Pump Peugeot Expert 2003 Owner's Manual

[x] Cancel search | Manufacturer: PEUGEOT, Model Year: 2003, Model line: Expert, Model: Peugeot Expert 2003Pages: 128, PDF Size: 5.15 MB

Page 44 of 128

22-04-2003

CHECKS*59IV-2

Beware:When working under the bonnet, the cooling fan could operate if

the engine is hot (even when switched off). The engine oil level should be checked frequently between services (as recommended by the manufacturer), as well as before long journeys.

Priming pump Refer to the section

Ç Diesel

injection equipment È.

CoolantThe level should be bet- ween the maximum andminimum marks on the

reservoir. If the engine is hot, wait 15 minutes.Oil quality: see Ç Lubricants and

fluids È.

Never work on the cooling sys- tem if the engine is hot. (see

Ç Levels È).

Windscreen, rear screenand headlamp washerfluid It is recommended to use

manufacturer approved products.

12 volt batterySee Ç Emergency starting

with a slave battery È. Engine oilCheck with the vehicle on level ground, and the

engine off for at least

10 minutes. Level: see Ç Levels È.

Oil quality: see Ç Lubricants and

fluids È.

Take out the oil dipstick.The level must be bet- ween the MAX and MINmarks on the dipstick.

It must not exceed

the maximum mark. Brake fluid The level should be bet- ween the maximum andminimum marks on the

reservoir. Level: see Ç Levels È.

Oil quality: see Ç Lubricants and

fluids È.

If the warning lamp comes on: stop the vehicle

Power steering oilCheck the level with the

engine switched off. Level: see Ç Levels È.

Oil quality: see Ç Lubricants and

fluids È.

A

Air filter Follow the recommendations in the maintenance guide.

B

Max Min

* According to model or country

Page 47 of 128

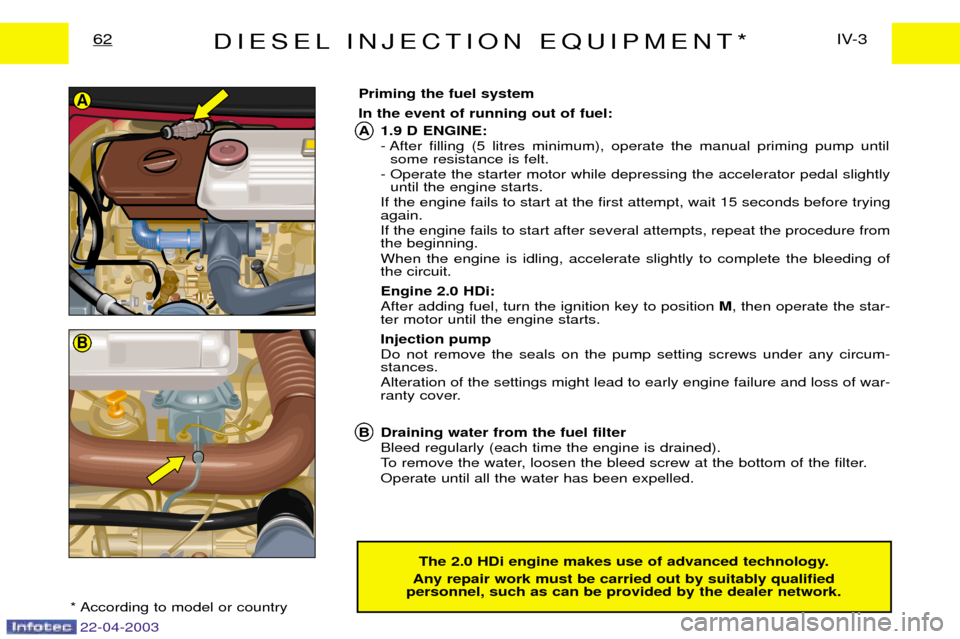

DIESEL INJECTION EQUIPMENT*IV-3

62

The 2.0 HDi engine makes use of advanced technology.

Any repair work must be carried out by suitably qualified

personnel, such as can be provided by the dealer network.

Priming the fuel system In the event of running out of fuel:

A 1.9 D ENGINE: - After filling (5 litres minimum), operate the manual priming pump untilsome resistance is felt.

- Operate the starter motor while depressing the accelerator pedal slightly until the engine starts.

If the engine fails to start at the first attempt, wait 15 seconds before trying again. If the engine fails to start after several attempts, repeat the procedure from the beginning. When the engine is idling, accelerate slightly to complete the bleeding of the circuit. Engine 2.0 HDi: After adding fuel, turn the ignition key to position M, then operate the star-

ter motor until the engine starts. Injection pump Do not remove the seals on the pump setting screws under any circum- stances. Alteration of the settings might lead to early engine failure and loss of war-

ranty cover.

B Draining water from the fuel filter Bleed regularly (each time the engine is drained).

To remove the water, loosen the bleed screw at the bottom of the filter.Operate until all the water has been expelled.

22-04-2003

* According to model or country

A

B

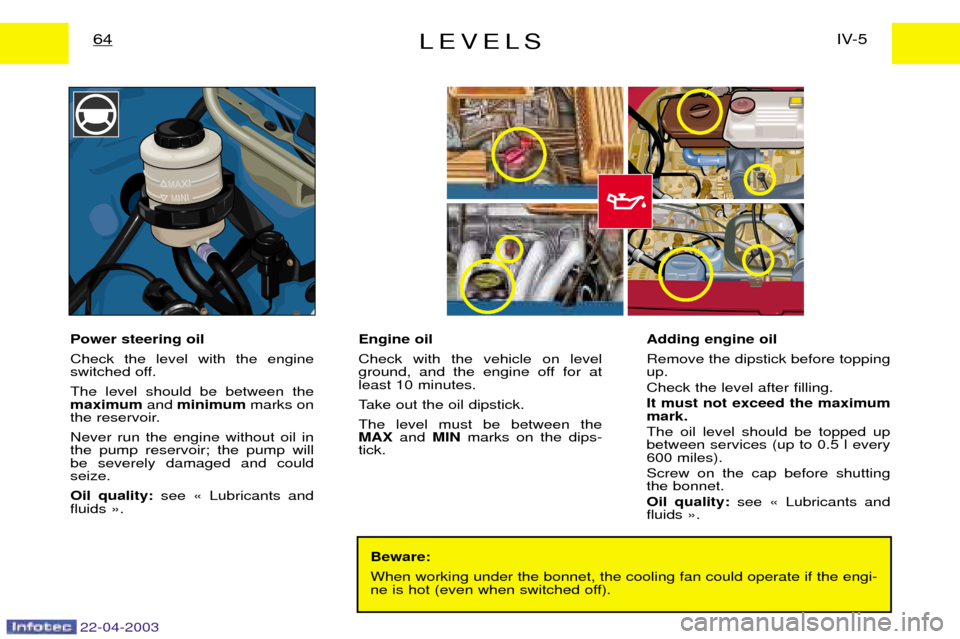

Page 49 of 128

LEVELSIV-5

64

Beware: When working under the bonnet, the cooling fan could operate if the engi-

ne is hot (even when switched off).

Power steering oil Check the level with the engine

switched off. The level should be between the maximum

and minimum marks on

the reservoir. Never run the engine without oil in the pump reservoir; the pump willbe severely damaged and couldseize. Oil quality: see Ç Lubricants and

fluids È.

22-04-2003

Engine oil Check with the vehicle on level

ground, and the engine off for atleast 10 minutes.

Take out the oil dipstick.The level must be between the MAX and MIN marks on the dips-

tick. Adding engine oil Remove the dipstick before topping up. Check the level after filling.It must not exceed the maximum mark. The oil level should be topped up between services (up to 0.5 l every600 miles). Screw on the cap before shutting the bonnet. Oil quality:

see Ç Lubricants and

fluids È.

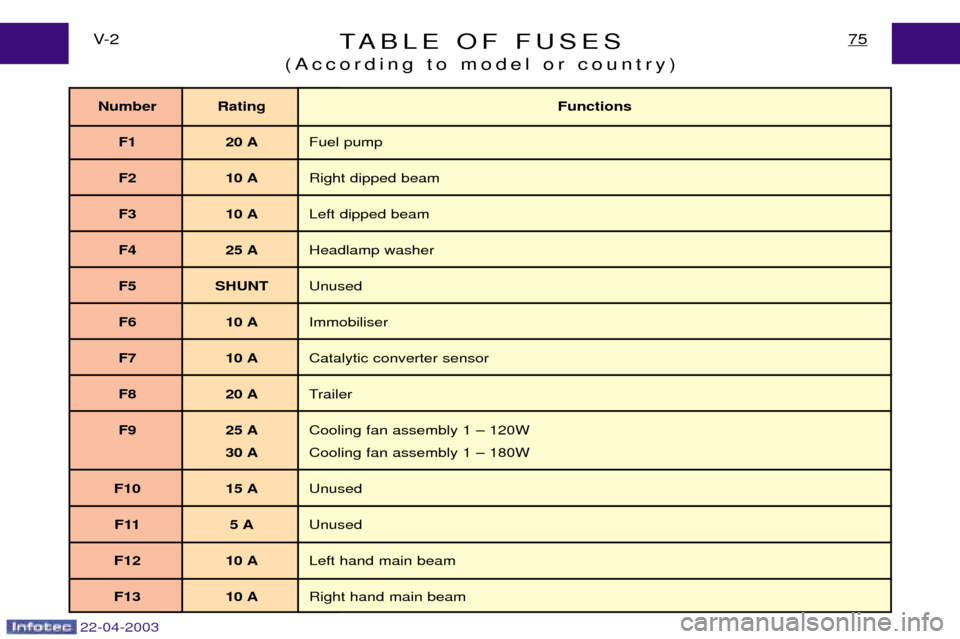

Page 95 of 128

22-04-2003

TABLE OF FUSES

(According to model or country)75V- 2

Number Rating Functions

F1 20 A Fuel pump

F2 10 A Right dipped beam

F3 10 A Left dipped beam

F4 25 A Headlamp washer

F5 SHUNT Unused

F6 10 A Immobiliser

F7 10 A Catalytic converter sensor

F8 20 A Trailer

F9 25 A Cooling fan assembly 1 Ð 120W

30 A Cooling fan assembly 1 Ð 180W

F10 15 A Unused

F11 5 A Unused

F12 10 A Left hand main beam

F13 10 A Right hand main beam

Page 97 of 128

22-04-2003

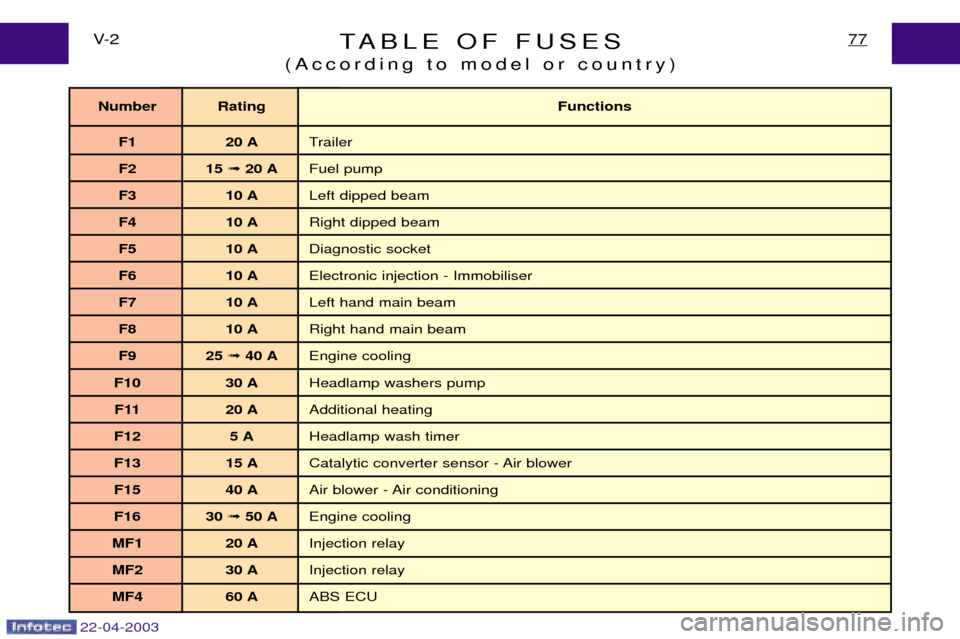

TABLE OF FUSES

(According to model or country)77V- 2

Number Rating Functions

F1 20 A Trailer

F2 15 ➟ 20 A Fuel pump

F3 10 A Left dipped beam

F4 10 A Right dipped beam

F5 10 A Diagnostic socket

F6 10 A Electronic injection - Immobiliser

F7 10 A Left hand main beam

F8 10 A Right hand main beam

F9 25 ➟ 40 A Engine cooling

F10 30 A Headlamp washers pump

F11 20 A Additional heating

F12 5 A Headlamp wash timer

F13 15 A Catalytic converter sensor - Air blower

F15 40 A Air blower - Air conditioning

F16 30 ➟ 50 A Engine cooling

MF1 20 A Injection relay

MF2 30 A Injection relay

MF4 60 A ABS ECU