PEUGEOT 108 2018 Owners Manual

Manufacturer: PEUGEOT, Model Year: 2018, Model line: 108, Model: PEUGEOT 108 2018Pages: 180, PDF Size: 7.14 MB

Page 101 of 180

99

F Push the exterior safety catch to the left and raise the bonnet.

F

U

nclip the bonnet stay from its housing.

F

F

ix the stay in the notch to hold the bonnet

open.

Do not open the bonnet under very windy

conditions.

When the engine is hot, handle the

exterior safety catch and the stay with

care (risk of burns).

The cooling fan may star t after

switching off the engine: take care

with articles and clothing that might be

caught by the fan blades.

Because of the presence of electrical

equipment under the bonnet, it is

recommended that exposure to water

(rain, washing, etc.) be limited.

Closing

F Take the stay out of the support notch.

F C lip the stay in its housing.

F

L

ower the bonnet and release it near the

end of its travel.

F

P

ull on the bonnet to check that it is fully

latched.

To avoid damaging the electrical units,

never use a

high-pressure jet wash in the

engine compartment.

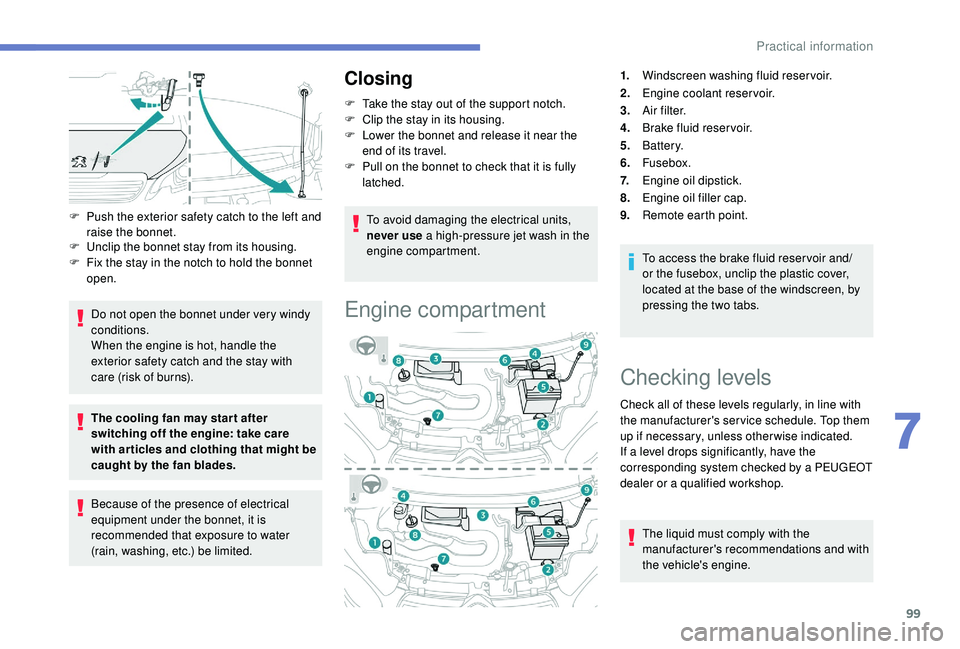

Engine compartment

1. Windscreen washing fluid reservoir.

2. Engine coolant reservoir.

3. A i r f i l t e r.

4. Brake fluid reser voir.

5. Battery.

6. Fusebox.

7. Engine oil dipstick.

8. Engine oil filler cap.

9. Remote earth point.

To access the brake fluid reser voir and/

or the fusebox, unclip the plastic cover,

located at the base of the windscreen, by

pressing the two tabs.

Checking levels

Check all of these levels regularly, in line with

the manufacturer's service schedule. Top them

up if necessary, unless other wise indicated.

If a

level drops significantly, have the

corresponding system checked by a

PEUGEOT

dealer or a

qualified workshop.

The liquid must comply with the

manufacturer's recommendations and with

the vehicle's engine.

7

Practical information

Page 102 of 180

100

Take care when working under the bonnet,

as certain areas of the engine may be

extremely hot (risk of burns) and the

cooling fan could start at any time (even

with the ignition off).

Used products

Avoid prolonged contact of used oil or

fluids with the skin.

Most of these fluids are harmful to health

or indeed very corrosive.Do not discard used oil or fluids into

sewers or onto the ground.

Take used oil to a

PEUGEOT dealer

or a

qualified workshop and dispose

of in the containers reser ved for this

purpose.

Engine oil level

The check is carried out either

using the oil level indicator on the

instrument panel when the ignition is

switched on, for vehicles equipped

with an electric gauge, or using the

dipstick. To ensure that the reading is correct, your

vehicle must be parked on a

level sur face

with the engine stopped for more than

30

minutes.

It is normal to top up the oil level between

two ser vices (or oil changes). PEUGEOT

recommends that you check the level, and top

up, if necessary, every 3,000 miles (5,000 km).

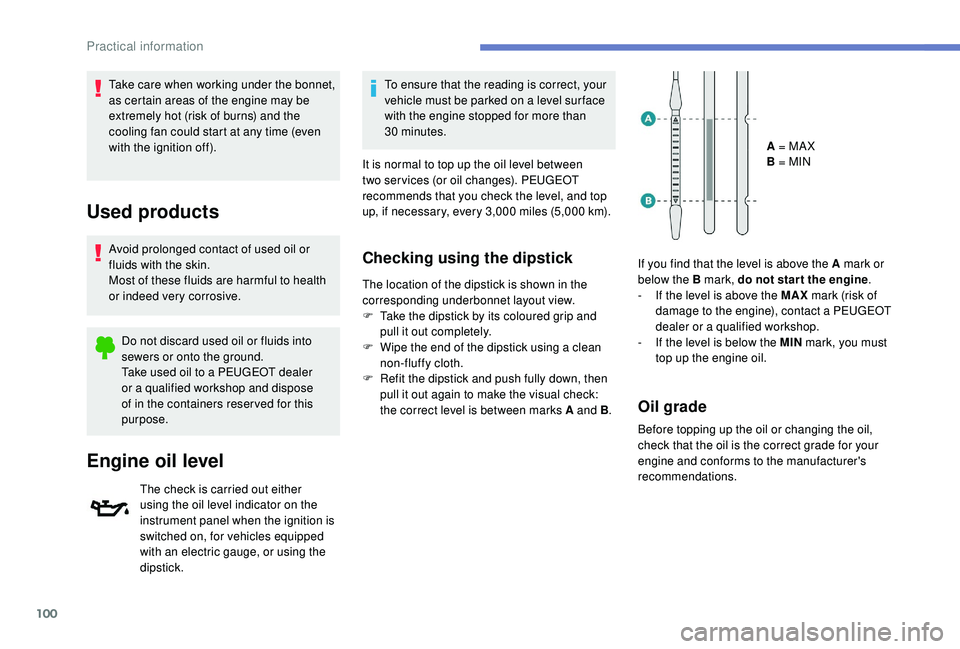

Checking using the dipstick

The location of the dipstick is shown in the

corresponding underbonnet layout view.

F

T

ake the dipstick by its coloured grip and

pull it out completely.

F

W

ipe the end of the dipstick using a clean

non-fluffy cloth.

F

R

efit the dipstick and push fully down, then

pull it out again to make the visual check:

the correct level is between marks A and B .A = MA X

B = MIN

If you find that the level is above the A mark or

below the B mark, do not star t the engine .

- I f the level is above the MAX mark (risk of

damage to the engine), contact a

PEUGEOT

dealer or a

qualified workshop.

-

I

f the level is below the MIN mark, you must

top up the engine oil.

Oil grade

Before topping up the oil or changing the oil,

check that the oil is the correct grade for your

engine and conforms to the manufacturer's

recommendations.

Practical information

Page 103 of 180

101

Topping up the engine oil level

The location of the oil filler cap is shown in the

corresponding underbonnet layout view.

F

U

nscrew the oil filler cap to access the filler

opening.

F

A

dd oil in small quantities, avoiding any

spills on engine components (risk of fire).

F

W

ait a few minutes before checking the

level again using the dipstick.

F

A

dd more oil if necessary.

F

A

fter checking the level, carefully refit the oil

filler cap and the dipstick in its tube.

Engine oil change

In order to maintain the reliability of the engine

and emissions control system, never use

additives in the engine oil.

Brake fluid level

The fluid level should be close to the

"MA X" mark. If it is not, check the

brake pad wear.

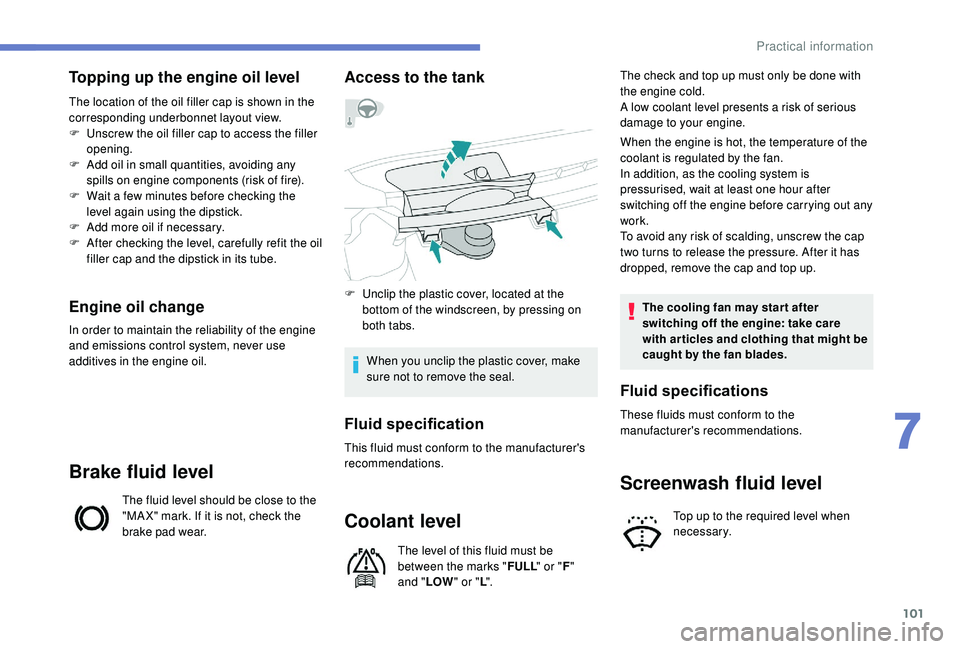

Access to the tank

F Unclip the plastic cover, located at the bottom of the windscreen, by pressing on

both tabs.

When you unclip the plastic cover, make

sure not to remove the seal.

Fluid specification

This fluid must conform to the manufacturer's

recommendations.

Coolant level

The level of this fluid must be

between the marks " FULL" or "F"

and " LOW " or "L". The check and top up must only be done with

the engine cold.

A low coolant level presents a

risk of serious

damage to your engine.

When the engine is hot, the temperature of the

coolant is regulated by the fan.

In addition, as the cooling system is

pressurised, wait at least one hour after

switching off the engine before carrying out any

work.

To avoid any risk of scalding, unscrew the cap

two turns to release the pressure. After it has

dropped, remove the cap and top up.

The cooling fan may star t after

switching off the engine: take care

with articles and clothing that might be

caught by the fan blades.

Screenwash fluid level

Top up to the required level when

necessary.

Fluid specifications

These fluids must conform to the

manufacturer's recommendations.

7

Practical information

Page 104 of 180

102

Checks

Unless otherwise indicated, check these

components in accordance with the

manufacturer's service schedule.

Other wise, have them checked by a PEUGEOT

dealer or a

qualified workshop.

12 V battery

The battery does not require any

maintenance.

However, check regularly that the

terminals are correctly tightened

(versions without quick release terminals)

and that the connections are clean.

For more information on the precautions

to take before starting work on the 12 V

battery , refer to the corresponding

section.

Air filter

Depending on the environment

(e.g. dusty atmosphere) and the

use of the vehicle (e.g. city driving),

replace it twice as often if

necessary .

Passenger compartment

filter

Depending on the environment

(e.g. dusty atmosphere) and the

use of the vehicle (e.g. city driving),

replace it twice as often if

necessary. A clogged passenger compartment

filter may have an adverse effect on

the per formance of the air conditioning

system and generate undesirable odours.

Oil filter

Change the oil filter each time the

engine oil is changed.

Manual gearbox

The gearbox does not require any

maintenance (no oil change).

Clutch

Versions equipped with Stop & Start are

fitted with a

12 V lead-acid battery of

specific technology and specification.

Its replacement should be carried out

only by a

PEUGEOT dealer or a qualified

workshop.

The clutch is mechanically operated and

requires regular adjustment.If there is a

malfunction (for example,

difficulty in pulling away), contact

a

PEUGEOT dealer or a qualified

workshop.

Fluid specification

The screenwash fluid must be topped up with

a ready for use mix.

In winter (temperatures below zero), a fluid with

antifreeze must be used that is appropriate for

the prevailing conditions, in order to preser ve

the elements of the system (pump, tank, ducts,

e t c .) .

Filling with pure water is prohibited under all

circumstances (risk of freezing, limestone

deposits, etc.).

Practical information

Page 105 of 180

103

Brake pads

Brake wear depends on the style

of driving, particularly in the case

of vehicles used in town, over short

distances. It may be necessary to

have the condition of the brakes

checked, even between vehicle

services.

Unless there is a

leak in the circuit, a drop in

the brake fluid level indicates that the brake

pads are worn.

Brake disc/drum wear

For information on checking

brake disc/drum wear, contact

a

PEUGEOT dealer or a qualified

workshop.

Parking brake

If excessive travel or a loss of

e ffectiveness of this system is

noticed, the parking brake must

be checked, even between two

services.

This system must be checked by a

PEUGEOT

dealer or a

qualified workshop.

Wheels and tyres

The pressure must be checked on

all tyres, including the spare wheel,

when the tyres are "cold", at least

once a month and before a long

j o u r n ey. Driving with worn or damaged tyres reduces

braking efficiency and control of the vehicle's

steering. Regular inspections of the condition

of tyres (tread and sides) and rims are

recommended as well as making sure that

valves are fitted.

Using different size wheels and tyres from

those specified can affect the lifetime of tyres,

wheel rotation, ground clearance and the

speedometer reading and have an adverse

effect on road holding.

Fitting different tyres on the front and rear axles

can cause the ESC to mistime.

Only use products recommended by

PEUGEOT or products of equivalent

quality and specification.

In order to optimise the operation of

components as important as those in the

braking system, PEUGEOT selects and

offers very specific products.

After washing the vehicle, dampness, or

in wintry conditions, ice can form on the

brake discs and pads: braking efficiency

may be reduced. Make light brake

applications to dry and defrost the brakes.

ETG gearbox

The ETG gearbox does not require

any maintenance (no oil change).

The pressures given on the tyre pressure label

are valid for "cold" tyres. If you have driven for

more than 10

minutes or more than 6 miles

(10

kilometres) at more than 31 mph (50 km/h),

0.3

bar (30 kPa) should be added to the values

given on the label.

Under-inflation increases fuel consumption.

Non-compliant tyre pressure causes premature

wear on tyres and has an adverse effect on the

vehicle's road holding – Risk of an accident!

7

Practical information

Page 106 of 180

104

Temporary puncture

repair kit

Scan the QR code on page 3 to view

e xplanatory videos.

Comprising a

compressor and a sealant

cartridge, it allows the temporary repair of

a

tyre so that you can drive to the nearest

garage.

It is designed to repair most punctures which

could affect the tyre, located on the tyre tread

or shoulder.

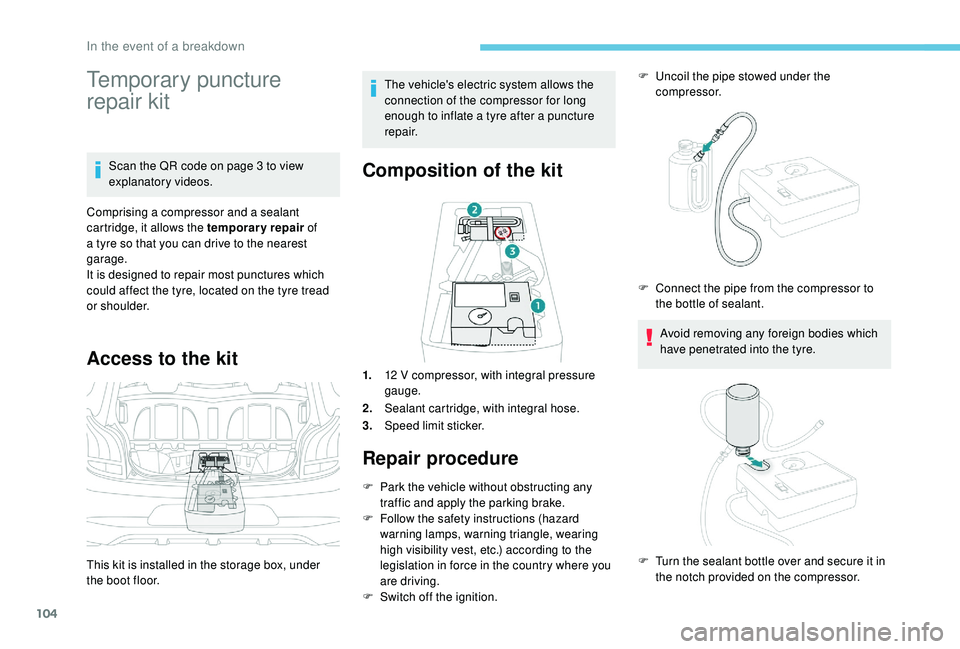

Access to the kit

This kit is installed in the storage box, under

the boot floor. The vehicle's electric system allows the

connection of the compressor for long

enough to inflate a

tyre after a puncture

repair.

Composition of the kit

1. 12 V compressor, with integral pressure

gauge.

2. Sealant cartridge, with integral hose.

3. Speed limit sticker.

Repair procedure

F Park the vehicle without obstructing any

traffic and apply the parking brake.

F

F

ollow the safety instructions (hazard

warning lamps, warning triangle, wearing

high visibility vest, etc.) according to the

legislation in force in the country where you

are driving.

F

S

witch off the ignition. F

U

ncoil the pipe stowed under the

compressor.

Avoid removing any foreign bodies which

have penetrated into the tyre.

F

C

onnect the pipe from the compressor to

the bottle of sealant.

F

T

urn the sealant bottle over and secure it in

the notch provided on the compressor.

In the event of a breakdown

Page 107 of 180

105

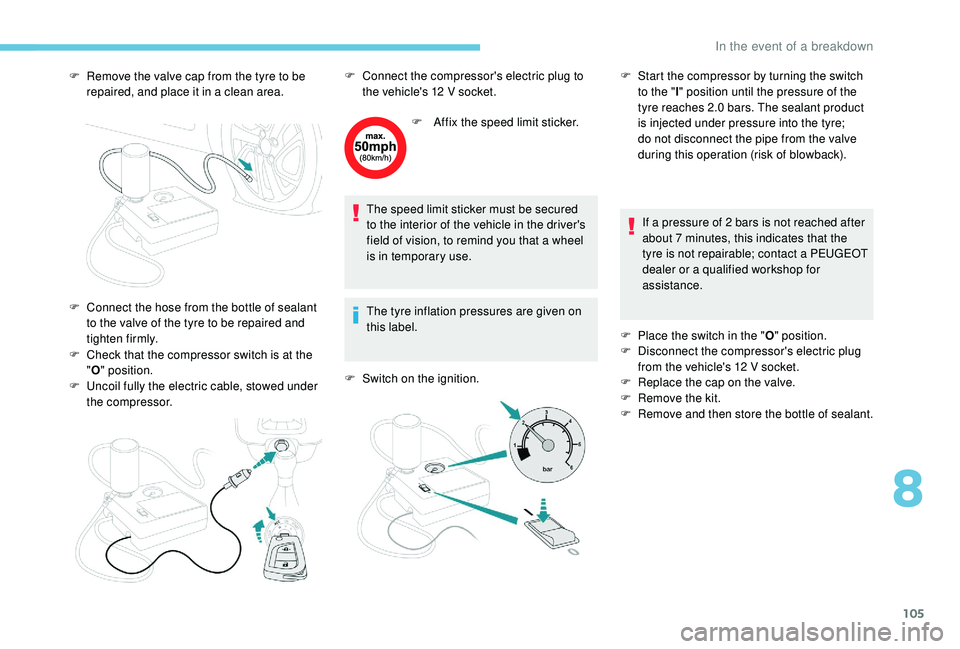

F Remove the valve cap from the tyre to be repaired, and place it in a clean area.

F

C

heck that the compressor switch is at the

" O " position.

F

U

ncoil fully the electric cable, stowed under

the compressor. F

A

ffix the speed limit sticker.

The speed limit sticker must be secured

to the interior of the vehicle in the driver's

field of vision, to remind you that a

wheel

is in temporary use.

The tyre inflation pressures are given on

this label.

F

S

witch on the ignition.If a

pressure of 2 bars is not reached after

about 7

minutes, this indicates that the

tyre is not repairable; contact a

PEUGEOT

dealer or a

qualified workshop for

assistance.

F

P

lace the switch in the "O" position.

F

D

isconnect the compressor's electric plug

from the vehicle's 12

V socket.

F

R

eplace the cap on the valve.

F

R

emove the kit.

F

R

emove and then store the bottle of sealant.

F

C

onnect the hose from the bottle of sealant

to the valve of the tyre to be repaired and

tighten firmly. F

C onnect the compressor's electric plug to

the vehicle's 12 V socket.F

S tart the compressor by turning the switch

to the " l" position until the pressure of the

tyre reaches 2.0

bars. The sealant product

is injected under pressure into the tyre;

do not disconnect the pipe from the valve

during this operation (risk of blowback).

8

In the event of a breakdown

Page 108 of 180

106

Take care, the sealant product is harmful

if swallowed and causes irritation to the

eyes.

Keep this product out of the reach of

children.

The use-by date of the fluid is marked on

the bottle.

After use, do not discard the bottle in

standard waste, take it to a PEUGEOT

dealer or an authorised waste disposal

site.

Do not forget to obtain a

new bottle of

sealant, available from a

PEUGEOT

dealer or a

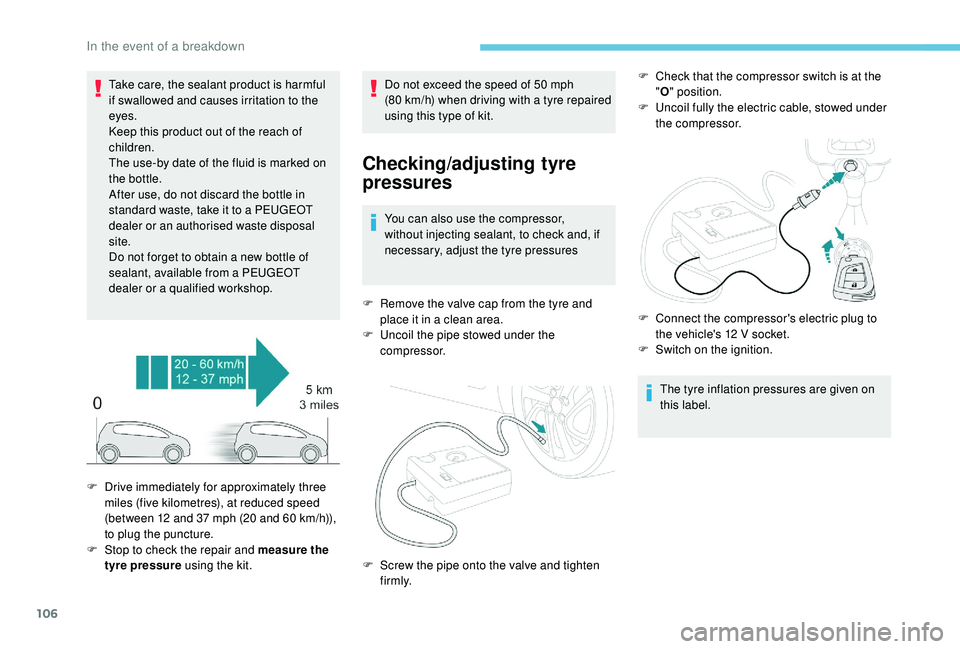

qualified workshop. Do not exceed the speed of 50

mph

(80 km/h) when driving with a tyre repaired

using this type of kit.

Checking/adjusting tyre

pressures

You can also use the compressor,

without injecting sealant, to check and, if

necessary, adjust the tyre pressures

F

R

emove the valve cap from the tyre and

place it in a

clean area.

F

U

ncoil the pipe stowed under the

compressor. F

C

heck that the compressor switch is at the

" O " position.

F

U

ncoil fully the electric cable, stowed under

the compressor.

The tyre inflation pressures are given on

this label.

F

D

rive immediately for approximately three

miles (five kilometres), at reduced speed

(between 12

and 37

mph (20

and 60

km/h)),

to plug the puncture.

F

S

top to check the repair and measure the

tyre pressure using the kit. F

S

crew the pipe onto the valve and tighten

f i r m l y. F

C

onnect the compressor's electric plug to

the vehicle's 12

V socket.

F

S

witch on the ignition.

In the event of a breakdown

Page 109 of 180

107

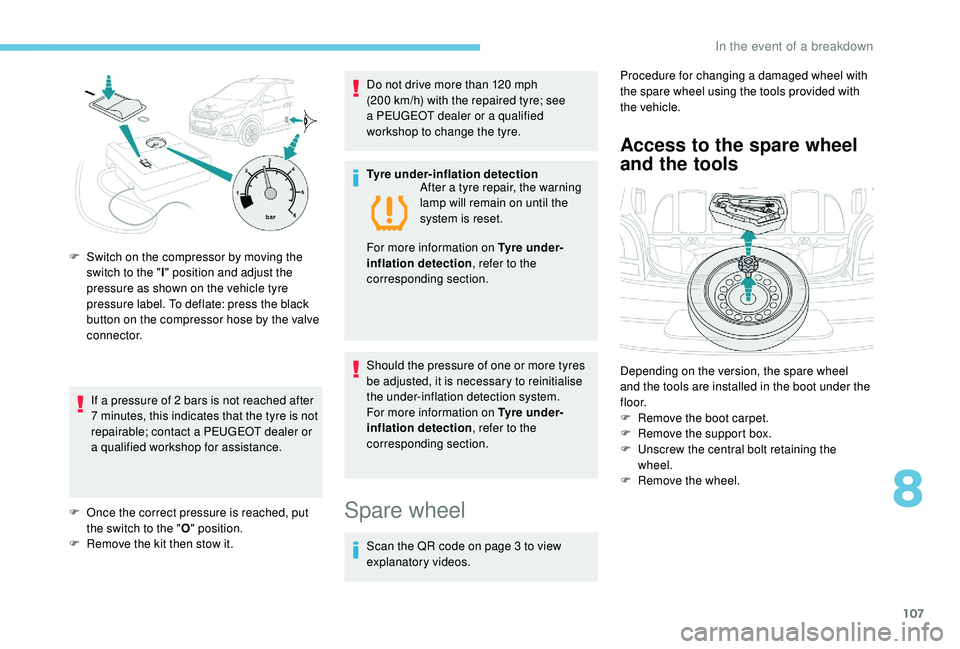

If a pressure of 2 bars is not reached after

7 minutes, this indicates that the tyre is not

repairable; contact a

PEUGEOT dealer or

a

qualified workshop for assistance.

F

O

nce the correct pressure is reached, put

the switch to the " O" position.

F

R

emove the kit then stow it. Do not drive more than 120

mph

(200 km/h) with the repaired tyre; see

a PEUGEOT dealer or a qualified

workshop to change the tyre.

Tyre under-inflation detection After a tyre repair, the warning

lamp will remain on until the

system is reset.

For more information on Tyre under-

inflation detection , refer to the

corresponding section.

Should the pressure of one or more tyres

be adjusted, it is necessary to reinitialise

the under-inflation detection system.

For more information on Tyre under-

inflation detection , refer to the

corresponding section.

F

S

witch on the compressor by moving the

switch to the " I" position and adjust the

pressure as shown on the vehicle tyre

pressure label. To deflate: press the black

button on the compressor hose by the valve

connector.

Spare wheel

Scan the QR code on page 3 to view

e xplanatory videos. Procedure for changing a

damaged wheel with

the spare wheel using the tools provided with

the vehicle.

Access to the spare wheel

and the tools

Depending on the version, the spare wheel

and the tools are installed in the boot under the

f l o o r.

F

R

emove the boot carpet.

F

R

emove the support box.

F

U

nscrew the central bolt retaining the

wheel.

F

R

emove the wheel.

8

In the event of a breakdown

Page 110 of 180

108

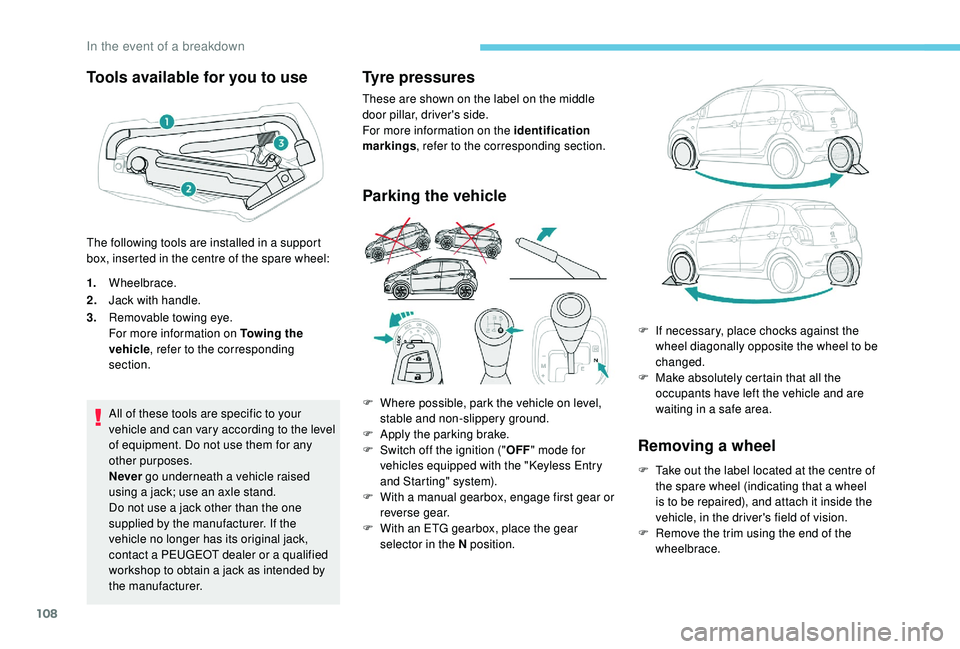

Tools available for you to use

1.Wheelbrace.

2. Jack with handle.

3. Removable towing eye.

For more information on Towing the

vehicle , refer to the corresponding

section.

All of these tools are specific to your

vehicle and can vary according to the level

of equipment. Do not use them for any

other purposes.

Never go underneath a

vehicle raised

using a

jack; use an axle stand.

Do not use a

jack other than the one

supplied by the manufacturer. If the

vehicle no longer has its original jack,

contact a

PEUGEOT dealer or a qualified

workshop to obtain a

jack as intended by

the manufacturer.

Tyre pressures

These are shown on the label on the middle

door pillar, driver's side.

For more information on the identification

markings , refer to the corresponding section.

Parking the vehicle

Removing a wheel

F Take out the label located at the centre of the spare wheel (indicating that a wheel

is to be repaired), and attach it inside the

vehicle, in the driver's field of vision.

F

R

emove the trim using the end of the

wheelbrace.

The following tools are installed in a

support

box, inserted in the centre of the spare wheel:

F

W

here possible, park the vehicle on level,

stable and non-slippery ground.

F

A

pply the parking brake.

F

S

witch off the ignition ("

OFF" mode for

vehicles equipped with the " K

eyless Entry

and Starting" system).

F

W

ith a

manual gearbox, engage first gear or

reverse gear.

F

W

ith an ETG gearbox, place the gear

selector in the N position. F

I

f necessary, place chocks against the

wheel diagonally opposite the wheel to be

changed.

F

M

ake absolutely certain that all the

occupants have left the vehicle and are

waiting in a safe area.

In the event of a breakdown