warning light Peugeot Boxer 2020 Owner's Guide

[x] Cancel search | Manufacturer: PEUGEOT, Model Year: 2020, Model line: Boxer, Model: Peugeot Boxer 2020Pages: 196, PDF Size: 5.1 MB

Page 89 of 196

87

Driving

6Audible rear parking sensors

Refer to the General recommendations on the

use of driving and manoeuvring aids .

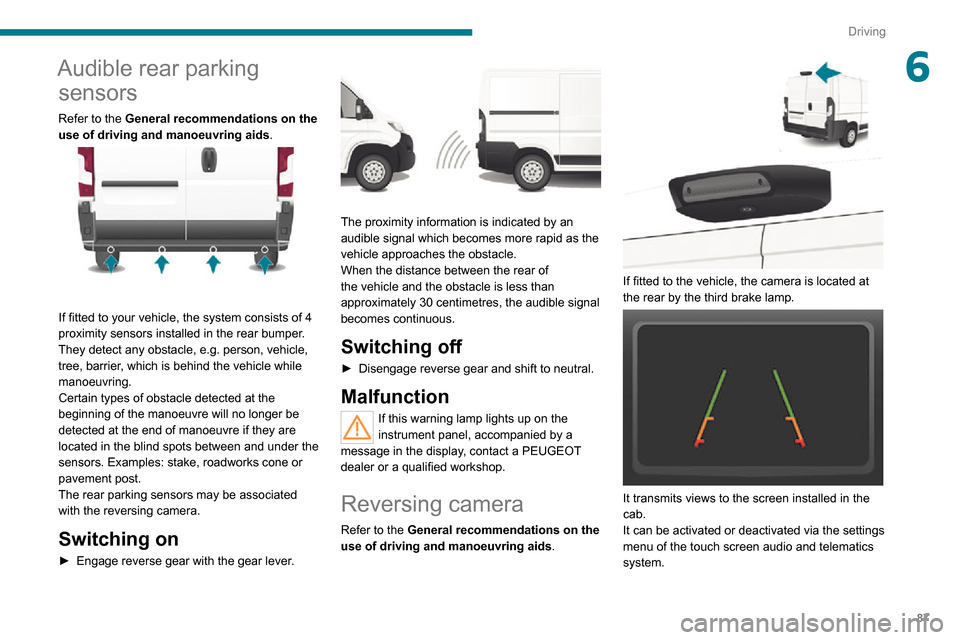

If fitted to your vehicle, the system consists of 4

proximity sensors installed in the rear bumper.

They detect any obstacle, e.g. person, vehicle,

tree, barrier, which is behind the vehicle while

manoeuvring.

Certain types of obstacle detected at the

beginning of the manoeuvre will no longer be

detected at the end of manoeuvre if they are

located in the blind spots between and under the

sensors. Examples: stake, roadworks cone or

pavement post.

The rear parking sensors may be associated

with the reversing camera.

Switching on

► Engage reverse gear with the gear lever .

The proximity information is indicated by an

audible signal which becomes more rapid as the

vehicle approaches the obstacle.

When the distance between the rear of

the vehicle and the obstacle is less than

approximately 30 centimetres, the audible signal

becomes continuous.

Switching off

► Disengage reverse gear and shift to neutral.

Malfunction

If this warning lamp lights up on the

instrument panel, accompanied by a

message in the display, contact a PEUGEOT

dealer or a qualified workshop.

Reversing camera

Refer to the General recommendations on the

use of driving and manoeuvring aids .

If fitted to the vehicle, the camera is located at

the rear by the third brake lamp.

It transmits views to the screen installed in the

cab.

It can be activated or deactivated via the settings

menu of the touch screen audio and telematics

system.

Page 107 of 196

105

In the event of a breakdown

8► Disconnect hose I and directly connect it

to the tyre valve; the cartridge will thereby be

connected to the compressor and the sealant will

not be injected.

If the tyre needs to be deflated, connect hose

I to the tyre valve and press the yellow button

located in the centre of the compressor switch.

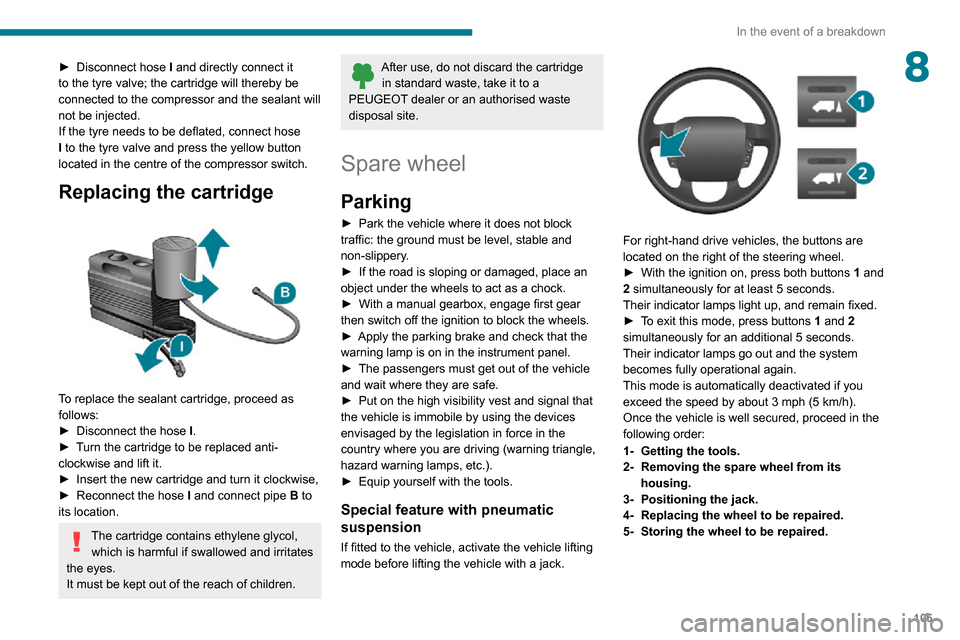

Replacing the cartridge

To replace the sealant cartridge, proceed as

follows:

► Disconnect the hose I.► Turn the cartridge to be replaced anti-clockwise and lift it.► Insert the new cartridge and turn it clockwise,► Reconnect the hose I and connect pipe B to

its location.

The cartridge contains ethylene glycol, which is harmful if swallowed and irritates

the eyes.

It must be kept out of the reach of children.

After use, do not discard the cartridge in standard waste, take it to a

PEUGEOT dealer or an authorised waste

disposal site.

Spare wheel

Parking

► Park the vehicle where it does not block traffic: the ground must be level, stable and

non-slippery.

► If the road is sloping or damaged, place an object under the wheels to act as a chock.► With a manual gearbox, engage first gear then switch off the ignition to block the wheels.► Apply the parking brake and check that the warning lamp is on in the instrument panel.► The passengers must get out of the vehicle and wait where they are safe.► Put on the high visibility vest and signal that the vehicle is immobile by using the devices

envisaged by the legislation in force in the

country where you are driving (warning triangle,

hazard warning lamps, etc.).

► Equip yourself with the tools.

Special feature with pneumatic

suspension

If fitted to the vehicle, activate the vehicle lifting

mode before lifting the vehicle with a jack.

For right-hand drive vehicles, the buttons are

located on the right of the steering wheel.

► With the ignition on, press both buttons 1 and

2 simultaneously for at least 5 seconds.

Their indicator lamps light up, and remain fixed.

► To exit this mode, press buttons 1 and 2

simultaneously for an additional 5 seconds.

Their indicator lamps go out and the system

becomes fully operational again.

This mode is automatically deactivated if you

exceed the speed by about 3 mph (5 km/h).

Once the vehicle is well secured, proceed in the

following order:

1- Getting the tools.

2- Removing the spare wheel from its

housing.

3- Positioning the jack.

4- Replacing the wheel to be repaired.

5- Storing the wheel to be repaired.

Page 119 of 196

11 7

In the event of a breakdown

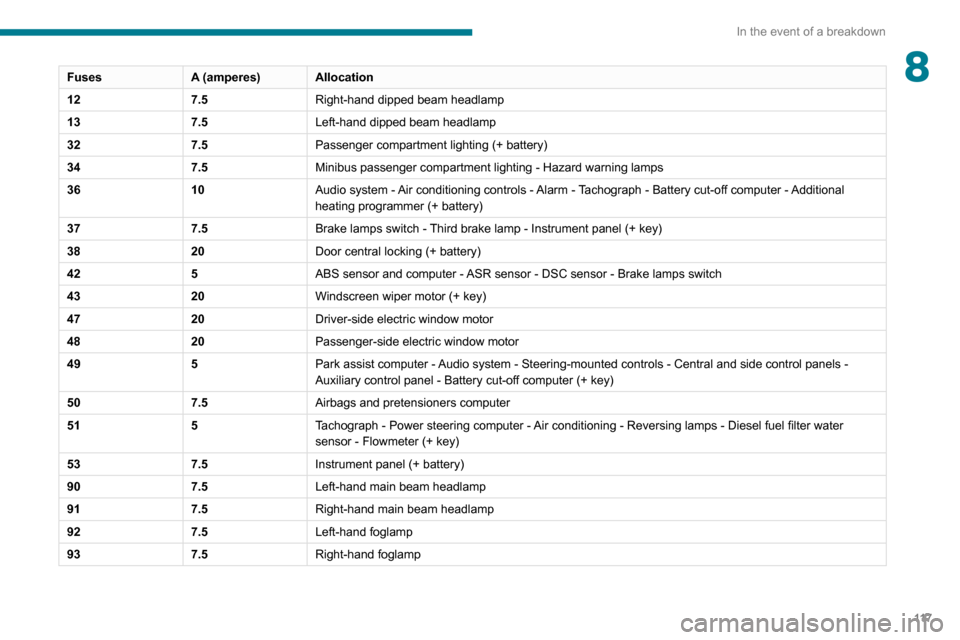

8FusesA (amperes)Allocation

12 7.5Right-hand dipped beam headlamp

13 7.5Left-hand dipped beam headlamp

32 7.5Passenger compartment lighting (+ battery)

34 7.5Minibus passenger compartment lighting - Hazard warning lamps

36 10Audio system - Air conditioning controls - Alarm - Tachograph - Battery cut-off computer - Additional

heating programmer (+ battery)

37 7.5Brake lamps switch - Third brake lamp - Instrument panel (+ key)

38 20Door central locking (+ battery)

42 5ABS sensor and computer - ASR sensor - DSC sensor - Brake lamps switch

43 20Windscreen wiper motor (+ key)

47 20Driver-side electric window motor

48 20Passenger-side electric window motor

49 5Park assist computer - Audio system - Steering-mounted controls - Central and side control pane\

ls -

Auxiliary control panel - Battery cut-off computer (+ key)

50 7.5Airbags and pretensioners computer

51 5Tachograph - Power steering computer - Air conditioning - Reversing lamps - Diesel fuel filter water

sensor - Flowmeter (+ key)

53 7.5Instrument panel (+ battery)

90 7.5Left-hand main beam headlamp

91 7.5Right-hand main beam headlamp

92 7.5Left-hand foglamp

93 7.5Right-hand foglamp

Page 148 of 196

146

Special features

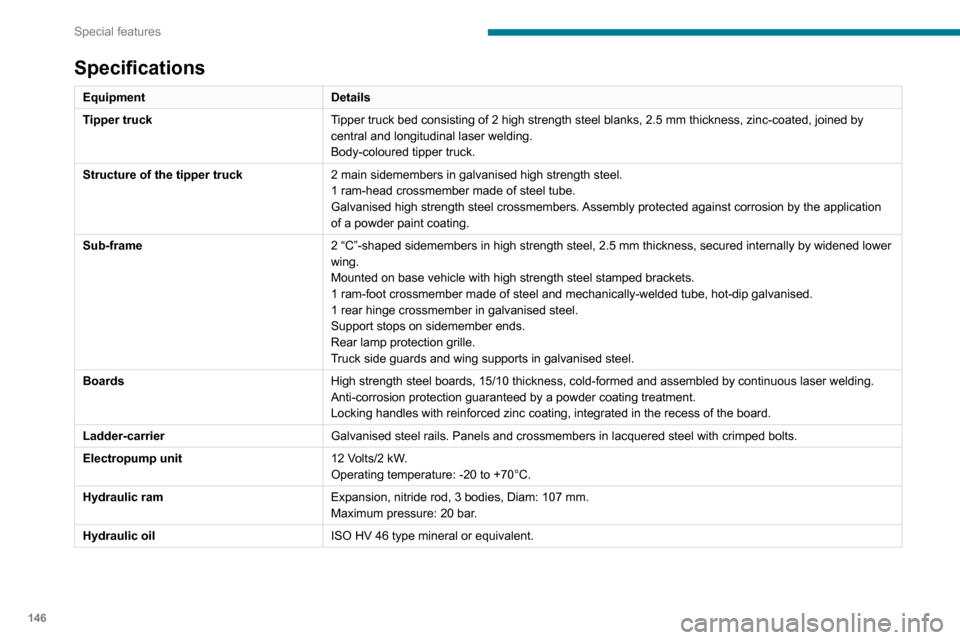

Specifications

EquipmentDetails

Tipper truck Tipper truck bed consisting of 2 high strength steel blanks, 2.5 mm thickness, zinc-coated, joined by

central and longitudinal laser welding.

Body-coloured tipper truck.

Structure of the tipper truck 2 main sidemembers in galvanised high strength steel.

1 ram-head crossmember made of steel tube.

Galvanised high strength steel crossmembers. Assembly protected against corrosion by the application

of a powder paint coating.

Sub-frame 2 “C”-shaped sidemembers in high strength steel, 2.5 mm thickness, secured internally by widened lower

wing.

Mounted on base vehicle with high strength steel stamped brackets.

1 ram-foot crossmember made of steel and mechanically-welded tube, hot-dip galvanised.

1 rear hinge crossmember in galvanised steel.

Support stops on sidemember ends.

Rear lamp protection grille.

Truck side guards and wing supports in galvanised steel.

Boards High strength steel boards, 15/10 thickness, cold-formed and assembled by continuous laser welding.

Anti-corrosion protection guaranteed by a powder coating treatment.

Locking handles with reinforced zinc coating, integrated in the recess of the board.

Ladder-carrier Galvanised steel rails. Panels and crossmembers in lacquered steel with crimped bolts.

Electropump unit 12 Volts/2 kW.

Operating temperature: -20 to +70°C.

Hydraulic ram Expansion, nitride rod, 3 bodies, Diam: 107 mm.

Maximum pressure: 20 bar.

Hydraulic oil ISO HV 46 type mineral or equivalent.

Dimensions

This adaptation is available only on L2 single

cab; refer to the table below for the specifications

of the tipper truck.

Tipper truck (in mm)

Useable length 3,200

Overall length 3,248

Useable width 2,000

Overall width 2,100

Height of boards 350

Weight of the conversion (in

kg) 550

For the L2 chassis cab specifications,

refer to the Dimensions section of the

platform version.

Weights and towed loads

(kg)

The braked trailer weight with load transfer can be increased, provided that the equivalent of this

load is removed from the vehicle so as not to

exceed the GTW. Warning! Towing using a lightly

loaded vehicle can adversely affect roadholding.

The kerb weight is equal to the unladen weight +

driver (75 kg) + tank full to 90%.

Page 149 of 196

147

Special features

10Dimensions

This adaptation is available only on L2 single

cab; refer to the table below for the specifications

of the tipper truck.

Tipper truck (in mm)

Useable length3,200

Overall length 3,248

Useable width 2,000

Overall width 2,100

Height of boards 350

Weight of the conversion (in

kg) 550

For the L2 chassis cab specifications,

refer to the Dimensions section of the

platform version.

Weights and towed loads

(kg)

The braked trailer weight with load transfer can be increased, provided that the equivalent of this

load is removed from the vehicle so as not to

exceed the GTW. Warning! Towing using a lightly

loaded vehicle can adversely affect roadholding.

The kerb weight is equal to the unladen weight +

driver (75 kg) + tank full to 90%.

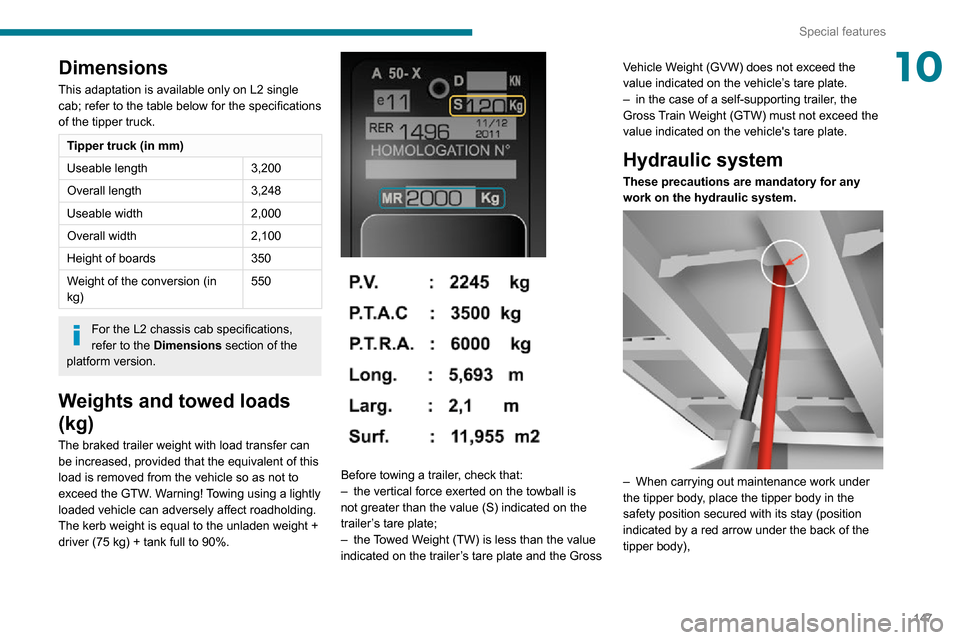

Before towing a trailer, check that:– the vertical force exerted on the towball is not greater than the value (S) indicated on the

trailer’s tare plate;

– the Towed Weight (TW) is less than the value indicated on the trailer’s tare plate and the Gross Vehicle Weight (GVW) does not exceed the

value indicated on the vehicle’s tare plate.

– in the case of a self-supporting trailer

, the Gross Train Weight (GTW) must not exceed the

value indicated on the vehicle's tare plate.

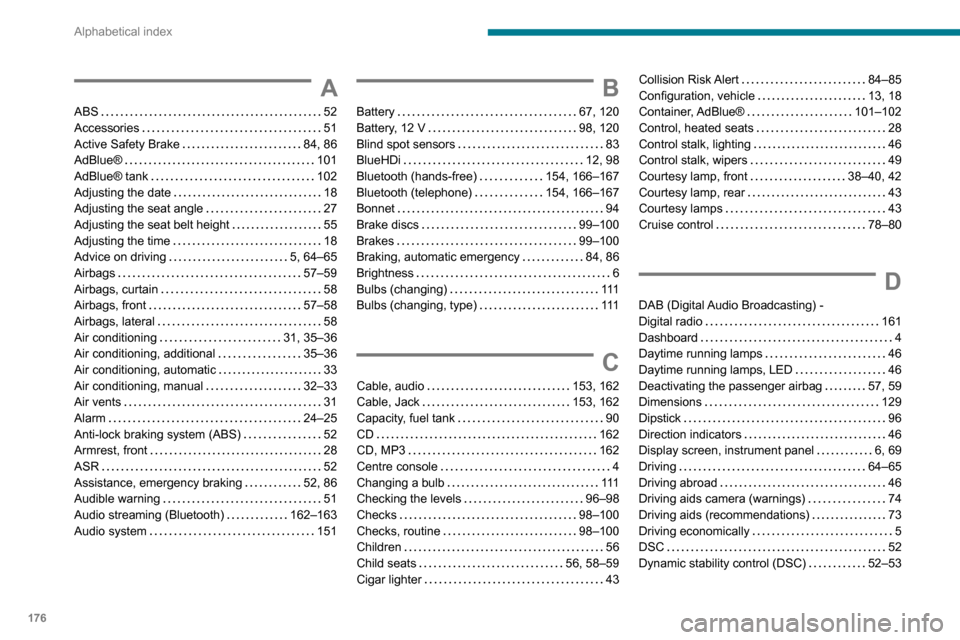

Hydraulic system

These precautions are mandatory for any

work on the hydraulic system.

– When carrying out maintenance work under the tipper body, place the tipper body in the

safety position secured with its stay (position

indicated by a red arrow under the back of the

tipper body),

Page 178 of 196

176

Alphabetical index

A

ABS 52Accessories 51Active Safety Brake 84, 86AdBlue® 101AdBlue® tank 102Adjusting the date 18Adjusting the seat angle 27

Adjusting the seat belt height 55Adjusting the time 18Advice on driving 5, 64–65Airbags 57–59Airbags, curtain 58Airbags, front 57–58Airbags, lateral 58Air conditioning 31, 35–36Air conditioning, additional 35–36Air conditioning, automatic 33Air conditioning, manual 32–33Air vents 31Alarm 24–25Anti-lock braking system (ABS) 52Armrest, front 28ASR 52Assistance, emergency braking 52, 86Audible warning 51Audio streaming (Bluetooth) 162–163Audio system 151

B

Battery 67, 120Battery, 12 V 98, 120Blind spot sensors 83BlueHDi 12, 98Bluetooth (hands-free) 154, 166–167Bluetooth (telephone) 154, 166–167Bonnet 94

Brake discs 99–100Brakes 99–100Braking, automatic emergency 84, 86Brightness 6Bulbs (changing) 111Bulbs (changing, type) 111

C

Cable, audio 153, 162Cable, Jack 153, 162Capacity, fuel tank 90CD 162CD, MP3 162Centre console 4Changing a bulb 111Checking the levels 96–98Checks 98–100Checks, routine 98–100Children 56Child seats 56, 58–59Cigar lighter 43

Collision Risk Alert 84–85Configuration, vehicle 13, 18Container, AdBlue® 101–102Control, heated seats 28Control stalk, lighting 46Control stalk, wipers 49Courtesy lamp, front 38–40, 42Courtesy lamp, rear 43Courtesy lamps 43

Cruise control 78–80

D

DAB (Digital Audio Broadcasting) - Digital radio 161Dashboard 4Daytime running lamps 46Daytime running lamps, LED 46Deactivating the passenger airbag 57, 59Dimensions 129Dipstick 96Direction indicators 46Display screen, instrument panel 6, 69Driving 64–65Driving abroad 46Driving aids camera (warnings) 74Driving aids (recommendations) 73Driving economically 5DSC 52Dynamic stability control (DSC) 52–53

Page 179 of 196

177

Alphabetical index

E

EBA 52EBFD 52Eco-driving (advice) 5Electric windows 25Electronic brake force distribution (EBFD) 52Emergency warning lamps 51Emissions control system, SCR 101

Engine compartment 95Engine, Diesel 91, 95, 125Engines 124–125Environment 5ESP/ASR 53

F

Filling the AdBlue® tank 98, 101–102Filling the fuel tank 90Filter, air 98Filter, Diesel fuel 96, 100Filter, oil 99Filter, particle 99Filter, passenger compartment 31, 98Fittings, front 38–42Fittings, interior 38–42Flap, fuel filler 90Flashing indicators 46Fluid, brake 97–98Fluid, engine coolant 97–98Fluid, power steering 97–98

Foglamps, front 46Foglamps, rear 46Front doors 23Fuel 5, 91Fuel consumption 5Fuel tank 90

G

Gauge, fuel 90Gearbox, manual 69–70, 99Glove box 38–41

H

Hazard warning lamps 51Headlamp flash 46Headlamps, dipped beam 46Headlamps, main beam 46Head restraints, front 27Heating 31–33Heating, additional 35–36Hill Descent Control 54–55Hill start assist 70Horn 51

I

Immobiliser, electronic 66

Indicator, coolant temperature 11Indicator, engine oil level 10–11Indicators, direction 46Inflating tyres 100Information, vehicle 168Infrared camera 74Instrument panel 74Instruments and controls 4Intelligent Traction Control 53–54

J

Jack 153, 162

K

Kit, hands-free 154, 166–167

L

Lane Departure Warning System (LDWS) 81Level, AdBlue® 98Level, brake fluid 97Level, engine coolant 11, 97Level, engine oil 96Level, power steering fluid 97Levels 97–98Levels and checks 96–97Lighting dimmer 6