bulb PONTIAC FIERO 1988 Service Manual PDF

[x] Cancel search | Manufacturer: PONTIAC, Model Year: 1988, Model line: FIERO, Model: PONTIAC FIERO 1988Pages: 1825, PDF Size: 99.44 MB

Page 1612 of 1825

INSTRUMENT PANEL, GAGES & CONSOLE 8C-'I

SECTION 8C

NSTRUMENT PANEL, GAGES & CONSOLE

CONTENTS

General Description ................................... 8C-1

Instrument Panel and Gages ........................ 8C-1

Printed Circuit .......................................... 8C-1

Instruments ................................................... 8C- 1

Speed Sensors

............................ .. ............. 8C- 1

Pinion Gear

............................................. 8C-2

Photo Speed Sensor ................................ 8C-2

PM Generator ................... .. ...... ............... 8C-2

Speedometer ................................................ 8C-2

Mechanical ....................... .. .................... 8C-2

Quartz ........................ .. .......................... 8C-2

Digital .................... .. ...... ................. 8C-2

Fuel Gage .................................................... 8C-2

Temperature Warning Light ...................... 8C-3

Generator Warning Light ............................ 8C-3

Engine Oil Pressure Light ............................ 8C-3

"Service Engine Soon" Light ....................... 8C-3

Upshift Indicator Light .............................. 8C-3

Diagnosis .................... .. ........................... 8C-3

General Information .................................. 8C-3

Instrument Panel & Gages ...................... ..... 8C-3

On-Car Service ......................... .. ........... 8C-4

Instrument Panel Pad ................................... 8C-4

Instrument Panel Cluster ........................... 8C-4

Instrument Panel Carrier ............................. 8C-4

Headlight Switch .......................................... 8C-4

Console Mounted Switches and

Accessories

............................................... 8C-4

Console ......................................................... 8C-4

Speedometer .................................................. 8C-5

Illustra3ions ................................................. 8C-5

IP Pad ........................................................... 8C-5

IP Carrier ................................................... 8C-6

Instrument Cluster ....................................... 8C-6

Lower IP Covers ......................................... 8C-7

IP Trimplates ............................................... 8C-7

IP Hush Panels; with A/C .......................... 8C-8

..................... IP Lower Trim Pad (Console) 8C-8

Map Holder or Map Pocket ........................ 8C-8

IP Hush Panels; without A/C ..................... 8C-9

Radio Mounting ........................................... 8C-9

Subwoofer & Hatch Release

Switches/Covers ........................................ 8C- 10

Foglamp Switch/Cover ................................ 8C- 10

Oil Pressure and Temperature

Switches

..................................................... 8C-11

Heater/Ventilation/Defroster

Ductwork .................................................. 8C- 12

A/C and Defroster Ductwork ..................... 8C-13

Ram Vent System Ductwork ....................... 8C-14

Console Mounted Switches

&

Accessories ................................................. 8C- 14

Dash Insulators

............................................ 8C- 15

Heater Floor Outlet

..................................... 8C-15

................ Headlamp/Parking Lamp Switch 8C- 15

............. Dash Mounted Accessory Switches 8C- 15

GENERAL DESCRIPTION

INSTRUMENT PANEL AND GAGES

INSTRUMENTS

Instruments consist of fuel gage, temperature

The instrument panel on most cars is a sing,e unit indicator light, generator light, oil pressure indicator

design and all parts attach to the main instrument light, and speedometer. See Section 9F for optional

panel with clips and screws. To service the instrument Gages and tachometer. Service on instruments

panel and components see on-car service information, can be obtained through authorized repair stations.

However, knowledge of instrument circuit checks will

PRINTED CIRCUIT

All models are equipped with printed circuits

which supply current to most instrument panel lights

and instruments. These circuits are made of copper foil

which is die cut and bonded to a polyester base film

(usually mylar). The printed circuit electrical power is

supplied by a connector containing several wires, as

shown in the instrument panel wiring harness

installation instructions. The connector also helps

retain the printed circuit to the speedo cluster. The rest

of the circuit is retained by additional connectors (if

used) and snap-in

bulbs/sockets. For individual

printed circuit diagrams, see Section

8A-80/8 1/82/83,

'Instrument Panel'. help

in determining if operating difficulties lie in the

instrument itself or its related circuit.

Instruments have been designed for easy removal

by elimination of separate wiring. With the wiring

provisions integrated with the instrument panel wiring,

the instruments can be removed after removing the

trim and lens.

SPEED SENSORS

There are three speed sensors currently in use:

1. PINION GEAR; used in mechanical systems

2. PHOTO SPEED SENSORS; used in mechanical

systems

3. PM GENERATOR; used in electronic systems

Page 1614 of 1825

INSTRUMENT PANEL. GAGES & CONSOLE 8C-3

tank only when ignition switch is turned to "ON" or

"ACCESSORY" positions.

When ignition is turned to "OFF" or "START"

positions, the pointer may come to rest at any position.

The letters

"E" and "F" on the fuel gage are used to

point out direction of indicator travel only.

TEMPERATURE WARNING LIGHT

The engine temperature warning light is

controlled by a thermal switch which senses engine

coolant temperatures.

When the ignition switch is turned to "START"

position, a test circuit is closed and the light will come

on to indicate whether the light is functioning properly.

It is important to note that with low boiling-point

coolants (such as plain water) the temperature light

may not come on even though the coolant is boiling.

GENERATOR WARNING LIGHT

The generator warning light, located in the

instrument cluster, should come on when the ignition

switch is turned

"ON" and engine is not running. If

not, either the bulb is burned out or wiring to generator

has an open circuit.

When the generator voltage output becomes

greater than the battery voltage, the

"GEN" light

should go out. This does not, however, indicate

whether the battery is being charged or if the voltage

regulator is functioning properly.

Checks of the charging system are covered in

Section 6D, 'Engine Electrical'.

ENGINE OIL PRESSURE LIGHT

The engine oil pressure warning light is mounted

in the instrument cluster and controlled by a pressure

operated switch located on the engine block. When the ignition switch is

in the

"run" or "start9' position, the

oil pressure light should come on. If not, the bulb is

burned out, there is an open circuit between the bulb

and the oil pressure switch, or there is an open circuit

between the oil pressure switch and the choke heater.

After the engine is running, the oil pressure light

should go out when the oil pressure reaches the correct

specification. If not an oil pressure problem, a faulty oil

pressure switch or an open circuit from the choke

heater fuse to the oil pressure switch is indicated.

"SERVICE ENGINE SOON" LIGHT

All cars have a "SERVICE ENGINE SOON"

light mounted in the instrument cluster. The

"SERVICE ENGINE SOON9' light should come on

during engine starting. The light may stay on

a short

time after the engine starts.

If the light comes on while

driving, service to the emission control system may be

required. See Section

6E and Section 8A-80,

'Instrument Cluster', for complete diagnosis and

wiring diagrams of the

""P;RVICE ENGINE SOON"

light circuit.

UPSHIFT INDICATOR LIGHT

If your vehicle has a manual transmission, there

may be an

''Upshift" light on the instrument panel.

This light is illuminated to indicate optimum shift

points throughout the range from optimum fuel

economy to optimum performance. When this light is

on, shift your transmission to the next higher gear

range if conditions permit. For fuel economy,

accelerate slowly and shift when the light goes on. For

performance, accelerate as desired and shift when the

light goes on.

Safe operation of the vehicle may require shifting

differently than indicated by the "Upshift" light to

adapt to weather, road or traffic conditions.

Downshifting one or more gears may be required

to keep the engine running smoothly or to maintain

satisfactory performance.

DIAGNOSIS

Diagnostic information for all instrument panel

electrical systems is found in Section

8A-80,

'Instrument Panel'.

CAUTION: When removing or

installing any electrical units,

disconnect the negative battery cable

to prevent possible short circuits

which could lead to personal injury

and/or property damage. When

replacing a speedometer or

odometer assembly, the law requires the

odometer reading of the replacement unit to

be set to register the same mileage as the

prior odometer.

if the same mileage cannot be

set, the

law requires that the replacement

odometer be set to zero and a label be

installed on the driver's door frame to show

the previous odometer reading and the date

of replacement.

GENERAL BNFORMATlOM

INSTRUMENT PANEL AND GAGES

The instrument panel is a single unit design and

and screws. To service the instrument panel and

all parts attach to the main instrument panel with clips components see Figs. 601 through 610.

Page 1703 of 1825

2H-6 STATIONARY GLASS - F STYLE

all traces of factory installed adhesive must be

removed prior to reinstallation.

5. Wipe sanded mirror support with clean paper

towel saturated with alcohol and allow to dry.

6. Follow directions on manufacturer's kit to

prepare

rearview mirror support prior to

installation on glass.

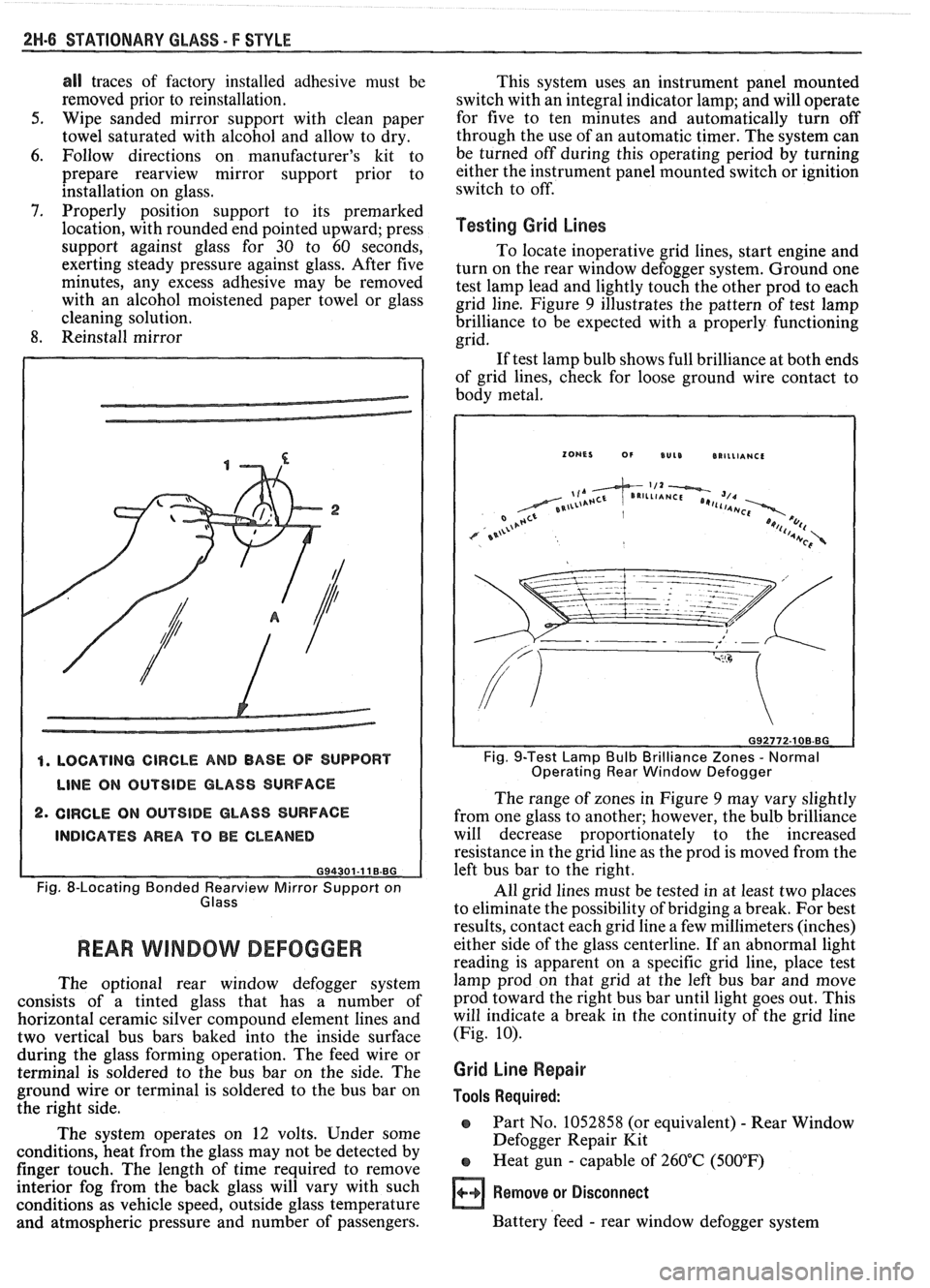

7. Properly position support to its premarked

location, with rounded end pointed upward; press

support against glass for 30 to 60 seconds,

exerting steady pressure against glass. After five

minutes, any excess adhesive may be removed

with an alcohol moistened paper towel or glass

cleaning solution.

8. Reinstall mirror

4. LOCATING CIRCLE AND BASE OF SUPPORT

LINE ON OUTSIDE GLASS SURFACE

2. CIRCLE ON OUTSIDE GLASS SURFACE

INDICATES AREA TO BE CLEANED

G94301-11 B.BG

Fig. 8-Locating Bonded earv view Mirror Support on

Glass

REAR WlMBOW DEFOGGER

The optional rear window defogger system

consists of a tinted glass that has a number of

horizontal ceramic silver compound element lines and

two vertical bus bars baked into the inside surface

during the glass forming operation. The feed wire or

terminal is soldered to the bus bar on the side. The

ground wire or terminal is soldered to the bus bar on

the right side.

The system operates on 12 volts. Under some

conditions, heat from the glass may not be detected by

finger touch. The length of time required to remove

interior fog from the back glass will vary with such

conditions as vehicle speed, outside glass temperature

and atmospheric pressure and number of passengers. This

system uses an instrument panel mounted

switch with an integral indicator lamp; and will operate

for five to ten minutes and automatically turn off

through the use of an automatic timer. The system can

be turned off during this operating period by turning

either the instrument panel mounted switch or ignition

switch to off.

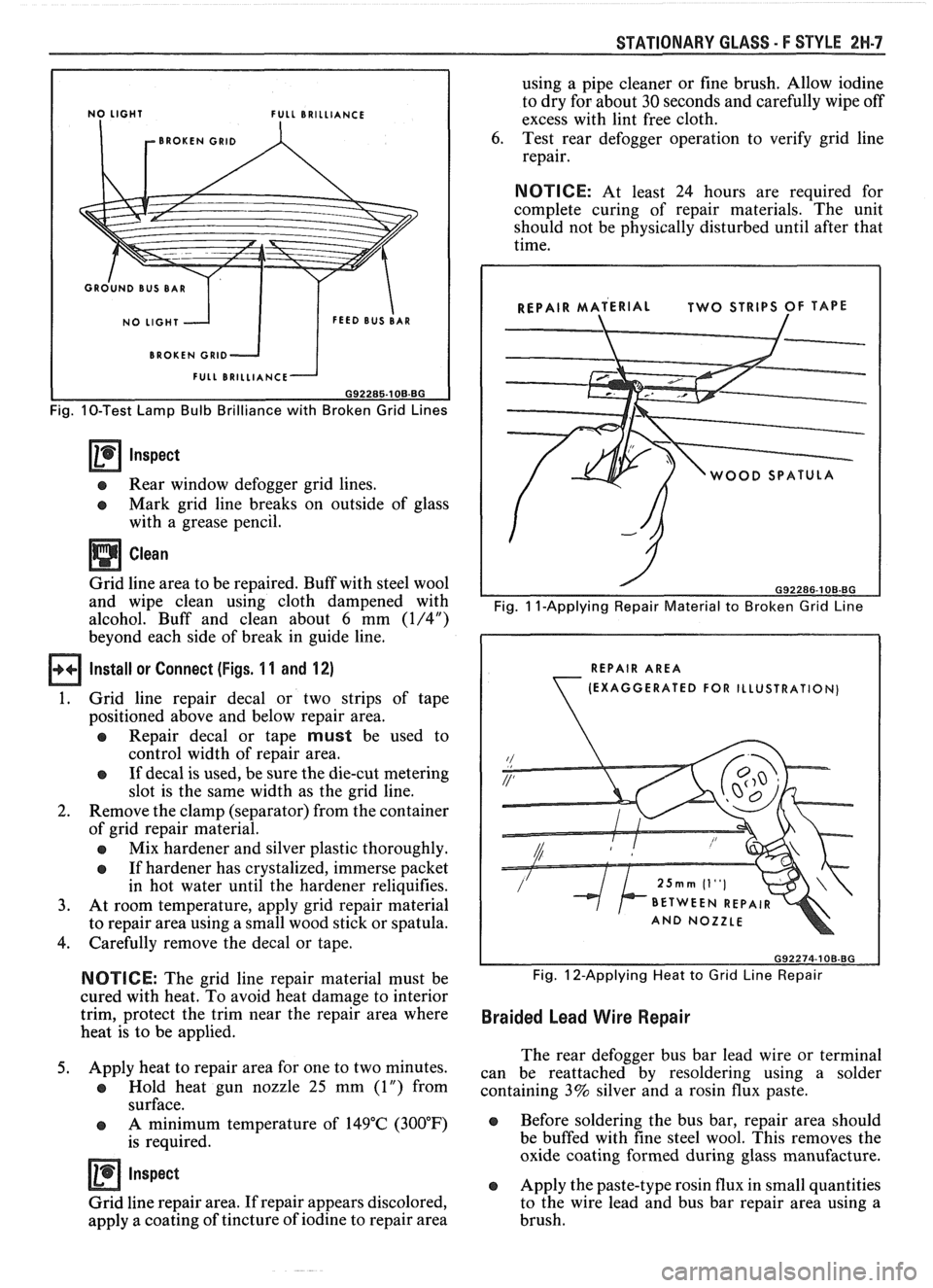

Testing Grid Lines

To locate inoperative grid lines, start engine and

turn on the rear window defogger system. Ground one

test lamp lead and lightly touch the other prod to each

grid line. Figure

9 illustrates the pattern of test lamp

brilliance to be expected with a properly functioning

grid.

If test lamp bulb shows full brilliance at both ends

of grid lines, check for loose ground wire contact to

body metal.

Fig. 9-Test Lamp Bulb Brilliance Zones - Normal

Operating Rear Window Defogger

The range of zones in Figure 9 may vary slightly

from one glass to another; however, the bulb brilliance

will decrease proportionately to the increased

resistance in the grid line as the prod is moved from the

left bus bar to the right.

All grid lines must be tested in at least two places

to eliminate the possibility of bridging a break. For best

results, contact each grid line a few millimeters (inches)

either side of the glass centerline. If an abnormal light

reading is apparent on a specific grid line, place test

lamp prod on that grid at the left bus bar and move

prod toward the right bus bar until light goes out. This

will indicate a break in the continuity of the grid line

(Fig.

10).

Grid Line Repair

Tools Required:

o Part No. 1052858 (or equivalent) - Rear Window

Defogger Repair Kit

e Heat gun - capable of 260°C (500°F)

Remove or Disconnect

Battery 'feed - rear window defogger system

Page 1704 of 1825

STATIONARY GLASS - F STYLE 2W.7

L BRILLIANCE

BROKEN

GRlD

BROKEN GRlD

Fig. 10-Test Lamp Bulb Brilliance with Broken Grid Lines

Inspect

e Rear window defogger grid lines.

e Mark grid line breaks on outside of glass

with a grease pencil.

Clean

Grid line area to be repaired. Buff with steel wool

and wipe clean using cloth dampened with

alcohol. Buff and clean about

6 mm (1/4")

beyond each side of break in guide line.

Install or Connect (Figs. 1 1 and 12)

1. Grid

line repair decal or two strips of tape

positioned above and below repair area.

a Repair decal or tape must be used to

control width of repair area.

e If decal is used, be sure the die-cut metering

slot is the same width as the grid line.

2. Remove the clamp (separator) from the container

of grid repair material.

a Mix hardener and silver plastic thoroughly.

e If hardener has crystalized, immerse packet

in hot water until the hardener reliquifies.

3. At room temperature, apply grid repair material

to repair area using a small wood stick or spatula.

4. Carefully remove the decal or tape.

NOTICE: The grid line repair material must be

cured with heat. To avoid heat damage to interior

trim, protect the trim near the repair area where

heat is to be applied.

5. Apply heat to repair area for one to two minutes.

a Hold heat gun nozzle 25 mm (1") from

surface.

e A minimum temperature of 149°C (300°F)

is required.

Inspect

Grid line repair area. If repair appears discolored,

apply a coating of tincture of iodine to repair area using

a pipe cleaner or fine brush. Allow iodine

to dry for about

30 seconds and carefully wipe off

excess with lint free cloth.

6. Test rear defogger operation to verify grid line

repair.

NOTICE: At least 24 hours are required for

complete curing of repair materials. The unit

should not be physically disturbed until after that

time.

WOOD SPATUL

Fig. 1 I-Applying Repair Material to Broken Grid Line

REPAIR AREA

(EXAGGERATED

FOR ILLUSTRATION)

Fig. 12-Applying Heat to Grid Line Repair

Braided Lead Wire Repair

The rear defogger bus bar lead wire or terminal

can be reattached by resoldering using a solder

containing 3% silver and a rosin flux paste.

e Before soldering the bus bar, repair area should

be buffed with fine steel wool. This removes the

oxide coating formed during glass manufacture.

e Apply the paste-type rosin flux in small quantities

to the wire lead and bus bar repair area using a

brush.

Page 1756 of 1825

REAR END - F STYLE 7W-13

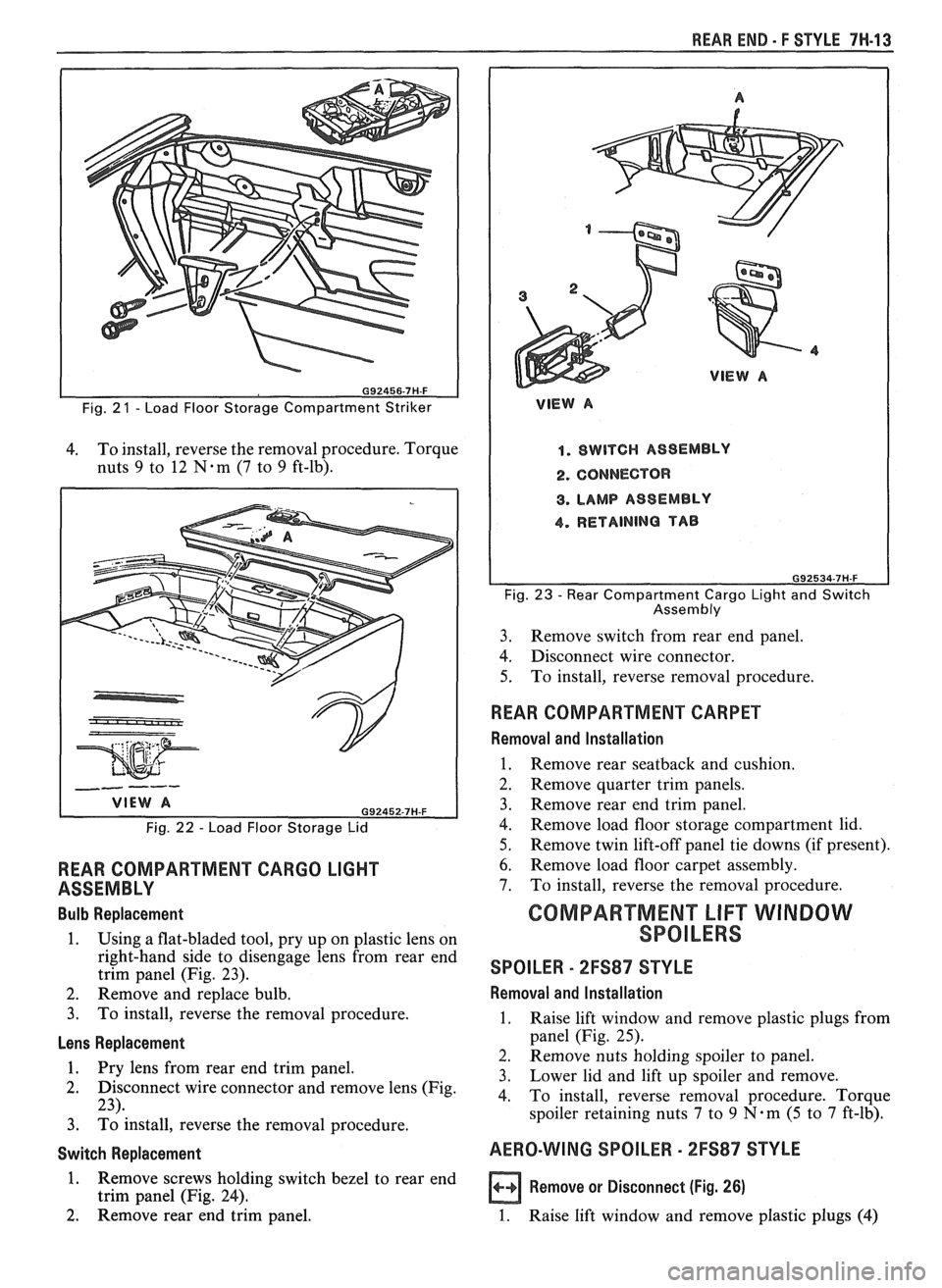

Fig. 2 1 - Load Floor Storage Compartment Striker

4. To

install, reverse the removal procedure. Torque

nuts

9 to 12 N-m (7 to 9 ft-lb).

Fig. 22 - Load Floor Storage Lid

REAR COMPARTMENT CARGO LIGHT

ASSEMBLY

Bulb Replacement

1. Using a flat-bladed tool, pry up on plastic lens on

right-hand side to disengage lens from rear end

trim panel (Fig. 23).

2. Remove and replace bulb.

3. To install, reverse the removal procedure.

Lens Replacement

1. Pry lens from rear end trim vanel.

2. Disconnect wire connector and remove lens (Fig.

23).

3. ~d install, reverse the removal procedure.

Switch Replacement

1. Remove screws holding switch bezel to rear end

trim panel (Fig. 24).

2. Remove rear end trim panel.

VlEW A

1. SWITCH ASSEMBLY

2. CONNECTOR

8. LAMP ASSEMBLY

4. RETAINING TAB

Fig. 23 - Rear Compartment Cargo Light and Switch

Assembly

3. Remove

switch from rear end panel.

4. Disconnect wire connector.

5. To

install, reverse removal procedure.

WEAR COMPARTMENT CARPET

Removal and Installation

1. Remove rear seatback and cushion.

2. Remove quarter trim panels.

3. Remove rear end trim panel.

4. Remove load floor storage compartment lid.

5. Remove twin lift-off panel tie downs (if present).

6. Remove load floor carpet assembly.

7. To install, reverse the removal procedure.

GOMPARTMEN"FLlFT WINDOW

SPOILERS

SPOILER - 2FS87 STYLE

Removal and lnstallation

1. Raise lift window and remove plastic plugs from

panel (Fig. 25).

2. Remove nuts holding spoiler to panel.

3. Lower lid

and lift up spoiler and remove.

4. To install, reverse removal procedure. Torque

spoiler retaining nuts

7 to 9 N.m (5 to 7 ft-lb).

AERO-WING SPOILER - 2FS87 STYLE

a Remove or Disconnect (Fig. 26)

1. Raise lift window and remove plastic plugs (4)

Page 1758 of 1825

WEAR END - F STYLE 7H-15

A

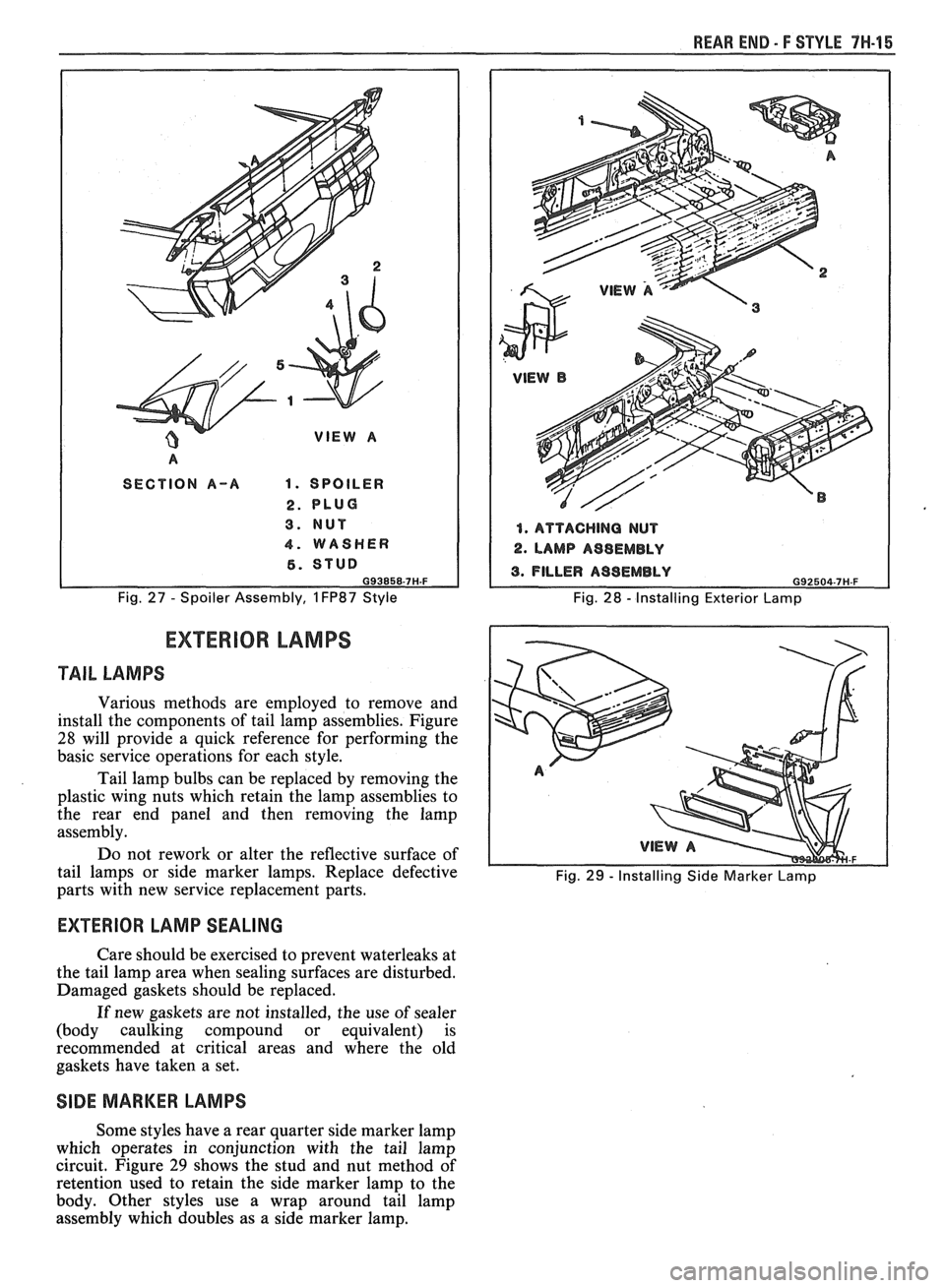

SECTION A-A 1. SPOILER

2. PLUG

3. NUT

4. WASHER

6. STUD 093858-7H.F

Fig. 27 - Spoiler Assembly, 1 FP87 Style

1. ATTACHING NUT

2. LAMP A98EMBLY

Fig. 28 - Installing Exterior Lamp

EXTERIOR LAMPS

TAIL LAMPS

Various methods are employed to remove and

install the components of tail lamp assemblies. Figure

28 will provide a quick reference for performing the

basic service operations for each style.

Tail lamp bulbs can be replaced by removing the

plastic wing nuts which retain the lamp assemblies to

the rear end panel and then removing the lamp

assembly.

Do not rework or alter the reflective surface of

tail lamps or side marker lamps. Replace defective

Fig. 29 - Installing Side Marker Lamp parts with new service replacement parts.

EXTERIOR LAMP SEALING

Care should be exercised to prevent waterleaks at

the tail lamp area when sealing surfaces are disturbed.

Damaged gaskets should be replaced.

If new gaskets are not installed, the use

of sealer

(body caulking compound or equivalent) is

recommended at critical areas and where the old

gaskets have taken a set.

SIDE MARKER LAMPS

Some styles have a rear quarter side marker lamp

which operates in conjunction with the tail lamp

circuit. Figure

29 shows the stud and nut method of

retention used to retain the side marker lamp to the

body. Other styles use a wrap around tail lamp

assembly which doubles as a side marker lamp.

Page 1760 of 1825

ROOF - F STYLE 8H-1

SECTION 8H

ROOF

CONTENTS

Formed Headlining .......................................... 8H- 1

Interior Roof Attachments

.............................. 8H- 1

Interior Garnish Moldings .............................. 8H-2

Exterior Roof Moldings and

Attachments

.................................... .... ... 8H-3

Twin Lift-off Panel

......................................... 8H-3

Convertible Top

Top Operation

............................................ 8H-7

Header Inner Garnish

................................. 8H-8

"A" Pillar Inner Garnish

........... .;. .............. 8H-9

Header

"A" Pillar Seal ................................ 8H-9

Side Rail Seal and Retainer

......................... 8H-9

Main Pillar Seal and Retainer

..................... 8H-9

No.

5 Bow Seal .......................................... 8H-9

No. 1 Bow Garnish Molding

....................... 8H-9

Top Cover Assembly

.................................... 8H- 1 1

Side Stay Pads ............................................. 8H-13

Rear Stay Pads ............................................ 8H- 13

No.

1 and No. 2 Bows ................................. 8H- 13 NO. 3

BOW

.................................................... 8H-15

NO. 4 BOW ................................................ 8H-15

NO. 5 BOW ................................................. 8H-15

Top Stack Assembly Complete .................... 8H- 16

Quarter Inner Upper Trim Cap

.................. 8H- 17

Quarter Trim Panel

.................................... 8H- 17

Quarter Cap Belt Molding

........................... 8H- 17

Tonneau Panel Latch

................................. 8H- 17

Tonneau Release Solenoid

........................... 8H- 17

No. 5 Bow Release Handle

.......................... 8H- 19

No.

5 Bow Latch ....................................... 8H-19

Tonneau Panel

.......................................... 8H- 19

Tonneau Panel Seal

............................. ......... 8H-20

Deck Lid Spoiler ........................................ 8H-2 1

Center High Mount Stop Lamp .................. 8H-21

Deck Lid .................................................... 8H-21

Deck Lid Panel Seal

................................. 8H-22

Door Cap Belt Molding ............................... 8H-22

Front Belt Retractor Assembly ................... 8H-22

FORMED HEADLINING 1. Load the headlining through the rear

The one-piece formed headlining (Fig. 1) consists

of a molded fiberglass substrate covered with a foam

and cloth facing. The one-piece construction requires

the headlining be serviced as a complete assembly.

The headlining is held partially in place by

retaining fasteners located in the headlining which fit

into slots in the roof panel. Final attachment is

accomplished when the interior moldings and

attaching screws that retain the sunshade brackets,

dome lamp base and coat hooks are installed.

Removal

1. Remove the following items:

e Back body opening upper garnish molding

r Windshield side upper garnish molding (1,

Fig. 3 or

6)

e Rear vertical garnish molding

a Windshield header courtesy reading and

console lamp

e Sunshades

e Partially remove shoulder belt bezel and

belt

a Coat hooks and rail panel inserts

2. Grasp headlining assembly with both hands at

outer edges and move to the right of centerline to

disengage fastener assemblies from front

attaching slots.

3. Remove headlining assembly through right front

door.

lnstallation

Care must be exercised when loading assembly.

Excessive flexing may result in damage. compartment

opening.

2. Align headlining with cutouts for sunshades and

dome lamp and install sunshade brackets and

dome lamp base. Do not tighten sunshade bracket

and dome lamp attaching retainers completely

until headlining is aligned properly at all

hardware attaching locations.

3. Align headlining to roof inner panel with

fasteners positioned over holes in roof panel and

using palm of hand, push up on headlining at

fastener locations.

4. Install all previously removed hardware and

interior moldings.

INTERIOR ROOF ATTACHMENTS

DOME LAMPS

The dome lamp operates in conjunction with the

door jamb switch and/or the

headlamp switch. The

dome lamp harness extends up the right windshield

pillar, outboard of the sunshade support and across the

roof inner panel to the dome lamp.

Removal and Installation (Typical)

1. Grasp lens portion of dome lamp assembly,

squeeze and pull down to remove.

2. Remove bulb from terminal clips.

3. Remove retainers from studs.

4. Disengage wire harness from lamp housing and

remove dome lamp housing.

5. To install dome lamp assembly, reverse removal

procedure.

Page 1817 of 1825

2 - CHASSIS INDEX

Backup Lamp Switch (Circuit) .......... 8A- 1 12. 7A 1-5

Backup Lights

..................................................... 8B-1

...................................................... Battery Section 6D 1

............................ Battery Specification Chart 6D 1-7

.................................... Body Identification ... .... OA- 1

Borg Warner Rear Axle .......................... Section 4B1

...................................................... Blower Motor 1A-14

Blower Switch

.................................................... 1 A- 13

Booster Assembly

............................................. 5D2-2

Brakes

- General ......................................... Section 5

Adjustment

.................................................... 5C3-4

Booster Assembly

. Tandem

Diaphragm

................... .... ..................... 5D2- 1

................................................ Components 5C3- 1

Diagnosis and Inspection

................................. 5-3

Disc Brake Caliper Assembly

.................................................... 3548 Series 5B6-1

Drum Brake Assembly ........................ Section 5C3

General Description

.......................................... 5-2

On-Car Service

.................................................... 5-7

Specifications & Special Tools ......................... .5 F. 1

...................................................... Unit Repair 5A3- 1

.......................................... Warning System 8A-4 1-0

............ Brake Pedal Mounting .. ......................... 5-1 7

Bulb Usage Chart

............................................ 8B-10

............................................ Bumpers Section 2B,3 D.6

Bumper Energy Absorbing Units

.................... 2B-2

Bench Testing

................................................ 2B-3

........................................ Damage/Leakage 2B-3

................................ Removal After Collision 2B-2

............................................. Fascia Rub Strips .2 B. 1

.................................................... Front Bumper 2B-2

Assembly

........................................................ 2B-4

Energy Absorber

........................................... 2B-4

............................................................. Fascia .2 B. 1

On-Vehicle Service

...................................... 2B-4

Rear Bumper

.................................... .... ............ 2B-2

........................................................ Assembly 2B-5

Energy Absorber

............................................ 2B-4

............. .................... Fascia Molding Strip .. 2B-5 ........................................... Service Procedures .2 B. 1

.................................................. Specifications 2B-5

C

Caliper Assembly . Disc Brake

.............................................. 3000/3 100 Series 5B 1-2

3548 Series

...................................................... 5B6-2

Caliper Overhaul

....................... 3000/3 100 Series .. ............... 5B 1-4

3548 Series

.................................................... 5B6-5

Caster and Camber Adjustment

........................ 3A- 1

............................................. Catalytic Converter 6F-2

Center High-Mounted Stoplight

....................... ... 8B- 1

Charging System

...................... 8A.30.7, Section 6D3

Chassis Electrical

.................................... Section 8B

Center High Mounted Stoplight

...................... 8B-1 ................................. Exterior Light Monitor .8 B. 1

................................................................ Chimes 8A-77

................................ Cigar Lighter (Circuit) 8A- 1

14-0

.............................. Circuit Breaker Details Section 8A

Power ACC Circuit Breaker .... 8A- 10.1.10.3.10.5.

11-3

.... Window Circuit Breaker 8A~10~1,10~3.10~5.1 1.4

Clutch

........................................................ Section 7C

......................................... General Description .7 C. 1 ........................................................... Diagnosis 7C-2 Bleeding

Hydraulic Clutch System

................. .7 C.2

Preliminary Checks ..................................... ... 7C-2

On-Vehicle Service

........................................... 7C-5

Clutch Hydraulic System

.................................. 7C-5

Clutch Pedal ...................................................... 7C-6

Pilot Bearing

..................................................... 7C-6

Pressure Plate and Disc

.................................... 7C-6

Special Tools

......................... ....... ................ 7C-8

Specifications

................................................... 7C-8

Coil Springs and Insulators .............................. 3D-1

Component Fluid Capacities

................................ OB-6

Component Location Views

........................ 8A-201-0

Composite Master Cylinder

................... Section 5A3

Compression Test

.................. .. ............................. 6-5

Condenser Mounting

....................................... 1B 1-24

Connectors

.................................................... 8A-202-0

Coolant Fan Temperature Switch

...................... 8A-3 1

Cooling and Radiator

................................ Section 6B

Cooling System Capacities

................................. OB-6

Cooling System Diagnosis

.................................... 6B-3

Cranking System

...................................... Section 6P*

Diagnosis ..................................................... 6~2

General Description ................................ 6D2- 1

Cranking System

........................................ 6D2- 1

Solenoid

................................................... 6D2- 1

Starter Motor ......................................... 6D2-1

On-Vehcile Service

...................................... 6D2-4

Specifications

............................................ 6D2- 1

Starter

........................................................ 6D2-4

Unit Repair

............................................ 6D2-6- 11

Service Procedures

...................................... 6D2-3

Cruise Control

.............................. 8A-34-0, Section 9B

Diagnosis

............................................................ 9B-4

Cruise Set Speed High or Low

.................... 9B-4

Cruise System Surges

.................................. 9B-4

Cruise Tap-Up and Tap-Down

...................... 9B-4

Excessive Cruise Speed Loss on

Hills

........................................................... 9B-4

General Description

........................................ 9B-1

Electrical and Vacuum Release

Switches

...................................................... 9B-4

Electrical Harness

.......................................... 9B-A

Electronic Controller (Module) .................... 9B .

Off/On/Resume/Accel Switch

Operation

.................................................. .91 B-

Servo Unit

.................................................... 9B-2

Set/Coast Button Switch .............................. 9B-1

................................................ Speed Sensors 9B-3

Vacuum Supply

............................................ 9B-4

On-Car Service

.................................................. 9B-6

................................ Cruise Release Switches 9B-6

.......................................... Servo Mounting 9B-10

Vacuum Harness and Cable Routing

VIN

E ................................. .. .................. 9B,7

.................................................... VIN F, 8 9B-9

....................................................... VIN S 9B-8

........................ Vacuum Tank - VIN S,F,E, 9B-10

.............................. Cruise Control (Circuit) 8A-34-0

D

......................................... Defogger (Circuit) $A-6 1-0

..................... ...... Defroster Duct Assembly ... .812 C-

Diagnosis

Air Conditioning

- General ........................... 1B-5

.................... Automatic Transmission - General 7A

Automatic Transmission

- ................ HD-700-R4-2

Page 1821 of 1825

6- CHASSIS INDEX

Upper Air Outlet Deflectors ...................... 8C-12

Interior Lights ............................................. 8A- 1 17-0

Intermediate Shaft (Steering Column)

.............. 3B5-3

J

Jump Starting .................................................... 6D 1-4

Junction Block

((2238) ................................. 8A-202-2

L

Lamp Monitoring ......................................... 8A- 1 1 1-0

License Plate Lights .............................................. 8B-2

Light Switch

.................................................... 8A- 12-0

Lighting Systems and Horns

...................... Section 8B

General Description ......................................... .8 B- 1

Exterior Lights

............................................ 8B- 1

Horns ....................... .. ................................. 8B-3

On-Car Service

.................................................. 8B-3

Exterior Lights 8B-3

Horns

.............................................................. 8B-9

Replacement Bulb Specifications .................... 8B-10

Lights (Exterior) Electrical Diagnosis

Back-up

...................................................... 8A- 1 12-0

Fog ............................................... 8A- 100.3,10 3.0

Front

Marker/Park/Hazard .................... 8A-110-0

Hazard with Lamp Monitor .................... 8A-103-0

Headlights .................................................. 8A- 100-0

High Level Stop

..................................... 8A-110-0

License .................................................. .8A.110.3, 4

Rear Marker

........................................... .8 A. 1 10.3, 4

Stop ........................................................... 8A-110-1

Tail ......................................................... .8 A. 1 10.3, 4

Tail with Monitor

................ .... ........... 8A- 1 1 1-2

Turn

......................................................... 8A- 1 10-0

Lights (Interior) Electrical

Diagnosis Cargo Compartment

............................. 8A- 1 14- 1

Courtesy

................................................. 8A- 1 14-0

Dome

.................................. .. ...................... 8A- 1 14-0

Glove Box .................................................. 8A- 1 14-0

Lights Dimming

...................................... 8A- 1 17-0

Reading

...................................................... 8A- 1 14-0

Lower Heater Outlet

........................................ 1A-14

Lubrication Fitting Locations .............................. OB-6

M

Maintenance and Lubrication .................... Section OB

Manual Transmission

. 5 Speed 77 mm .... Section 7B

Diagnosis

........... .. ............................................ 7B-2

On-Vehicle Service

.......................................... 7B-3

Repairs

................................... .... .................... 7B- 12

Special Tools

................................................. 7B-20

. Specifications .............................................. 7B 19

Maintenance Items

................................................ OB-2

Master Cylinder

........................................ Section 5A3

General Description

...................................... ..5A 3.2

On-car Sevice

................................................ 5A3-2

Unit Repair ..................................................... .5A 3.2

Master Cylinder Overhaul

......................... .5A 3.2

Master Cylinder Reservoir

......................... .5A 3.3

Metric Fasteners

................................................ OA- 1

Metric-English Conversion Table ..................... .O A. 10

Miscellaneous Accessories

........................ Section 9G

Diagnosis

.......................................................... 9G-2

Dash/Console Mounted Accessory

Switches

.................................................... 9G-4 Electric

Rear Window Defogger

................ 9G-2

Power Remote Control

Rearview

......................... Mirror ...................... .. 9G-2

Rally Gages

................................................. 9G-2

Tachometer

.................................................. 9G-2

..................................... General Description 9G-4

Electric Glare Control Monitor

.................. 9G-4

Electric Rear Window Defogger

................ 9G-2

Power Remote Control

Rearview

Mirror ..................................................... 9G-2

Rally Gages

................................................. 9G-1

Tachometer

................................................. 9G-1

Trip Odometer

............................................ 9G-1

............................................. On-Car Service 9G-4

Power Remote Control Mirror

.................... 9G-4

Rally Gages. Tach

..................................... 9G-4

Rear Window Defogger

.............................. 9G-4

Mirrors..Power ............................................ 8A- 141-0

Automatic

Day/Night ............................. 8A- 143-0

..................................... Defogger. Mirror 8A-61-0

.......................................... Model Identification OA-'

Muffler ................................................................. 6Fi

N

Neutral Start and Back-Up Lamp

Switch

...................................... ..

0

On-Vehicle Service

Air Conditioning

.................................... ... . 1B-20

Automatic Transmission

............................... .7A 1.3

Battery

........................................................ 6D1-5

................................ ......................... Brakes ... 5-7

Bumpers

......................................................... 2B-4

Charging System

.............................. ... ........... 6D3-2

Chassis Sheet Metal

.......................................... 2C-7

Clutch

................................................................ 7C-5

Cranking System

............................................ 6D2-4

Cruise Control ............................................... 9B-6

Disc Brake Caliper Assembly,

3000/3 100 Series .......................................... 5BliC

Disc Brake Caliper Assembly,

3548 Series

................................................... 5B6-3

Drum Brake Assembly .................................... 5C3-1

Engine (V-6) .................................................... 6A2-7

Engine (V-8) ................................................ -6A3-5

Engine Cooling ....................................... .. .... 6B- 14

Front Suspension

........................................... 3C-1

Horns and Lighting System .............................. 8B-3

Ignition System

.............................................. 6D4-5

Instrument Panel, Gages and

Console

.......................................................... 8C-4

Lighting System and Horns

.......................... .... 8B-3

Miscellaneous Accessories

.......................... .... 9G-4

Power Head Assembly

. Tandem

Diaphragm

................................................. 5D-2

Power Steering Gear and Pump

.................... 3B7-3

Propeller Shaft

............................................. 4A-1

.......................... Radio Systems and Antennas 9A-9

Rear Axle

.......................................................... 4B-8

Rear Axle (Borg Warner)

........................... ... 4B 1-7

Steering Linkage ............................................. 3B6-2

........................ Steering Wheels and Columns 3B5-2

Wheel Alignment

......................................... 3A-2

Windshield Wiper

- Washer System ................ 8E-3

Page 1823 of 1825

8- CHASSIS INDEX

Recommended Fluids and Lubricants ................ OB-6

Relay Rod

......................................................... 3B6-2

Remote Mirror Control

...... See Body Service Section

5H.1. 15

Repair Procedures

.......................................... 88-50

S

........................................ Scheduled Maintenance OB- 1

Seats (Power) ....................................... Lumbar Support 8A- 145-0

............................. Sequential Fuel Injection 6E3-C2- 1

Service Engine Soon Light

.................................... 8C-3

Sheet Metal and Grille

................................ Section 2C

......................................... General Description .2 C. 1

........................................... Service Procedures .2 C. 1

................................................................. Hood .2 C. 1

...................................................... Hood Hinge 2C-2

Hood Latch and Cable

...................................... 2C-2

Paint

.............................................. Color Matching 2C-5

................................................ Identification -32-6

Interior Plastic Parts ...................................... 2C-6

................................................ Shock Absorbers 3D-

1

Shoe and Lining Assembly

. Brake

............................................ 3000/3 100 Series 5B1-3

3548 Series ...................................................... 5B6-4

Side Marker Lights

.............................................. 8B-2

........ Speakers See 8A- 150-0 & Body

Manual Section

6H- 1

.................... Spark Plug Gap .. .................. 6E3-13-3

................................ Speaker and Speaker Grille 9A-9

Special Tools

............................................ Air Conditioning 1 B-3 5

Air Conditioning Compressor

................................................. Overhaul 1D1-21

........................ Automatic Transaxle AT-700-R4-64

................................................................ Brakes SF-1

Clutch ................................................................ 7C-8

................................................................ Rear 4B1-20

....................................... Rear (Borg Warner) 4B-20

........................... Driveability and Emissions .6 E. 17

................................................ Engine Cooling 6B- 14

Power Steering Pump

& Gear ...................... 3B7-17

............................................... Propeller Shaft .4 A. 12

Steering Wheels and Columns

.......................... 5-35

Specifications Automatic Transmission Unit

............................................ Repair AT-700-R4-59

..................................................... Battery 6D 1-7

................................................................ Brakes 5F-1

Bumpers

......................................................... 2B-5

Charging System

................ .. ................... 6D3-3

.............................................................. Clutch .7 (2.8

....................................... Cranking System 6D2- 1 1

Driveability and Emissions ............................ 6E-23

................................................ Engine (V-6) ..6A 2.26

Engine (V-8) .................................................. 683-28

........................................ Front Suspension 3C- 10

Power Steering Gear and Pump

.................. 3B7-18 ............................................. Propeller Shaft .4 A. 12 ........................................................ Rear Axle 4B-19 ............................ Rear Axle (Borg Warner) 4B 1- 19

Rear Suspension

.............................................. 3D-9

.......................................... Replacement Bulbs 8Br 10 .............................................. Steering Linkage 3B6-6

Steering Wheels and Columns

...................... 3B5-35

........................................ Wheel Alignments 3A-4

....................................................... Speedometer 8C-2

........................................ Speedometer (Removal) 8C-5

...................................................... Speed Sensors 8C-1

Starter ........................................ Section 6D2. 8A-30-0

............................................. Starter (Circuit) 8A-30-0

Steering Linkage ...................................... Section 3B6

....................................... General Description 3B6-1

........................ Maintenance and Adjustments 3B6-1

................................................ On-Car Service 3B6-2

..................................................... Idler Arm 3B6-4

................................................ Pitman Arm 3B6-5

.................................................... Relay Rod 3B6-3

Tie Rods

...................................................... 3B6-2

.................................................. Specifications 3B6-6

Steering, Suspension, Tires and

Wheels Diagnosis

............................................................. 3-1

Steering Wheels and Columns

............................ 3B5-1

..................................... General Information 3B5- 1

Maintenance and Adjustments

...................... 3B5-'

On-Car Service .............................. .. ........... 3B5

Checking for Accident Damage

.................. 3B5-5

Intermediate Shaft ............... .. .................... 3B5-3

Park Lock Cable .......................................... 3B5-4

Standard Column

............................. Automatic Transaxle 3B5-13

Manual Transaxle ................................. 3B5- 19

Tilt Column

.............................. Automatic Transaxle 3B5-27

.................................. Manual Transaxle 3B5-19

Unit Repair Intermediate Shaft

...................................................... Assembly 3B5-6

................................................. Special Tools 3B5-35

Torque Specifications

.................................... 3B5-35

............................................. Starting System 8A-30-0

........................................ Strut Assembly (Front) 3C-4

.................................... ..... Symbols Chart ... 8A-3-0

T

.......................................................... Tachometer 9G-1

Tail/Stop/Turn Signal/Lights .......................... 8B-2

Temperature Cable

.............................................. 112 A-

Temperature Warning Light ................................ 8C-3

Theft Deterrent (Circuit)

.............................. 8A-133-0

Tie Rods

.............................................................. 3B6-2

Tires and Wheels

........................................ Section 3E

Diagnosis

.................................................. Section 3

General Information

......................................... 3E-1

................................................... Metric Tires 3E-2

....................................... Replacement Tires .31 E-

.................................................... Tire Placard 3E-2

........................................................... Wheels 3E-2

Maintenance and Adjustments

.......................... 3E-2

.......................... Aluminum Wheel Cleaning 3E-9

............................. ......... Inflation of Tires .. 3E-3

........................................ Tire Chain Usage 3E-4

.................................................. Tire Rotation 3E-3

.............................................. Wheel Repair 3E-2

...................................... Wheel Studs/Nuts 3E-3

........................................... Service Operations 3E-4

........................ Aluminum Wheel Cleaning 3E-9

.................................... Balance Precautions 3E-7

............................ Balancing Tire and Wheel 3E-7

.............................................. Compact Spare 3E-6

........................ Correcting Nonuniform Tires 3E-8