PONTIAC FIERO 1988 Service Repair Manual

Manufacturer: PONTIAC, Model Year: 1988, Model line: FIERO, Model: PONTIAC FIERO 1988Pages: 1825, PDF Size: 99.44 MB

Page 1061 of 1825

700-R4-10 AUTOMATIC TRANSMISSION

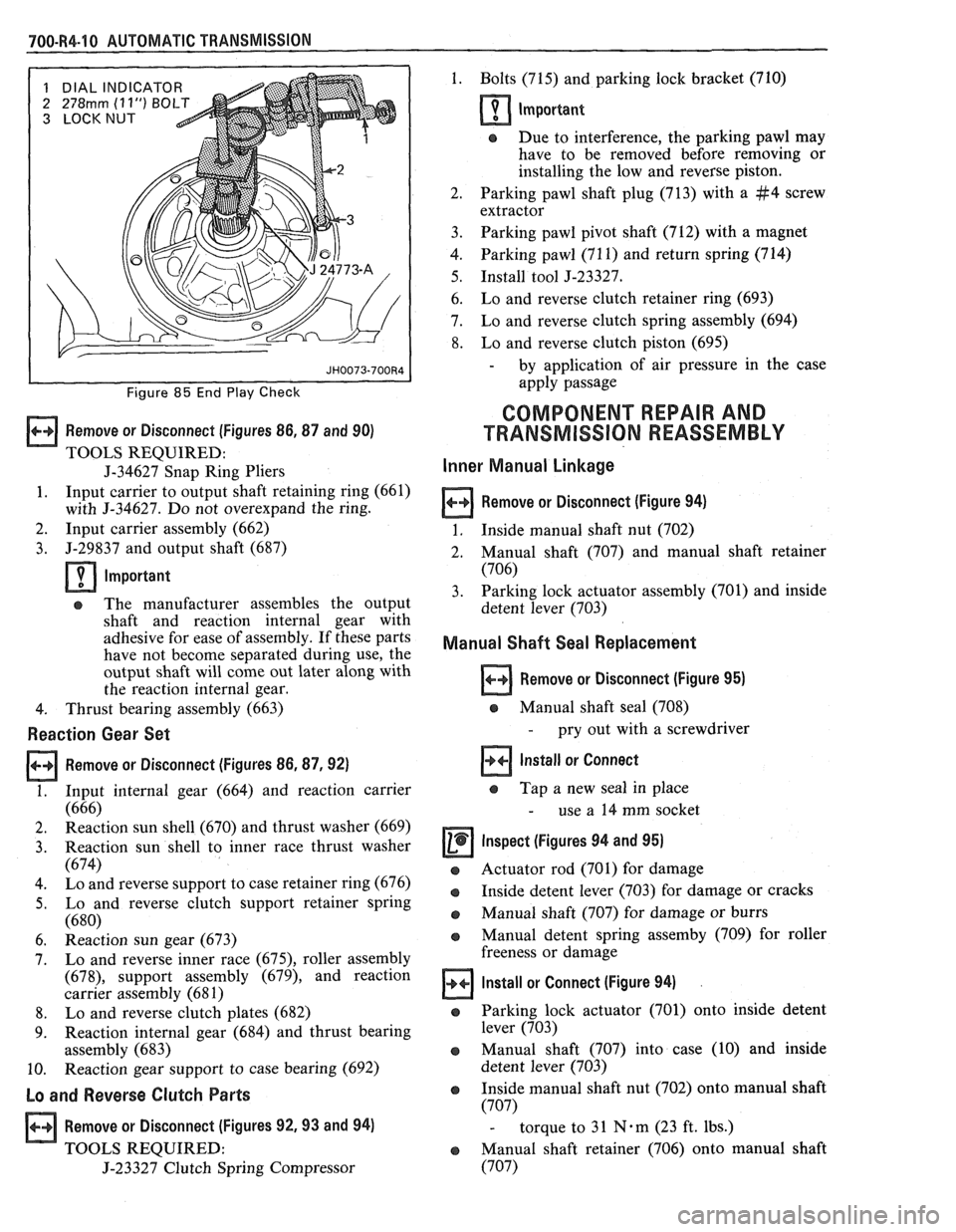

1 DIAL INDICATOR

2

278rnm (1 1") BOLT

3 LOCKNUT

Figure 85 End Play Check

Remove or Disconnect (Figures 86,87 and 90)

TOOLS REQUIRED:

J-34627 Snap Ring Pliers

1. Input

carrier to output shaft retaining ring (661)

with

5-34627. Do not overexpand the ring.

2. Input carrier assembly (662)

3. J-29837

and output shaft (687)

lmportant

a The manufacturer assembles the output

shaft and reaction internal gear with

adhesive for ease of assembly. If these parts

have not become separated during use, the

output shaft will come out later along with

the reaction internal gear.

4. Thrust bearing assembly (663)

Reaction Gear Set

Remove or Disconnect (Figures 86.87.92)

1. Input internal gear (664) and reaction carrier

(666)

2. Reaction

sun shell (670) and thrust washer (669)

3. Reaction

sun shell to inner race thrust washer

(674)

4. Lo and reverse support to case retainer ring (676)

5. Lo and reverse clutch support retainer spring

(680)

6. Reaction sun gear (673)

7. Lo and reverse inner race

(675), roller assembly

(678), support assembly (679), and reaction

carrier assembly (68 1)

8. Lo and reverse clutch plates (682)

9. Reaction internal

gear (684) and thrust bearing

assembly (683)

10. Reaction

gear support to case bearing (692)

Lo and Reverse Clutch Parts

Remove or Disconnect (Figures 92,93 and 94)

TOOLS REQUIRED:

J-23327 Clutch Spring Compressor 1.

Bolts (715) and parking lock bracket (710)

Important

r Due to interference, the parking pawl may

have to be removed before removing or

installing the low and reverse piston.

2. Parking pawl shaft plug (713) with a

#4 screw

extractor

3. Parking pawl pivot shaft (712) with a magnet

4. Parking pawl (71 1) and return spring (714)

5. Install tool J-23327.

6. Lo

and reverse clutch retainer ring (693)

7. Lo

and reverse clutch spring assembly (694)

8. Lo and reverse clutch piston (695)

- by application of air pressure in the case

apply passage

COMPONENT REPAIR AND

TRANSMISSION REASSEMBLY

Inner Manual Linkage

Remove or Disconnect (Figure 94)

1. Inside manual shaft nut (702)

2. Manual shaft

(707) and manual shaft retainer

(706)

3. Parking

lock actuator assembly (701) and inside

detent lever (703)

Manual Shaft Seal Replacement

Remove or Disconnect (Figure 95)

a Manual shaft seal (708)

- pry out with a screwdriver

Install or Connect

Tap a new seal in place

- use a 14 mm socket

Inspect (Figures 94 and 95)

a Actuator rod (701) for damage

a Inside detent lever (703) for damage or cracks

e Manual shaft (707) for damage or burrs

Manual detent spring

assemby (709) for roller

freeness or damage

lnstall or Connect (Figure 94)

a Parking lock actuator (701) onto inside detent

lever (703)

a Manual shaft (707) into case (10) and inside

detent lever (703)

a Inside manual shaft nut (702) onto manual shaft

(707)

- torque to 31 N-m (23 ft. lbs.)

r Manual shaft retainer (706) onto manual shaft

(707)

Page 1062 of 1825

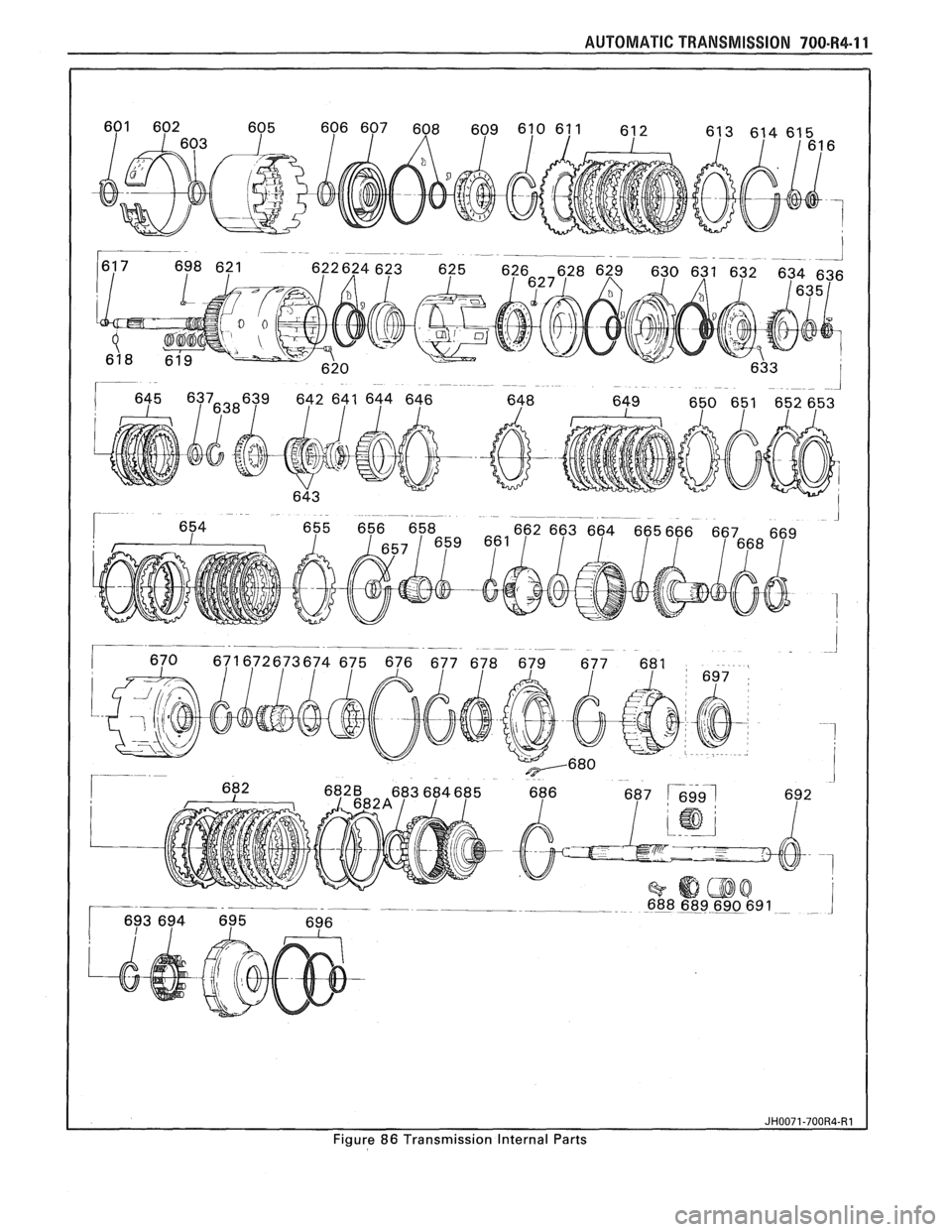

Figure 86 Transmission Internal Parts

Page 1063 of 1825

700-R4-12 AUTOMATIC TRANSMISSION

ILL.

I NO. DESCRIPTION

601 WASHER, THRUST (PUMP TO DRUM)

602 BAND ASSEMBLY, 2-4

603 BUSHING, REVERSE INPUT CL. (FRONT)

605 HOUSING

& DRUM ASSEMBLY, REVERSE

INPUT CLUTCH

606 BUSHING, REVERSE INPUT CLUTCH (REAR)

607 PISTON ASM., REVERSE INPUT CLUTCH

608 SEALS, REVERSE INPUT CLUTCH

(INNER

& OUTER)

609 SPRING ASM., REVERSE INPUT CLUTCH

610 RING, REVERSE INPUT CLUTCH SPRING

RETAINER

61 1 PLATE. REVERSE INPUT CLUTCH

(BELLEVILLEI

612 PLATE ASM., REVERSE INPUT CLUTCH

613 PLATE, REVERSE INPUT CLUTCH BACKING

(SELECTIVE)

614 RING, REVERSE INPUT CL. RETAINING

61 5 BEARING ASSEMBLY, STATOR

SHAFT1

SELECTIVE WASHER

61 6 WASHER, THRUST (SELECTIVE)

617 RETAINER

& BALL ASM., CHECK VALVE

61 8 SEAL, "0" RlNG (TURBINE SHAFT/

SELECTIVE WASHER)

61 9 RING, OIL SEAL (SOLID)

620 RETAINER

& CHECK BALL ASSEMBLY

621 HOUSING & SHAFT ASSEMBLY, INPUT

622 SEAL, "0" RlNG INPUT TO FORWARD HSG.

623 PISTON, 3RD

& 4TH CLUTCH

624 SEAL, 3RD & 4TH CL. (INNER & OUTER)

625 RING, 3RD

& 4TH CLUTCH APPLY

626 SPRING ASSEMBLY, 3RD & 4TH CLUTCH

627 RETAINER & BALL ASSEMBLY, FORWARD

CLUTCH HOUSING

628 HOUSING, FORWARD CLUTCH

629 SEAL, FORWARD CLUTCH (INNER

& OUTER)

630 PISTON, FORWARD CLUTCH

631 SEAL, OVERRUN CLUTCH (INNER

& OUTER)

632 PISTON, OVERRUN CLUTCH

633 BALL, OVERRUN CLUTCH

634 SPRING ASSEMBLY, OVERRUN CLUTCH

635 SNAP RING, OVERRUN CLUTCH SPRING

RETAINER

636 SEAL, INPUT HOUSING TO OUTPUT SHAFT

637 BEARING ASSEMBLY, INPUT SUN GEAR

638 SNAP RING, OVERRUN CL. HUB RETAINING

639 HUB, OVERRUN CLUTCH

641 RETAINER

& RACE ASSEMBLY, SPRAG

642 FORWARD SPRAG ASSEMBLY

643 RETAINER RINGS, SPRAG ASSEMBLY

644 RACE, FORWARD CLUTCH (OUTER)

645 PLATE ASSEMBLY, OVERRUN CLUTCH

646 PLATE, FORWARD CLUTCH APPLY

648 PLATE, FORWARD CLUTCH (WAVED)

649 PLATE ASSEMBLY, FORWARD CLUTCH

650 PLATE. FORWARD CLUTCH BACKING

(SEL.) 651 RING, FORWARD CLUTCH BACKING PLATE I RETAINER

I

. . - . . . . . . - . .

652 PLATE, 3RD & 4TH CLUTCH RlNG RETAINER

653 PLATE, 3RD & 4TH CLUTCH APPLY

(STEPPED)

654 PLATE ASSEMBLY, 3RD

& 4TH CLUTCH

655 PLATE, 3RD & 4TH CLUTCH BACKING (SEL.)

ILL.

NO. DESCRIPTION

656 RING, 3RD & 4TH CLUTCH BACKING

PLATE RETAINER

657 BUSHING, INPUT SUN GEAR (FRONT)

658 GEAR, INPUT SUN

659 BUSHING, INPUT SUN GEAR (REAR)

661 RET., OUTPUT SHAFT TO INPUT CARRIER

662 CARRIER ASSEMBLY, INPUT (COMPLETE)

663 BEARING ASSEMBLY, THRUST (INPUT

CARRIER TO REACTION SHAFT)

664 GEAR, INPUT INTERNAL

665 BUSHING, REACTION CARRIER SHAFT

(FRONT)

666 SHAFT, REACTION CARRIER

667 BUSHING, REACTION CARRIER SHAFT

(REAR)

668 RING, REACTION

SHAFTIINTERNAL GEAR

RETAINER

669 WASHER, THRUST (REACTION

SHAFT1 SHELL)

670 SHELL, REACTION SUN

671 RING, REACTION SUN GEAR RETAINER

672 BUSHING, REACTION SUN

673 GEAR, REACTION SUN

674 WASHER, THRUST

(RACE/REACTION SHELL)

675 RACE, LO & REVERSE ROLLER CLUTCH

676 RING, LO & REVERSE SUPPORT TO CASE

RETAINER

677 RING, LO

& REVERSE RETAINER (ROLLER

ASSEMBLYICAM)

678 CLUTCH ASSEMBLY, LO & REVERSE ROLLER

679 SUPPORT ASM., LO & REVERSE CLUTCH

680 SPRING, TRANSMISSION (LO & REVERSE

CLUTCH SUPPORT RETAINER)

681 CARRIER ASSEMBLY, REACTION

682 PLATE ASSEMBLY, LO

& REVERSE CLUTCH

682A PLATE, LO & REVERSE CLUTCH (WAVED)

682B PLATE, SPACER LO

& REV. CL. (SELECTIVE)

683 BEARING ASSEMBLY, THRUST (REACTION

CARRIERISUPPORT)

684 GEAR, INTERNAL REACTION

685 SUPPORT, INTERNAL REACTION GEAR

686 RING, REACTION

GEARISUPPORT RETAINER

687 SHAFT, OUTPUT

688 CLIP, SPEEDO DRIVE GEAR

689 GEAR, SPEEDO DRIVE

690 SLEEVE, OUTPUT SHAFT

691 SEAL, OUTPUT SHAFT

692 BRG., REACTION GEAR SUPPORT TO CASE

693 RING, LO

& REVERSE CLUTCH RETAINER

694 SPRING ASSEMBLY, LO & REVERSE CLUTCH

695 PISTON,

LO & REVERSE CLUTCH

696 SEAL,

TRANSMISSION (LO & REVERSE

CLUTCH - OUTER, CENTER, INNER)

697 DEFLECTOR, OIL (HIGH OUTPUT

MODELS ONLY)

698 PLUG.

ORIFICED CUP

699 ROTOR, INTERNAL TRANSMISSION SPEED

SENSOR

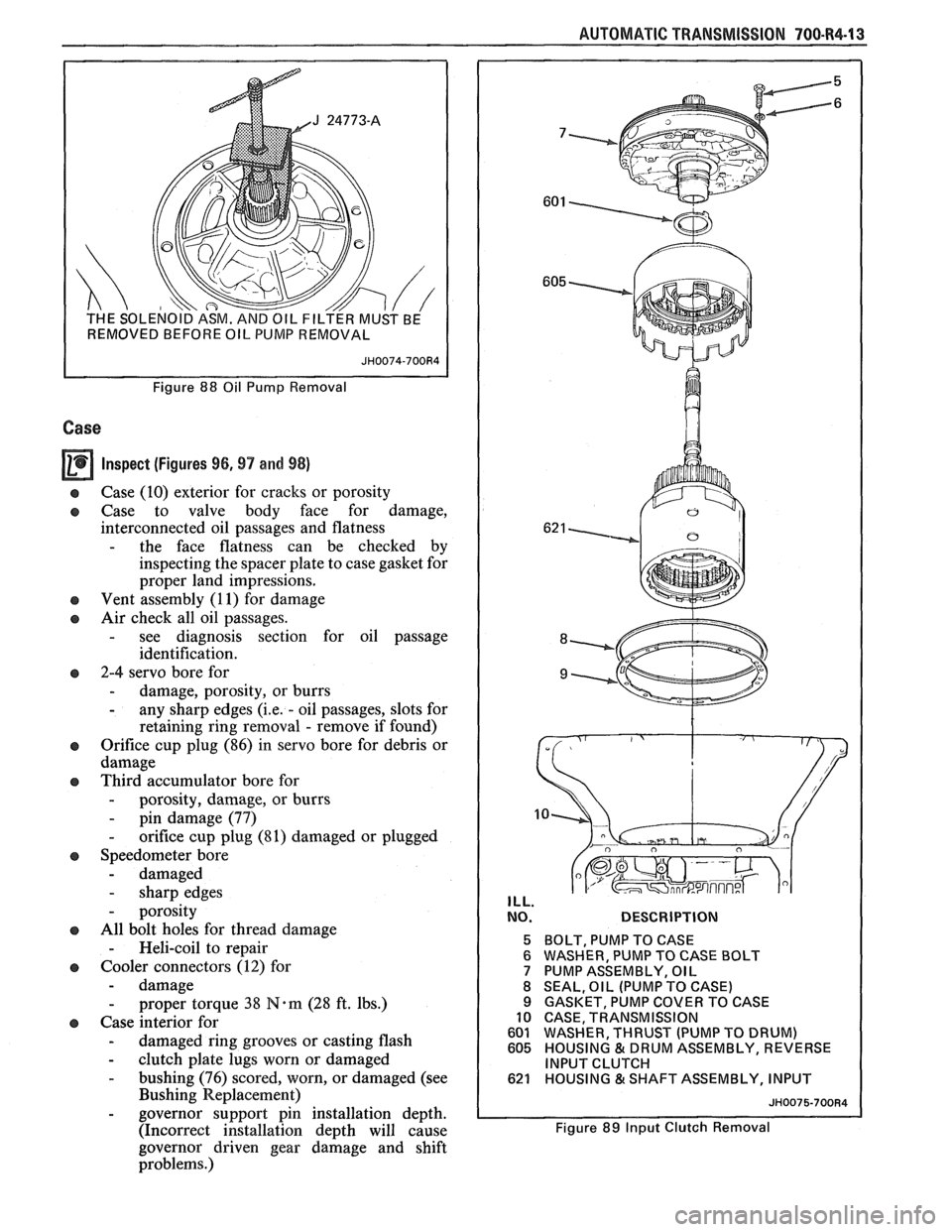

Figure

Page 1064 of 1825

AUTOMAnIC TRANSMISSION 700-R4-13

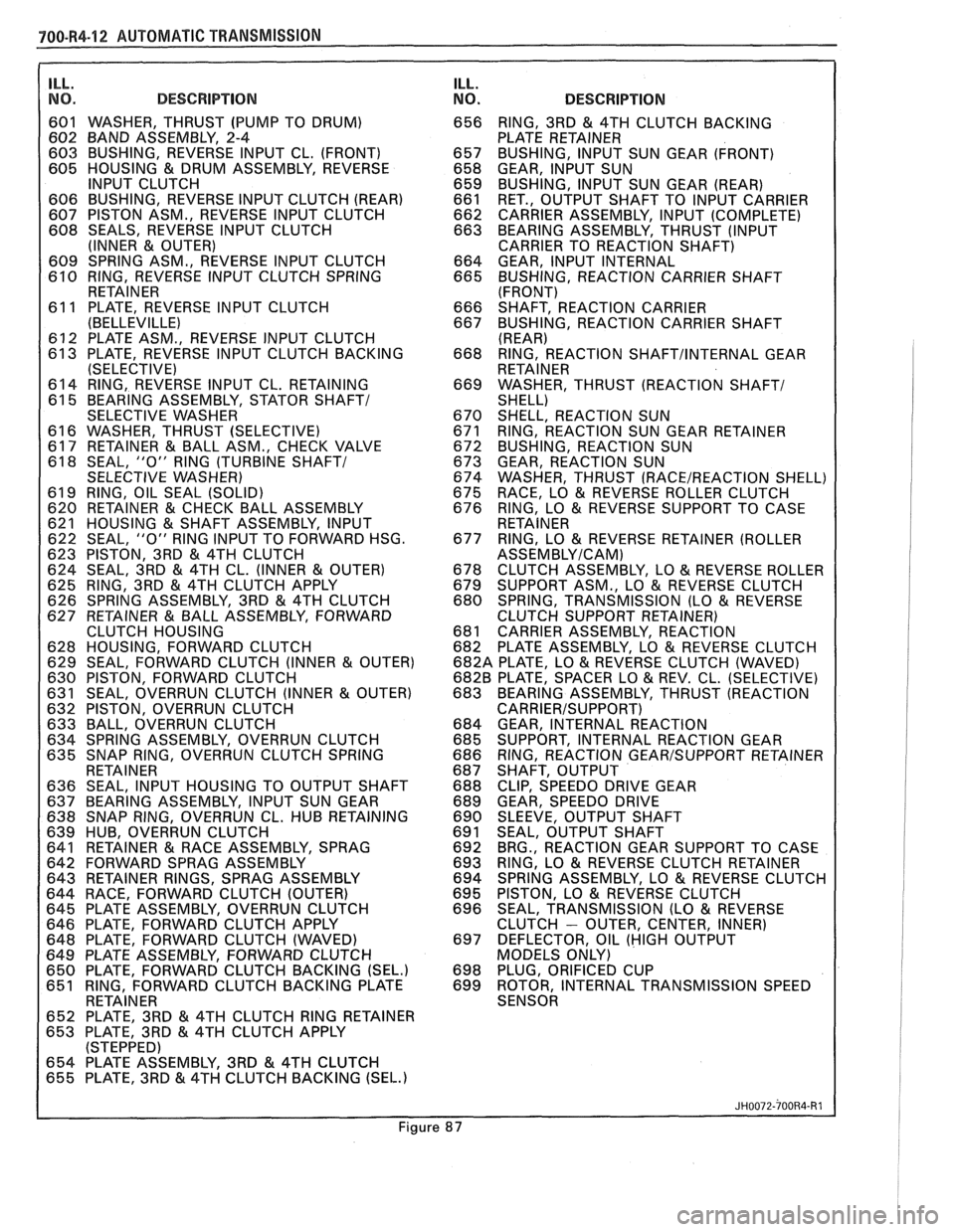

I REMOVED BEFORE OIL PUMP REMOVAL I

Figure 88 Oil Pump Removal

Case

Inspect (Figures 96.97 and 98)

Case (10) exterior for cracks or porosity

Case to valve body face for damage,

interconnected oil passages and flatness

- the face flatness can be checked by

inspecting the spacer plate to case gasket for

proper land impressions.

Vent assembly (1

1) for damage

Air check all oil passages.

- see diagnosis section for oil passage

identification.

2-4 servo bore for

- damage, porosity, or burrs - any sharp edges (i.e. - oil passages, slots for

retaining ring removal

- remove if found)

Orifice cup plug (86) in servo bore for debris or

damage

Third accumulator bore for

- porosity, damage, or burrs

- pin damage (77) - orifice cup plug (81) damaged or plugged

Speedometer bore

- damaged

- sharp edges

- porosity

All bolt holes for thread damage

- Heli-coil to repair

Cooler connectors

(12) for

- damage - proper torque 38 N.m (28 ft. lbs.)

Case interior for

- damaged ring grooves or casting flash - clutch plate lugs worn or damaged

- bushing (76) scored, worn, or damaged (see

Bushing Replacement)

- governor support pin installation depth.

(Incorrect

installation depth will cause

governor driven gear

clamage and shift

problems.)

NO. DESCRIPTION

5 BOLT, PUMP TO CASE

6 WASHER, PUMP TO CASE BOLT

7 PUMP ASSEMBLY, OIL

8 SEAL, OIL (PUMP TO CASE)

9 GASKET, PUMP COVER TO CASE

10 CASE, TRANSMISSION

601 WASHER, THRUST (PUMP TO DRUM)

605 HOUSING

& DRUM ASSEMBLY, REVERSE

INPUT CLUTCH

621 HOUSING &SHAFT ASSEMBLY, INPUT

JH0075-700R4

Figure 89 Input Clutch Removal

Page 1065 of 1825

700-R4-14 AUTOMATIC TRANSMISSION

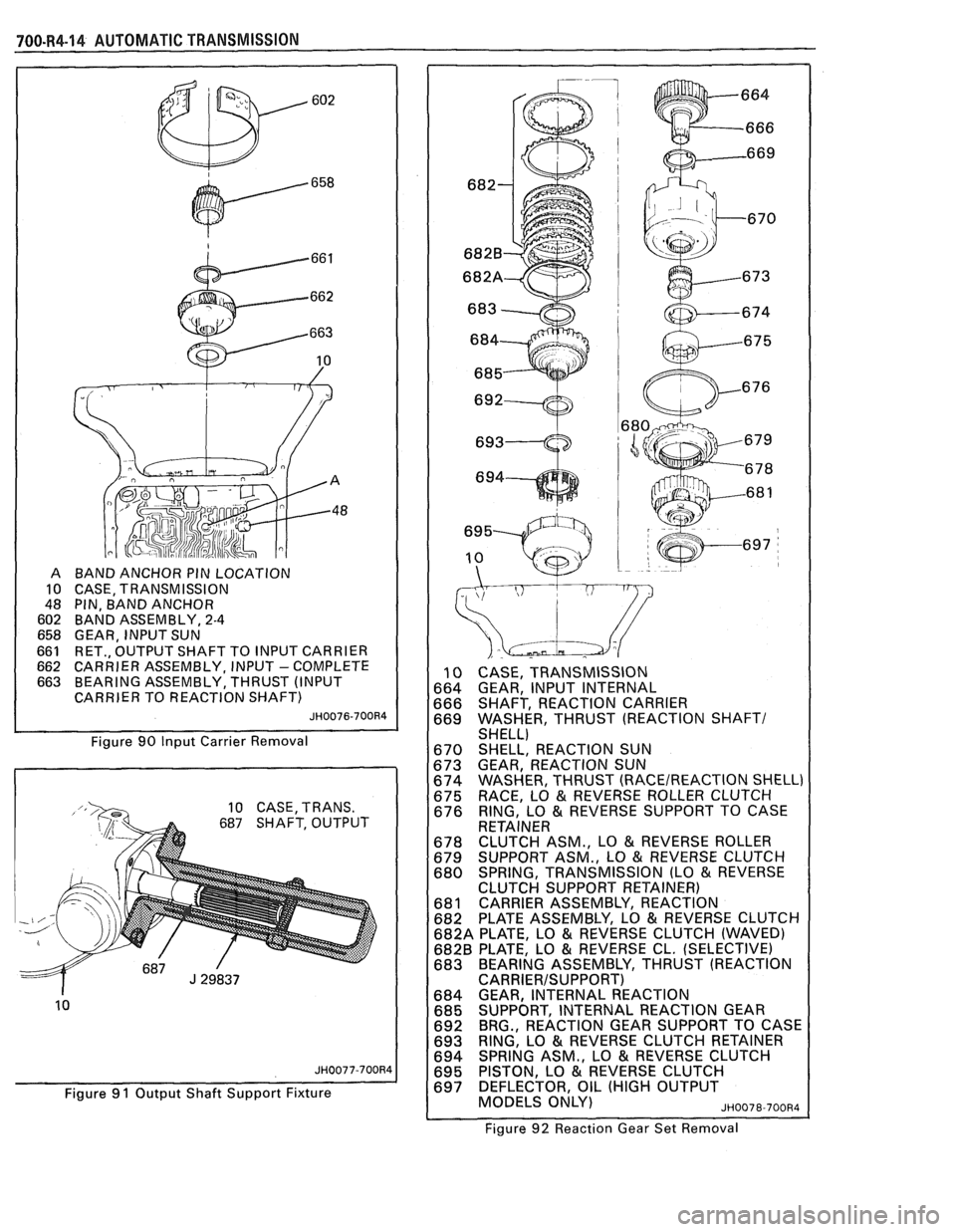

BAND ANCHOR PIN LOCATION

CASE, TRANSMISSION

PIN, BAND ANCHOR

BAND ASSEMBLY,

2-4

GEAR, INPUT SUN

RET., OUTPUT SHAFT TO INPUT CARRIER

CARRIER ASSEMBLY, INPUT

- COMPLETE

BEARING ASSEMBLY, THRUST (INPUT

CARRIER TO REACTION SHAFT)

JH0076-700R4

Figure 90 Input Carrier Removal

10 CASE, TRANS.

687 SHAFT, OUTPUT

10

JH0077-700R4

Figure 91 Output Shaft Support Fixture

10 CASE, TRANSMISSION

664 GEAR, INPUT INTERNAL

666 SHAFT, REACTION CARRIER

669 WASHER, THRUST (REACTION

SHAFT/ SHELL)

670 SHELL, REACTION SUN

673 GEAR, REACTION SUN

674 WASHER, THRUST

(RACEIREACTION SHELL)

675 RACE, LO & REVERSE

ROLLER CLUTCH

676 RING, LO

& REVERSE SUPPORT

TO CASE

RETAINER

678 CLUTCH ASM.,

LO

& REVERSE ROLLER

679 SUPPORT

ASM., LO

& REVERSE CLUTCH

680 SPRING,

TRANSMISSION (LO & REVERSE

CLUTCH SUPPORT RETAINER)

681 CARRIER ASSEMBLY, REACTION

682 PLATE

ASSEMBLY, LO

& REVERSE CLUTCH

682A PLATE, LO

& REVERSE CLUTCH (WAVED)

682B PLATE, LO & REVERSE CL. (SELECTIVE)

683 BEARING ASSEMBLY, THRUST (REACTION

CARRIERISUPPORT) 684 GEAR, INTERNAL REACTION

685 SUPPORT, INTERNAL REACTION GEAR

692 BRG.,

REACTION GEAR SUPPORT TO CASE

693 RING, LO

& REVERSE

CLUTCH RETAINER

694 SPRING

ASM., LO & REVERSE CLUTCH

695 PISTON, LO & REVERSE

CLUTCH

697 DEFLECTOR, OIL (HIGH OUTPUT

MODELS ONLY)

~~0078-700~4

Figure 92 Reaction Gear Set Removal

Page 1066 of 1825

AUTOMATIC TRANSMISSION 700.84-1 5

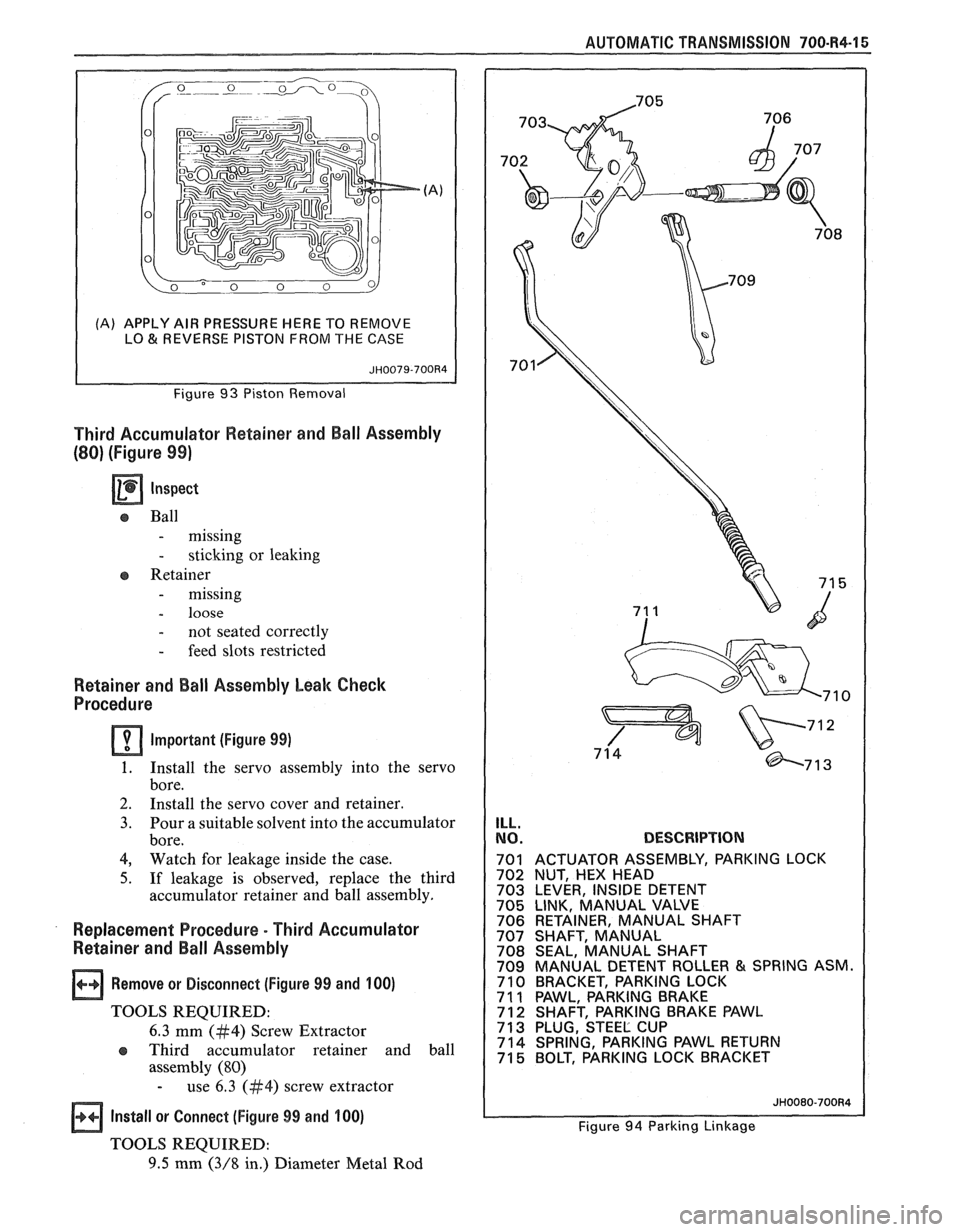

(A) APPLY AIR PRESSURE WERE TO REMOVE

LO & REVERSE PISTON FROM THE CASE

Third Accumulator Retainer and Ball Assembly

(80) (Figure 99)

Ball

- missing

- sticking or leaking

Retainer

- missing

- loose

- not seated correctly

- feed slots restricted

Retainer and Ball Assembly Leak Check

Procedure

Important (Figure 99)

1. Install the servo assembly into the servo

bore.

2. Install the servo cover and retainer.

3. Pour a suitable solvent into the accumulator

bore.

DESCRIPTION

701 ACTUATOR ASSEMBLY, PARKING LOCK

Replacement Procedure - Third Accumulator 706 RETAINER, MANUAL SHAFT

707 SHAFT, MANUAL Retainer and Ball Assembly 708 SEAL, MANUAL SHAFT 709 MANUAL DETENT ROLLER & SPRING ASM.

1 Remove or Disconnect (Figure 99 and 100) 710 BRACKET, PARKING LOCK 7 1 1 PAWL, PARKING BRAKE TOOLS REQUIRED: 7 12 SHAFT, PARKING BRAKE PAWL

6.3 mm (#4) Screw Extractor 71 3 PLUG, STEEL CUP

assembly (80)

- use 6.3 (#4) screw extractor

1 Install or Connect (Figure 99 and 100) Figure 94 Parking Linkage

TOOLS REQUIRED:

9.5 mm (3/8 in.) Diameter Metal Rod

Page 1067 of 1825

700-R4-16 AUTOMATIC TRANSMISSION

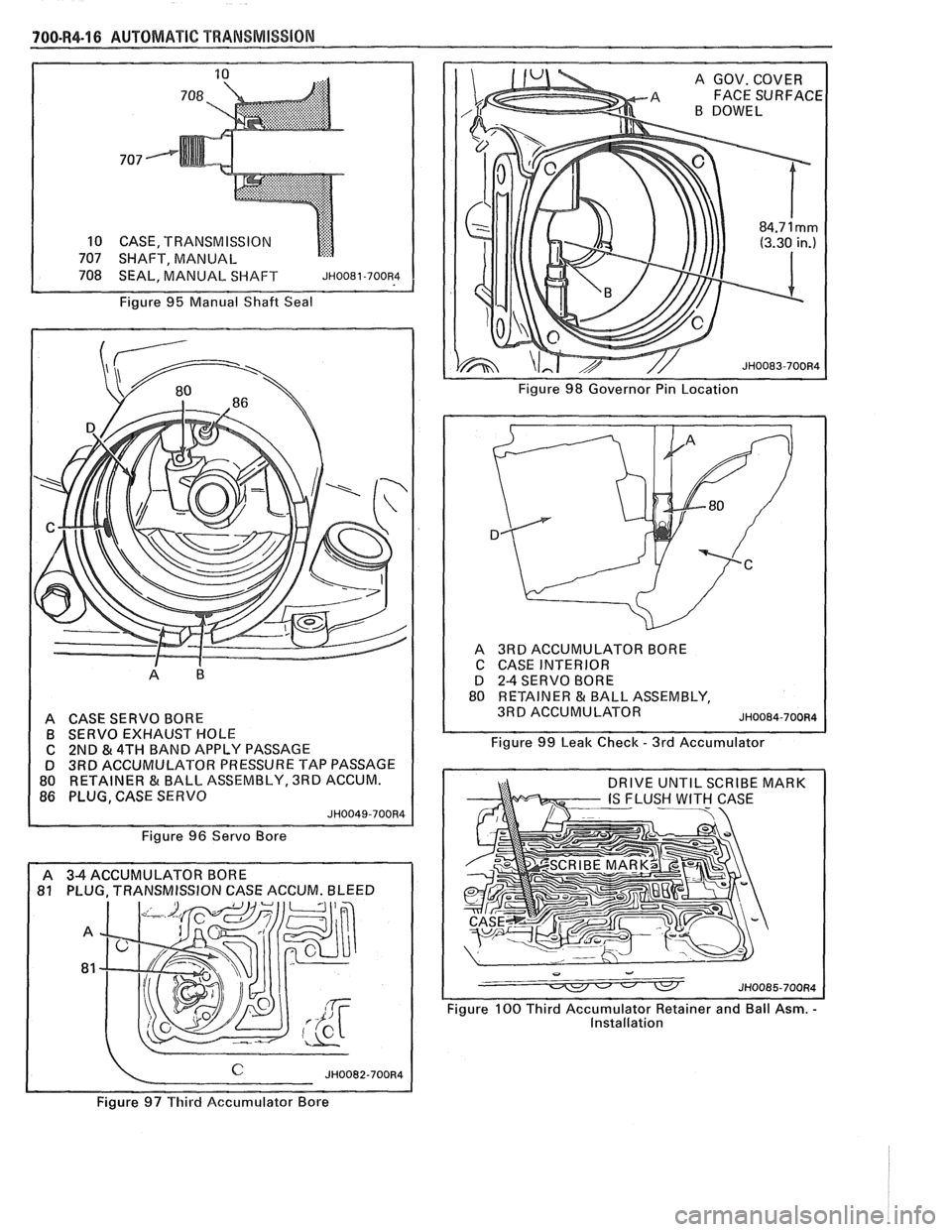

707

10 CASE, TRANSMISSION

707 SHAFT, MANUAL

Figure

95 Manual Shaft Seal

~igu-r; 98 Governor Pin Location 1

A CASE SERVO BORE B SERVO EXHAUST HOLE

C 2ND

& 4TH BAND APPLY PASSAGE

D 3RD ACCUMULATOR PRESSURE TAP PASSAGE

80 RETAINER & BALL. ASSEMBLY, 3RD ACCUM.

86 PLUG, CASE SERVO

JH0049-700R4

Figure 96 Servo Bore

81 PLUG. TRANSMISSION CASE ACCUM. BLEED A

3RDACCUMULATOR BORE

C CASE INTERIOR

D

2-4 SERVO BORE

80 RETAINER & BALL ASSEMBLY,

3RD ACCUMULATOR

JH0084-700R4

Figure 99 Leak Check - 3rd Accumulator

Figure

100 Third Accumulator Retainer and Ball Asm. - Installation

~i~ure97Ttiird Aecumularor Bore

Page 1068 of 1825

AUTOMATIC TRANSMISSION 700-R4-17

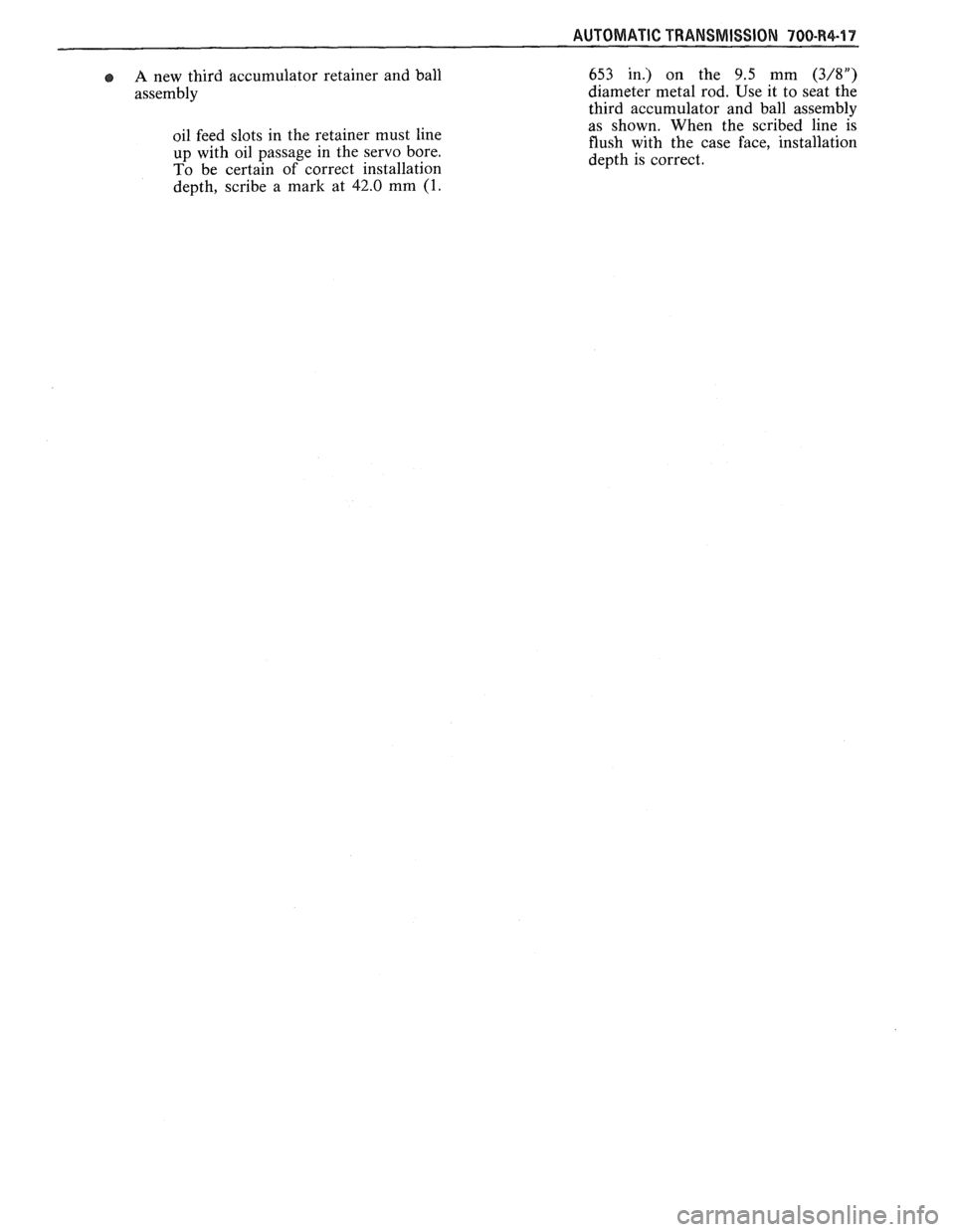

A new third accumulator retainer and ball

assembly

oil feed slots in the retainer must line

up with oil passage in the servo bore.

To be certain of correct installation 653 in.) on the 9.5 mm (3/8")

diameter metal rod. Use it to seat the

third accumulator and ball assembly

as shown. When the scribed line is

flush with the case face, installation

depth is correct.

depth, scribe a mark at

42.0 mm (1.

Page 1069 of 1825

700-R4.18 AUTOMATIC TRANSMISSION

Case Assembly

a Clean

o Thoroughly with solvent

a Air dry

- do not wipe with cloth

Lo and Reverse Clutch Assembly

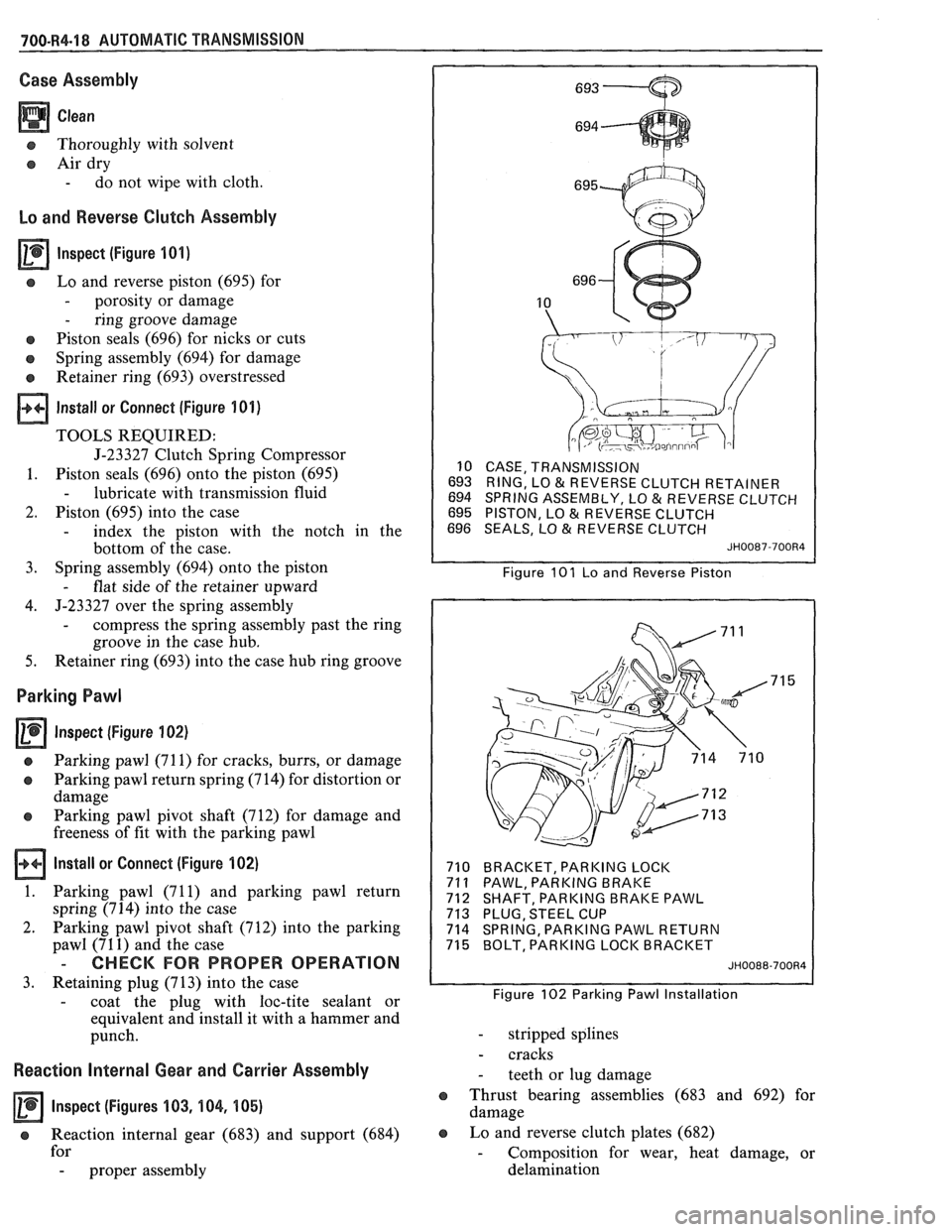

lnspect (Figure 101)

s Lo and reverse piston (695) for

- porosity or damage

- ring groove damage

e Piston seals (696) for nicks or cuts

o Spring assembly (694) for damage

Retainer ring (693) overstressed

Install or Connect (Figure 101)

TOOLS REQUIRED:

J-23327 Clutch Spring Compressor

1. Piston seals (696) onto the piston (695)

- lubricate with transmission fluid

2. Piston (695) into the case

- index the piston with the notch in the

bottom of the case.

3. Spring

assembly (694) onto the piston

- flat side of the retainer upward

4. J-23327 over

the spring assembly

- compress the spring assembly past the ring

groove in the case hub.

5. Retainer ring (693) into the case hub ring groove

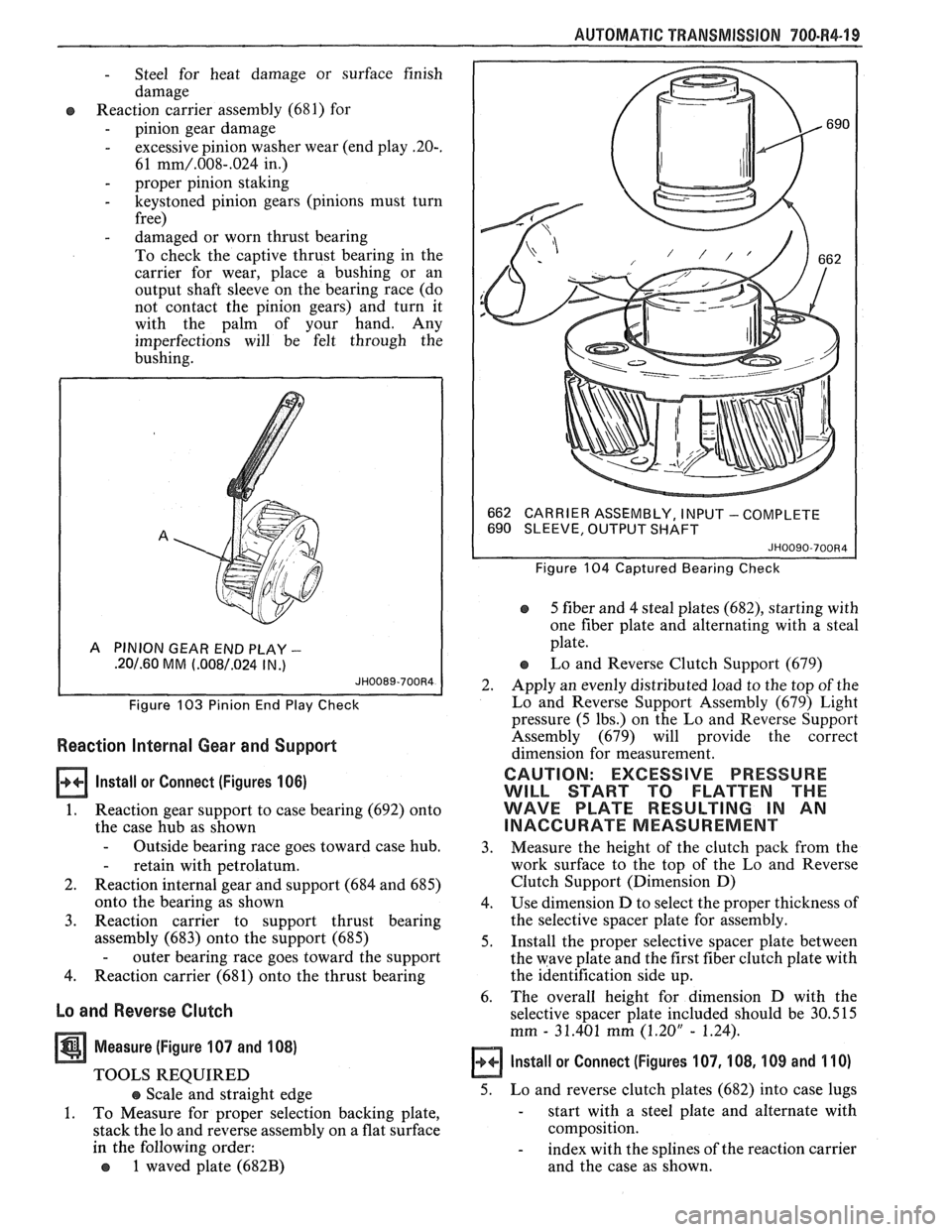

Parking Pawl

Inspect (Figure 102)

a Parking pawl (71 1) for cracks, burrs, or damage

o Parking pawl return spring (714) for distortion or

damage

e Parking pawl pivot shaft (712) for damage and

freeness of fit with the parking pawl

Install or Connect (Figure 102)

1. Parking pawl (71 1) and parking pawl return

spring (714) into the case

2. Parking pawl pivot shaft (712) into the parking

pawl (71

1) and the case

- CHECK FOR PROPER OPERATION

3. Retaining plug (713) into the case

- coat the plug with loc-tite sealant or

equivalent and install it with a hammer and

punch.

Reaction Internal Gear and Carrier Assembly

Inspect (Figures 103, 104, 105)

e Reaction internal gear (683) and support (684)

for

- proper assembly

10 CASE, TRANSMISSION

693 RING, LO

& REVERSE CLUTCH RETAINER

694 SPRING ASSEMBLY, LO & REVERSE CLUTCH

695 PISTON, LO & REVERSE CLUTCH

696 SEALS, LO & REVERSE CLUTCH

JH0087-700R4

Figure 101 Lo and Reverse Piston

710 BRACKET, PARKING LOCK

71

1 PAWL, PARKING BRAKE

712 SHAFT, PARKING BRAKE PAWL

713 PLUG, STEEL CUP

714 SPRING, PARKING PAWL RETURN

715 BOLT, PARKING LOCK BRACKET

JH0088-700R4

Figure 102 Parking Pawl Installation

- stripped splines

- cracks

- teeth or lug damage

e Thrust bearing assemblies (683 and 692) for

damage

e Lo and reverse clutch plates (682)

- Composition for wear, heat damage, or

delamination

Page 1070 of 1825

AUTOMATIC TRANSMISSION 700-R4-19

- Steel for heat damage or surface finish

damage

Reaction carrier assembly (681) for

- pinion gear damage

- excessive pinion washer wear (end play -20-.

61 mm/.008-.024 in.)

- proper pinion staking

- keystoned pinion gears (pinions must turn

free)

- damaged or worn thrust bearing

To check the captive thrust bearing in the

carrier for wear, place a bushing or an

output shaft sleeve on the bearing race (do

not contact the pinion gears) and turn it

with the palm of your hand. Any

imperfections will be felt through the

bushing.

A PINION GEAR END PLAY -

.20/.60 MM (.008/.024 IN .)

Figure 103 Pinion End Play Check

Reaction Internal Gear and Support

lnstall or Connect (Figures 106)

1. Reaction gear support to case bearing (692) onto

the case hub as shown

- Outside bearing race goes toward case hub.

- retain with petrolatum.

2. Reaction internal gear and support (684 and 685)

onto the bearing as shown

3. Reaction carrier to support thrust bearing

assembly (683) onto the support (685)

- outer bearing race goes toward the support

4. Reaction carrier (681) onto the thrust bearing

Lo and Reverse Clutch

Measure (Figure 107 and 108)

TOOLS REQUIRED

e Scale and straight edge

1. To Measure for proper selection backing plate,

stack the lo and reverse assembly on a flat surface

in the following order:

o 1 waved plate (682B)

662

CARRIER ASSEMBLY, I NPU'T - COMPLETE

690 SLEEVE, OUTPUT SHAFT

JH0090-700R4

Figure 104 Captured Bearing Check

5 fiber and 4 steal plates (682), starting with

one fiber plate and alternating with a steal

plate.

Lo and Reverse Clutch Support (679)

2. Apply an evenly distributed load to the top of the

Lo and Reverse Support Assembly (679) Light

pressure (5 lbs.) on the Lo and Reverse Support

Assembly (679) will provide the correct

dimension for measurement.

CAUTION: EXCESSIVE PRESSURE

WILL START TO FLATTEN THE

WAVE PLATE RESULTING IN AN

INACCURATE MEASUREMENT

3. Measure

the height of the clutch pack from the

work surface to the top of the Lo and Reverse

Clutch Support (Dimension D)

4. Use dimension D to select the proper thickness of

the selective spacer plate for assembly.

5. Install the proper selective spacer plate between

the wave plate and the first fiber clutch plate with

the identification side up.

6. The

overall height for dimension D with the

selective spacer plate included should be 30.515

mm

- 31.401 mm (1.20" - 1.24).

Install or Connect (Figures 107, 108, 109 and 110)

5. Lo and reverse clutch plates (682) into case lugs

- start with a steel plate and alternate with

composition.

- index with the splines of the reaction carrier

and the case as shown.