wheel OPEL ZAFIRA C 2014 Manual user

[x] Cancel search | Manufacturer: OPEL, Model Year: 2014, Model line: ZAFIRA C, Model: OPEL ZAFIRA C 2014Pages: 299, PDF Size: 9.03 MB

Page 251 of 299

Vehicle care249

Press the MENU button to select the

Vehicle Information Menu X .

Turn the adjuster wheel to select the

tyre pressure monitoring system.

System status and pressure warnings

are displayed by a message with the

corresponding tyre flashing in the

Driver Information Centre.

A detected low tyre pressure

condition is indicated by the control

indicator w 3 115.

If w illuminates, stop as soon as

possible and inflate the tyres as

recommended 3 285.

After inflating, driving may be

required to update the tyre pressure

values in the DIC. During this time w

may illuminate.

If w illuminates up at lower

temperatures and extinguishes after

some driving, this could be an

indicator for getting low pressure.

Check tyre pressure.

Vehicle messages 3 123.

If the tyre pressure must be reduced

or increased, switch off ignition.

Only mount wheels with pressure

sensors, otherwise the tyre pressure

will not be displayed and w

illuminates continuously.

A spare wheel or temporary spare

wheel is not equipped with pressure

sensors. The tyre pressure

monitoring system is not operational

for these wheels. Control indicator w

illuminates. For the further three

wheels the system remains

operational.

Page 252 of 299

250Vehicle care

The use of commercially available

liquid tyre repair kits can impair the

function of the system. Factory-

approved repair kits can be used.

External high-power radio equipment

could disrupt the tyre pressure

monitoring system.

Each time the tyres are replaced, tyre pressure monitoring system sensors

must be dismounted and serviced.

For the screwed sensor, replace

valve core and sealing ring. For

clipped sensor, replace complete

valve stem.

Vehicle loading status Adjust tyre pressure to load condition according to the tyre information labelor tyre pressure chart 3 285, and

select the appropriate setting in the

menu Tire Load in the Driver

Information Centre, Vehicle

Information Menu 3 117.

Select:

■ Light for comfort pressure up to

3 people

■ Eco for Eco pressure up to

3 people

■ Max for full loading

Auto learn function

After changing wheels, the vehicle

must be stationary for approx.

20 minutes, before the system

recalculates. The following relearn

process takes up to 10 minutes of

driving with a minimum speed of

20 km/h. In this case $ can be

displayed or pressure values can

swap in the Driver Information Centre.

If problems occur during the relearn

process, a warning message is

displayed in the Driver Information

Centre.

Temperature dependency Tyre pressure depends on the

temperature of the tyre. During

driving, tyre temperature and

pressure increase.

The tyre pressure value displayed in

the Driver Information Centre shows

the actual tyre pressure. Therefore it

is important to check tyre pressure

with cold tyres.

Tread depth Check tread depth at regular

intervals.

Tyres should be replaced for safety

reasons at a tread depth of 2-3 mm (4 mm for winter tyres).

Page 253 of 299

Vehicle care251

For safety reasons, it is

recommended that the tread depth of

the tyres on one axle should not vary

by more than 2 mm.

The legally permissible minimum

tread depth (1.6 mm) has been

reached when the tread has worn

down as far as one of the tread wear

indicators (TWI). Their position is

indicated by markings on the

sidewall.

If there is more wear at the front than

the rear, swap round front wheels and

rear wheels periodically. Ensure that

the direction of rotation of the wheels

remains the same.

Tyres age, even if they are not used.

We recommend tyre replacement

every 6 years.

Changing tyre and wheel

size If tyres of a different size than those

fitted at the factory are used, it may be necessary to reprogramme the

speedometer as well as the nominal

tyre pressure and make other vehicle

modifications.

After converting to a different tyre

size, have the label with tyre

pressures replaced.9 Warning

Use of unsuitable tyres or wheels

may lead to accidents and will

invalidate the vehicle type

approval.

Wheel covers

Wheel covers and tyres that are

factory approved for the respective

vehicle and comply with all of the

relevant wheel and tyre combination requirements must be used.

If the wheel covers and tyres used are

not factory approved, the tyres must

not have a rim protection ridge.

Wheel covers must not impair brake

cooling.9 Warning

Use of unsuitable tyres or wheel

covers could lead to sudden

pressure loss and thereby

accidents.

Page 254 of 299

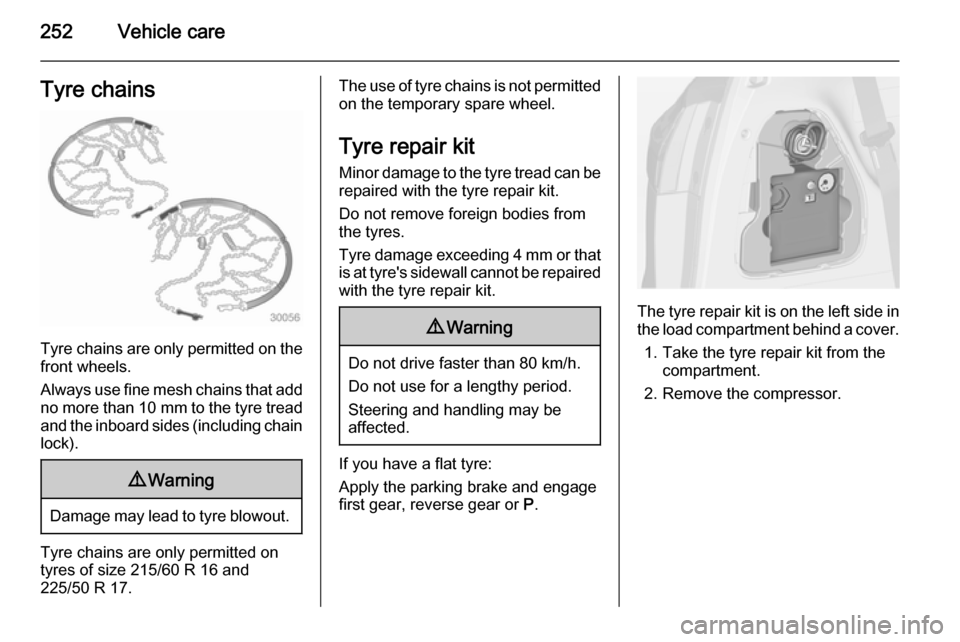

252Vehicle careTyre chains

Tyre chains are only permitted on the

front wheels.

Always use fine mesh chains that add no more than 10 mm to the tyre tread

and the inboard sides (including chain lock).

9 Warning

Damage may lead to tyre blowout.

Tyre chains are only permitted on

tyres of size 215/60 R 16 and

225/50 R 17.

The use of tyre chains is not permitted on the temporary spare wheel.

Tyre repair kit

Minor damage to the tyre tread can be

repaired with the tyre repair kit.

Do not remove foreign bodies from

the tyres.

Tyre damage exceeding 4 mm or that

is at tyre's sidewall cannot be repaired with the tyre repair kit.9 Warning

Do not drive faster than 80 km/h.

Do not use for a lengthy period.

Steering and handling may be

affected.

If you have a flat tyre:

Apply the parking brake and engage

first gear, reverse gear or P.

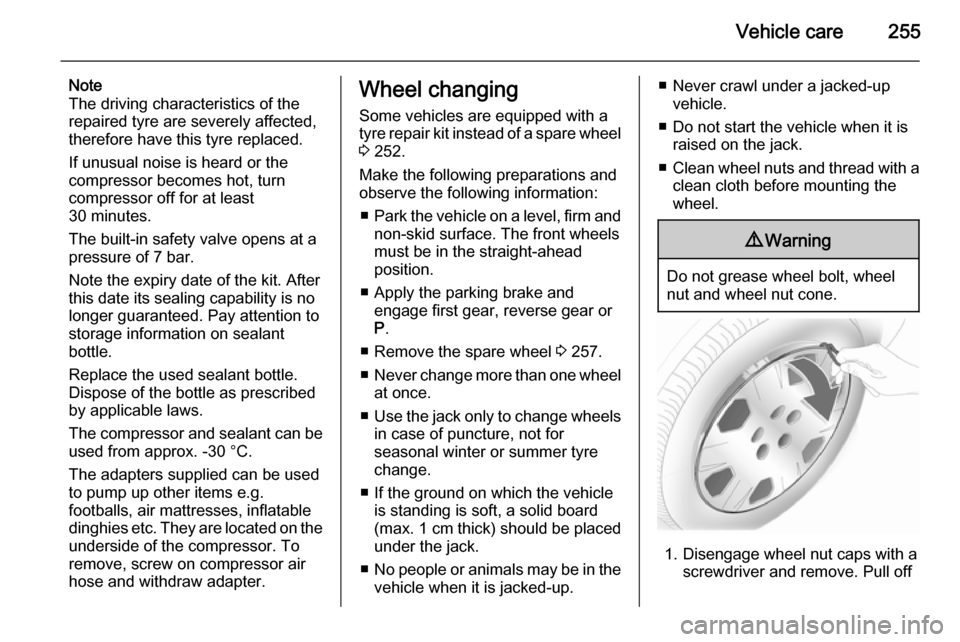

The tyre repair kit is on the left side in

the load compartment behind a cover.

1. Take the tyre repair kit from the compartment.

2. Remove the compressor.

Page 257 of 299

Vehicle care255

Note

The driving characteristics of the

repaired tyre are severely affected, therefore have this tyre replaced.

If unusual noise is heard or the

compressor becomes hot, turn

compressor off for at least

30 minutes.

The built-in safety valve opens at a

pressure of 7 bar.

Note the expiry date of the kit. After

this date its sealing capability is no

longer guaranteed. Pay attention to

storage information on sealant

bottle.

Replace the used sealant bottle. Dispose of the bottle as prescribed

by applicable laws.

The compressor and sealant can be used from approx. -30 °C.

The adapters supplied can be used

to pump up other items e.g.

footballs, air mattresses, inflatable

dinghies etc. They are located on the

underside of the compressor. To

remove, screw on compressor air hose and withdraw adapter.Wheel changing

Some vehicles are equipped with a

tyre repair kit instead of a spare wheel 3 252.

Make the following preparations and

observe the following information:

■ Park the vehicle on a level, firm and

non-skid surface. The front wheels

must be in the straight-ahead

position.

■ Apply the parking brake and engage first gear, reverse gear or

P .

■ Remove the spare wheel 3 257.

■ Never change more than one wheel

at once.

■ Use the jack only to change wheels

in case of puncture, not for

seasonal winter or summer tyre

change.

■ If the ground on which the vehicle is standing is soft, a solid board

(max. 1 cm thick) should be placed

under the jack.

■ No people or animals may be in the

vehicle when it is jacked-up.■ Never crawl under a jacked-up vehicle.

■ Do not start the vehicle when it is raised on the jack.

■ Clean wheel nuts and thread with a

clean cloth before mounting the

wheel.9 Warning

Do not grease wheel bolt, wheel

nut and wheel nut cone.

1. Disengage wheel nut caps with a screwdriver and remove. Pull off

Page 258 of 299

256Vehicle care

the wheel cover with the hook.

Vehicle tools 3 246.

Alloy wheels: Disengage wheel

nut caps with a screwdriver and

remove. To protect the wheel,

place a soft cloth between the

screwdriver and the alloy wheel.

2. Fold out the wheel wrench and install ensuring that it locates

securely and loosen each wheel

nut by half a turn.

3. Some versions may have covered

the vehicle jacking point. Pull out

the cover sideways.

4. Ensure the jack is correctly positioned under the relevant

vehicle jacking point.

5. Set the jack to the necessary height. Position it directly below

the jacking point in a manner that

prevents it from slipping.

Page 259 of 299

Vehicle care257

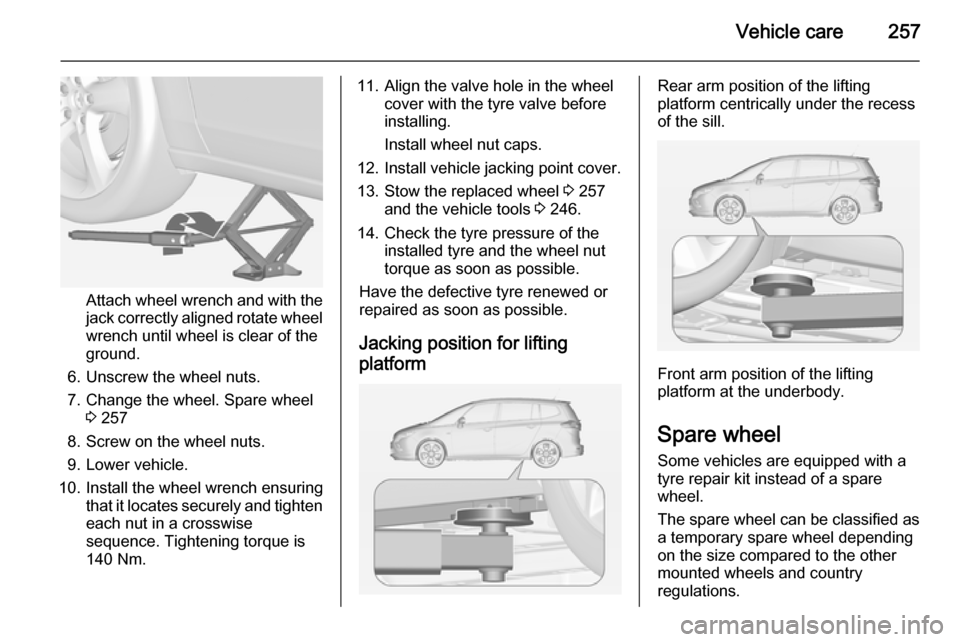

Attach wheel wrench and with the

jack correctly aligned rotate wheel wrench until wheel is clear of the

ground.

6. Unscrew the wheel nuts. 7. Change the wheel. Spare wheel 3 257

8. Screw on the wheel nuts.

9. Lower vehicle.

10. Install the wheel wrench ensuring that it locates securely and tighten

each nut in a crosswise

sequence. Tightening torque is

140 Nm.

11. Align the valve hole in the wheel cover with the tyre valve before

installing.

Install wheel nut caps.

12. Install vehicle jacking point cover.

13. Stow the replaced wheel 3 257

and the vehicle tools 3 246.

14. Check the tyre pressure of the installed tyre and the wheel nuttorque as soon as possible.

Have the defective tyre renewed or

repaired as soon as possible.

Jacking position for liftingplatformRear arm position of the lifting

platform centrically under the recess

of the sill.

Front arm position of the lifting

platform at the underbody.

Spare wheel Some vehicles are equipped with a

tyre repair kit instead of a spare

wheel.

The spare wheel can be classified as

a temporary spare wheel depending

on the size compared to the other

mounted wheels and country

regulations.

Page 260 of 299

258Vehicle care

The spare wheel has a steel rim.Caution

The use of a spare wheel that issmaller than the other wheels or in combination with winter tyres

could affect driveability. Have the defective tyre replaced as soon as

possible.

The spare wheel is located in a holder

beneath the vehicle floor.

1. Open the stowage in the load compartment 3 246.

2. Remove both caps above the hexagon bolts.

3. Fit the wheel wrench on onehexagon bolt and turn it anti-

clockwise until a resistance is

noticeable.

4. Proceed with the other hexagon bolt in the same way.5. Lift the spare wheel holder andunhook both catches.

6. Lower the spare wheel holder.

7. Detach the safety cable.

Page 261 of 299

Vehicle care259

8. Lower holder all the way andremove spare wheel.

9. Change the wheel. The damaged wheel has to be

secured in the load compartment,

see below.

10. Lift the empty spare wheel holder and insert the safety cable.

11. Lift the spare wheel holder farther

and engage in both catches. The

open sides of the catches must

point in the direction of travel.

12. Close the empty spare wheel holder by turning both hexagon

bolts clockwise successively

using the wheel wrench.

13. Fit the caps above both hexagon bolts.

14. Stow wheel wrench and the jack in the stowage in front of the

tailgate.

15. Close the stowage compartment cover.

When stowing again the spare wheel

in the spare wheel holder, note that

the wheel is positioned with the tyre

valve above the recess of the wheel

holder.

Stowing a damaged wheel in the load compartment

The spare wheel holder is not

designed for other tyre sizes than

spare wheel.

A damaged wheel wider than the spare wheel has to be stowed in the

load compartment and secured with a strap. Vehicle tools 3 246.The seats of the third row must be

folded in 3 78.

1. Position the wheel close to the left

sidewall of the load compartment.

2. Place the loop end of the strap through the front lashing eye on

the left side.

3. Place the hook end of the strap through the loop and pull it until

the strap is fastened securely to

the lashing eye.

Page 262 of 299

260Vehicle care

4. Insert the strap through thespokes of the wheel as shown in

the illustration.

5. Mount the hook to the rear left lashing eye.

6. Tighten the strap and secure it using the buckle.

9 Danger

Always drive with folded up and

engaged rear seat backrests when stowing a damaged full size wheel

in the load compartment.

9 Warning

Storing a jack, a wheel or other

equipment in the load

compartment could cause injury if they are not fixed properly. During a sudden stop or a collision, looseequipment could strike someone.

Store jack and tools always in the

respective storage compartments

and secure them by fixing.

Damaged wheel placed in the load

compartment must always be

secured by the strap.

Temporary spare wheel

The use of the temporary spare wheel

could affect driveability. Have the

defective tyre renewed or repaired as soon as possible.

Only mount one temporary spare

wheel. Do not drive faster than

80 km/h. Take curves slowly. Do not

use for a long period of time.

If your vehicle gets a flat tyre on the

rear while towing another vehicle,

mount the temporary spare wheel in the front and the full tyre in the rear.

Tyre chains 3 252.

Directional tyres

Fit directional tyres such that they roll in the direction of travel. The rolling

direction is indicated by a symbol

(e.g. an arrow) on the sidewall.

The following applies to tyres fitted

opposing the rolling direction:

■ Driveability may be affected. Have the defective tyre renewed or

repaired as soon as possible.

■ Drive particularly carefully on wet and snow-covered road surfaces.