PEUGEOT 106 2001.5 Manual Online

Manufacturer: PEUGEOT, Model Year: 2001.5, Model line: 106, Model: PEUGEOT 106 2001.5Pages: 107, PDF Size: 2.92 MB

Page 81 of 107

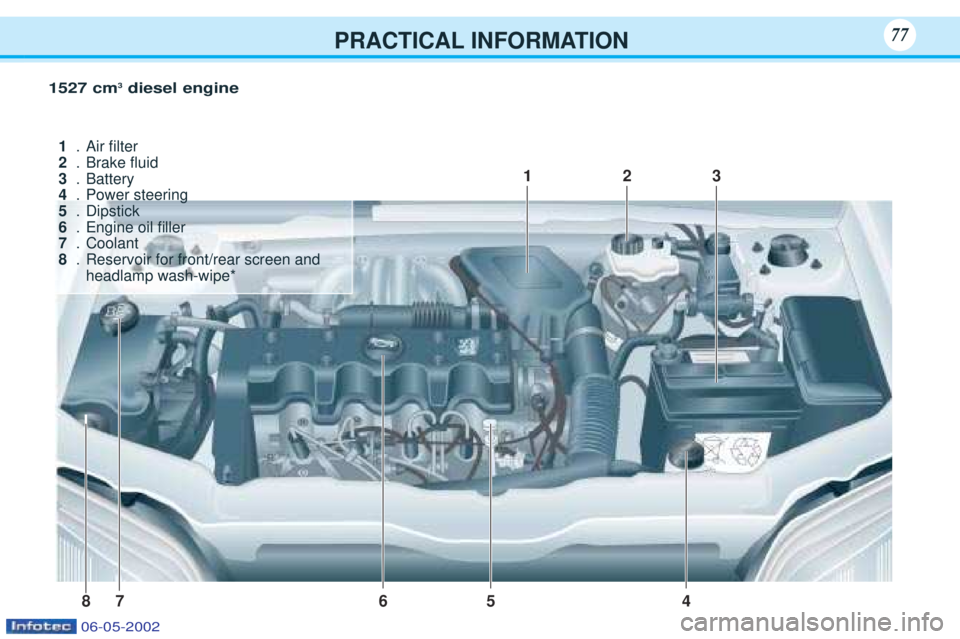

PRACTICAL INFORMATION7777

1527 cm3

diesel engine

4

1

3

5

6

87 2

1

.Air Þlter

2 .Brake ßuid

3 .Battery

4 .Power steering

5 .Dipstick

6 .Engine oil Þller

7 .Coolant

8 .Reservoir for front/rear screen and headlamp wash-wipe*

06-05-2002

Page 82 of 107

CHECKING THE LEVELS 1. Air filter

The air filter element must be changed at the recommendedintervals. If you drive in a dustyatmosphere, change it twice asoften. Follow the recommendations given in the maintenance schedule. 2. Brake fluid

The level must always be above the

DANGER mark on the reservoir. Inthe event of a signiÞcant drop in theßuid level, consult a PEUGEOT

dealer immediately. Use fluids

approved by the manufacturer,which conform to DOT 3 or DOT 4standards. 3. Battery

At the beginning of winter, have the battery checked by a PEUGEOT

dealer. In summer (30¡C and above) or if the battery is in heavy use, checkthe level of electrolyte; it must coverthe separator plates at all times. If

necessary, top up with distilled

water. 4. Power steering* When the engine is cold, the level must always be above the MINmark, close to the MAX mark. 5. Dipstick Check the oil level on ßat ground, with the engine cold and preferably

before the Þrst journey of the day. Never exceed the maximum level.

Check the level regularly.

6. T

opping up with oil

Y our oil must be changed in accor-

dance with the maintenance sche- dule. The oil must be topped up between oil changes. Regularly check and top-up the oil level. Maximum oil consumption is 0.5 litres per 600 miles (1000 km). 7. Coolant Engine cold: the coolant level must be between the min and max marksin the expansion chamber with the

cap removed. To close, turn the capto the second notch*. Cooling circuit Always use the coolant which is approved by the manufacturer

(PROCOR TM108 / GLYSANTING33 or REVKOGEL 2000). If this isnot possible, top up with distilledwater and have the protection level

checked by a PEUGEOT dealer. When the engine is hot, the coolant temperature is regulated by the fan.As the fan can operate with theignition key removed, and as thecooling circuit is pressurised,

do

not carry out any work for atleast an hour after switching offthe engine .

Note: the coolant does not need tobe renewed.

8. Front/rear screen and headlamp wash reservoir*

For optimum cleaning quality and

for your safety, it is best to use cleaning products approved byPEUGEOT (capacity 4.5 litreswithout headlamp wash, 5.5 litreswith headlamp wash). * According to speciÞcation

PRACTICAL INFORMATION7878

06-05-2002

Page 83 of 107

PRACTICAL INFORMATION79

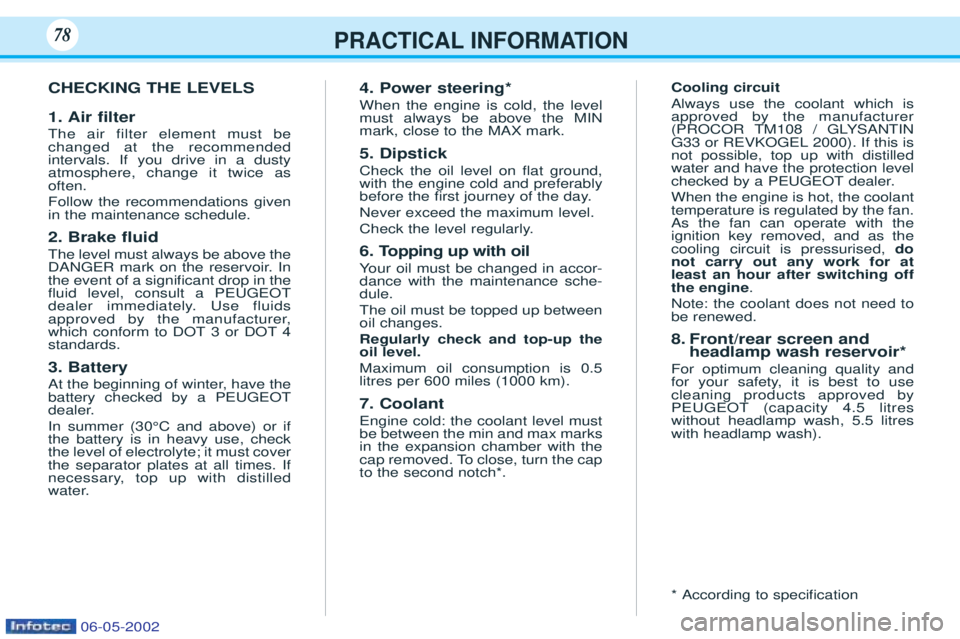

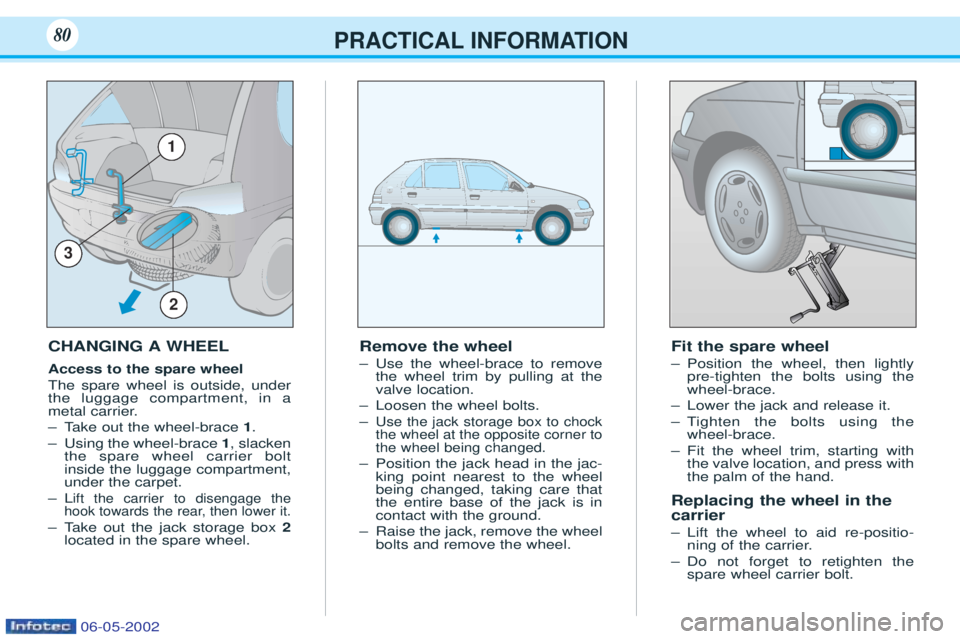

Visual brake pad wear indicator*

The front brakes are Þtted with visual wear indicators. Regularly check the thickness of the brake pads.

To check: turn the wheels to full lock on the side to be checked. The thickness of pad remaining is represented by the measu-

rement X. When the measurement is zero, the brake pads must be changed. Advice As brake pad wear depends on the way in which the vehicle is driven, particularly if the vehicle is used for urban driving or f or

short journeys, or is driven in a very sporty manner, it may be necessary to check the thickness of the pads even between ser- vice intervals. * According to speciÞcation

79

06-05-2002

Page 84 of 107

PRACTICAL INFORMATION80

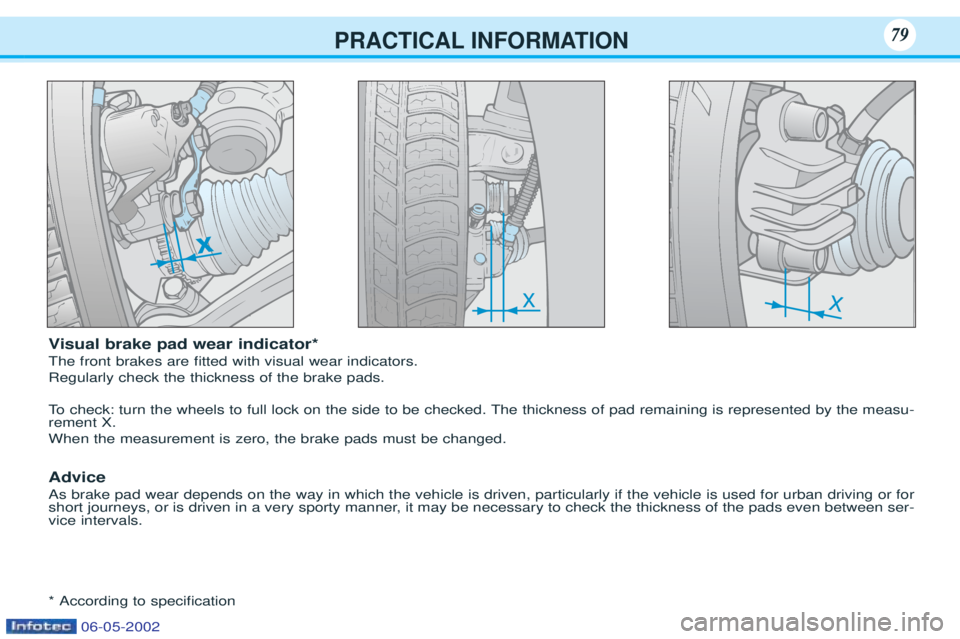

CHANGING A WHEEL Access to the spare wheel The spare wheel is outside, under the luggage compartment, in a

metal carrier. ÐTake out the wheel-brace 1.

Ð Using the wheel-brace 1, slacken

the spare wheel carrier bolt inside the luggage compartment,under the carpet.

ÐL

ift the carrier to disengage the

hook towards the rear, then lower it.

ÐT ake out the jack storage box 2

located in the spare wheel. Remove the wheel Ð

Use the wheel-brace to remove the wheel trim by pulling at thevalve location.

Ð Loosen the wheel bolts.

Ð

Use the jack storage box to chockthe wheel at the opposite corner tothe wheel being changed.

Ð Position the jack head in the jac-king point nearest to the wheelbeing changed, taking care thatthe entire base of the jack is incontact with the ground.

Ð Raise the jack, remove the wheelbolts and remove the wheel. Fit the spare wheel Ð

Position the wheel, then lightly pre-tighten the bolts using thewheel-brace.

Ð Lower the jack and release it.

ÐT ighten the bolts using the

wheel-brace.

Ð Fit the wheel trim, starting withthe valve location, and press withthe palm of the hand.

Replacing the wheel in the carrier Ð Lift the wheel to aid re-positio-

ning of the carrier.

Ð Do not forget to retighten thespare wheel carrier bolt.

80

3

2

1

06-05-2002

Page 85 of 107

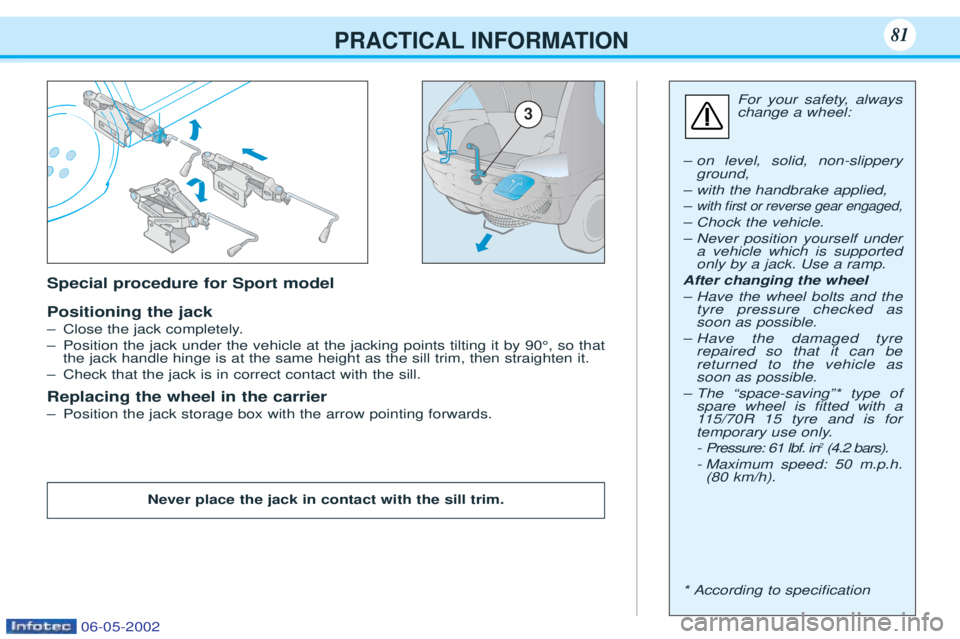

Special procedure for Sport model Positioning the jack ÐClose the jack completely.

Ð Position the jack under the vehicle at the jacking points tilting it by 90¡, so that the jack handle hinge is at the same height as the sill trim, then straighten it.

Ð Check that the jack is in correct contact with the sill.

Replacing the wheel in the carrier Ð Position the jack storage box with the arrow pointing forwards.

PRACTICAL INFORMATION8181

For your safety, always change a wheel:

Ð on level, solid, non-slipperyground,

Ð with the handbrake applied,

Ð

with Þrst or reverse gear engaged,

Ð Chock the vehicle.

Ð Never position yourself undera vehicle which is supportedonly by a jack. Use a ramp.

After changing the wheel Ð Have the wheel bolts and the tyre pressure checked assoon as possible.

Ð Have the damaged tyrerepaired so that it can bereturned to the vehicle assoon as possible.

Ð The Òspace-savingÓ* type ofspare wheel is Þtted with a115/70R 15 tyre and is for

temporary use only. - Pressure: 61 lbf. in 2

(4.2 bars).

- Maximum speed: 50 m.p.h. (80 km/h).

* According to speciÞcation

3

Never place the jack in contact with the sill trim.

06-05-2002

Page 86 of 107

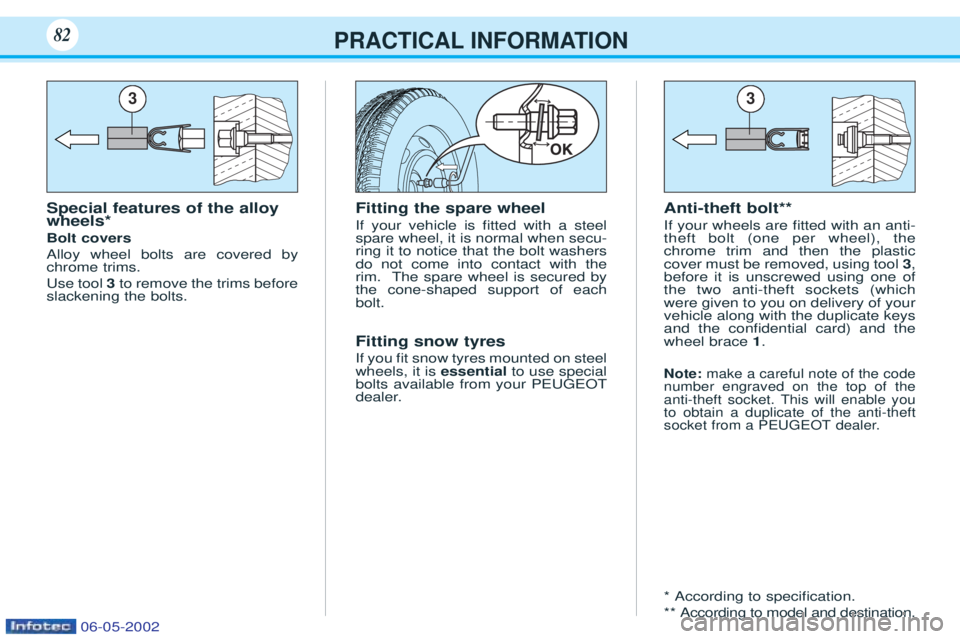

Special features of the alloy wheels* Bolt covers Alloy wheel bolts are covered by chrome trims. Use tool 3to remove the trims before

slackening the bolts.

PRACTICAL INFORMATION82

Anti-theft bolt** If your wheels are Þtted with an anti- theft bolt (one per wheel), thechrome trim and then the plasticcover must be removed, using tool 3,

before it is unscrewed using one ofthe two anti-theft sockets (whichwere given to you on delivery of yourvehicle along with the duplicate keysand the conÞdential card) and thewheel brace 1.

Note: make a careful note of the code

number engraved on the top of theanti-theft socket. This will enable youto obtain a duplicate of the anti-theft

socket from a PEUGEOT dealer.

* According to speciÞcation. ** According to model and destination.

Fitting the spare wheel If your vehicle is Þtted with a steel spare wheel, it is normal when secu-ring it to notice that the bolt washersdo not come into contact with therim. The spare wheel is secured bythe cone-shaped support of eachbolt. Fitting snow tyres If you Þt snow tyres mounted on steel wheels, it is

essentialto use special

bolts available from your PEUGEOT

dealer.

33

06-05-2002

Page 87 of 107

PRACTICAL INFORMATION83

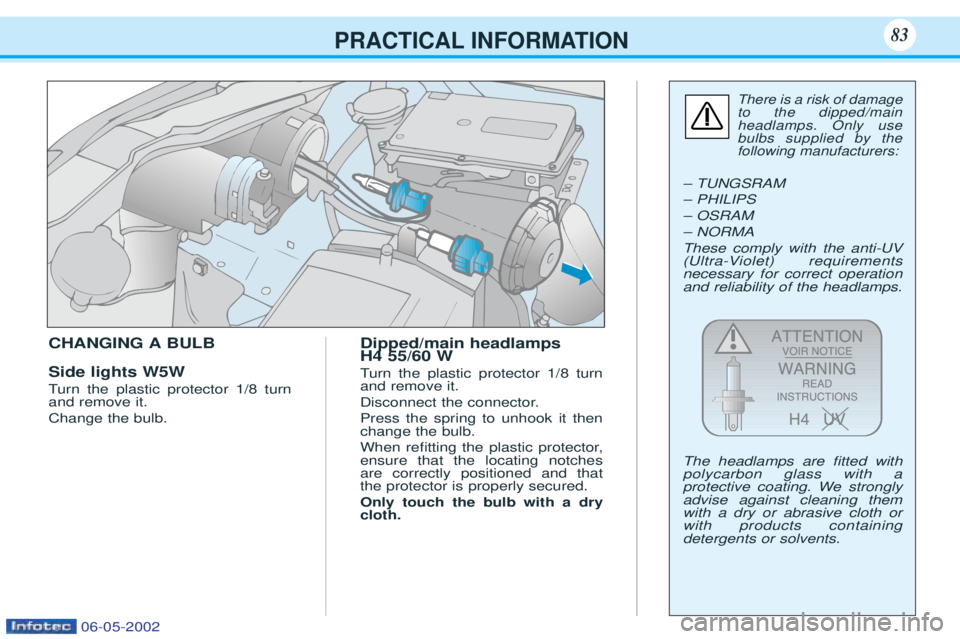

CHANGING A BULB Side lights W5W Turn the plastic protector 1/8 turn

and remove it. Change the bulb. Dipped/main headlamps H4 55/60 W T

urn the plastic protector 1/8 turn

and remove it.

Disconnect the connector.Press the spring to unhook it then change the bulb.

When reÞtting the plastic protector, ensure that the locating notchesare correctly positioned and thatthe protector is properly secured. Only touch the bulb with a dry cloth.

There is a risk of damage to the dipped/mainheadlamps. Only usebulbs supplied by thefollowing manufacturers:

Ð TUNGSRAM

Ð PHILIPS

Ð OSRAM

Ð NORMA

These comply with the anti-UV

(Ultra-Violet) requirementsnecessary for correct operationand reliability of the headlamps. The headlamps are Þtted with polycarbon glass with a

protective coating. We stronglyadvise against cleaning themwith a dry or abrasive cloth orwith products containingdetergents or solvents.

06-05-2002

Page 88 of 107

PRACTICAL INFORMATION

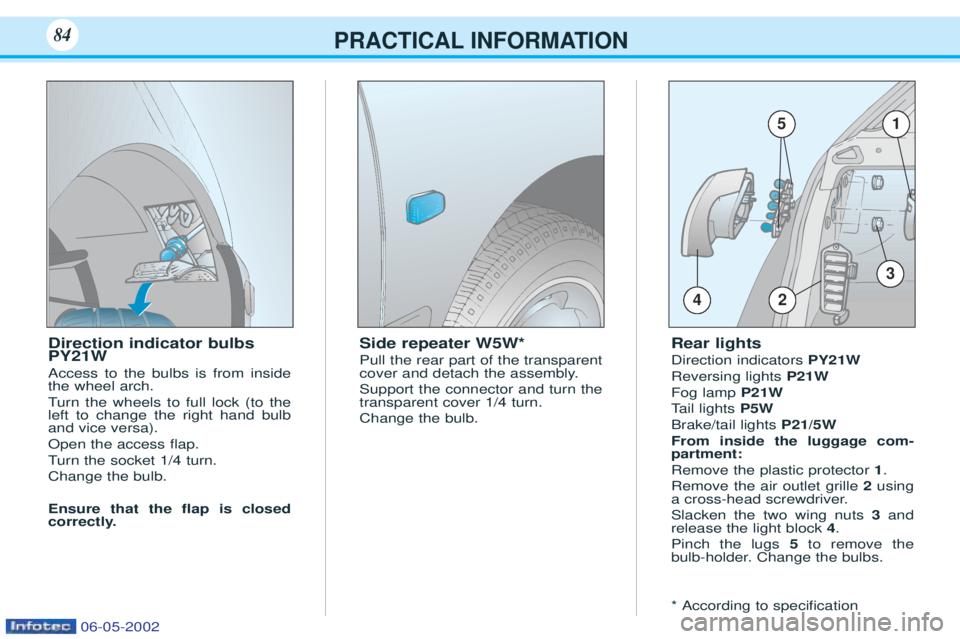

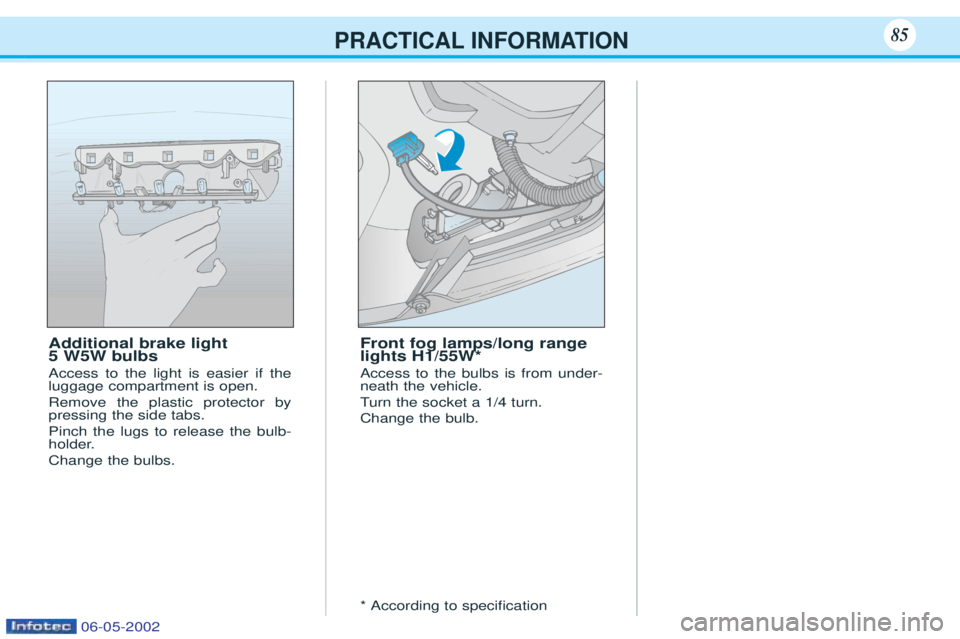

Direction indicator bulbs PY21W Access to the bulbs is from inside the wheel arch. Turn the wheels to full lock (to the

left to change the right hand bulb and vice versa). Open the access ßap.T urn the socket 1/4 turn.

Change the bulb. Ensure that the flap is closed

correctly. Side repeater W5W* Pull the rear part of the transparent

cover and detach the assembly. Support the connector and turn the transparent cover 1/4 turn. Change the bulb.

Rear lights Direction indicators

PY21W

Reversing lights P21W

Fog lamp P21W

T ail lights P5W

Brake/tail lights P21/5W

From inside the luggage com- partment: Remove the plastic protector 1.

Remove the air outlet grille 2using

a cross-head screwdriver. Slacken the two wing nuts 3and

release the light block 4.

Pinch the lugs 5to remove the

bulb-holder. Change the bulbs. * According to speciÞcation

84

4

3

1

2

5

06-05-2002

Page 89 of 107

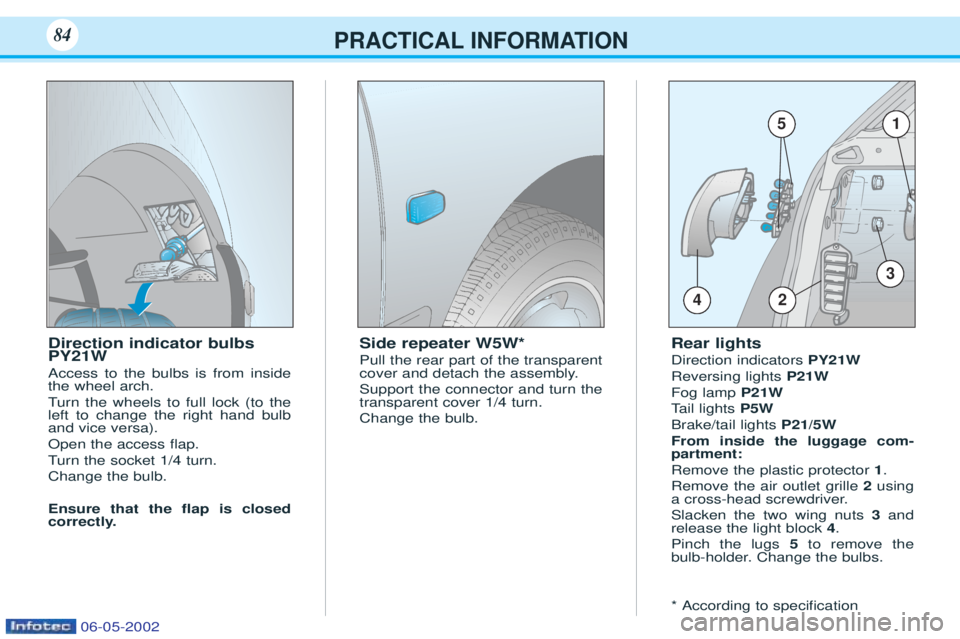

PRACTICAL INFORMATION

Additional brake light 5 W5W bulbs Access to the light is easier if the luggage compartment is open. Remove the plastic protector by pressing the side tabs. Pinch the lugs to release the bulb-

holder. Change the bulbs.Front fog lamps/long range lights H1/55W* Access to the bulbs is from under- neath the vehicle. T

urn the socket a 1/4 turn.

Change the bulb. * According to speciÞcation

85

06-05-2002

Page 90 of 107

PRACTICAL INFORMATION

Direction indicator bulbs PY21W Access to the bulbs is from inside the wheel arch. Turn the wheels to full lock (to the

left to change the right hand bulb and vice versa). Open the access ßap.T urn the socket 1/4 turn.

Change the bulb. Ensure that the flap is closed

correctly. Side repeater W5W* Pull the rear part of the transparent

cover and detach the assembly. Support the connector and turn the transparent cover 1/4 turn. Change the bulb.

Rear lights Direction indicators

PY21W

Reversing lights P21W

Fog lamp P21W

T ail lights P5W

Brake/tail lights P21/5W

From inside the luggage com- partment: Remove the plastic protector 1.

Remove the air outlet grille 2using

a cross-head screwdriver. Slacken the two wing nuts 3and

release the light block 4.

Pinch the lugs 5to remove the

bulb-holder. Change the bulbs. * According to speciÞcation

84

4

3

1

2

5

06-05-2002