bulb PONTIAC FIERO 1988 Service Owner's Guide

[x] Cancel search | Manufacturer: PONTIAC, Model Year: 1988, Model line: FIERO, Model: PONTIAC FIERO 1988Pages: 1825, PDF Size: 99.44 MB

Page 1408 of 1825

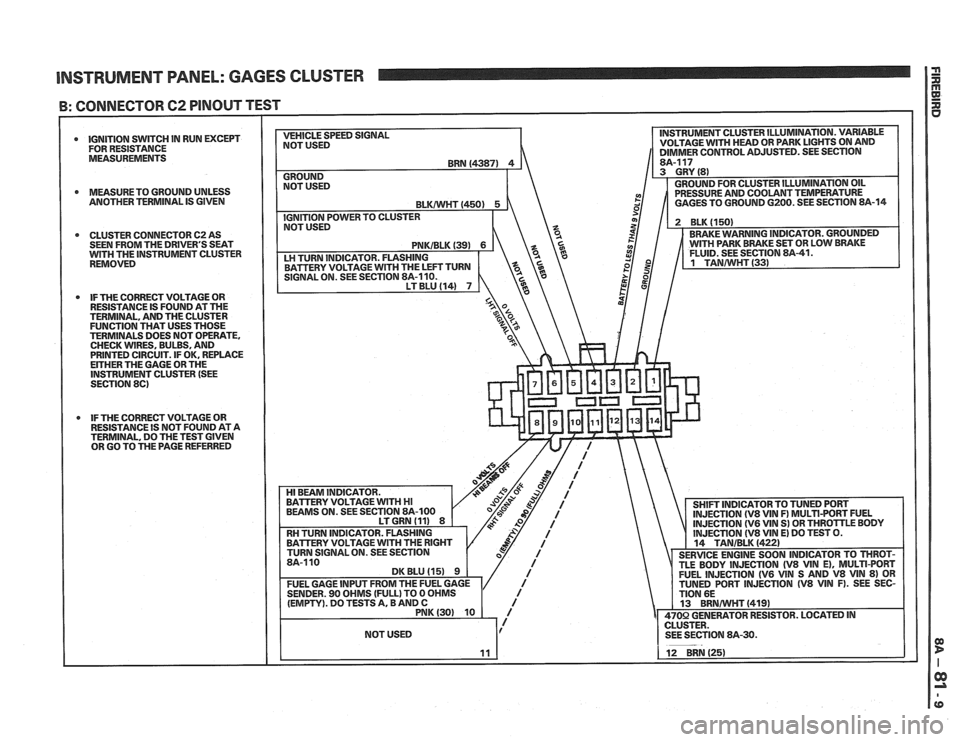

INSTRUMENT PANEL: GAGES CLUSTER I i

B: CONNECTOR 62 PINOUT TEST

0 IGNITION SWITCH IN RUN EXCEPT

FOR RESISTANCE

MEASUREMENTS

0 MEASURETO GROUND UNLESS

ANOTHER TERMINAL IS GIVEN

0 CLUSTER CONNECTOR 62 AS

SEEN FROM THE DRIVER'S SEAT

WlTH THE INSTRUMENT CLUSTER

REMOVED

IF THE CORRECT VOLTAGE OR

RESISTANCE IS FOUND AT THE

TERMINAL, AND THE CLUSTER

FUNCTION THAT USES THOSE

TERMINALS DOES NOT OPERATE.

CHECK WIRES, BULBS, AND

PRINTED CIRCUIT. IF OK. REPLACE

EITHER THE GAGE OR THE INSTRUMENT CLUSTER (SEE

SECTION 86)

IF THE CORRECT VOLTAGE OR

RESISTANCE IS NOT FOUND AT A TERMINAL, DO THE TEST GIVEN

OR GO TO THE PAGE REFERRED VEHICLE

SPEED SIGNAL

NOT USED INSTRUMENT

CLUSTER ILLUMINATION. VARIABLE

VOLTAGE

WlTH HEAD OR PARK LIGHTS ON AND 11 DIMMER CONTROL ADJUSTED. SEE SECTION I

Page 1411 of 1825

(Continued from previous page)

If the Speedometer reads correctly, refer to

Vehicle Speed Sensor, Section

8A-33 for fur-

ther diagnosis.

If the Speedometer reads incorrectly, check

LT GRN (537) wire and the Instrument Clus-

ter Printed Circuit for opens. Replace the

Speedometer Assembly if the wire and

Printed Circuit are good (see Section

8C).

O: UPSHIFT INDICATOR WIRE TEST

Disconnect ECM connector C207. Put the Igni-

tion Switch in RUN and measure the voltage at

terminal

H (see section 8A-21 or 22).

If battery voltage is present, see section

6E

for ECM diagnosis.

If battery voltage is not present, check the

TANIBLK (422) wire for an open or short to

Ground.

CIRCUIT OPERATION

The operation of an indicator is explained in

the operation of the circuit it is apart of. See the

circuit referred to for a complete description of

that indicator and the other components that

work with it. Only the gages and indicators that

do not appear in other schematics are described

in this section.

Tachometer

The Tachometer displays engine speed in

rpm. Voltage pulses are taken from the Ignition

System and sent to the Tachometer. Solid State

circuits process these pulses into a signal that

drives the pointer of the meter. The Tachometer

responds to the frequency of the voltage pulses.

These pulses increase with engine speed.

Fuel Gage

The pointer of the Fuel Gage is moved by the

magnetic field of two coils. The coils are at right

angles to each other. Battery voltage is applied

to the E coil and the circuit divides at the

opposite end of this coil. One path continues to

ground through the F coil. Another goes to

ground through the variable resistor of the Fuel

Gage Sender Unit.

When the tank is low, the resistance of the

Fuel Gage Sender is low. A large flow of current

passes through the E coil and the Fuel Gage

Sender resistor. This moves the pointer

towards E on the scale. When the tank is

full,

the sender resistance is high. More current

flows through the F coil, moving the pointer

toward F on the scale.

With two coils operating the pointer, the Fuel

Gage is not affected by changes in the voltage

of the system.

011 Pressure Gage

The engine oil pressure is displayed by the Oil

Pressure Gage. The pointer of the gage is

moved by two coils, and its operation is similar

to that of the Fuel Gage. The

Oil Pressure Sender is connected to the

junction of the two coils.

It has low resistance

when the oil pressure is low, and 90 ohms

resistance when the oil pressure is high. This

changing resistance changes the current flow

through the coils. The magnetic fields of the

coils move the pointer to indicate high or low

coolant temperature.

Voltmeter

The Voltmeter measures the electrical sys-

tem voltage with the Ignition Switch in RUN,

BULB TEST, or START. With the engine

stopped, the Voltmeter indicates battery condi-

tion. With the engine

running, the Voltmeter

indicates Charging System operation.

Coolant Temperature Gage

The Coolant Temperature Gage is also oper-

ated by two coils. Battery voltage is applied to

both coils. One is grounded directly

and the

other is grounded through the Coolant Tem-

perature Sender. This has 54 ohms resistance at

260

OF, 130 "C (hot coolant) and its resistance

becomes greater at lower temperatures. It is

appr~ximately 1284 ohms at 100 OF (40 '6). This

causes the current through the sender and one

coil to vary as the coolant temperature charges

and this moves the pointer.

Page 1412 of 1825

INSTRUMENT PANEL: GAGES CLUSTER

Speedorneter and Odometers

The Speedometer is operated by an electronic

circuit. The Vehicle Speed Sensor (VSS),

located in the transmission, generates an AC

voltage whose frequency is proportional to the

speed of the vehicle. This goes to the Vehicle

Speed Sensor Buffer and then to the Speedom-

eter circuit board in the Instrument Cluster.

The Solid State circuit drives the pointer of the

Speedometer. There is no speedometer cable

in

the vehicle.

The same speed signal from the Vehicle Speed

Buffer is processed by the Speedometer circuit

board to drive the Odometers. They are oper-

ated by a motor that responds to pulses from

the Speedometer circuit.

UpshiN Indicator

With Manual Transmission, the indicator

lights when the car should be shifted to the next

higher gear for better fuel economy. Battery

voltage is applied to one side of the bulb. The

other side of the bulb is switched to ground by

the ECM which uses engine data to compute an

efficient shift point.

Page 1419 of 1825

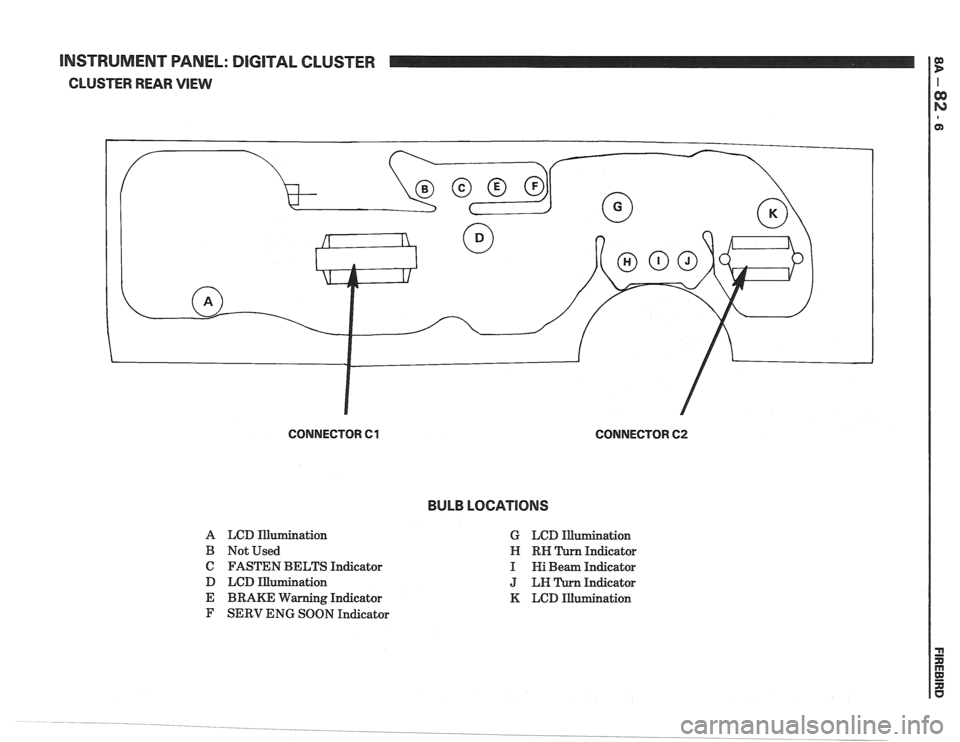

[NSTRUMENT WNEL: DIGITAL CLUSTER

CLUSTER REAR VlEW

CONNECTOR 61 CONNECTOR 62

BULB LOCATIONS

A LCD Illurnination

B Not Used

C FASTEN BELTS Indicator

D LCD Illumination

E BRAKE Warning Indicator

F SERV ENG SOON Indicator G

LCD Illumination

Indicator

Indicator

Indicator

K LCD Illumination

Page 1424 of 1825

INSTRUMENT PANEL: DIGITAL CLUSTER

(Continued from previous page)

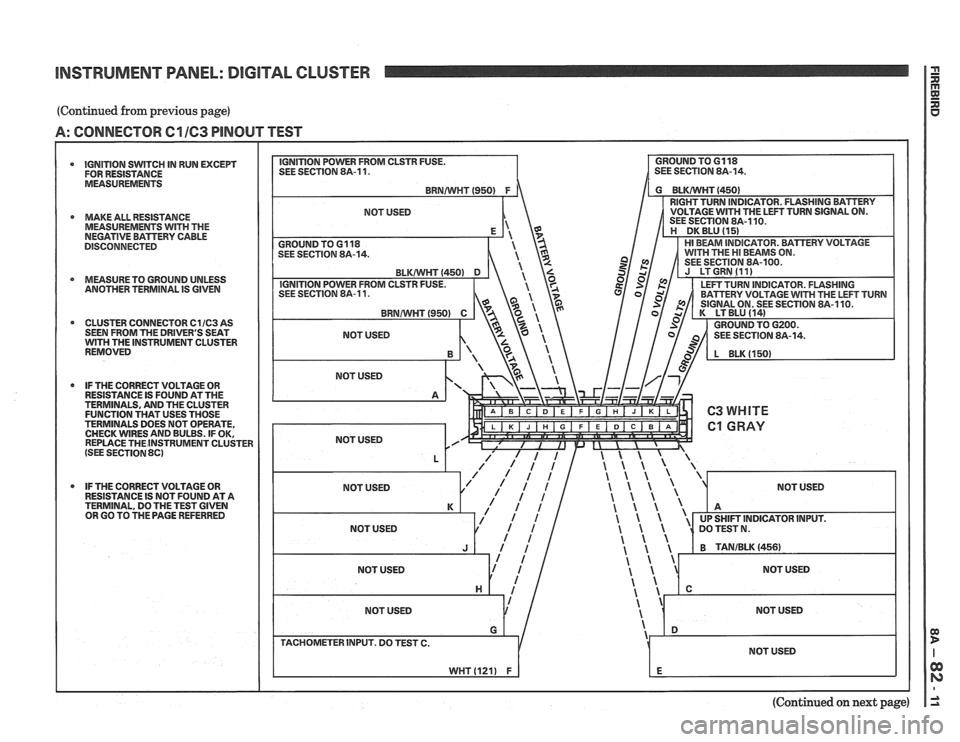

A: CONNECTOR C1 163 PINOUT TEST

IGNITION SWITCH IN RUN EXCEPT

FOR RESISTANCE

MEASUREMENTS

* MAKE ALL RESISTANCE

MEASUREMENTS WITH THE

NEGATIVE BAmERV CABLE

DISCONNECTED

4 MEASURETO GROUND UNLESS

ANOTHER TERMlNAL IS GIVEN

CLUSTER CONNECTOR

C11C3 AS - - - - . -. . - - . . . . - - . - . . - . . - - . . - SEEN FROM THE DRIVER'S SEAT WITH THE INSTRUMENT CLUSTER

REMOVED

* IF THE CORRECT VOLTAGE OR

RESISTANCE IS FOUND AT THE

TERMINALS, AND THE CLUSTER

FUNCTION THAT USES THOSE

TERMINALS DOES NOT OPERATE,

CHECK WIRES AND BULBS. IF OK,

REPLACE THEINSTRUMENT CLUSTER

(SEE SECTION 8C)

IF THE CORRECT VOLTAGE OR

RESISTANCE IS NOT FOUND AT A

TERMINAL, DO THE TEST GIVEN

OR GO TO

TI-IE PAGE REFERRED

NOT USED

(Continued on next page)

Page 1425 of 1825

INSTRUMENT PANEL: DIGITAL CLUSTER

(Continued from previous page)

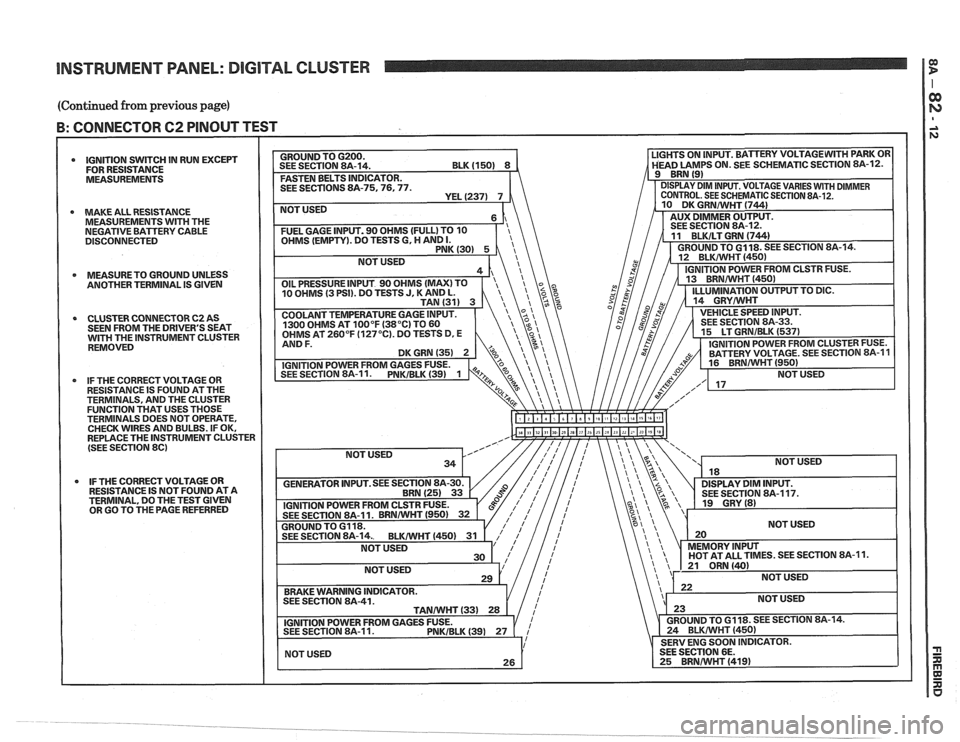

B: CONNECTOR 62 PINOUT TEST I I

IGNITION SWITCH IN RUN EXCEPT

FOR RESISTANCE

MEASUREMENTS

MAKE ALL RESISTANCE

MEASUREMENTS

WITH THE

NEGATIVE BATTERY CABLE

DISCONNECTED

MEASURETO GROUND UNLESS

ANOTHER TERMINAL IS

GIVEN

CLUSTER CONNECTOR C2 AS

SEEN FROM THE DRIVER'S SEAT

GH THE INSTRUMENT CLUSTER

REMOVED

IF THE CORRECT VOLTAGE OR

RESISTANCE IS FOUND AT THE

TERMINALS, AND THE CLUSTER

FUNCTION THAT USES THOSE

TERMINALS DOES NOT OPERATE,

CHECK WIRES AND BULBS. IF OK,

REPLACE THE INSTRUMENT CLUSTER

(SEE SECTION

86)

IF THE CORRECT VOLTAGE OR

RESISTANCE IS NOT FOUND AT A

TERMINAL, DO THE TEST GIVEN

OR GO TO THE PAGE REFERRED SEE

SECTIONS 8A-75.76,

NOT USED

ES. SEE SECTION 8A-11.

Page 1429 of 1825

INSTRUMENT PANEL: GAGES CLUSTER

Indicators

See the circuit referred to for the complete op-

eration of an indicator and the other components

that work with it.

Upshift Indicator

With Manual Transmission, the indicator

lights when the car should be shifted to the next

higher gear for better fuel economy. Battery

voltage is applied to one side of the bulb. The

other side of the bulb is switched to ground by

the ECM which uses engine data to compute

an

efficient shift point.

Page 1437 of 1825

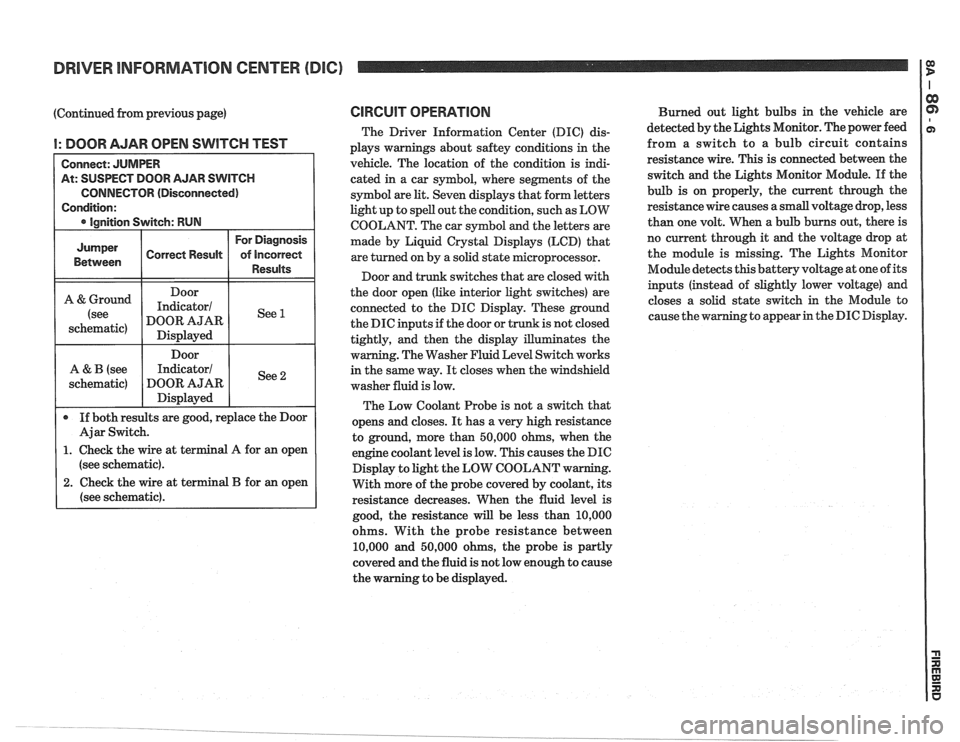

DRIVER INFORMATION CENTER (DIC) I $

(Continued from previous page)

I: DOOR AJAR OPEN SWITCH TEST

At: SUSPECT DOOR AJAR SWITCH

CONNECTOR (Disconnected)

(see schematic).

2. Check the wire at terminal B for an open

(see schematic).

CIRCUIT OPERATION

The Driver Information Center (DIC) dis-

plays warnings about

saftey conditions in the

vehicle. The location of the condition is indi-

cated in a car symbol, where segments of the

symbol are

lit. Seven displays that form letters

light up to spell out the condition, such as LOW

COOLANT. The car symbol and the letters are

made by Liquid

Crystal Displays (LCD) that

are turned on by a solid state microprocessor.

Door and trunk switches that are closed with

the door open (like interior light switches) are

connected to the DIC Display. These ground

the DIC inputs if the door or trunk is not closed

tightly, and then the display illuminates the

warning. The Washer Fluid Level Switch works

in the same way.

It closes when the windshield

washer fluid is low.

The Low Coolant Probe is not a switch that

opens and closes.

It has a very high resistance

to ground, more than 50,000 ohms, when the

engine coolant level is low. This causes the DIC

Display to light the LOW COOLANT w

With more of the probe covered by coolant, its

resistance decreases. When the fluid level is

good, the resistance

will be less than 10,000

ohms. With the probe resistance between

10,000 and 50,000 ohms, the probe is partly

covered and the fluid is not low enough to cause

the warning to be displayed. Burned

out light bulbs in the vehicle are

detected by the Lights Monitor. The power feed

from a switch to a bulb circuit contains

resistance wire. This is connected between the

switch and the Lights Monitor Module.

If the

bulb is on properly, the current through the

resistance wire causes a small voltage drop, less

than one volt. When a bulb burns out, there is

no current through it

and the voltage drop at

the module is missing. The Lights Monitor

Module detects this battery voltage at one of its

inputs (instead of slightly lower voltage) and

closes a solid state switch in the Module to

g to appear in the DIC Display.

Page 1474 of 1825

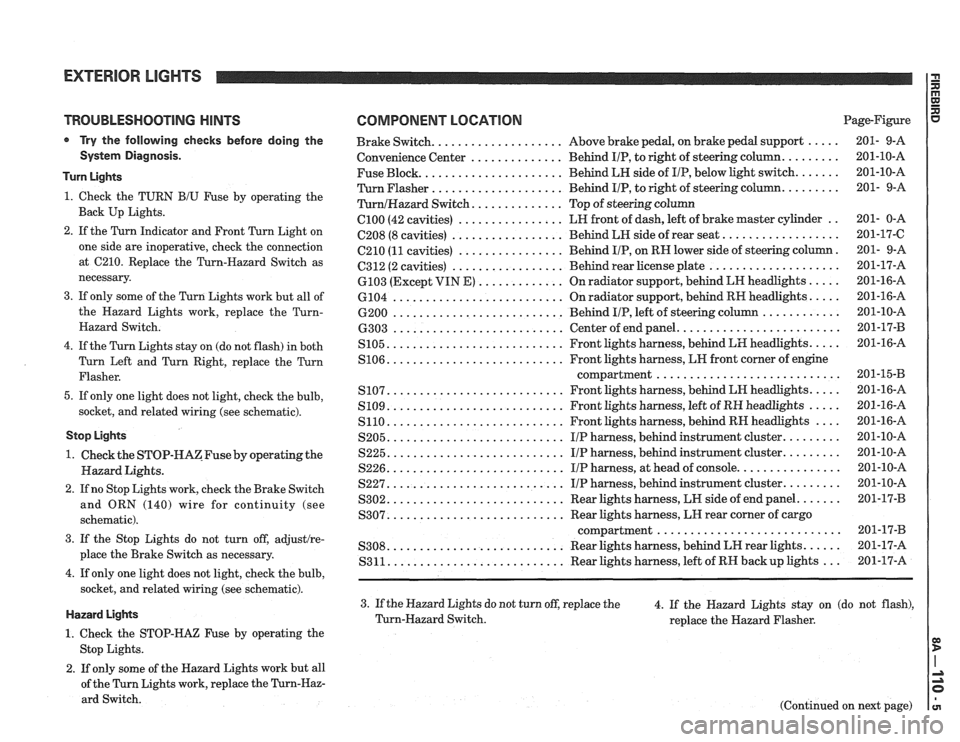

TROUBLESHOOTING HINTS

Try the following checks before doing the

System Diagnosis.

Turn Lights

1. Check the TURN B/U Fuse by operating the

Back Up Lights.

2. If the Turn Indicator and Front Turn Light on

one side are inoperative, check the connection

at

C210. Replace the Turn-Hazard Switch as

necessary.

3. If only some of the Turn Lights work but all of

the Hazard Lights work, replace the

Turn-

Hazard Switch.

4. If the Turn Lights stay on (do not flash) in both

Turn Left and Turn Right, replace the Turn

Flasher.

5. If only one light does not light, check the bulb,

socket, and related wiring (see schematic).

Stop Lights

1. Check the STOP-HAZFuse by operating the

Hazard Lights.

2. If no Stop Lights work, check the Brake Switch

and ORN (140) wire for continuity (see

schematic).

3. If the Stop Lights do not turn off, adjustlre-

place the Brake Switch as necessary.

4. If only one light does not light, check the bulb,

socket, and related wiring (see schematic).

Hazard Lights

1. Check the STOP-HAZ Fuse by operating the

Stop Lights.

2. If only some of the Hazard Lights work but all

of the Turn Lights work, replace the

Turn-Haz-

ard Switch.

COMPONENT LOCATION Page-Figure

................... ..... Brake Switch. Above

brake pedal, on brake pedal support 201- 9-A

.............. ........ Convenience

Center Behind IIP, to right of steering column. 201-10-A

Fuse Block.

..................... Behind LH side of IIP, below light switch. ...... 201-10-A

Turn Flasher

.................... Behind IIP, to right of steering column. ........ 201- 9-A

............. TurnlHazard Switch. Top of steering column

C100 (42 cavities) ................ LH front of dash, left of brake master cylinder .. 201- 0-A

................. ................. C208 (8 cavities) Behind LH side of rear seat. 201-17-C

C210

(11 cavities) ................ Behind IIP, on RN lower side of steering column. 201- 9-A

................. .................... 6312 (2 cavities) Behind rear license plate 201-17-A

............. ..... 6103 (Except VIN E) On radiator support, behind LN headlights 201-16-A

.......................... .... 6104

On radiator support, behind RH headlights. 201-16-A

.......................... ............ 6200 Behind IIP, left of steering column 201-10-A

........................ .......................... 6303 Center of end panel. 201-17-B

.......................... .... S105. Front lights harness, behind LH headlights. 201-16-A

.......................... S106. Front lights harness, LN front corner of engine

compartment..

.......................... 201-1543

.......................... .... S107. Front lights harness, behind LH headlights. 201-16-A

.......................... ..... S109. Front lights harness, left of RH headlights 201-16-A

S110. .......................... Front lights harness, behind RH headlights .... 201-16-A

S205. .......................... IIP harness, behind instrument cluster. ........ 201-10-A

S225. .......................... IIP harness, behind instrument cluster. ........ 201-10-A

S226. .......................... IIP harness, at head of console. ............... 201-10-A

S227. .......................... IIP harness, behind instrument cluster. ........ 201-10-A

S302. .......................... Rear lights harness, LW side of end panel. ...... 201-17-B

.......................... S307. Rear lights harness, LH rear corner of cargo

compartment..

.......................... 201-17-B

.......................... ..... S308. Rear lights harness, behind LH rear lights. 201-17-A

S311. .......................... Rear lights harness, left of RH backup lights ... 201-17-A

3. If the Hazard Lights do not turn off, replace the

4. If the Hazard Lights stay on (do not flash),

Turn-Hazard Switch.

replace the Hazard Flasher.

(Continued on next page)

Page 1476 of 1825

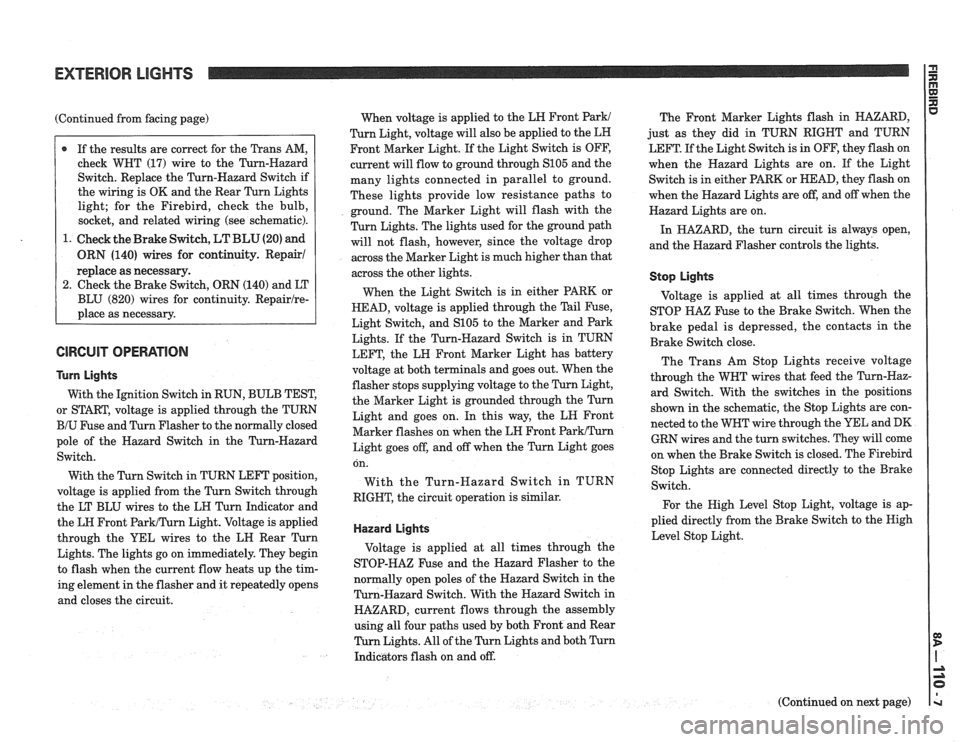

(Continued from facing page)

@ If the results are correct for the Trans AM,

check WHT (17) wire to the Turn-Hazard

Switch. Replace the Turn-Hazard Switch if

the wiring is OK and the Rear Turn Lights

light; for the Firebird, check the bulb,

socket, and related wiring (see schematic).

1. Check the Brake Switch,

LT BLU (20) and

ORN (140) wires for continuity. Repair1

replace as necessary.

2. Check the Brake Switch, ORN (140) and LT

BLU (820) wires for continuity.

Repairlre-

place as necessary.

GlRGUlT OPERATION

Turn Lights

With the Ignition Switch in RUN, BULB TEST,

or START, voltage is applied through the TURN

BIU Fuse and Turn Flasher to the normally closed

pole of the Hazard Switch in the Turn-Hazard

Switch.

With the Turn Switch in TURN LEFT position,

voltage is applied from the Turn Switch through

the LT BLU wires to the LH Turn Indicator and

the LH Front

ParWTurn Light. Voltage is applied

through the YEL wires to the LH Rear Turn

Lights. The lights go on immediately. They begin

to flash when the current flow heats up the tim-

ing element in the flasher and it repeatedly opens

and closes the circuit. When

voltage is applied to the LH Front

Park1

Turn Light, voltage will also be applied to the LH

Front Marker Light. If the Light Switch is OFF,

current will flow to ground through

S105 and the

many lights connected in parallel to ground.

These lights provide low resistance paths to

ground. The Marker Light will flash with the

Turn Lights. The lights used for the ground path

will not flash, however, since the voltage drop

across the Marker Light is much higher than that

across the other lights.

When the Light Switch is in either PARK or

HEAD, voltage is applied through the Tail Fuse,

Light Switch, and

S105 to the Marker and Park

Lights. If the Turn-Hazard Switch is in TURN

LEFT, the LH Front Marker Light has battery

voltage at both terminals and goes out. When the

flasher stops supplying voltage to the Turn Light,

the Marker Light is grounded through the Turn

Light and goes on. In this way, the LN Front

Marker flashes on when the LH Front

ParkITurn

Light goes off, and off when the Turn Light goes The

Front Marker Lights flash in HAZARD,

just as they did in TURN RIGHT and TURN

LEFT. If the Light Switch is in OFF, they flash on

when the Hazard Lights are on. If the Light

Switch is in either PARK or HEAD, they flash on

when the Hazard Lights are off, and off when the

Hazard Lights are on.

In HAZARD, the turn circuit is always open,

and the Hazard Flasher controls the lights.

Stop Lights

Voltage is applied at all times through the

STOP

HA% Fuse to the Brake Switch. When the

brake pedal is depressed, the contacts in the

Brake Switch close.

The Trans Am Stop Lights receive voltage

through the WHT wires that feed the Turn-Haz-

ard Switch. With the switches in the positions

shown in the schematic, the Stop Lights are con-

nected to the WHT wire through the YEL and DK

GRN wires and the turn switches. They will come

on when the Brake Switch is closed. The

Firebird on.

With

RIGHT, Stop

Lights are connected directly to the Brake

the Turn-Hazard Switch in TURN

Switch.

the circuit operation is similar.

For the High Level Stop Light, voltage is ap-

plied directly from the Brake Switch to the Nigh

Hazard Lights Level Stop Light.

Voltage is applied at all times through the

STOP-HAZ Fuse and the Hazard Flasher to the

normally open poles of the Hazard Switch in the

Turn-Hazard Switch. With the Hazard Switch in

HAZARD, current flows through the assembly

using all four paths used by both Front and Rear

Turn Lights. All of the Turn Lights and both Turn

Indicators flash on and off.

(Continued on next page)