jacking Peugeot Partner 2020 Owner's Manual

[x] Cancel search | Manufacturer: PEUGEOT, Model Year: 2020, Model line: Partner, Model: Peugeot Partner 2020Pages: 260, PDF Size: 7.76 MB

Page 155 of 260

153

In the event of a breakdown

8With a tyre repaired using this type of kit,

do not exceed a speed of 50 mph

(80

km/h) and do not drive more than

125

miles (200 km).

Contact a PEUGEOT dealer or a qualified

workshop to have the tyre changed.

Checking / adjusting tyre

pressures

The compressor can be used, without injecting

sealant, to check and, if necessary, adjust the

tyre pressures.

►

Remove the valve cap from the tyre and keep

it in a clean place.

►

Uncoil

the pipe stowed under the compressor.

►

Screw the pipe onto the valve and tighten

firmly

.

►

Check that the compressor switch is in

position " O

".

►

Fully uncoil the electric cable stowed under

the compressor

.

►

Connect the compressor's electric plug to the

vehicle's 12

V socket.

►

Switch on the ignition.

Only the 12 V socket located at the front

of the vehicle can be used to power the

compressor .

The tyre inflation pressures are given on

this label.

► Start the compressor by placing the switch at

position " I

" and adjust the pressure to the value

shown on the vehicle's tyre pressure label. To

deflate: press the black button located on the

compressor pipe, near the valve connection.

If after 7 minutes the pressure of 2 bars

is not reached, this indicates that the tyre

is damaged; contact a PEUGEOT

dealer or a

qualified workshop for assistance.

►

Once the correct pressure is reached, put the

switch in position " O

".

►

Remove the kit and stow it.

Should the pressure of one or more tyres

be adjusted, it is necessary to reinitialise

the under-inflation detection system.

For more information on Tyre under-inflation

detection, refer to the corresponding section.

Spare wheel

Scan the QR code on page 3 to view

explanatory videos.

Procedure for changing a damaged wheel with

the spare wheel using the tools provided with the

vehicle.

For more information on the Tool kit,

refer to the corresponding section.

►

Park the vehicle, taking care to avoid

obstructing traffic, and apply the parking brake.

►

Follow the safety instructions (hazard

warning lamps, warning triangle, wearing high

visibility vest, etc.) according to the legislation in

force in the country where you are driving.

►

Switch off the ignition.

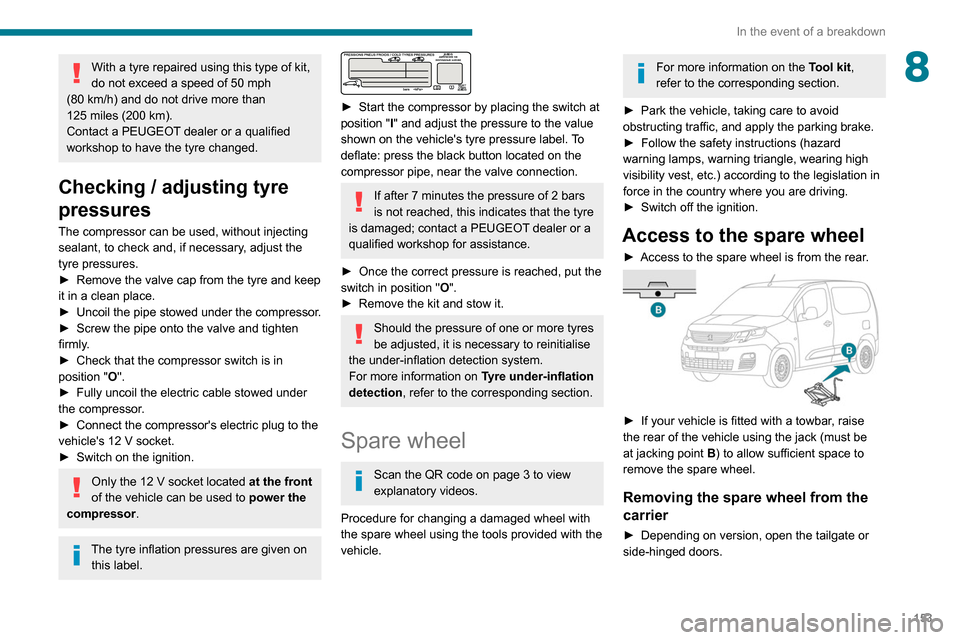

Access to the spare wheel

► Access to the spare wheel is from the rear .

► If your vehicle is fitted with a towbar, raise

the rear of the vehicle using the jack (must be

at jacking point B) to allow sufficient space to

remove the spare wheel.

Removing the spare wheel from the

carrier

► Depending on version, open the tailgate or

side-hinged doors.

Page 157 of 260

155

In the event of a breakdown

8► With a steel wheel, remove the wheel trim

using tool 7

.

►

With an alloy wheel, remove the cap from

each of the bolts using tool 7

.

►

If the vehicle is so equipped, fit security bolt

socket

8 to wheelbrace 5 to slacken the security

bolt.

►

Slacken

(without removing) the other wheel

bolts using just wheelbrace 5.

Wheel with wheel trim

When removing the wheel, first remove

the wheel trim by pulling at the valve aperture

using the wheelbrace.

► Place the foot of the jack on the ground and

ensure that it is directly below the A

or B jacking

point provided on the underbody, whichever is

closest to the wheel to be changed.

► Extend jack 6 until its head comes into

contact with jacking point A or B, whichever is

used; the contact surface A or B of the vehicle

must be correctly engaged with the central part

of the head of the jack.

►

Raise the vehicle until there is sufficient

space between the wheel and the ground to

admit the spare (not punctured) wheel easily

.

Risk of injury!

Ensure that the jack is stable. If the

ground is slippery or loose, the jack may slip

or collapse.

Ensure that the jack is positioned strictly at

one of the jacking points A or B under the

vehicle, making sure that the vehicle's contact

surface is correctly centred on the head of the

jack. Otherwise, there is a risk of damage to

the vehicle and/or of the jack collapsing.

► Remove the bolts and store them in a clean

place.

►

Remove the wheel.