bulb PONTIAC FIERO 1988 Service User Guide

[x] Cancel search | Manufacturer: PONTIAC, Model Year: 1988, Model line: FIERO, Model: PONTIAC FIERO 1988Pages: 1825, PDF Size: 99.44 MB

Page 665 of 1825

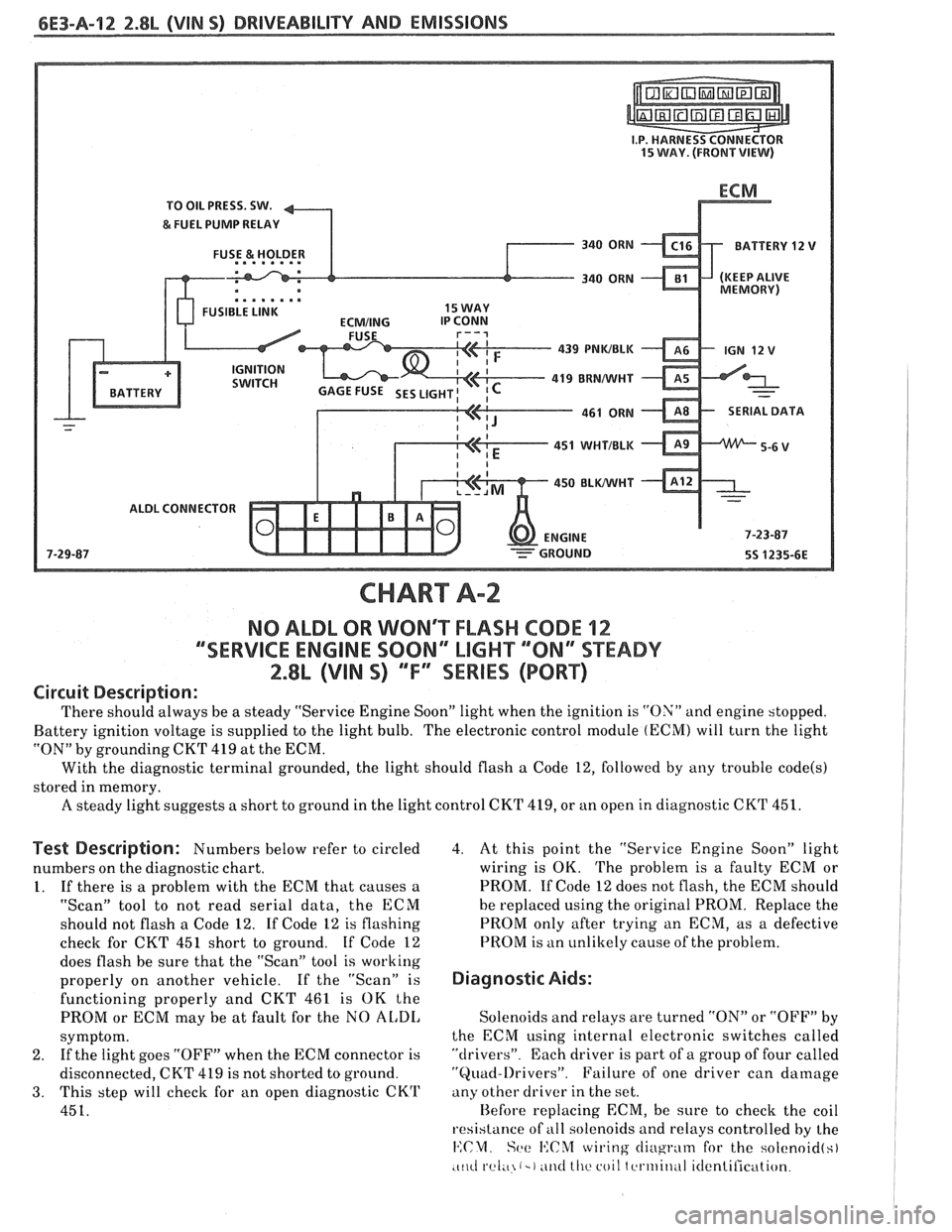

6E3-A-92 2.8b (VIN SI DRIVEABILITY AND EMISSIONS

TO OIL PRESS. SW.

&FUEL PUMP RELAY

FUSE

& HOLDER BATTERY 12

V

.. am.. . FUSIBLE LINK 15 WAY

439

PNWBLK

- 419 BUNNVHT

SERIAL DATA

451

WHTIBLK

450 BLWHT

ALDL CONNECTOR

CHART A-2

NO ALDL OR WONT FLASH CODE 12

""SERVICE ENGlNE SOON" MGHT ""8N13SPEADY

2.8L (VIN S) ""FYSERlES (PORT)

Circuit Description:

There should always be a steady "Service Engine Soon" light when the ignition is "ON" and engine stopped.

Battery ignition voltage is supplied to the light bulb. The electronic control module

(ECM) will turn the light

"ON" by grounding CKT

419 at the ECM.

With the diagnostic terminal grounded, the light should flash

a Code 12, followed by any trouble code(s)

stored in memory.

A steady light suggests a short to ground in the light control CKT 419, or an open in diagnostic CKT 451.

Test Description: Numbers below refer to circled

numbers on the diagnostic chart.

1. If there is a problem with the ECM that causes a

"Scan" tool to not read serial data, the ECM

should not flash a Code 12. If Code 12 is flashing

check for CKT

451 short to ground. If Code 12

does flash be sure that the "Scan" tool is working

properly on another vehicle. If the "Scan" is

functioning properly and CKT 461 is OK the

PROM or ECM may be at fault for the NO

AL,DI,

symptom.

2. If

the light goes "OFF" when the ECM connector is

disconnected, CKT 419 is not shorted to ground.

3. This step will check for an open diagnostic CKrl'

451.

4. At this point the "Service Engine Soon" light

wiring is OK. The problem is a faulty ECM or

PROM. If Code 12 does not flash, the ECM should

he replaced using the original PROM. Replace the

PROM only after trying an ECM, as a defective

PROM is an unlikely cause of the problem.

Diagnostic Aids:

Solenoids and relays are turned "ON" or "OFF" by

the ECM using internal electronic switches called

"drivers". Each driver is part of a group of four called

"Quad-l)rivers". Failure of one driver can damage

any other driver in the set.

Hefore replacing ECM, be sure to check the coil

resistance of

all solenoids and relays controlled by the

14:CM. Set: I':C%f wiring cliugrntn for the solcnoid(s)

.c~~cl rel;~ (-1 ~ititl lllc coil tcrtriitlul itlentilication.

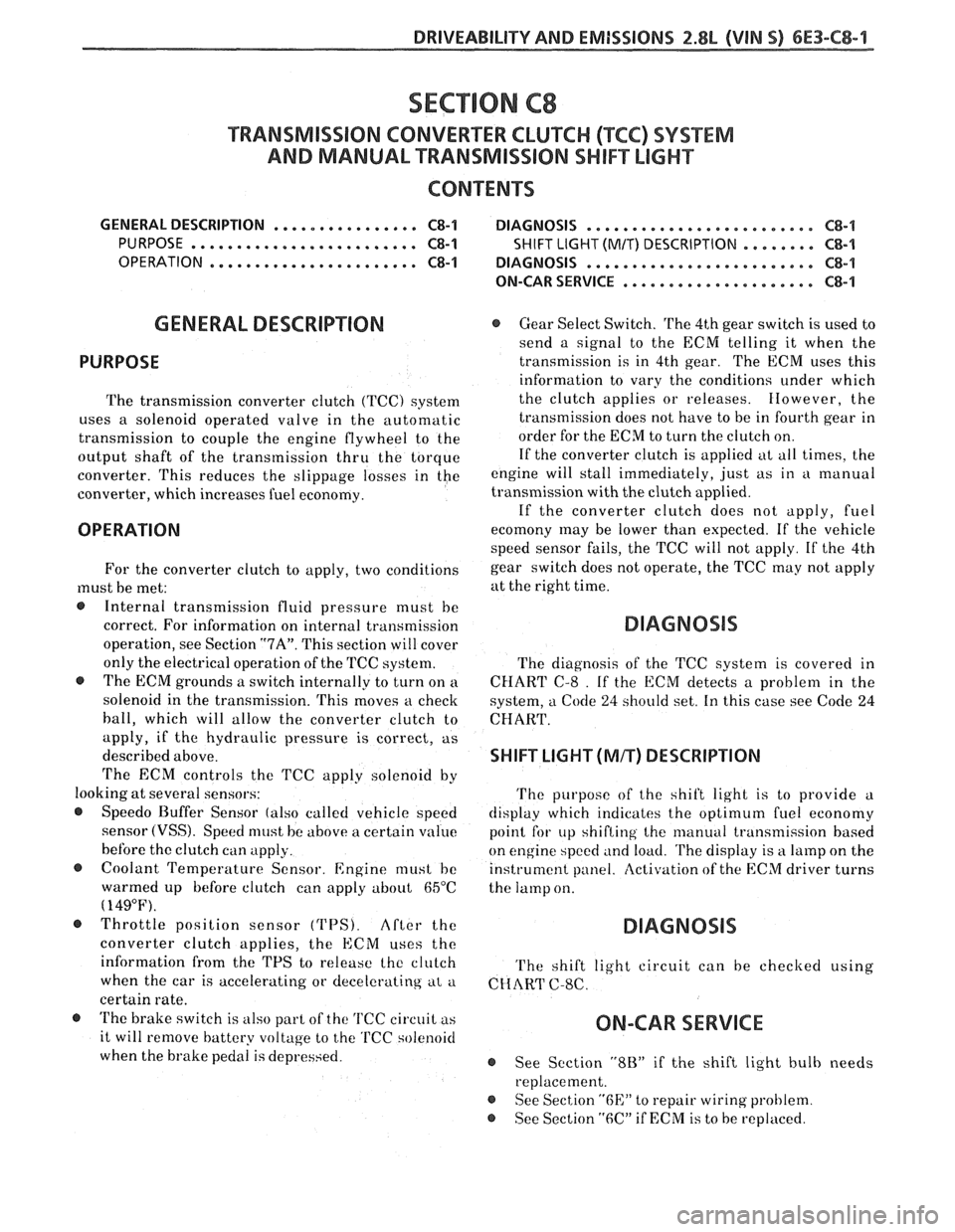

Page 786 of 1825

DRIVEABILITY AND EMlSSlONS 2.8L (VIN %I 6E3-C8-1

TRANSMISSION CONVERTER CLUTCH (KC) SYSTEM

AND MANUAL

TRANSMISSION SHIFT LIGHT

CONTENTS

GENERAL DESCRIPTION ................ C8-1 DIAGNOSIS ..........ee...ee....e.e. C8-1

PURPOSE ......................... C8-1 SHIFT LIGHT (MIT) DESCRIPTION ........ C8-1

OPERATION ....................... C8-1 DIAGNOSIS ....................... .. C8-1

ON-CAR SERVICE ...................*. C8-1

GENERAL DESCRIPTION

PURPOSE

The transmission converter clutch (TCC) svstem

uses a solenoid operated valve in the automatic

transmission to couple the engine flywheel to the

output shaft of the transmission thru the torque

converter. This reduces the slippage losses in the

converter, which increases fuel economy.

OPERATION

For the converter clutch to apply, two conditions

must be met:

o Internal transmission fluid pressure must be

correct. For information on internal transmission

operation, see Section

"7A". This section will cover

only the electrical operation of the TCC system.

@ The ECM grounds a switch internally to turn on a

solenoid in the transmission. This moves a check

ball, which will allow the converter clutch to

apply, if the hydraulic pressure is correct, as

described above.

The ECM controls the TCC apply solenoid by

looking at several sensors:

@ Speedo Buffer Sensor (also called vehicle speed

sensor

(VSS). Speed must be above a certain value

before the clutch can apply.

@ Coolant Temperature Sensor. Engine must be

warmed up before clutch can apply about

65OC

(149°F').

Throttle position sensor ('I'PS). After the

converter clutch applies, the

HCM uses the

information from the TPS to release thc clutch

when the car is accelerating or decelerating at a

certain rate.

@ 'I'he brake switch is also part of the 'I'CC circuit as

it will remove battery voltage to the 'KC solenoid

when the brake pedal is depressed.

@ Gear Select Switch. The 4th gear switch is used to

send a signal to the

ECM telling it when the

transmission is in 4th gear. The ECM uses this

information to vary the conditions under which

the clutch applies or releases.

IIowever, the

transmission does not have to be in fourth gear in

order for the ECM to turn the clutch on.

If the converter clutch is applied at all times. the

engine will stall immediately, just as in

u manual

transmission with the clutch applied.

If the converter clutch does not apply, fuel

ecomony

may be lower than expected. If the vehicle

speed sensor fails, the TCC will not apply. If the 4th

gear switch does not operate, the TCC may not apply

at the right time.

DIAGNOSIS

The diagnosis of the TCC system is covered in

CHART C-8

. If the ECM detects a problem in the

system,

a Code 24 should set. In this case see Code 24

CHART.

SHIFT LIGHT (MiT) DESCRIPTION

'The purpose of the shift light is to provide a

display which indicates the optimum fuel economy

point for up

shifling the manual transmission based

on engine speed

and load. 'I'he display is a lamp on the

instrument panel. Activation of the ECM driver turns

the lamp

on.

'I'he shift light circuit can he checlted using

CHAR?' C-8C.

ON-CAR SERVICE

@ See Section "8B" if the shift light bulb needs

replacement.

@ See Section "6E" to repair wiring problem.

@ See Section "6C" if ECM is to be replaced.

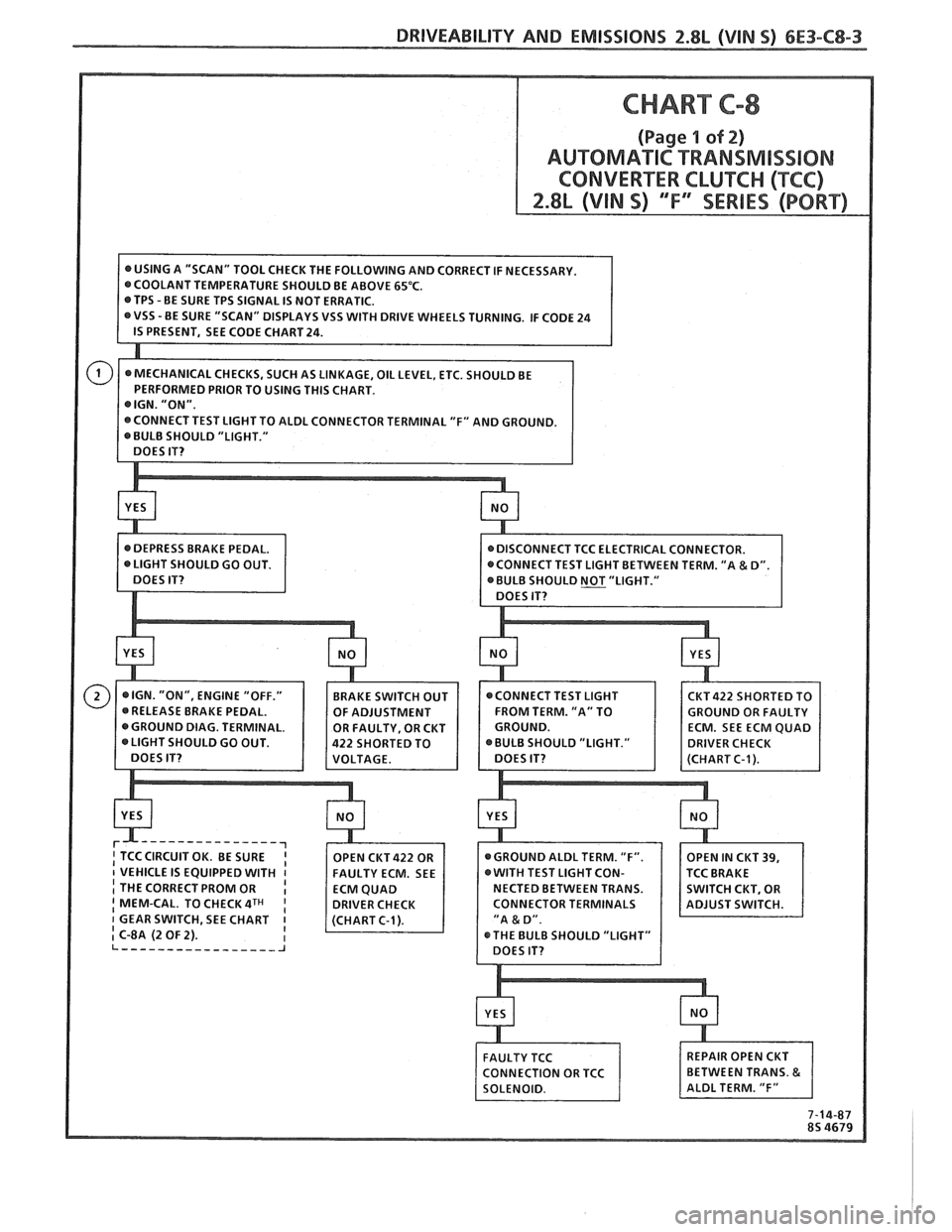

Page 788 of 1825

CHART C-8

(Page 1 of 2)

AUTOMATIC TRANSMlSS18N

CONVERTER CLUKC (("FCC)

VSS WITH DRIVE WHEELS TURNING. IF CODE 24

BULB SHOULD "LIGHT."

CKT422 SHORTED TO

FROM TERM. "A" TO

OULD GO OUT.

-------------

I THE CORRECT PROM OR I I MEM-CAL. TO CHECK 4TH CONNECTOR TERMINALS

1 GEAR SWITCH, SEE CHART

I C-8A (2 OF 2).

7-14-87

8s 4679

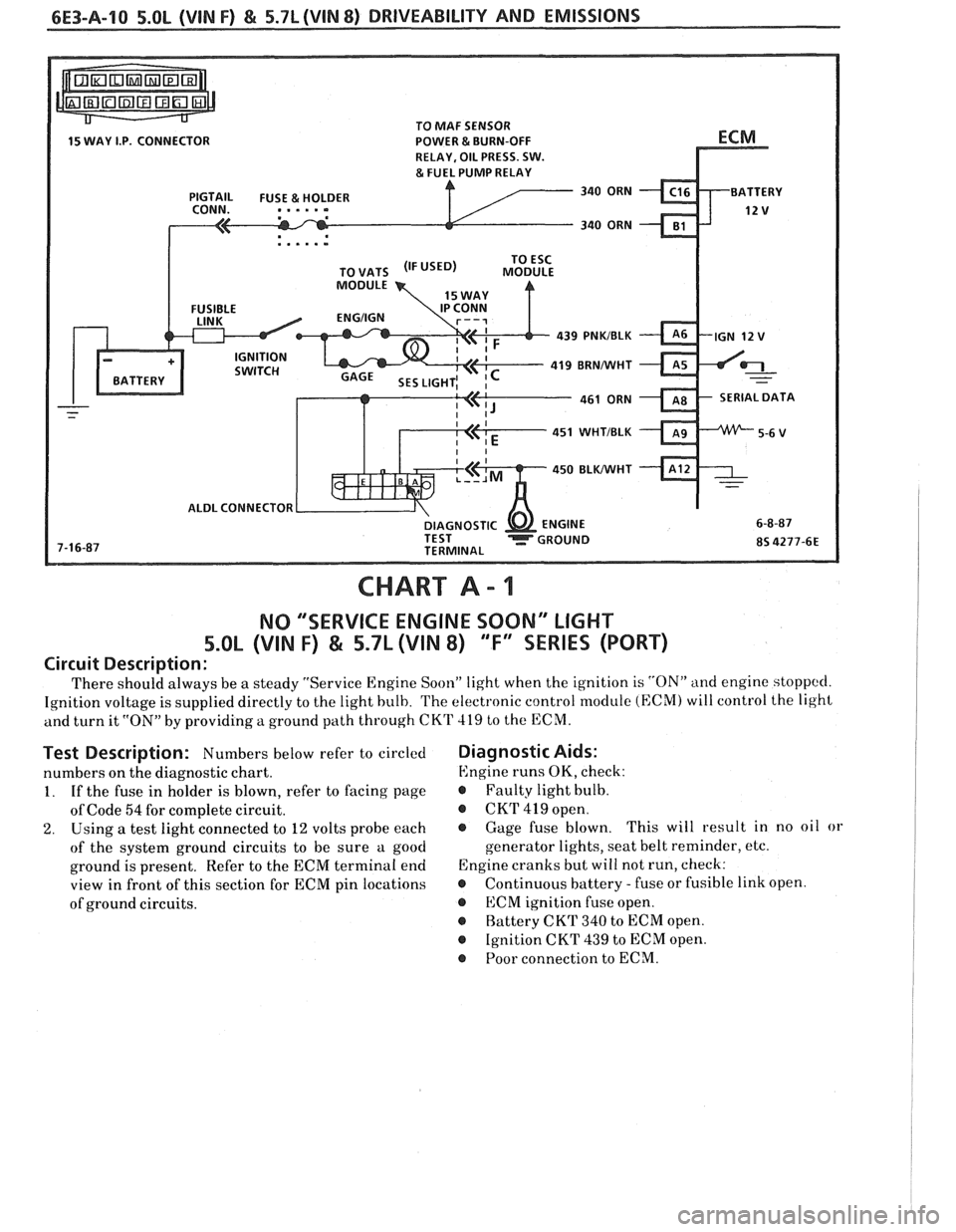

Page 813 of 1825

TO MAF SENSOR

POWER & BURN-OFF

RELAY, OIL PRESS. SW.

.....-

439 PNKIBLK

419 BRNNVHT

SERIAL DATA

451 WHTIBLK

450

BLWHT

ALDL CONNECTOR

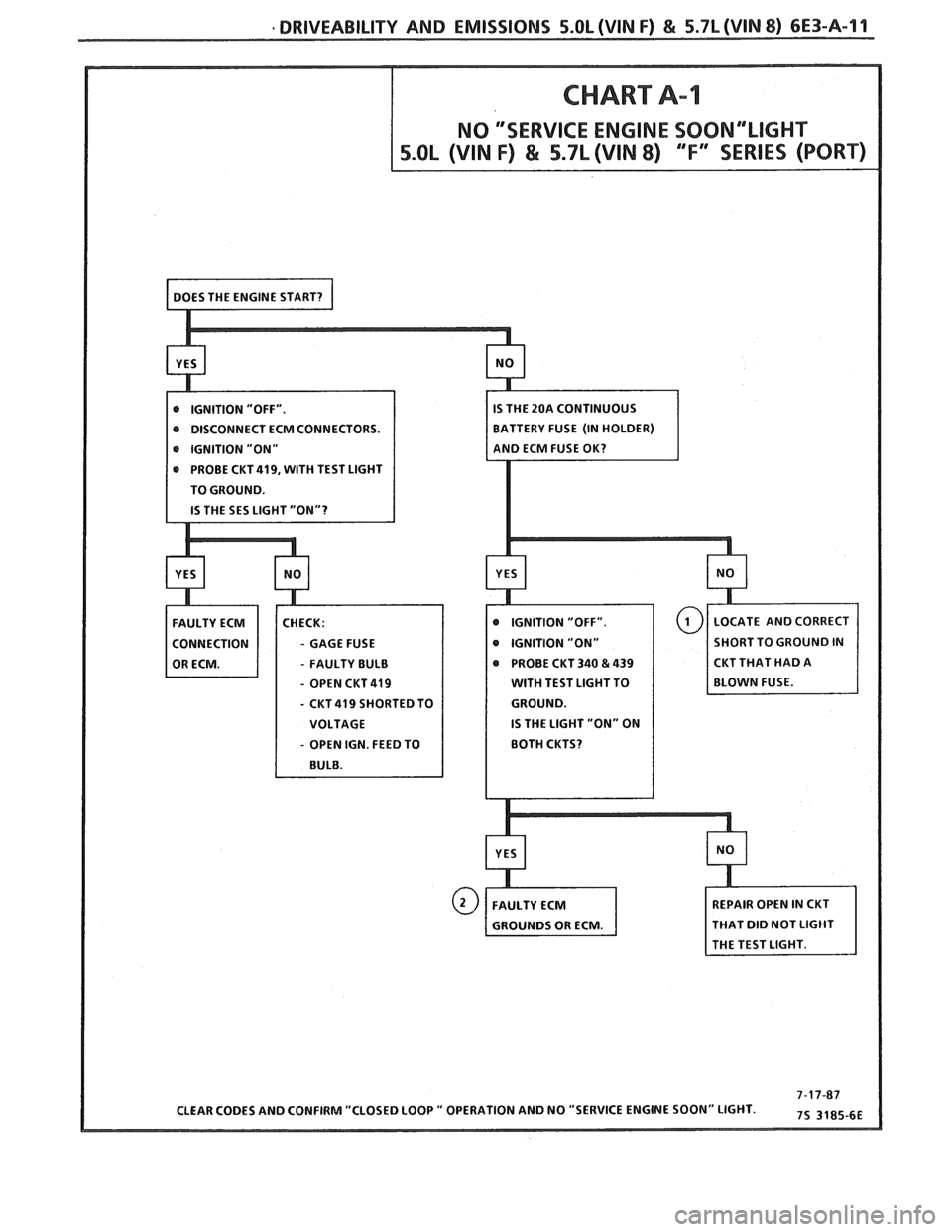

CHART A - 1

NO "'SERVICE ENGINE SOON" LIGHT

5.OL (VIN F) & 5.7L (VIN 8) "F'XSEBIE'S (PORT)

Circuit Description:

There should always be a steady "Service Engine Soon" light when the ignition is "ON" and engine stoppccl.

Ignition voltage is supplied directly to the light bulb. The electronic control module (ECM) will control the light

and turn it

"ON" by providing a ground path through CKT 419 to the ECM.

Test Description: Numbers below refer to circled

numbers on the diagnostic chart.

1. If the fuse in holder is blown, refer to facing page

of Code

54 for complete circuit.

2. Using a test light connected to 12 volts probe each

of the system ground circuits to be sure a good

ground is present. Refer to the ECM terminal end

view in front of this section for ECM pin locations

of ground circuits.

Diagnostic Aids:

Engine runs OK, check:

r Faulty light bulb.

@ CKrI' 419 open.

@ Gage fuse blown. This

will result in no oil or

generator lights, seat belt reminder, etc.

Engine cranks but will not run, check:

r Continuous battery - fuse or fusible link open.

@ ECM ignition fuse open.

r Battery CKT 340 to ECM open.

@ Ignition CKT 439 to ECM open.

@ Poor connection to ECM.

Page 814 of 1825

DRIVEABILITY AND EMISSIONS 5.0L (VIN F) & 5.7L (WIN 8) 6E3-A-11

@ DISCONNECT ECM CONNECTORS.

e IGNITION "ON"

PROBE

CKT419, WITH TEST LIGHT

TO GROUND.

- GAGE FUSE

- FAULTY BULB PROBE

CKT 340 & 439 CKT

THAT HAD A

- OPEN CKT 419 WITH TEST LIGHT TO

- CKT 419 SHORTED TO

IS THE LIGHT "ON" ON

- OPEN IGN. FEED TO

HAT DID NOT LIGHT

Page 815 of 1825

6E3-A-12 5.OL (VIN F) & 5.7L (VIN 8) DRIVEABILITY AND EMISSIONS

TO MAF SENSOR

POWER & BURN-OFF

, . . . . .

439 PNWBLK

419 BRNNVHT

SERIAL DATA

451

WHTIBLK

450 BLKIWHT

ALDL CONNECTOR

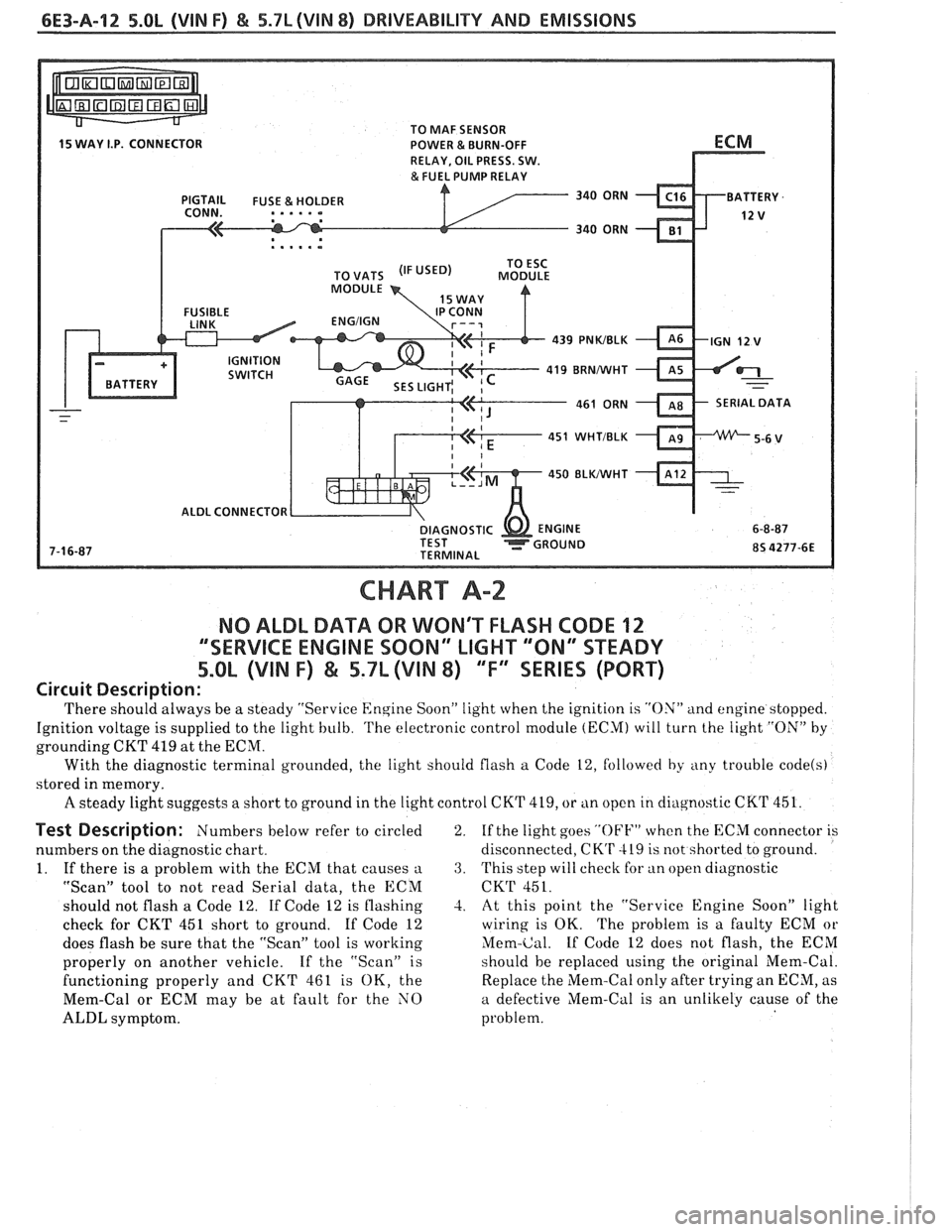

CHART A-2

NO ALDL DATA OR WON'T FLASH CODE 12

""SERVICE ENGINE SOON" LIGHT '"ON" STEADY

5.OL (VIN F) & 5.7L (VIN 8) ""FYEERIES (PORT)

Circuit Description:

'I'here should always be a steady "Service Engine Soon" light when the ignition is "ON" and engine stopped.

Ignition voltage is supplied to the light bulb.

'I'he electronic control module (ECM) will turn the light "ON" by

grounding CKT 419 at the ECM.

With the diagnostic terminal grounded, the light should flash

a Code 12, followed by any trouble code(s)

stored in memory.

A steady light suggests a short to ground in the light control CKT 419, or tin open in cliagnostic CKT 451.

Test Description: Numbers below refer to circled

numbers on the diagnostic chart.

1. If there is a problem with the ECM that causes

a

"Scan" tool to not read Serial data, the ECM

should not flash a Code 12. If Code 12 is flashing

check for CKT 451 short to ground. If Code 12

does flash be sure that the "Scan" tool is working

properly on another vehicle. If the "Scan" is

functioning properly and CKT 461 is OK, the

Mem-Cal or ECM may be at fault for the NO

ALDL symptom. 2.

If

the light goes

"OFF" when the ECM connector is

disconnected,

CK'r 419 is not shorted to ground.

3. This step will check for an open diagnostic

CKT 451.

-2. At this point the "Service Engine Soon" light

wiring is OK. The problem is a faulty ECM or

Mem-Cal. If Code 12 does not flash, the ECM

should be replaced using the original Mem-Cal.

Replace the Mem-Cal only after trying an ECM, as

a defective Mem-Cal is an unlikely cause of the

problem.

Page 942 of 1825

DWlVEABlLlTV AND EMISSIONS 5.01, QVIN F) & 5.71 (VIN 8) 6E3-C8-1

TRANSMISSION CONVERTER CLUTCH (KC) SYSTEM

AND MANUAL "TRANSMISSION SHlFT LBGH"O"=Ob ONLY

CONTENTS

................ GENERAL DESCRIPTION C8-1 DIAGNOSIS ....................... .. C8-1

........ PURPOSE ......................... CS-1 SHIFT LIGHT (MIT) DESCRIPTION C8-1

....................... OPERATION C8-1 DIAGNOSIS ......................... CS-1

OM-CAR SERVICE ..................... C8-1

GENERAL DESCRIPTION

PURPOSE

The transmission converter clutch (TCC) system

uses

a solenoid operated valve in the automatic

transmission to couple the engine flywheel to the

output shaft of the transmission thru the torque

converter. This reduces the slippage losses in the

converter, which increases fuel economy.

OPERATION

For the converter clutch to apply, two conditions

must be met:

e Internal transmission fluid pressure must be

correct. For information on internal transmission

operation, see Section

"7A". This section will

cover only the electrical operation of the TCC

system.

@ The ECM grounds a switch internally to turn

"ON" a solenoid in the transmission. This moves a

check ball, which will allow the converter clutch

to apply, if the hydraulic pressure is correct, as

described above.

The ECM controls the TCC apply solenoid by

looking at several sensors:

@ Speedo Buffer Sensor (also called Vehicle Speed

Sensor

(VSS) Speed must be above a certain value

before the clutch can apply.

@ Coolant Temperature Sensor Engine must be

warmed

LIP before clutch can apply about 65" C

(149°F).

Throttle Position Sensor (TPS) After the

converter clutch applies, the ECM uses the

information

from the TPS to release the clutch

when the car is accelerating or decelerating at

a

certain rate.

The brake switch

is also part of the 'I'CC circuit as

it will remove battery voltage to the

'FCC solenoid

when the brake pedal is depressed.

@ Gear Select Switch The 4th gear switch is used to

send a signal to the ECM telling it when the

transmission is in 4th

gear

The ECM uses this information to vary the conditions

under which the clutch applies or releases. However,

the transmission does not have to be in fourth gear in

order for the ECM to turn the clutch "ON".

If the converter clutch is applied at all times, the

engine will stall immediately, just as in a manual

transmission with the clutch applied.

If the converter

clutch does not apply, fuel

ecomony may be lower than expected. If the vehicle

speed sensor fails, the TCC will not apply. If the 4th

gear switch does not operate, the TCC may not apply

at the right time.

DIAGNOSIS

The diagnosis of the TCC system is covered in

CHART C-$A. If the ECM detects a problem in the

system, a Code 24 should set. In this case, see Code 24

CHART.

SHIFT LIGHT (MR) DESCRIPTION

The purpose of the shift light is to provide a

display which indicates the optimum fuel economy

point for up shifting the manual transmission based

on engine speed and load. The display is

a lamp on the

instrument panel. Activation

of the ECM driver turns

the lamp "ON".

DIAGNOSIS

The shift light circuit can be checked using

CEIAR'I' C-8B.

ON-CAR SERVICE

See Section "8B" if the shift light bulb needs

replacement.

See Section

"GE" to repair wiring problem.

@ See Section "C- 1" if ECM is to be replaced.

Page 965 of 1825

6E-4 DRIVEABILITY AND EMISSIONS - FUEL INJECnON

and ohms. You should understand what happens in a

circuit with an open or a shorted wire. You should be

able to read and understand a wiring diagram. A

short to ground

is referred to as a ground to

distinguish it from a short between wires.

Use of Circuit Testing Tools

You should know how to use a test light, how to

connect and use

a tachometer, and how to use jumper

wires to by-pass components to test circuits. Care

should be taken to not deform the terminal when

testing.

Use of Digital Volt-Ohm Meter (DVM)

You should be familiar with the digital volt-ohm

Meter, particularly essential tool J-29125-A,

J34029A

or equivalent. You should be able to measure voltage,

resistance, and current, and know how to use the

meter correctly.

The digital volt-ohm meter is covered in the

"Special

ToolsJ'portion of this section.

DIAGNOSTIC INFORMATION

The electronic control module (ECM) is equipped

with a self-diagnosis system which detects system

failure and aids the technician by identifying the

circuit at fault via a trouble code. Below is

information about the way the ECM displays a

problem and how this corresponds to a trouble code in

the ECM. The ECM can also indicate an "Open Loop"

or "Closed Loop" mode.

"'Service Engine Soonw Light

This light is on the instrument panel, and has two

functions:

@ It is used to tell the driver that a problem has

occurred, and that the vehicle should be taken for

service as soon as reasonably possible.

@ It is used by the technician to read out "Trouble

CodesJ' to help diagnose system problems.

As a bulb and system check, the light will come

"ON" with the key "ON" and the engine not running.

When the engine is started, the light will turn "OFF".

If the light remains "ONJ', the self-diagnostic system

has detected a problem. If the problem goes away, the

light will go out in most cases after 10 seconds, but a

Trouble Code will remain stored in the ECM.

Intermittent "Service Engine Soon" Light

The diagnostic charts in Section "A" are set up to

check whether or not a stored trouble code is

"intermittent" or "hard". An

"intermittent" code is one which does not

always reset when the code setting parameters are

met, or is not present while you are working on the

vehicle. This is often caused by

a loose connection.

The facing page will contain diagnostic aids to help in

detecting

intermittents.

A "hard" code is one which is present when you

are working on the vehicle and the condition still

exists while working on the vehicle. The chart with

the stored trouble code number will lead you to the

cause of the problem.

Trouble Codes

The engine control module (ECM) is really a

computer. It uses sensors to look at many engine

operating conditions. It has

a memory and it knows

what certain sensor readings should be under certain

conditions. These conditions are described on the

facing page of each Trouble Code chart. If a sensor

reading is not what the ECM thinks it should be, the

ECM will turn "ON" the "Service Engine Soon" light

on the instrument panel, and will store a Trouble Code

in the memory. The Trouble Code tells which circuit

the trouble is in. A circuit consists of a sensor (such as

coolant temperature), the wiring and connectors to it,

and the ECM.

i

To get a Trouble Code out of the ECM, we use the

assembly line diagnostic link (ALDL) connector.

!

ALDL Connector I

I

The assembly line diagnostic link (ALDL) is a

diagnostic connector located in the passenger

compartment (Figure 2). It has terminals which are

used in the assembly plant to check that the engine is

operating properly before it leaves the plant.

Terminal "B" is the Diagnostic terminal, and it can be

connected to terminal

"A", or ground, to enter the

Diagnostic mode, or the Field Service Mode.

The ALDL connector is also used by "ScanJ' tools to

read information from the ECM via the Serial Data

Line. Serial Data information

is used extensively

throughout the manual.

Diagnostic Mode

1

If the Diagnostic terminal is grounded with the

ignition "ON" and the engine stopped, the system will

enter the Diagnostic Mode. In this mode the ECM

will:

1. Display a Code 12 by flashing the "Service Engine

Soon" light (indicating the system is operating). A

Code 12 consists of one flash, followed by a short

pause, then two flashes in quick succession. This

code will be flashed three times. If no other codes

Page 1183 of 1825

TROUBLESHOOT1NG TOOLS

Electrical troubleshooting requires the use

of common electrical test equipment.

TEST LIGHTIVOLTMETER

Use a test light to check for voltage. A Test

Light (BT-7905 or equivalent) is made up of a

12-Volt light bulb with apair of leads attached.

After grounding one lead, touch the other lead

to various points along the circuit where volt-

age should be present. When the bulb goes on,

there is voltage at the point being tested.

A voltmeter can be used instead of a test

light. While a test light shows whether or not

voltage is present, a voltmeter indicates how

much voltage is present.

An increasing number of circuits include

solid state control modules. One example is the

Electronic Control Module

(ECM) used with

Computer Command Control and Electronic

Fuel Injection. Voltages in these circuits

should be tested only with a 10-megohm or

higher impedance digital voltmeter or multi-

meter (5-29125 or equivalent). Never use a test

light on circuits that contain solid state compo-

nents, since damage to these components may

result.

When testing for voltage or continuity at a

connection, you do not have to separate the

two halves of the connector. Unless you are

testing a "weather-pack" connector, you

should probe the connector from the back.

Always check both sides of the connector. An

accumulation of dirt and corrosion between

contact surfaces is sometimes a cause of elec-

trical problems.

CONNECTOR TEST ADAPTERS

A connector Adapter Kit is available

(535616) for making tests and measurements at

separated connectors. This kit contains an

assortment of probes which mate with many of

the types of connectors you will see. Avoid

using paper clips and other substitutes since

they can damage terminals and cause incorrect

measurements.

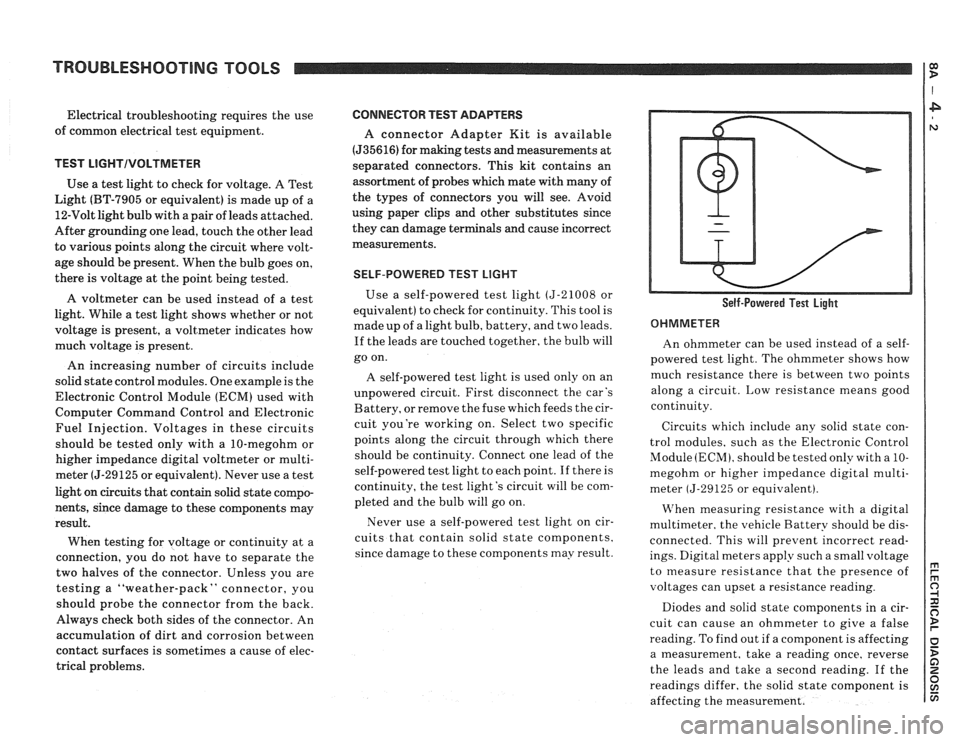

SELF-POWERED TEST LIGHT

Use a self-powered test light (5-21008 or

equivalent) to check for continuity. This tool is

made up of a light bulb, battery, and two leads.

If the leads are touched together, the bulb will

go on.

A self-powered test light is used only on an

unpowered circuit. First disconnect the car's

Battery, or remove the fuse which feeds the cir-

cuit you're working on. Select two specific

points along the circuit through which there

should be continuity. Connect one lead of the

self-powered test light to each point. If there is

continuity, the test light's circuit will be com-

pleted and the bulb will go on.

Never use a self-powered test light on cir-

cuits that contain solid state components,

since damage to these components may result. Self-Powered Test Light

OHMMETER

An ohmmeter can be used instead of a self-

powered test light. The ohmmeter shows how

much resistance there is between two points

along a circuit. Low resistance means good

continuity.

Circuits which include any solid state con-

trol modules, such as the Electronic Control

Module

(ECM), should be tested only with a 10-

megohm or higher impedance digital multi-

meter

(5-29125 or equivalent).

VIThen measuring resistance with a digital

multimeter. the vehicle Battery should be dis-

connected. This will prevent incorrect read-

ings. Digital meters apply such a small voltage

to measure resistance that the presence of

voltages can upset a resistance reading.

Diodes and solid state components in a cir-

cuit can cause an ohmmeter to give a false

reading. To find out if a component is affecting

a measurement, take a reading once, reverse

the leads and take a second reading.

If the

readings differ, the solid state component is

affecting the measurement.

Page 1209 of 1825

POWER DISTRIBUTION

CIRCUIT OPERATION

Electrical power for the car is provided by the

Generator when the engine is running. The

schematic diagram shows how each circuit gets

its power. For more details about the Gener-

ator, and connections to the Battery and

Starter, see Starter and Charging System, Sec-

tion

8A-30.

The car's Power Distribution System con-

sists of Fusible Links, Fuses, Circuit Breakers,

the Light Switch and the Ignition Switch. Fusi-

ble Links are short pieces of wire to which they

supply power. They are covered with a special

high-temperature insulation. When conducting

a high current, the Fusible Link will melt and

stop current flow. They are designed to protect

the car's electrical system from electrical

shorts where it is not protected by the Circuit

Breakers and Fuses. See Fuse Block Details

and Light Switch Details for complete wiring to

the first component in each circuit.

The Ignition Switch has six positions, five of

which have detents. The BULB TEST position

is after the RUN position and just before the

START position. BULB TEST does not have a

detent. As shown in the schematic, circuits

which are supplied from the Ignition Switch are

On (Hot) for different switch positions. Indi-

vidual schematics show their fuses supplied

from headings such as "Not In Run. "The head-

ing corresponds to the Ignition Switch position

in which power is On.