PONTIAC FIERO 1988 Service Repair Manual

Manufacturer: PONTIAC, Model Year: 1988, Model line: FIERO, Model: PONTIAC FIERO 1988Pages: 1825, PDF Size: 99.44 MB

Page 1091 of 1825

700-W4-40 AUTOMATIC TRANSMISSION

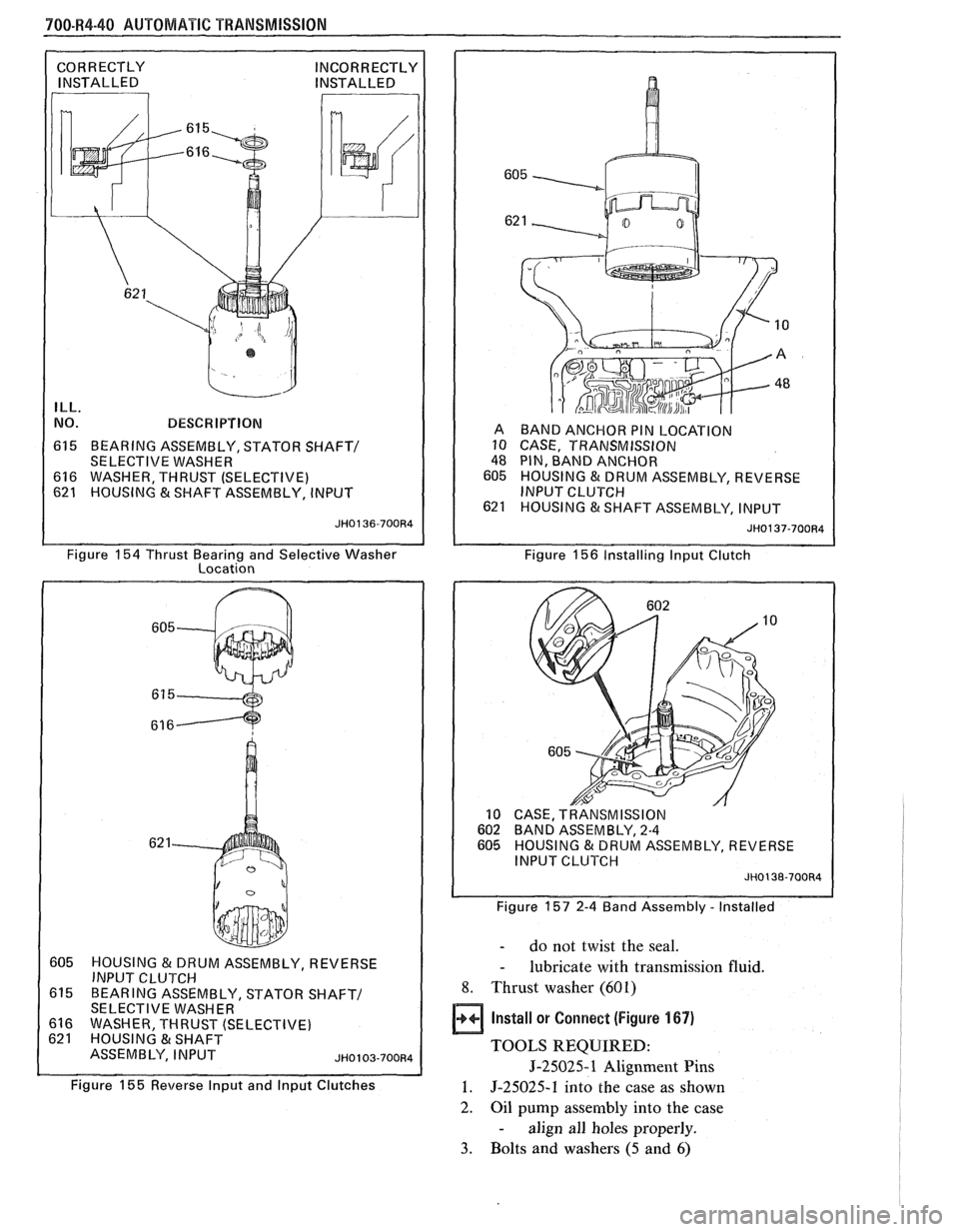

ILL.

NO. BESCW IPTIBN

615 BEARING ASSEMBLY, STATOR SHAFT/

SELECTIVE WASHER

616 WASHER, THRUST (SELECTIVE)

621 HOUSING & SHAFT ASSEMBLY, INPUT A

BAND ANCHOR PIN LOCATION

10 CASE, TRANSMISSION

48 PIN, BAND ANCHOR

605 HOUSING & DRUM ASSEMBLY, REVERSE

INPUT CLUTCH

621 HOUSING &SHAFT ASSEMBLY, INPUT

JH0137-700R4

Figure 154 Thrust Bearing and Selective Washer

Location Figure 156 Installirlg lnput

Clutch

605 HOUSING & DRUM ASSEMBLY, REVERSE I INPUT Cl-VTCH I

615 BEARING ASSEMBLY, STATOR SHAFT/ 1 SELECTIVE WASHER

616 WASHER THRUST (SELECTIVE)

Figure

155 Reverse lnput and lnput Clutches

CASE, TRANSMISSION BAND ASSEMBLY, 2-4

HOUSING & DRUM ASSEMBLY, REVERSE

I

INPUT CLUTCH JH0138-700R4 I

Figure 157 2-4 Band Assembly - Installed

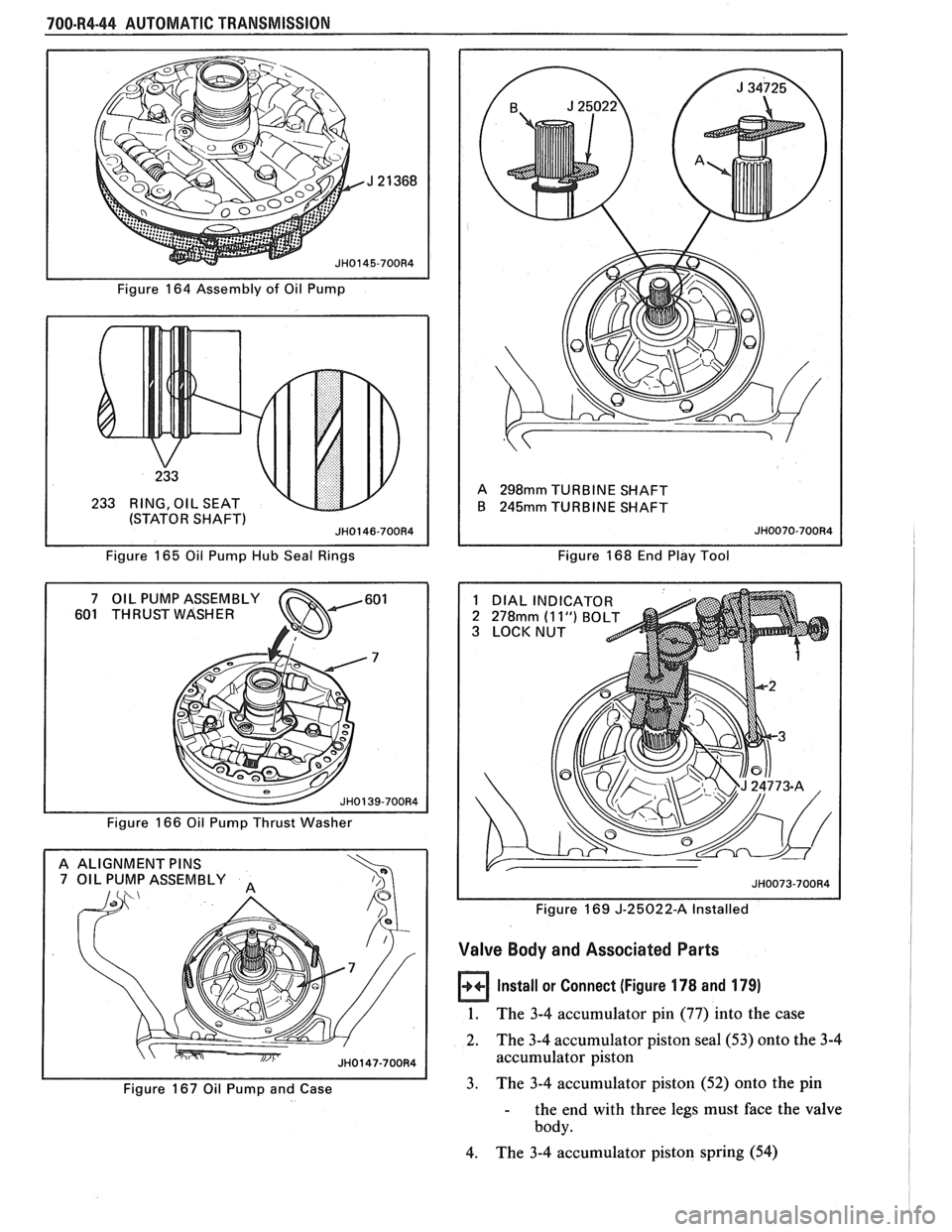

- do not twist the seal.

- lubricate with transmission fluid.

8. Thrust washer (601)

Install or Connect (Figure 167)

TOOLS REQUIRED:

5-25025-1 Alignment Pins

1. 5-25025-1 into the case as shown

2.

Oil pump assembly into the case

- align all holes properly.

3. Bolts and washers (5 and 6)

Page 1092 of 1825

AUTQMATIC TRANSMISSION 700-R4-41

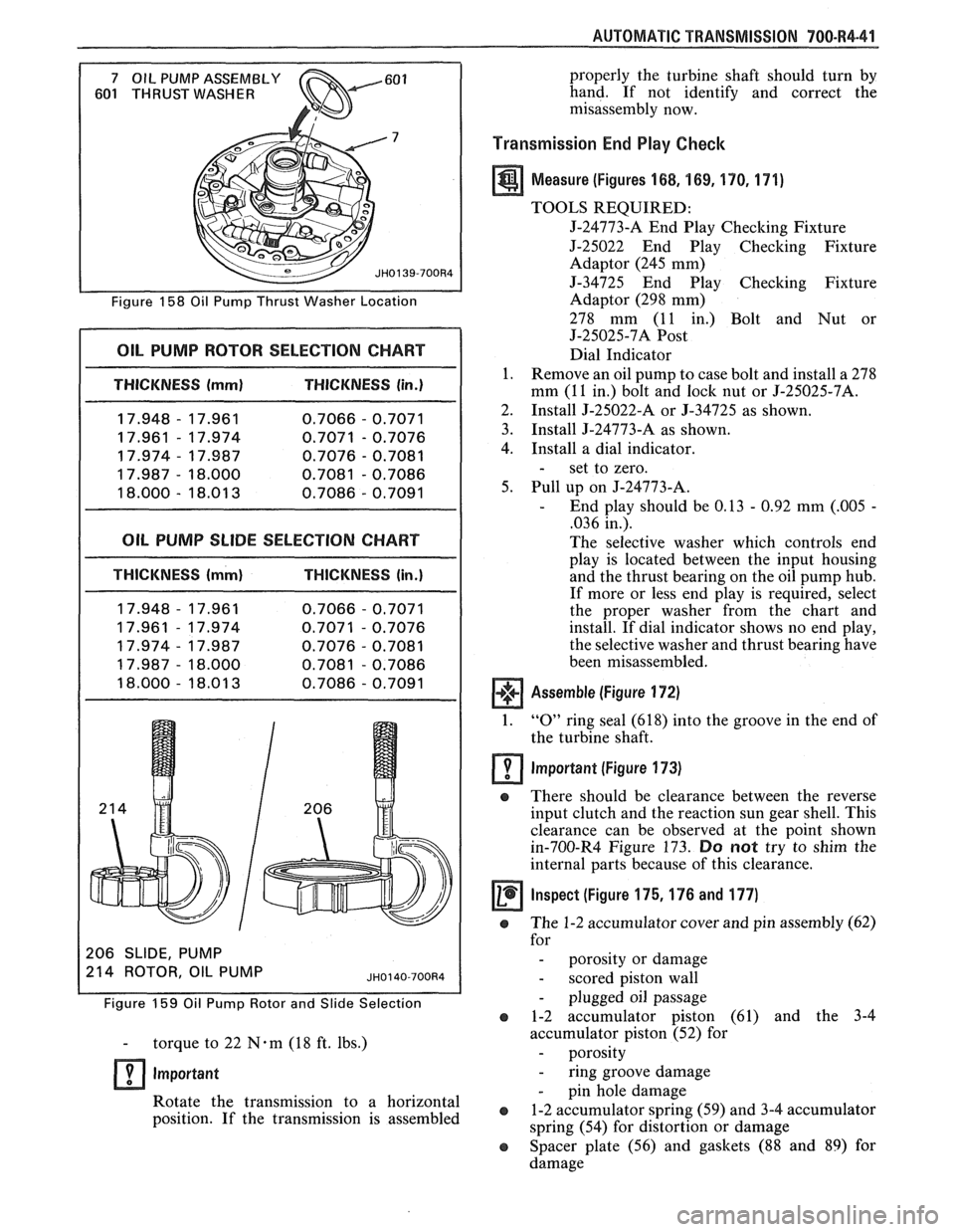

Figure 158 Oil Pump Thrust Washer Location

I OIL PUMP ROTOR SELECTION CHART I

I THICKNESS (mml THICKNESS (in.)

17.948 - 17.961

0.7066 - 0.7071

17.961

- 17.974 0.7071 - 0.7076

17.974

- 17.987 0.7076 - 0.7081

17.987

- 18.000 0.7081 - 0.7086

18.000

- 18.01 3 0.7086 - 0.7091

OIL PUMP SLlDE SELECTION CHART

THICKNESS (mm) THICKNESS (in.)

206 SLIDE, PUMP

214 ROTOR OIL PUMP

Figure 159 Oil Pump Rotor and Slide Selection

- torque to 22 N-m (18 ft. lbs.)

lmportant

Rotate the transmission to a horizontal

position. If the transmission is assembled properly

the turbine shaft should turn by

hand. If not identify and correct the

misassembly now.

Transmission End Play Checlc

a Measure (Figures 168, 169, 170. 171)

TOOLS REQUIRED:

5-24773-A End Play Checking Fixture

J-25022 End Play Checking Fixture

Adaptor (245 mm)

5-34725 End Play Checking Fixture

Adaptor (298 mm)

278 mm (11 in.) Bolt and Nut or

J-25025-7A

Post

Dial Indicator

1. Remove an oil pump to case bolt and install a 278

mm (11 in.) bolt and

lock nut or J-25025-7A.

2. Install 5-25022-A or

5-34725 as shown.

3. Install

J-24773-A as shown.

4. Install a dial indicator.

- set to zero.

5. Pull up on J-24773-A.

- End play should be 0.13 - 0.92 mm (.005 -

,036 in.).

The selective washer which controls end

play is located between the input housing

and the thrust bearing on the oil pump hub.

If more or less end play is required, select

the proper washer from the chart and

install. If dial indicator shows no end play,

the selective washer and thrust bearing have

been misassembled.

Assemble (Figure 172)

1. "0" ring seal (618) into the groove in the end of

the turbine shaft.

lmportant (Figure 173)

e There should be clearance between the reverse

input clutch and the reaction sun gear shell. This

clearance can be observed at the point shown

in-700-R4 Figure 173.

Do not try to shim the

internal parts because of this clearance.

Inspect (Figure 175,176 and 177) -

e The 1-2 accumulator cover and pin assembly (62)

for

- porosity or damage

- scored piston wall

- plugged oil passage

e 1-2 accumulator piston (61) and the 3-4

accumulator piston (52) for

- porosity

- ring groove damage

- pin hole damage

e 1-2 accumulator spring (59) and 3-4 accumulator

spring (54) for distortion or damage

e Spacer plate (56) and gaskets (88 and 89) for

damage

Page 1093 of 1825

700-R4-42 AUTOMATIC TRANSMISSION

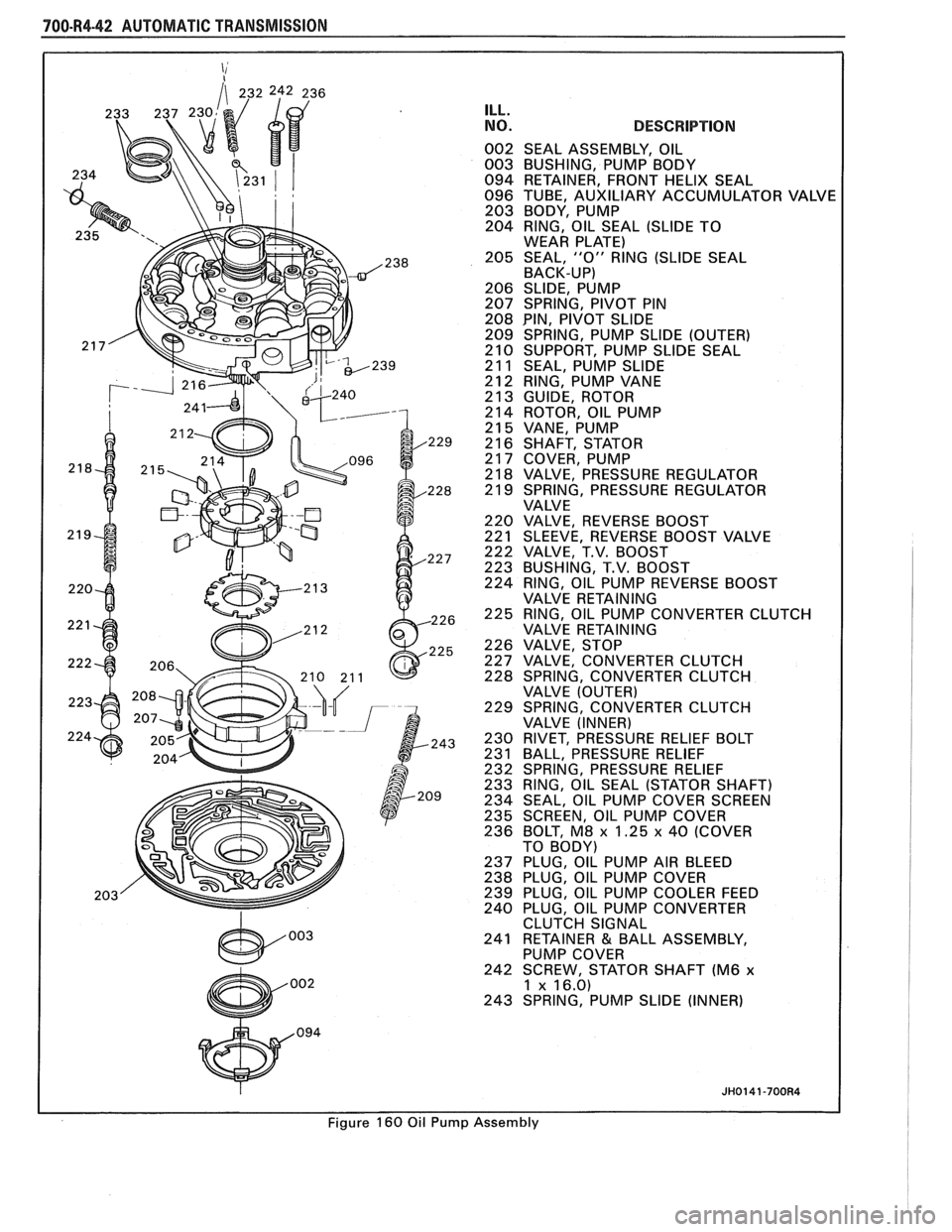

ILL.

NO.

Figure 160 Oil Puml

DESCRIPTION

SEAL ASSEMBLY, OIL

BUSHING, PUMP BODY

RETAINER, FRONT HELIX SEAL

TUBE, AUXILIARY ACCUMULATOR VAI

BODY, PUMP

RING, OIL SEAL (SLIDE TO

WEAR PLATE)

SEAL,

"0" RING (SLIDE SEAL

BACK-UP)

SLIDE, PUMP

SPRING, PIVOT PIN

PIN, PIVOT SLlDE

SPRING, PUMP SLlDE (OUTER)

SUPPORT, PUMP SLlDE SEAL

SEAL, PUMP SLlDE

RING, PUMP VANE

GUIDE, ROTOR

ROTOR, OIL PUMP

VANE, PUMP

SHAFT, STATOR

COVER, PUMP

VALVE, PRESSURE REGULATOR

SPRING, PRESSURE REGULATOR

VALVE

VALVE, REVERSE BOOST

SLEEVE, REVERSE BOOST VALVE

VALVE, T.V. BOOST

BUSHING, T.V. BOOST

RING, OIL PUMP REVERSE BOOST

VALVE RETAINING

RING, OIL PUMP CONVERTER CLUTCH

VALVE RETAINING

VALVE, STOP

VALVE. CONVERTER CLUTCH

SPRING,

CONVERTER CLUTCH

VALVE (OUTER)

SPRING, CONVERTER CLUTCH

VALVE (INNER)

RIVET, PRESSURE RELIEF BOLT

BALL, PRESSURE RELIEF

SPRING, PRESSURE RELIEF

RING, OIL SEAL (STATOR SHAFT)

SEAL, OIL PUMP COVER SCREEN

SCREEN, OIL PUMP COVER

BOLT,

M8 x 1.25 x 40 (COVER

TO BODY)

PLUG, OIL PUMP AIR BLEED

PLUG, OIL PUMP COVER

PLUG, OIL PUMP COOLER FEED

PLUG, OIL PUMP CONVERTER

CLUTCH SIGNAL

RETAINER

& BALL ASSEMBLY,

PUMP COVER

SCREW, STATOR SHAFT (M6

x 1 x 16.0)

SPRING, PUMP SLlDE (INNER)

Page 1094 of 1825

AUTOMATIC TRANSMISSION 700-R4-43

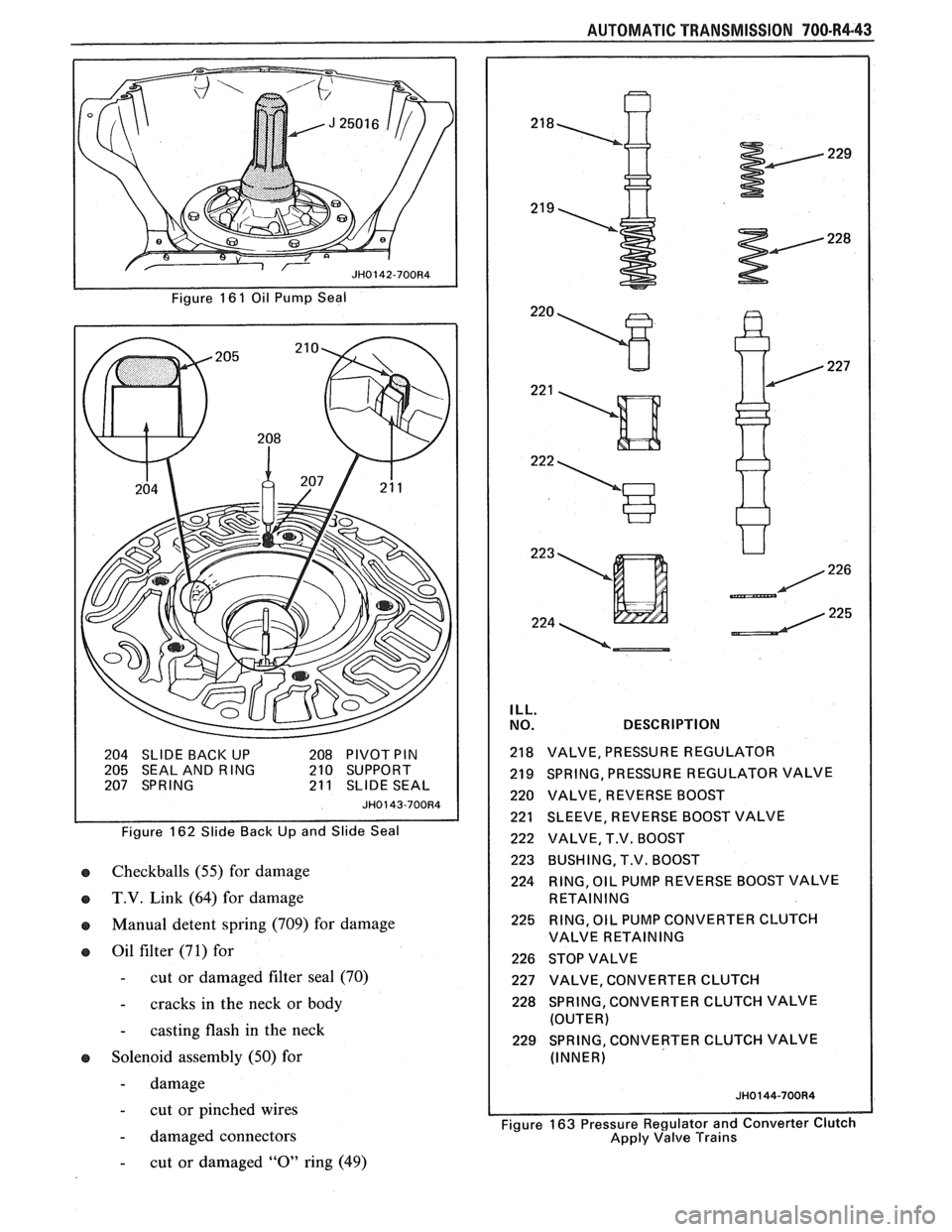

Figure 16 1 Oil Pump Seal

204 SLIDE

BACI< UP 208 PIVOT PIN 205 SEAL AND RING 210 SUPPORT

207 SPRING 21 1 SLIDE SEAL

JH0143-700R4

Figure 162 Slide Back Up and Slide Seal

o Checkballs (55) for damage

IB T.V. Link (64) for damage

IB Manual detent spring (709) for damage

o Oil filter (71) for

- cut or damaged filter seal (70)

- cracks in the neck or body

- casting flash in the neck

IB Solenoid assembly (50) for

- damage

- cut or pinched wires

- damaged connectors

ILL.

NO. DESCRIPTION

218 VALVE, PRESSURE REGULATOR

219 SPRING, PRESSURE REGULATOR VALVE

220 VALVE, REVERSE BOOST

221 SLEEVE, REVERSE BOOST VALVE

222 VALVE, T.V. BOOST

223 BUSHING, T.V. BOOST

224 RING,

OIL PUMP REVERSE BOOST VALVE

RETAINING

225 RING, OIL PUMP CONVERTER CLUTCH

VALVE RETAINING

226 STOP VALVE

227 VALVE, CONVERTER CLUTCH

228 SPRING, CONVERTER CLUTCH VALVE

(OUTER)

229 SPRING, CONVERTER CLUTCH VALVE

(INNER)

I Figure 163 Pressure Regulator and Converter Clutch

Apply Valve Trains

- cut or damaged "0" ring (49)

Page 1095 of 1825

700-R4-44 AUTOMATIC TRANSMISSION

Figure 164 Assembly of Oil Pump

233 RING, OIL SEAT

(STATOR SHAFT

Figure 165 Oil Pump Hub Seal Rings

601 THRUST WASHER

Figure 166 Oil Pump Thrust Washer

A ALIGNMENT

PINS 7 OIL PUMP ASSEMBLY

Figure 167 Oil Pump and Case A

298mm TURBINE

SHAFT

B

245mm TURBINE SHAFT

Figure 168 End Play Tool

1 DIAL INDICATOR

2

278mm (1 1") BO 3 LOCKNUT

Figure 169

J-25022-A Installed

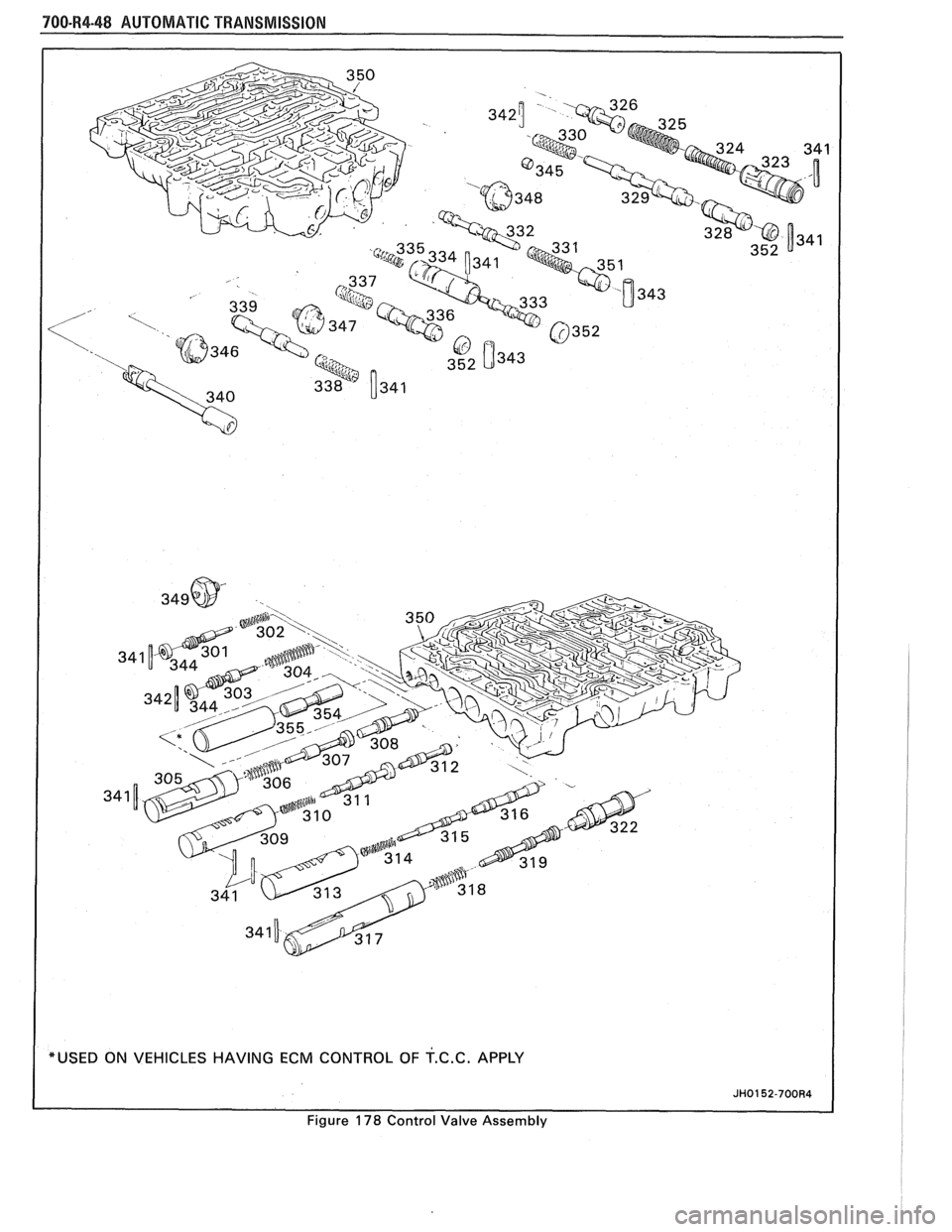

Valve Body and Associated Parts

Install or Connect (Figure 178 and 179)

1. The 3-4 accumulator pin (77) into the case

2. The

3-4 accumulator piston

sea1 (53) onto the 3-4

accumulator piston

3. The 3-4 accumulator piston (52) onto the pin

- the end with three legs must face the valve

body.

4. The 3-4 accumulator piston spring (54)

Page 1096 of 1825

AUTOMATIC TRANSMISSION 700-84-45

TRANSMISSION END PLAY

WASHER SELECTION

CI-IART

6 8

6 9

70

7 1

7 2

73

7 4

JH0148-700R4

Figure 170 End Play Chart

CORRECTLY INSTALLED INCORRECTLY

INSTALLED

,

ILL.

LY

NO. DESCRIPTION

615 BEARING ASSEMBLY, STATOR SHAFT/ SELECTIVE WASHER

616 WASHER, THRUST (SELECTIVE)

621 HOUSING & SHAFT ASSEMBLY, INPUT

Figure

17 1 Selective Washer and Thrust Bearing

Properly Installed

Install or Connect (Figures 177)

TOOLS REQUIRED:

J-25025-5 Guide Pins

1. Governor and converter clutch oil screens (47)

2. Four checkballs (55) into the case as shown

3. J-25025-5 into the case

4. Spacer plate to case gasket (88)

- gasket identified by a "C"

5. Spacer plate (56)

6.

Valve body to spacer plate gasket (89)

- gasket indentified by a "V"

USED WITH USED WITH 298 MM CONVERTER 245 MM CONVERTER

A SHAFT, TURBINE

618 SEAL,"O"RlNG(TURBINESHAFT/

SELECTIVE WASHER) 621 HOUSING & SHAFT

ASSEMBLY, INPUT

JH0109-700R4

Figure 172 Turbine Shaft "0" Ring Seal

A AS INSTALLED THESE TWO PARTS HAVE A

NORMAL END CLEARANCE OF APPROX.

3.8 MM

(.I50 IN) 10 CASE, TRANSMISSION 605 HOUSING & DRUM ASSEMBLY, REVERSE

INPUT CLUTCH

670 SHELL, REACTION SUN ~~0149-700~4

Figure 173 Clearance Between Reverse Input Clutch

and the Sun Gear Shell

Control Valve Assembly

Clean

- Control valve assembly (67) thoroughly in clean

solvent-move the valves with a pick or small

screwdriver to dislodge any dirt

br debris that

may have accumulated

e Air Dry

Disassemble (Figures 178 & 179)

e Control Valve Assembly

- Position as shown on a clean surface

- Remove valve trains beginning with the

upper left hand corner.

NOTE : Some

valves are under pressure

- cover the bores

while removing the roll pins

- Remove blind hole roll pins with a modified

drill bit

- Valves, springs and bushings must be laid

out on a clean surface in the exact sequence

they are removed

Page 1097 of 1825

700.R4.46 AUTOMATIC TRANSMISSION

64 THROTTLE LINK

65 LEVER & BRACKET

ASSEMBLY, THROTTLE

91 BALL, CARBON STEEL - T.V. EXHAUST

(LOCATED IN VALVE BODY)

Figure 174 Throttle Lever and Bracket Assembly

h

LARGE END

INSTALLED 59

IN PISTON

I ILL.

NO. DESCRIPTION

52 PISTON, 3-4 ACCUMULATOR

53 RING, OIL SEAL

(3-4 ACCUMULATOR PISTON)

54 SPRING, 3-4 ACCUMULATOR

56 PLATE, VALVE BODY SPACER

59 SPRING,

1-2 ACCUMULATOR (CONICAL) 60 RING, OIL SEAL (1-2 ACCUM. PISTON) 61 PISTON, 1-2 ACCUMULATOR

62 COVER & PIN ASSEMBLY, 1-2 ACCUM. 63 BOLT, ACCUMULATOR COVER 77 PIN, ACCUMULATOR PISTON

88 GASKET, SPACER PLATE TO CASE

89 GASKET, SPACER PLATE TO VALVE BODY

JH0063-700R4

Figure 175 1-2 and 3-4 Accumulator Assembly

PBM, PCM,TNM,TUM,TXM

FAM,FJM, FMM,MAM, MOM, MFM, MKM, MLM,MRM,MXM, 1 RED I RED THM,TJM,TKM,TLM,YKM,YNM

Figure 176 1-2 and 3-4 Accumulator Spring Chart

- Remove pressure switches

Clean

o All valves, springs, bushings and control valve

body in clean solvent

o Dry using compressed air

o All Valves and Bushings For:

- Porosity

- Scoring

- Nicks

- Scratches

e Springs for Damaged or Distorted Coils

e Valve Body Casting For:

- Porosity

- Cracks

- Interconnected Oil Passages

- Damaged Machined Surfaces

Assemble (Figures 178, 179)

e Control valve assembly (67) exactly as shown.

Notice the

positiori of the valve lands and bushing

passages.

Install or Connect (Figures 180, 182)

1. Two checkballs (55) and one checkball (9 1) into

the valve body assembly and one checkball (55

B)

into the Auxiliary Valve Body as shown.

Checkball (91) is the larger copper colored ball

shown as

# 10 on Figure 180.

- retain with petrolatum.

2. Valve body assembly (67)

- connect the manual valve link (705) to the

inside detent lever (703).

Page 1098 of 1825

AUTOMATIC TRANSMISSION 700-R4-47

Auxiliary Accumulator Valve Body Assembly

Clean (Figure 181)

e Auxiliary valve assembly (377) thoroughly in

clean solvent

- move the valves with a pick or small

screwdriver to dislodge any dirt or debris

that may have accumulated

e Air dry

+*+ Disassemble (Figure 181) m

1. (3) Bolts (373)

- Cover (371) is under spring pressure

2. Cover (371) and accumulator piston spring (370)

3. Piston (367)

4. Piston oil seal ring (53)

Disassemble (Figure 181)

e Position the auxiliary accumulator valve body on

a clean surface. Remove valve trains beginning

with the lower left hand corner. NOTE; valves

are under pressure-cover bores while removing

the roll pin.

e Valves and springs must be laid out on a clean

surface in the exact sequence as they are remvoed

Clean

a All valves and springs in clean solvent

e Air dry

Inspect

e Piston (367) for:

- cracks

- porosity

- damage

e Valves for:

- scoring

- nicks

- scratches

e Springs for damaged or distorted coils

a Auxiliary valve body (377) for:

- porosity

- damaged machined surfaces

e Orifice cup plug (359)

- remove only if damaged

Remove or Disconnect

Tools Required

#3 Screw Extractor

e Orifice cup plug (359). Use modified #3 screw

extractor.

Install or Connect

Tools Required

3/8" Rod

e Orifice cup plug (359). Use 3/8" rod.

- seat flush

Assemble (Figure 181)

e Auxiliary accumulator valve train exactly as

shown. Notice the valve lands

Assemble (Figure 181)

1. Piston oil seal ring (369) onto piston (367)

- lubricate with petrolatum

2. Piston (367)

3. Accumulator spring (370)

4. Cover

(371) and (3) bolts (373)

Install or Connect (Figures 181,184 and 185)

1. Check ball (55) into auxiliary accumulator valve

(377) - do not block orifice cup plug

- retain with petrolatum

2. Bolts (374-376) and auxiliary valve body (377)

- torque to 11 N-m (8 1bs.-ft.)

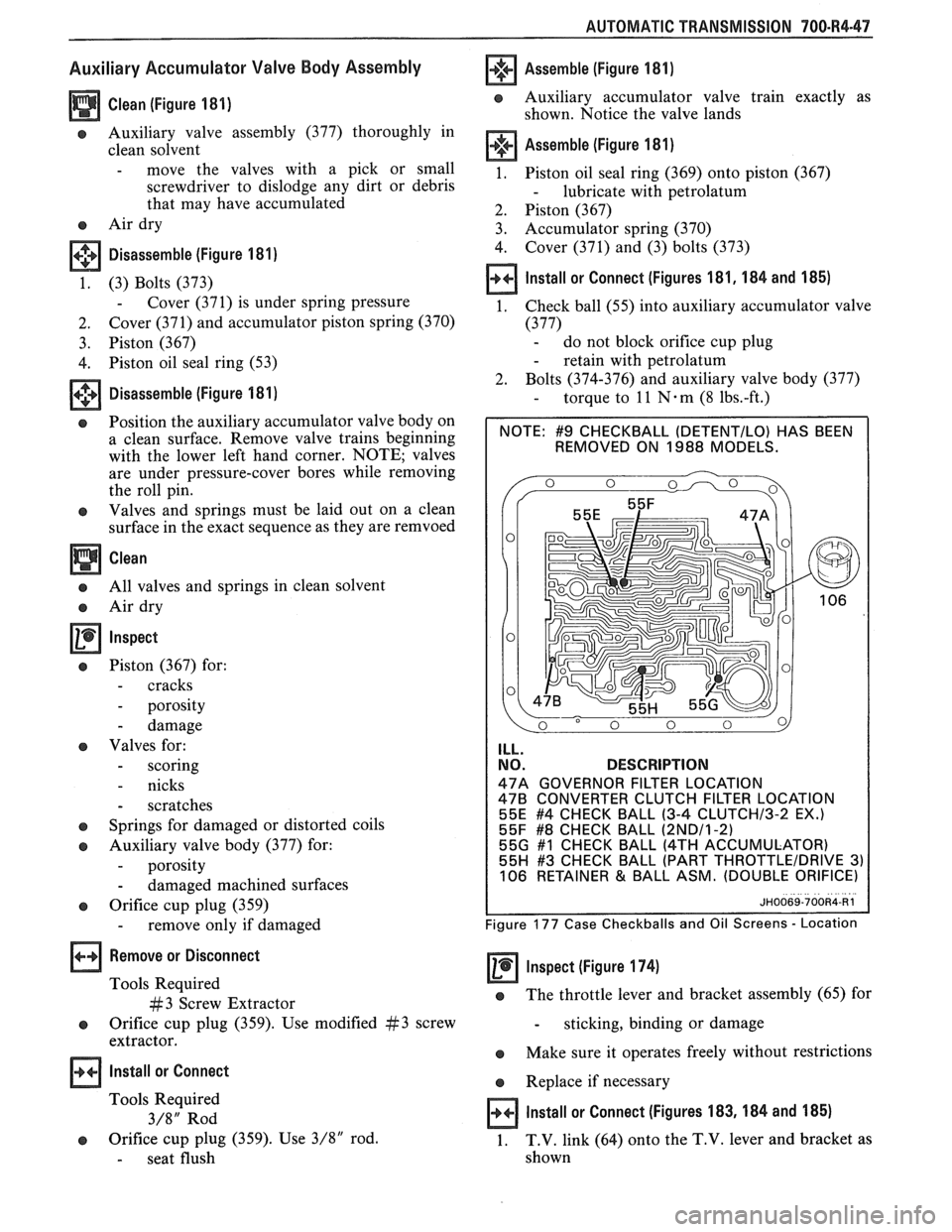

(DETENTILO) HAS BEEN

REMOVED ON 1988 MODELS.

ILL.

NO. DESCRIPTION

47A GOVERNOR FILTER LOCATION 478 CONVERTER CLUTCH FILTER LOCATION

55E #4 CHECK BALL (3-4 CLUTCHl3-2 EX.) 55F #8 CHECK BALL (2NDl1-2) 55G #I CHECK BALL (4TH ACCUMULATOR)

55H #3 CHECK BALL (PART THROTTLEIDRIVE 3) 106 RETAINER & BALL ASM. (DOUBLE ORIFICE)

Figure 177 Case Checkballs and Oil Screens - Location

Inspect (Figure 174) -

e The throttle lever and bracket assembly (65) for

- sticking, binding or damage

e Make sure it operates freely without restrictions

e Replace if necessary

Install or Connect (Figures 183,184 and 185)

1. T.V. link

(64) onto the T.V. lever and bracket as

shown

Page 1099 of 1825

Page 1100 of 1825

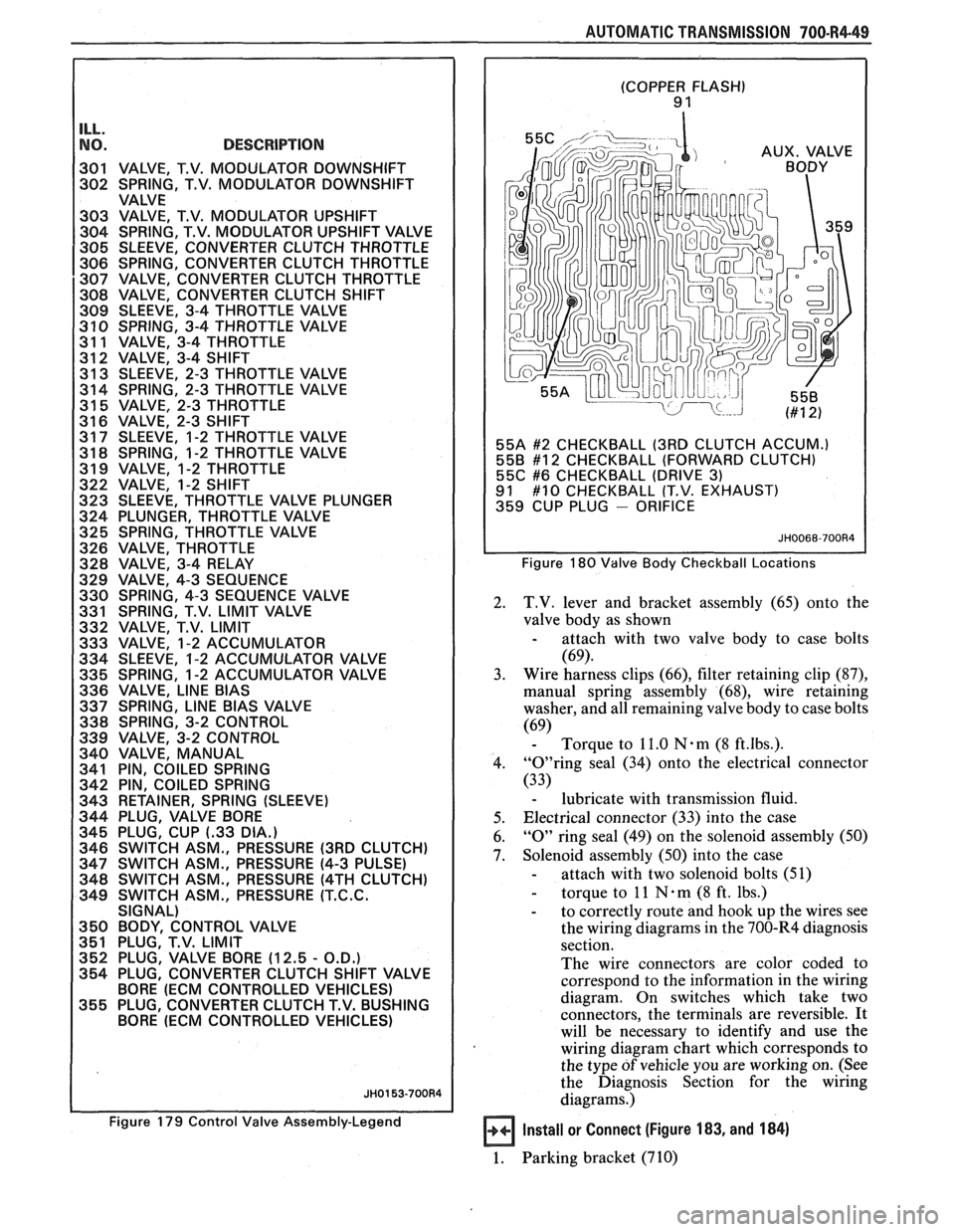

AUTOMATIC TRANSMISSION 700-R4-49

--

NO. DESCRIPTION I 301 VALVE, T.V. MODULATOR DOWNSHIFT

302 SPRING, T.V. MODULATOR DOWNSHIFT

VALVE

303 VALVE, T.V. MODULATOR UPSHIFT

304 SPRING, T.V. MODULATOR UPSHIFT VALVE

305 SLEEVE, CONVERTER CLUTCH THROTTLE

306 SPRING, CONVERTER CLUTCH THROTTLE

307 VALVE, CONVERTER CLUTCH THROTTLE

308 VALVE, CONVERTER CLUTCH SHlFT

309 SLEEVE, 3-4 THROTTLE VALVE

3 10 SPRING, 3-4 THROTTLE VALVE

31 1 VALVE, 3-4 THROTTLE

312 VALVE, 3-4 SHlFT

31 3 SLEEVE, 2-3 THROTTLE VALVE

314 SPRING, 2-3 THROTTLE VALVE

31

5 VALVE, 2-3 THROTTLE

31 6 VALVE, 2-3 SHlFT

31 7 SLEEVE, 1-2 THROTTLE VALVE

31

8 SPRING, 1-2 THROTTLE VALVE

31 9 VALVE, 1-2 THROTTLE

322 VALVE, 1-2 SHlFT

323 SLEEVE, THROTTLE VALVE PLUNGER

324 PLUNGER, THROTTLE VALVE

325 SPRING, THROTTLE VALVE

326 VALVE, THROTTLE

328 VALVE, 3-4 RELAY

329 VALVE, 4-3 SEQUENCE

330 SPRING, 4-3 SEQUENCE VALVE

331 SPRING, T.V.

LIMIT VALVE

332 VALVE, T.V.

LIMIT

333 VALVE, 1-2 ACCUMULATOR

334 SLEEVE, 1-2 ACCUMULATOR VALVE

335 SPRING, 1-2 ACCUMULATOR VALVE

336 VALVE,

LlNE BlAS

337 SPRING, LlNE BlAS VALVE

338 SPRING, 3-2 CONTROL

339 VALVE, 3-2 CONTROL

340 VALVE, MANUAL

341 PIN, COILED SPRING

342 PIN, COILED SPRING

343 RETAINER, SPRING (SLEEVE)

344 PLUG, VALVE BORE

345 PLUG, CUP

(-33 DIA.)

346 SWITCH ASM., PRESSURE (3RD CLUTCH)

347 SWITCH ASM., PRESSURE (4-3 PULSE)

348 SWITCH ASM., PRESSURE

(4TH CLUTCH)

349 SWITCH ASM., PRESSURE

(T.C.C.

SIGNAL)

350 BODY, CONTROL VALVE

351 PLUG, T.V. LIMIT

352 PLUG, VALVE BORE (12.5

- O.D.)

354 PLUG, CONVERTER CLUTCH SHlFT VALVE

BORE

(ECM CONTROLLED VEHICLES)

355 PLUG, CONVERTER CLUTCH T.V. BUSHING

BORE

(ECM CONTROLLED VEHICLES)

Figure 179 Control Valve Assembly-Legend

(COPPER FLASH) 9 1

55A

#2 CHECKBALL (3RD CLUTCH ACCUM.)

558 #12 CHECKBALL (FORWARD CLUTCH)

55C #6 CHECKBALL (DRIVE 3) 91 #10 CHECKBALL (T.V. EXHAUST)

359 CUP PLUG - ORIFICE

Figure 180 Valve Body Checkball Locations

2. T.V. lever and bracket assembly (65) onto the

valve body as shown

- attach with two valve body to case bolts

(69).

3. Wire harness

clips (66), filter retaining clip (87),

manual spring assembly (68), wire retaining

washer, and all remaining valve body to case bolts

(69) - Torque to 11.0 Nam (8 ft.lbs.).

4. "0"ring seal (34) onto the electrical connector

(33)

- lubricate with transmission fluid.

5. Electrical connector

(33) into the case

6.

"0" ring seal (49) on the solenoid assembly (50)

7. Solenoid assembly (50) into the case

- attach with two solenoid bolts (51)

- torque to 11 N . m (8 ft. lbs.)

- to correctly route and hook up the wires see

the wiring diagrams in the 700-R4 diagnosis

section.

The wire connectors are color coded to

correspond to the information in the wiring

diagram. On switches which take two

connectors, the terminals are reversible.

It

will be necessary to identify and use the

wiring diagram chart which corresponds to

the type

of vehicle you are working on. (See

the Diagnosis Section for the wiring

diagrams.)

Install or Connect (Figure 183, and 184)

1. Parking bracket (710)