaust .......................... 120

Engine identification ...................179

Engine oil ................... 140, 176, 181

Engine oil additives ....................176

Engine oil level ............................ 92

Engine oil pressure ......................88

Engine oil viscosity grades .........176

Enhanced Traction function 124, 125

Entry lighting .............................. 100

Event data recorders ..................193

Exhaust gases ....................120, 169

Exit lighting ................................ 100

Exterior care .............................. 171

Exterior light ................................. 89

Exterior lighting ......................14, 95

Exterior mirrors ............................. 38

F

Fault messages ............................ 91

First aid kit ................................... 72

Fixed air vents ........................... 110

Fog light ....................................... 89

Fog lights .............................. 98, 148

Fog tail light ............................... 151

Folding centre seatback ...............68

Folding front centre passenger seat ........................................... 46

Folding mirrors ............................. 38

Front airbag system .....................57