maintenance Peugeot Boxer 2020 User Guide

[x] Cancel search | Manufacturer: PEUGEOT, Model Year: 2020, Model line: Boxer, Model: Peugeot Boxer 2020Pages: 196, PDF Size: 5.1 MB

Page 136 of 196

134

Technical data

Colour

Code

Varnish

B

FOR TROUBLESHOOTING ONLY.

C

DANGER

AUTOMATIC ENGINE STARTING. REMOVE

THE IGNITION KEY WHEN THE BONNET IS

OPEN.

D

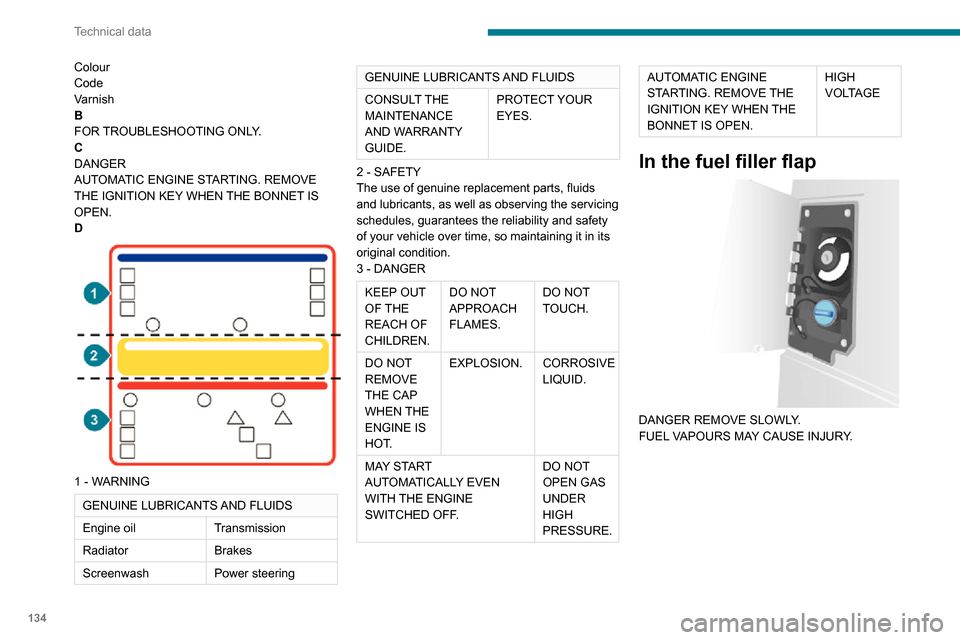

1 - WARNING

GENUINE LUBRICANTS AND FLUIDS

Engine oilTransmission

Radiator Brakes

Screenwash Power steering

GENUINE LUBRICANTS AND FLUIDS

CONSULT THE

MAINTENANCE

AND WARRANTY

GUIDE.PROTECT YOUR

EYES.

2 - SAFETY

The use of genuine replacement parts, fluids

and lubricants, as well as observing the servicing

schedules, guarantees the reliability and safety

of your vehicle over time, so maintaining it in its

original condition.

3 - DANGER

KEEP OUT

OF THE

REACH OF

CHILDREN. DO NOT

APPROACH

FLAMES.

DO NOT

TOUCH.

DO NOT

REMOVE

THE CAP

WHEN THE

ENGINE IS

HOT. EXPLOSION.

CORROSIVE

LIQUID.

MAY START

AUTOMATICALLY EVEN

WITH THE ENGINE

SWITCHED OFF. DO NOT

OPEN GAS

UNDER

HIGH

PRESSURE.

AUTOMATIC ENGINE

STARTING. REMOVE THE

IGNITION KEY WHEN THE

BONNET IS OPEN.HIGH

VOLTAGE

In the fuel filler flap

DANGER REMOVE SLOWLY.

FUEL VAPOURS MAY CAUSE INJURY.

On the rear bench seat

A

Push the backrest before folding it down.

B

PULL TO OPEN.

C

PULL LEVER 1 TO PARTIALLY TILT THE

BACKREST.

PULL LEVER 2 TO FOLD THE BACKREST

FULLY.

Page 149 of 196

147

Special features

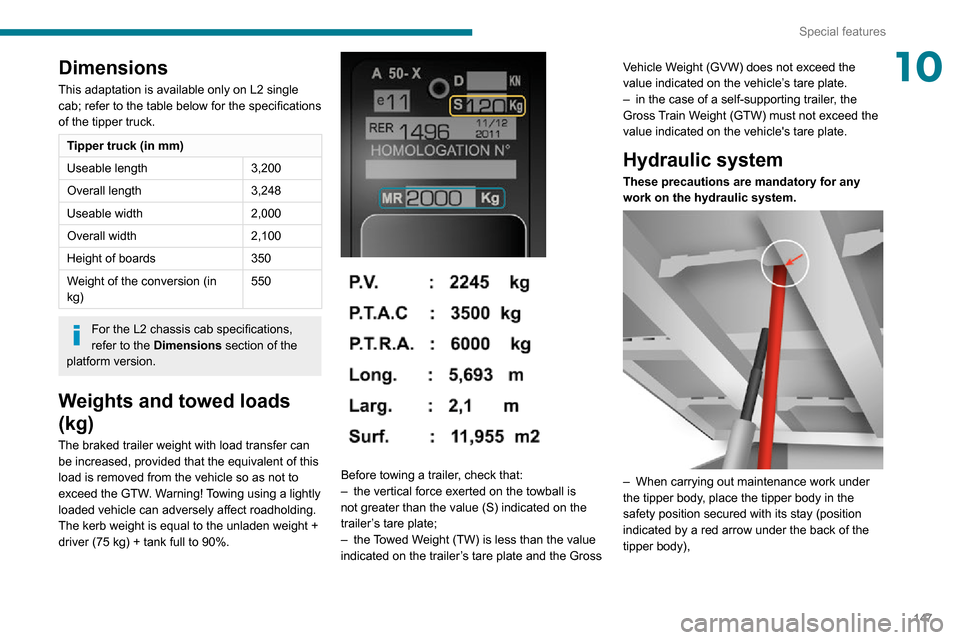

10Dimensions

This adaptation is available only on L2 single

cab; refer to the table below for the specifications

of the tipper truck.

Tipper truck (in mm)

Useable length3,200

Overall length 3,248

Useable width 2,000

Overall width 2,100

Height of boards 350

Weight of the conversion (in

kg) 550

For the L2 chassis cab specifications,

refer to the Dimensions section of the

platform version.

Weights and towed loads

(kg)

The braked trailer weight with load transfer can be increased, provided that the equivalent of this

load is removed from the vehicle so as not to

exceed the GTW. Warning! Towing using a lightly

loaded vehicle can adversely affect roadholding.

The kerb weight is equal to the unladen weight +

driver (75 kg) + tank full to 90%.

Before towing a trailer, check that:– the vertical force exerted on the towball is not greater than the value (S) indicated on the

trailer’s tare plate;

– the Towed Weight (TW) is less than the value indicated on the trailer’s tare plate and the Gross Vehicle Weight (GVW) does not exceed the

value indicated on the vehicle’s tare plate.

– in the case of a self-supporting trailer

, the Gross Train Weight (GTW) must not exceed the

value indicated on the vehicle's tare plate.

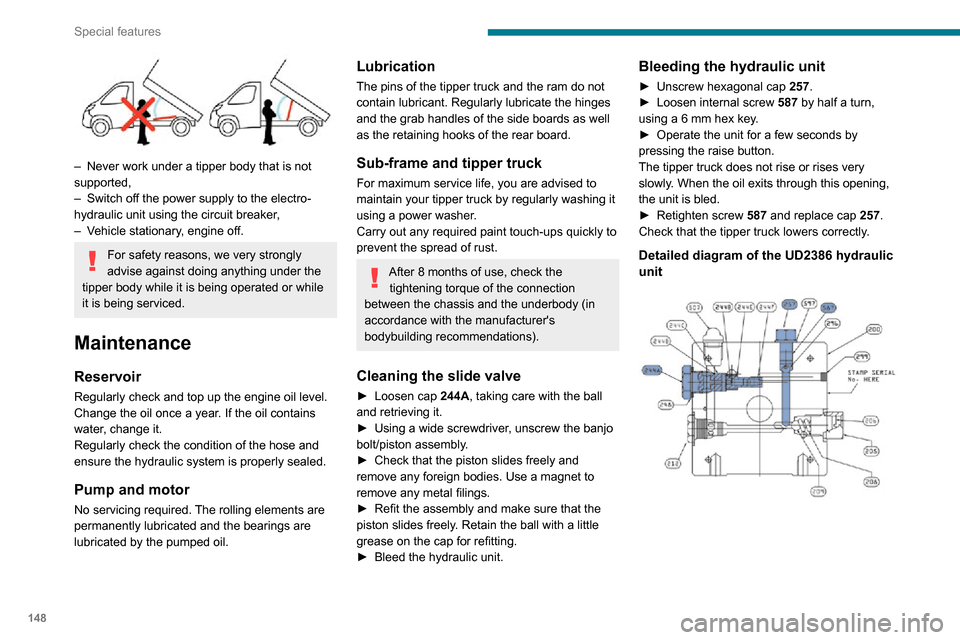

Hydraulic system

These precautions are mandatory for any

work on the hydraulic system.

– When carrying out maintenance work under the tipper body, place the tipper body in the

safety position secured with its stay (position

indicated by a red arrow under the back of the

tipper body),

Page 150 of 196

148

Special features

– Never work under a tipper body that is not supported,– Switch off the power supply to the electro-hydraulic unit using the circuit breaker,– Vehicle stationary, engine off.

For safety reasons, we very strongly

advise against doing anything under the

tipper body while it is being operated or while

it is being serviced.

Maintenance

Reservoir

Regularly check and top up the engine oil level.

Change the oil once a year. If the oil contains

water, change it.

Regularly check the condition of the hose and

ensure the hydraulic system is properly sealed.

Pump and motor

No servicing required. The rolling elements are

permanently lubricated and the bearings are

lubricated by the pumped oil.

Lubrication

The pins of the tipper truck and the ram do not

contain lubricant. Regularly lubricate the hinges

and the grab handles of the side boards as well

as the retaining hooks of the rear board.

Sub-frame and tipper truck

For maximum service life, you are advised to

maintain your tipper truck by regularly washing it

using a power washer.

Carry out any required paint touch-ups quickly to

prevent the spread of rust.

After 8 months of use, check the tightening torque of the connection

between the chassis and the underbody (in

accordance with the manufacturer's

bodybuilding recommendations).

Cleaning the slide valve

► Loosen cap 244A , taking care with the ball

and retrieving it.

► Using a wide screwdriver , unscrew the banjo

bolt/piston assembly.► Check that the piston slides freely and remove any foreign bodies. Use a magnet to

remove any metal filings.

► Refit the assembly and make sure that the piston slides freely. Retain the ball with a little

grease on the cap for refitting.

► Bleed the hydraulic unit.

Bleeding the hydraulic unit

► Unscrew hexagonal cap 257.► Loosen internal screw 587 by half a turn,

using a 6 mm hex key.

► Operate the unit for a few seconds by pressing the raise button.

The tipper truck does not rise or rises very

slowly. When the oil exits through this opening,

the unit is bled.

► Retighten screw 587 and replace cap 257.

Check that the tipper truck lowers correctly.

Detailed diagram of the UD2386 hydraulic unit

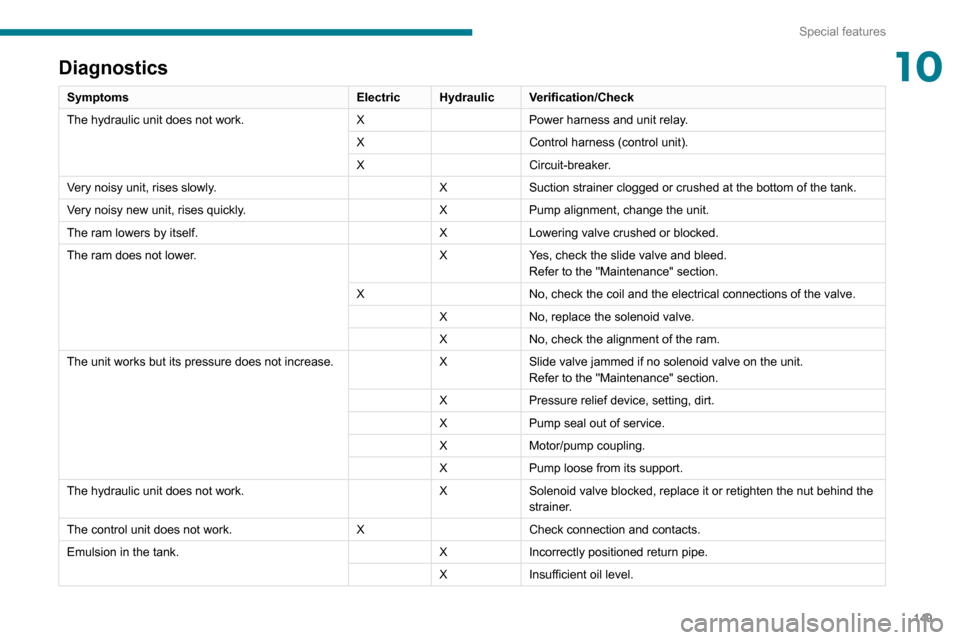

Diagnostics

Symptoms ElectricHydraulic Verification/Check

The hydraulic unit does not work. XPower harness and unit relay.

X Control harness (control unit).

X Circuit-breaker.

Very noisy unit, rises slowly. XSuction strainer clogged or crushed at the bottom of the tank.

Very noisy new unit, rises quickly. XPump alignment, change the unit.

The ram lowers by itself. XLowering valve crushed or blocked.

The ram does not lower. XYes, check the slide valve and bleed.

Refer to the "Maintenance" section.

X No, check the coil and the electrical connections of the valve.

X No, replace the solenoid valve.

X No, check the alignment of the ram.

The unit works but its pressure does not increase. XSlide valve jammed if no solenoid valve on the unit.

Refer to the "Maintenance" section.

X Pressure relief device, setting, dirt.

X Pump seal out of service.

X Motor/pump coupling.

X Pump loose from its support.

The hydraulic unit does not work. XSolenoid valve blocked, replace it or retighten the nut behind the

strainer.

The control unit does not work. XCheck connection and contacts.

Emulsion in the tank. XIncorrectly positioned return pipe.

X Insufficient oil level.

Page 151 of 196

149

Special features

10Diagnostics

SymptomsElectricHydraulic Verification/Check

The hydraulic unit does not work. XPower harness and unit relay.

X Control harness (control unit).

X Circuit-breaker.

Very noisy unit, rises slowly. XSuction strainer clogged or crushed at the bottom of the tank.

Very noisy new unit, rises quickly. XPump alignment, change the unit.

The ram lowers by itself. XLowering valve crushed or blocked.

The ram does not lower. XYes, check the slide valve and bleed.

Refer to the "Maintenance" section.

X No, check the coil and the electrical connections of the valve.

X No, replace the solenoid valve.

X No, check the alignment of the ram.

The unit works but its pressure does not increase. XSlide valve jammed if no solenoid valve on the unit.

Refer to the "Maintenance" section.

X Pressure relief device, setting, dirt.

X Pump seal out of service.

X Motor/pump coupling.

X Pump loose from its support.

The hydraulic unit does not work. XSolenoid valve blocked, replace it or retighten the nut behind the

strainer.

The control unit does not work. XCheck connection and contacts.

Emulsion in the tank. XIncorrectly positioned return pipe.

X Insufficient oil level.

Page 180 of 196

178

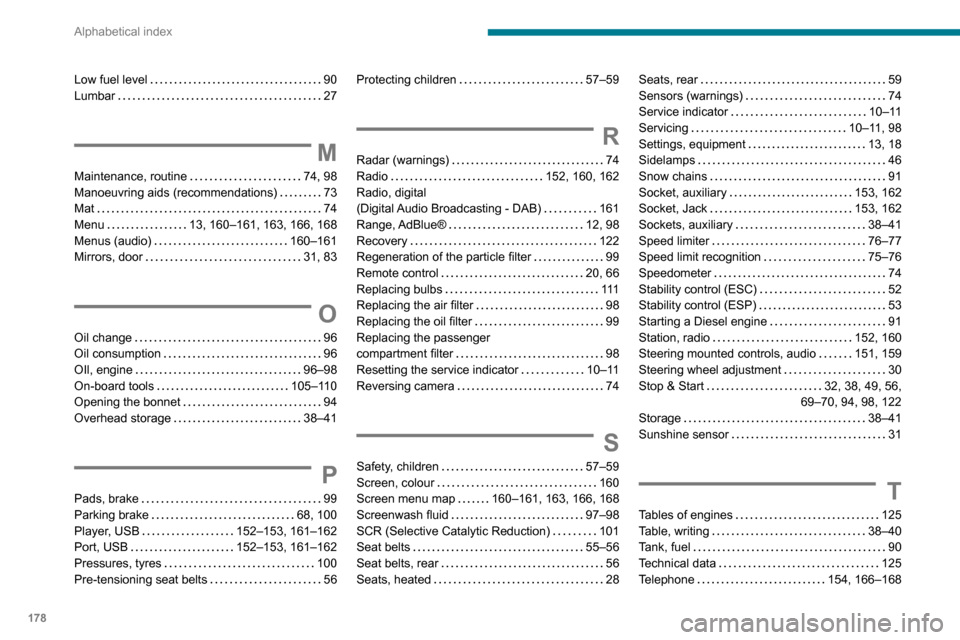

Alphabetical index

Low fuel level 90Lumbar 27

M

Maintenance, routine 74, 98Manoeuvring aids (recommendations) 73Mat 74

Menu 13, 160–161, 163, 166, 168Menus (audio) 160–161Mirrors, door 31, 83

O

Oil change 96Oil consumption 96OIl, engine 96–98On-board tools 105–110Opening the bonnet 94Overhead storage 38–41

P

Pads, brake 99Parking brake 68, 100Player, USB 152–153, 161–162Port, USB 152–153, 161–162Pressures, tyres 100Pre-tensioning seat belts 56

Protecting children 57–59

R

Radar (warnings) 74Radio 152, 160, 162Radio, digital (Digital Audio Broadcasting - DAB) 161

Range, AdBlue® 12, 98Recovery 122Regeneration of the particle filter 99Remote control 20, 66Replacing bulbs 111Replacing the air filter 98Replacing the oil filter 99Replacing the passenger compartment filter 98Resetting the service indicator 10–11Reversing camera 74

S

Safety, children 57–59Screen, colour 160Screen menu map 160–161, 163, 166, 168Screenwash fluid 97–98SCR (Selective Catalytic Reduction) 101Seat belts 55–56Seat belts, rear 56Seats, heated 28

Seats, rear 59Sensors (warnings) 74Service indicator 10–11Servicing 10–11, 98Settings, equipment 13, 18Sidelamps 46Snow chains 91Socket, auxiliary 153, 162Socket, Jack 153, 162

Sockets, auxiliary 38–41Speed limiter 76–77Speed limit recognition 75–76Speedometer 74Stability control (ESC) 52Stability control (ESP) 53Starting a Diesel engine 91Station, radio 152, 160Steering mounted controls, audio 151, 159Steering wheel adjustment 30Stop & Start 32, 38, 49, 56,

69–70, 94, 98, 122

Storage 38–41Sunshine sensor 31

T

Tables of engines 125Table, writing 38–40Tank, fuel 90Technical data 125Telephone 154, 166–168