PONTIAC BONNEVILLE 2003 Owners Manual

BONNEVILLE 2003

PONTIAC

PONTIAC

https://www.carmanualsonline.info/img/50/40803/w960_40803-0.png

PONTIAC BONNEVILLE 2003 Owners Manual

Trending: garage door opener, air filter, service interval, trip computer, trailer, height adjustment, lane assist

Page 311 of 418

Headlamp Aiming

Your vehicle has a visual optical headlamp aiming

system equipped with horizontal aim indicators. The aim

has been preset at the factory and should need no

further adjustment. This is true even though your

horizontal aim indicators may not fall exactly on

the

“0” (zero) marks on their scales.

If your vehicle is damaged in an accident, the headlamp

aim may be affected. Aim adjustment to the

low beam

may be necessary

if it is difficult to see lane markers

(for horizontal aim), or

if oncoming drivers flash

their high beams at you (for vertical aim).

If you believe

your headlamps need to be re-aimed, we recommend

that you take your vehicle to your dealer for service.

However, it is possible for you to re-aim your headlamps

as described in the following procedure.

Notice: To make sure your headlamps are aimed

properly, read all the instructions before beginning.

Failure

to follow these instructions could cause

damage to headlamp parts.

The vehicle should be properly prepared as follows:

The vehicle should be placed so the headlamps are

25 ft. (7.6 m) from a light colored wall or other flat

surface.

The vehicle must have all four tires on a perfectly

level surface which is level all the way to the wall

or other flat surface.

The vehicle should be placed so it is perpendicular

to the wall or other flat surface.

5-52

Page 312 of 418

0 The vehicle should not have any snow, ice or mud

attached to it.

* The vehicle should be fully assembled and all other

work stopped while headlamp aiming is being done.

0 The vehicle should be normally loaded with a

full tank of fuel and one person or

160 Ibs. (75 kg)

on the driver’s seat.

Tires should be properly inflated.

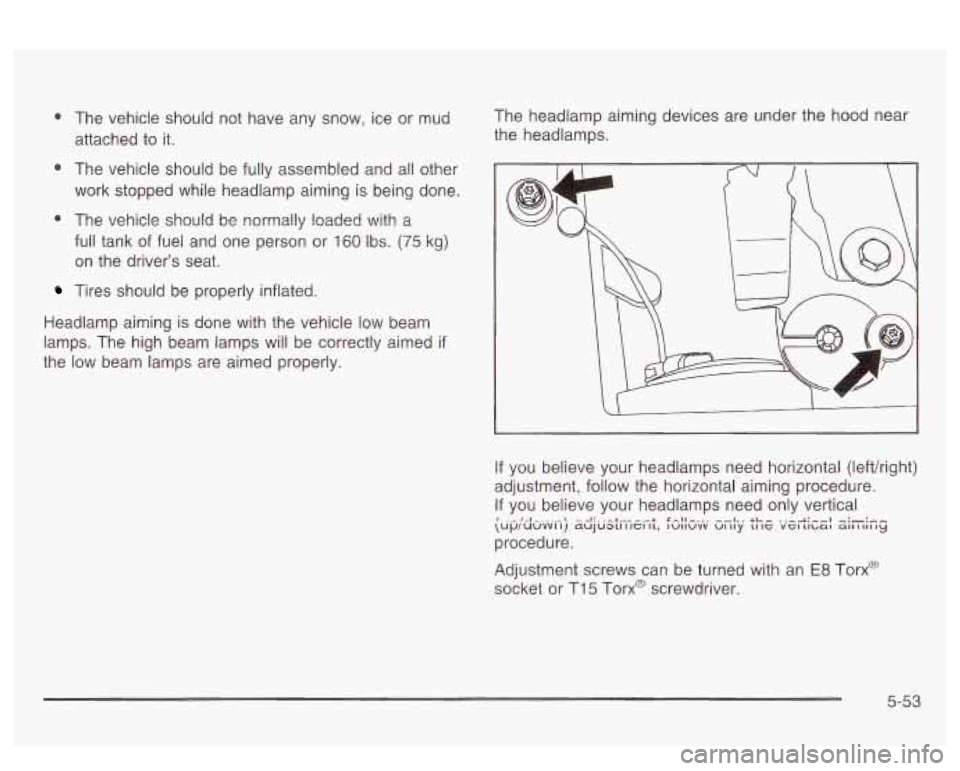

Headlamp aiming is done with the vehicle low beam

lamps. The high beam lamps will be correctly aimed

if

the low beam lamps are aimed properly. The

headlamp aiming devices are under the hood near

the headlamps.

If you believe your headlamps need horizontal (lefthight)

adjustment, follow the horizontal aiming procedure.

If you believe your headlamps need only vertical

procedure.

\Up/UUvvl I) ~UJU~CI I IGI 11, IUIIUVV UI IIY LI IC VGI Llbat all I 111 IY I 1-1 --l:..-L---L x-II ^.., --I., +I..^ .,-&:--I -:-:--

Adjustment screws can be turned with an E8 Torx@

socket or

Ti 5 Torx@ screwdriver.

5-53

Page 313 of 418

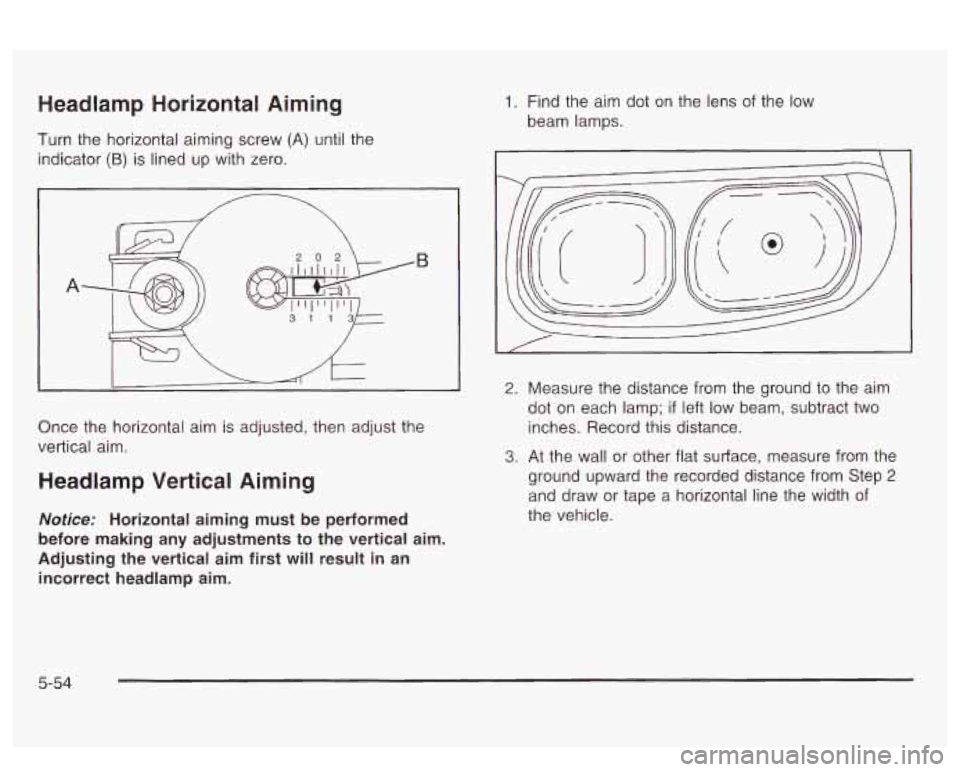

Headlamp Horizontal Aiming

Turn the horizontal aiming screw (A) until the

indicator

(B) is lined up with zero.

B

A

Once the horizontal aim is adjusted, then adjust the

vertical aim.

Headlamp Vertical Aiming

Notice: Horizontal aiming must be performed

before making any adjustments to the vertical aim.

Adjusting the vertical aim first will result in an incorrect headlamp aim.

1. Find the aim dot on the lens of the low

beam lamps.

2. Measure the distance from the ground to the aim

dot on each lamp;

if left low beam, subtract two

inches. Record this distance.

3. At the wall or other flat surface, measure from the

ground upward the recorded distance from Step

2

and draw or tape a horizontal line the width of

the vehicle.

5-54

Page 314 of 418

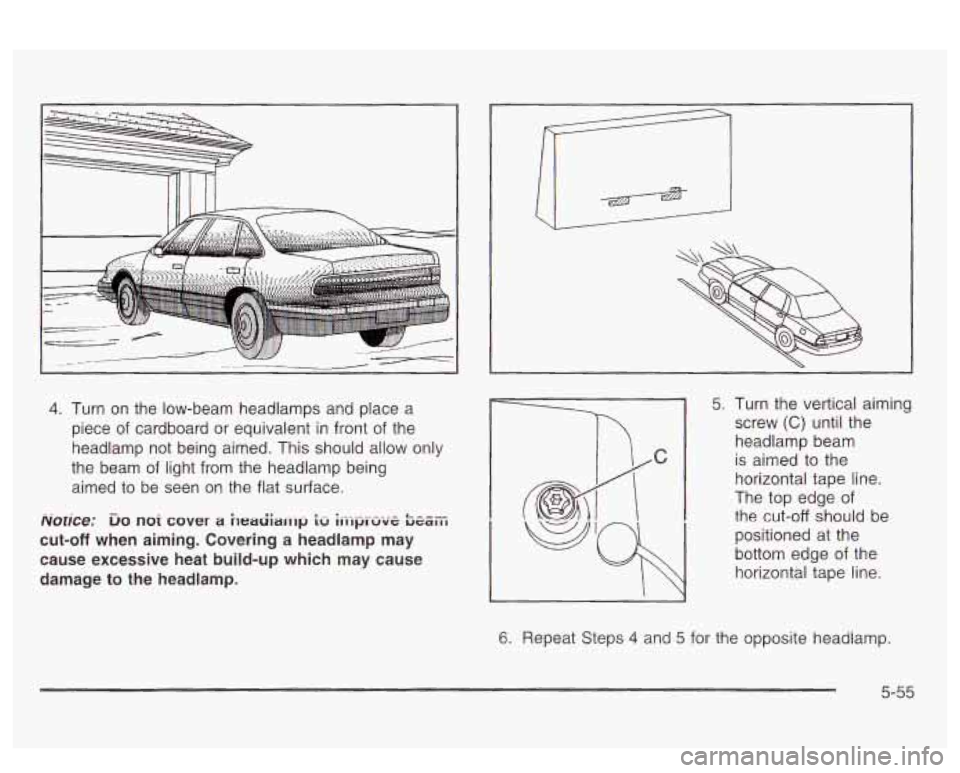

4. Turn on the low-beam headlamps and place a

piece of cardboard or equivalent in front of the

headlamp not being aimed. This should allow only

the beam of light from the headlamp being

aimed to be seen on the flat surface.

Norice: DO noi cover a heariiarnp iu iii-lpi-uie 5386~

cut-off when aiming. Covering a headlamp may

cause excessive heat build-up which may cause

damage to the headlamp. 5.

Turn the vertical aiming

screw

(C) until the

headlamp beam is aimed to the

horizontal tape line.

The top edge of

the cut-off should be

positioned at the bottom edge of the

horizontal tape line.

6. Repeat Steps

4 and 5 for the opposite headlamp.

5-55

Page 315 of 418

Bulb Replacement

For the type of bulb to use, see Replacement Bulbs on

page

5-60.

For any bulb changing procedure not listed in this

section, contact your dealer.

Halogen Bulbs

Headlamps

Halogen bulbs have pressurized gas inside

and can burst

if you drop or scratch the bulb.

You or others could be injured. Be sure

to read

and

follow the instructions on the bulb

package.

1. Reach behind the headlamp assembly, push in and

turn the bulb assembly counterclockwise to remove

the bulb assembly from the headlamp assembly.

5-56

Page 316 of 418

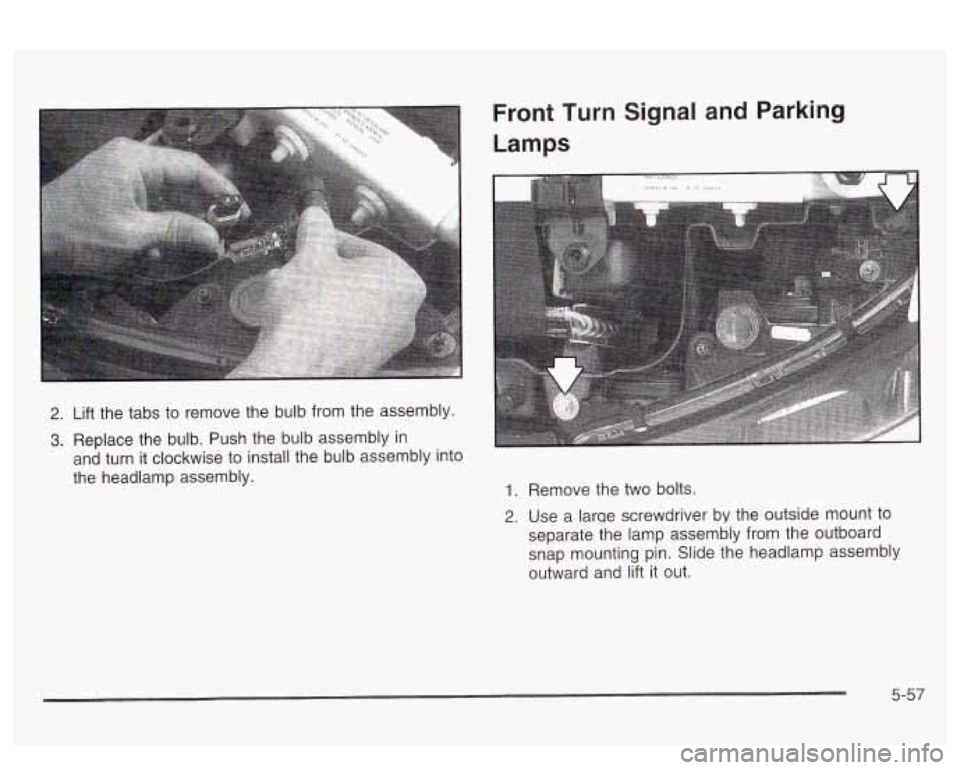

Front Turn Signal and Parking

Lamps

2. Lift the tabs to remove the bulb from the assembly.

3. Replace the bulb. Push the bulb assembly in

and turn it clockwise to install the bulb assembly into

the headlamp assembly.

1. Remove the two bolts.

2. Use a larqe screwdriver by the outside mount to

separate the lamp assembly from the outboard

snap mounting pin. Slide the headlamp assembly

outward and lift

it out.

5-57

Page 317 of 418

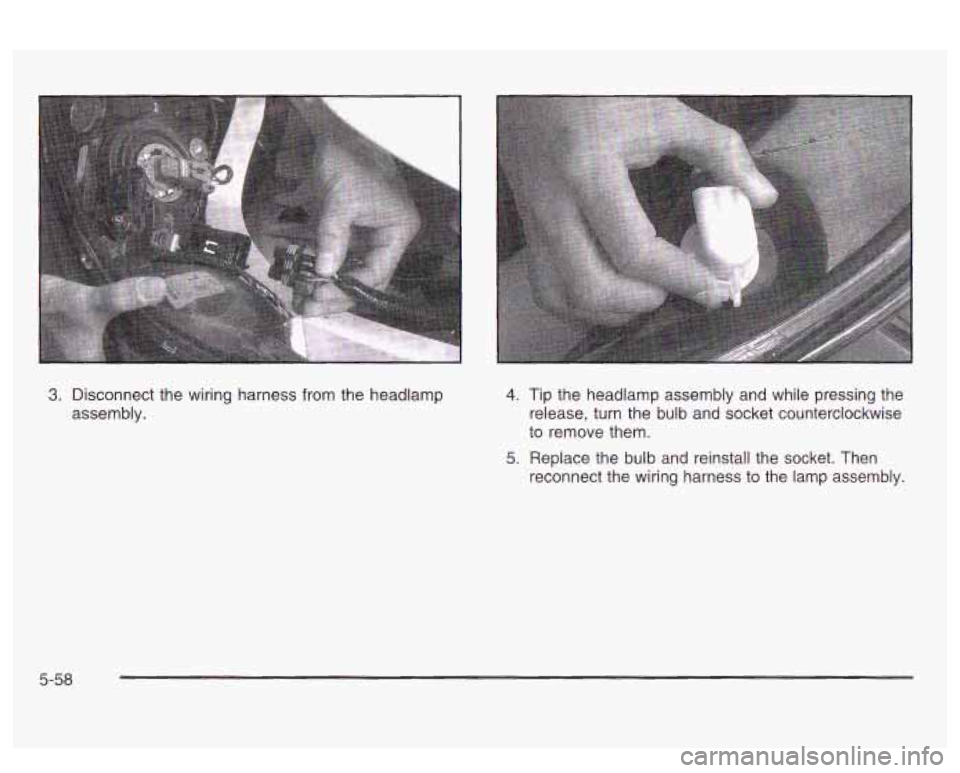

3. ~iSCOnneCt the wiring harness from the headlamp

assembly. 4.

5.

Tip the headlamp assembly and while pressing the

release, turn the bulb and socket counterclockwise

to remove them.

Replace the bulb and reinstall the socket. Then

reconnect the wiring harness to the lamp assembly.

5-58

Page 318 of 418

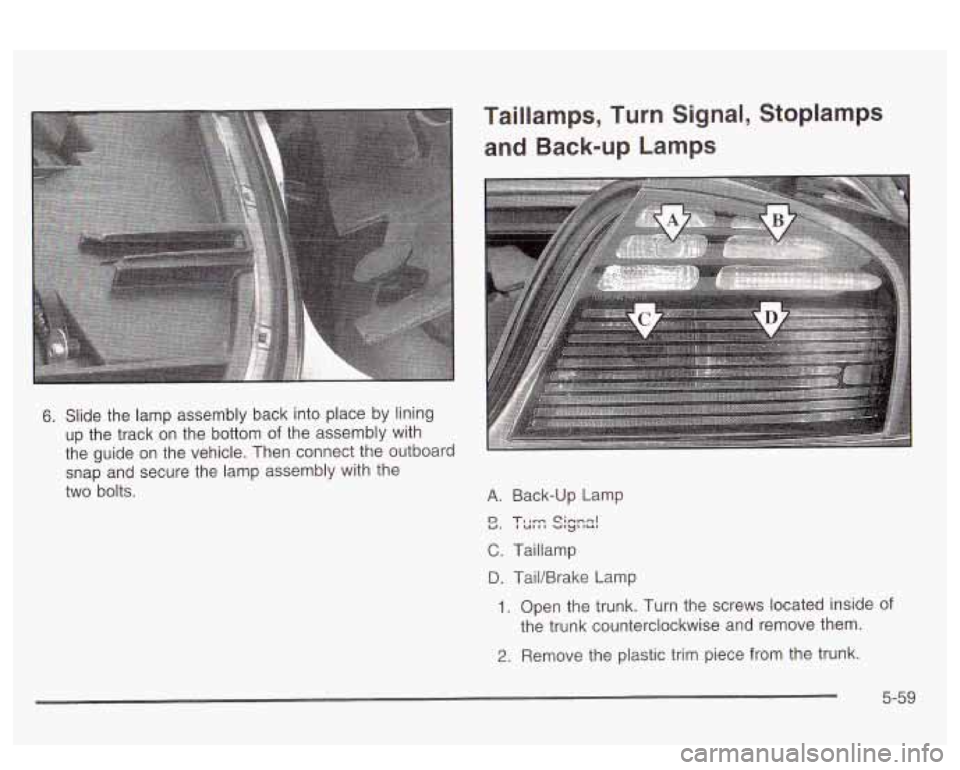

6. Slide the lamp assembly back into place by lining

up the track on the bottom

of the assembly with

the guide on the vehicle. Then connect the outboard

snap and secure the lamp assembly with the

two bolts.

C. Taillamp

D. PaiVBrake Lamp

1. Open the trunk. Turn the screws located inside of

the trunk counterclockwise and remove them.

2. Remove the plastic trim piece from the trunk.

5-59

Page 319 of 418

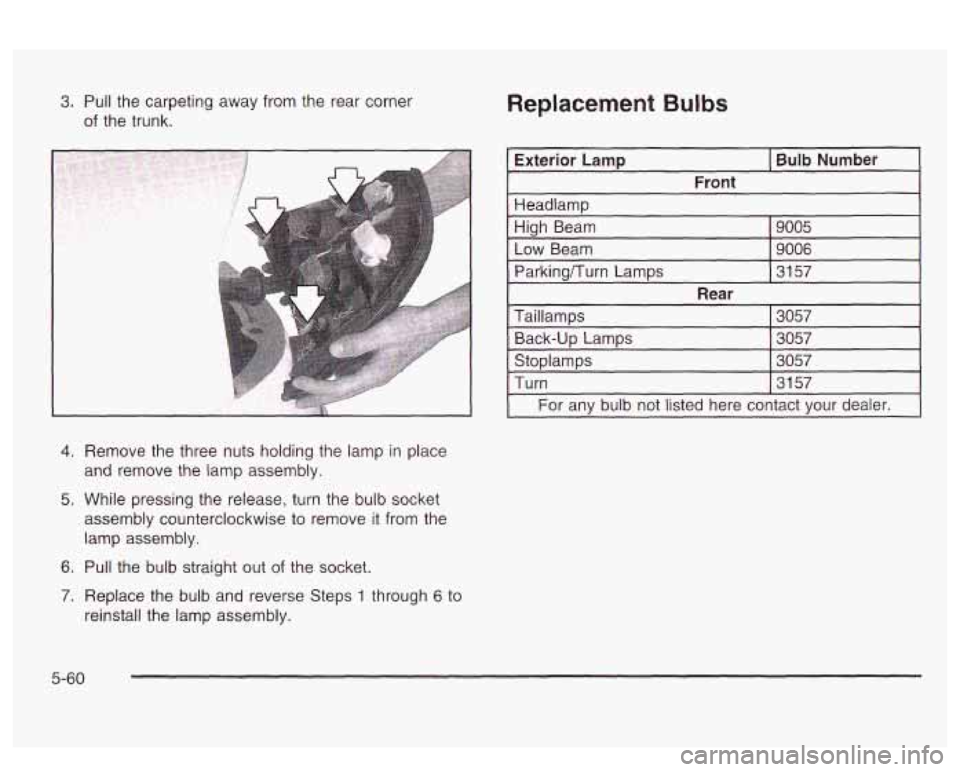

3. Pull the carpeting away from the rear corner

of the trunk.

4.

5.

6.

7.

A

Remove the three nuts holding the lamp in place

and remove the lamp assembly.

While pressing the release, turn the bulb socket

assembly counterclockwise to remove it from the

lamp assembly.

Pull the bulb straight out of the socket.

Replace the bulb and reverse Steps 1 through

6 to

reinstall the lamp assembly.

Replacement Bulbs

-

Exterior Lamp I Bulb Number

Front

I Headlamp I

-High Beam

~

9005

Low Beam 9006

Parkingnurn Lamps I 3157

Rear

Taillamps

Back-up Lamps 3057

3057

StoDlamDs 3057

Turn

I 3157

For any bulb not listed here contact Vour dealer.

5-60

Page 320 of 418

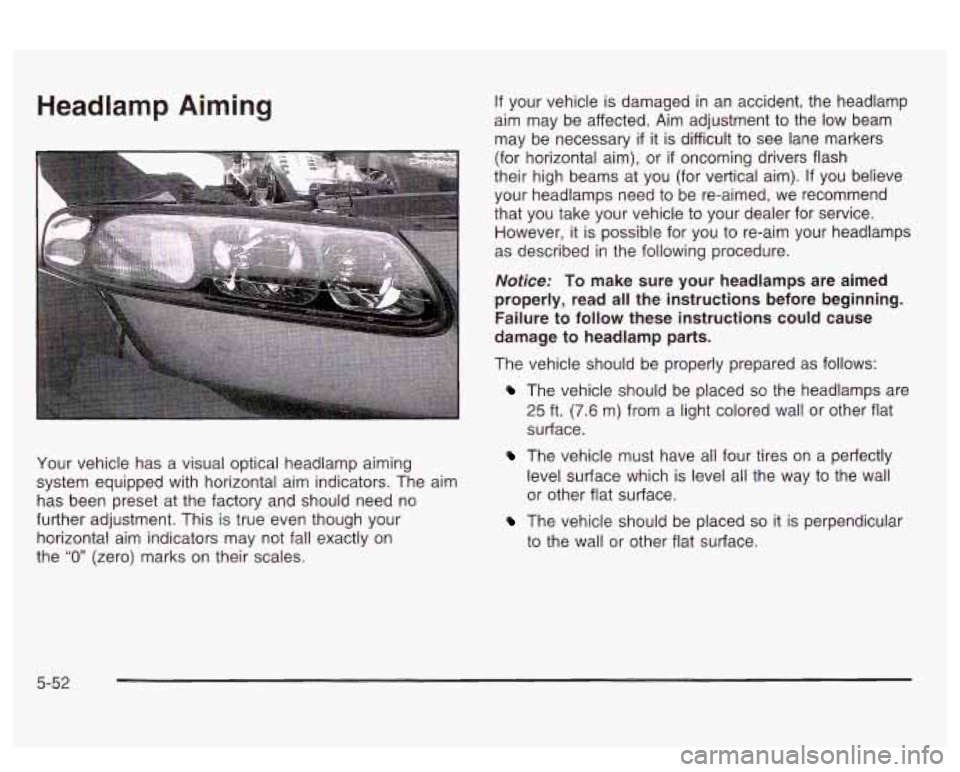

Windshield Wiper Blade Replacement

Windshield wiper blades should be inspected at least

twice a year for wear or cracking. See

Part B:

Owner Checks and Services on page 6-18 for more

information.

For the proper windshield wiper blade replacement

length and type, see

Normal Maintenance Replacement

Parts on page

5- 101.

To replace the wiper blade assembly:

the vertically-locked position.

1. Lift the wiper up from the windshield and set into

2. Press the tab that holds the wiper blade to the arm.

3. Slide the blade down and off the arm.

4. Slide in the new blade and snap into place.

5-6 1

Trending: dead battery, cruise control, sunroof, lane assist, lumbar support, battery, tire pressure