AUX PONTIAC FIERO 1988 Service Repair Manual

[x] Cancel search | Manufacturer: PONTIAC, Model Year: 1988, Model line: FIERO, Model: PONTIAC FIERO 1988Pages: 1825, PDF Size: 99.44 MB

Page 51 of 1825

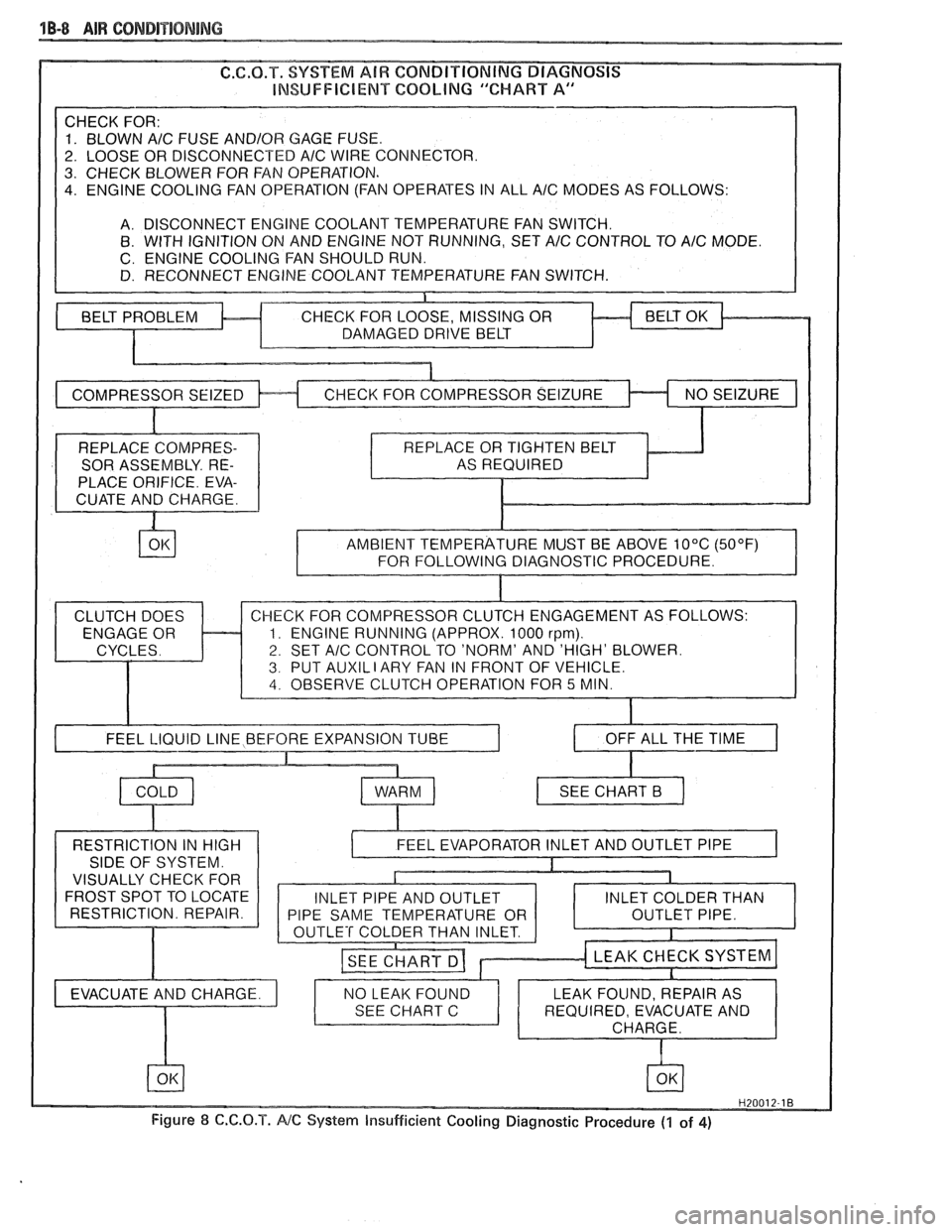

1B-8 AIR CONDITIONING

INSUFFICIENT COQblNG "CHART A

A/C FUSE AND/OR GAGE FUSE.

OR DISCONNECTED

AlC WIRE CONNECTOR.

. CHECK BLOWER FOR FAN OPERATION.

. ENGINE COOLING FAN OPERATION (FAN OPERATES IN ALL A/C MODES AS FOLLOWS:

A. DISCONNECT ENGINE COOLANT TEMPERATURE FAN SWITCH.

8. WITH IGNITION ON AND ENGINE NOT RUNNING, SET A/C CONTROL TO A/C MODE.

C. ENGINE COOLING FAN SHOULD RUN.

D. RECONNECT ENGINE COOLANT TEMPERATURE FAN SWITCH.

REPLACE COMPRES-

SOR ASSEMBLY. RE-

PLACE ORIFICE. EVA-

CUATE AND CHARGE. AS

REQUIRED

AND 'HIGH' BLOWER.

T

AUXIL I ARY FAN IN T OF VEHICLE.

I OFF ALL THE TIME I

RESTRICTION IN HIGH

SIDE OF SYSTEM.

VISUALLY CHECK FOR

FROST SPOT TO LOCATE

RESTRICTION. REPAIR.

Figure

8 C.C.O.T. NC System Insufficient Cooling Diagnostic Procedure (1 of 4)

Page 367 of 1825

6A2-16 2.8 LITER V-6

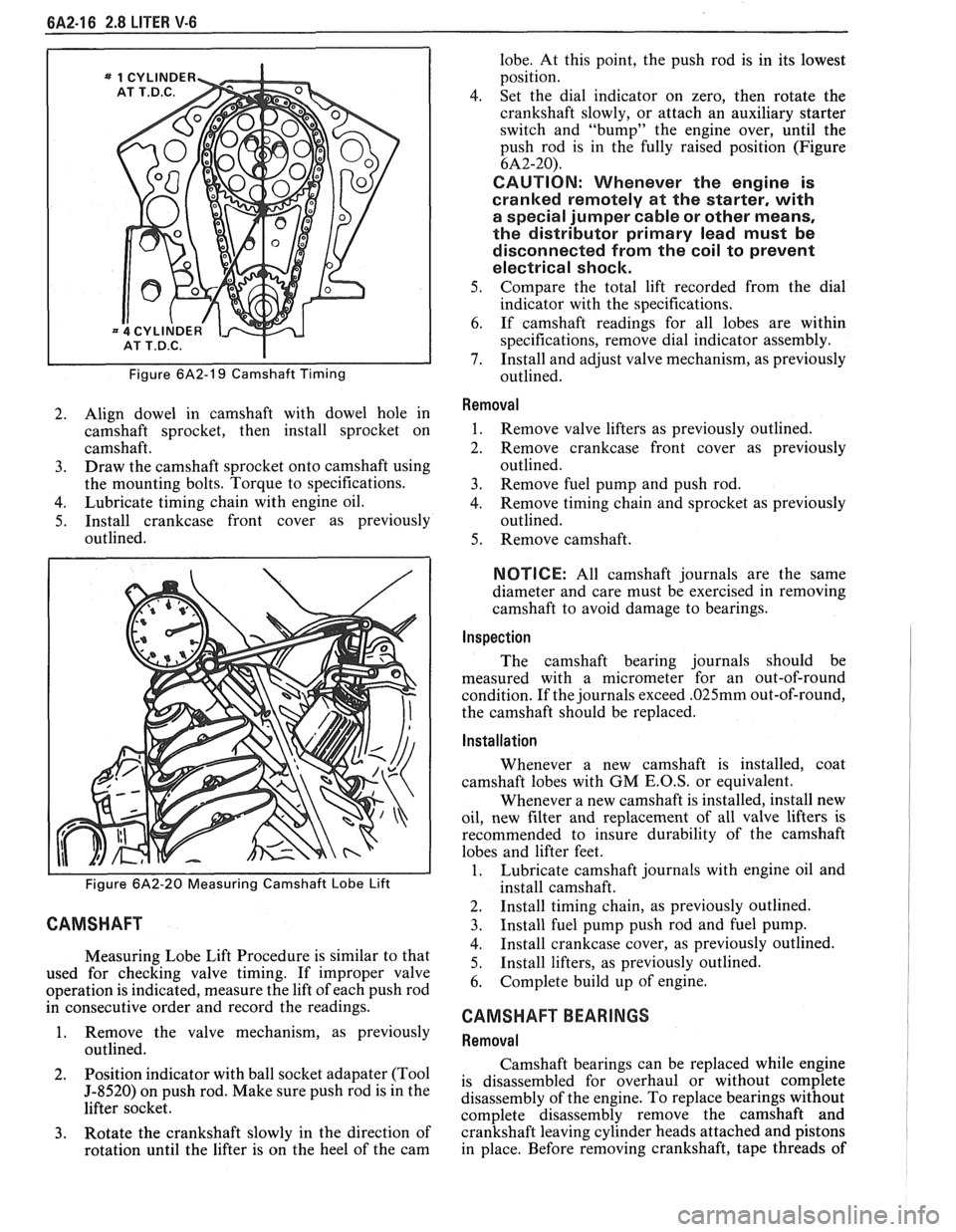

Figure 6A2-19 Camshaft Timing

2. Align dowel in camshaft with dowel hole in

camshaft sprocket, then install sprocket on

camshaft.

3. Draw the camshaft sprocket onto camshaft using

the mounting bolts. Torque to specifications.

4. Lubricate timing chain with engine oil.

5. Install crankcase front cover as previously

outlined.

Figure 6A2-20 Measuring Camshaft Lobe Lift

CAMSHAFT

Measuring Lobe Lift Procedure is similar to that

used for checking valve timing. If improper valve

operation is indicated, measure the lift of each push rod

in consecutive order and record the readings.

1. Remove the valve mechanism, as previously

outlined.

2. Position

indicator with ball socket adapater (Tool

5-8520) on push rod. Make sure push rod is in the

lifter socket.

3. Rotate the crankshaft slowly in the direction of

rotation until the lifter is on the heel of the cam lobe.

At this point, the push rod is in its lowest

position.

4. Set the dial indicator on zero, then rotate the

crankshaft slowly, or attach an auxiliary starter

switch and "bump" the engine over, until the

push rod is in the fully raised position (Figure

6A2-20).

CAUTION: Whenever the engine is

cranked remotely at the starter, with

a special jumper cable or other means,

the distributor primary lead must be

disconnected from the coil to prevent

electrical shock.

5. Compare the total lift recorded from the dial

indicator with the specifications.

6. If camshaft readings for all lobes are within

specifications, remove dial indicator assembly.

7. Install and adjust valve mechanism, as previously

outlined.

Removal

1. Remove valve lifters as previously outlined.

2. Remove crankcase front cover as previously

outlined.

3. Remove fuel pump and push rod.

4. Remove timing chain and sprocket as previously

outlined.

5. Remove camshaft.

NOTICE: All camshaft journals are the same

diameter and care must be exercised in removing

camshaft to avoid damage to bearings.

Inspection

The camshaft bearing journals should be

measured with a micrometer for an out-of-round

condition. If the journals exceed

.025mm out-of-round,

the camshaft should be replaced.

Installation

Whenever a new camshaft is installed, coat

camshaft lobes with

GM E.O.S, or equivalent.

Whenever a new camshaft is installed, install new

oil, new filter and replacement of all valve lifters is

recommended to insure durability of the camshaft

lobes and lifter feet.

1. Lubricate camshaft journals with engine oil and

install camshaft.

2. Install timing chain, as previously outlined.

3. Install fuel pump push rod and fuel pump.

4. Install crankcase cover, as previously outlined.

5. Install

lifters, as previously outlined.

6. Complete build up of engine.

CAMSHAFT BEARINGS

Removal

Camshaft bearings can be replaced while engine

is disassembled for overhaul or without complete

disassembly of the engine. To replace bearings without

complete disassembly remove the camshaft and

crankshaft leaving cylinder heads attached and pistons

in place. Before removing crankshaft, tape threads of

Page 396 of 1825

V-8 ENGINE 6A3.17

4. Set dial indicator on zero, then rotate the

crankshaft slowly, or attach an auxiliary starter

switch and "bump" the engine over, until the

push rod is fully raised position.

e Whenever the engine is cranked remotely at

the started, with a special jumper cable or

other means, the distributor primary lead

should be disconnected from the distributor

(coil).

5. Compare the total lift recorded from the dial

indicator with specifications.

6. If camshaft readings for all lobes are within

specifications, remove dial indicator assembly.

7. Install and adjust valve mechanism as outlined.

Removal

Fig. 6A3-30 Removing Camshaft

1.

Remove valve lifters as previously outlined.

2. Remove crankcase front cover as previously

outlined.

3. Remove grille.

4. Remove fuel pump push rod as outlined in

Section 6C.

5. Complete camshaft removal as follows:

e Sprocket is a light fit on camshaft. If

sprocket does not come off easily a light

blow on the lower edge of the sprocket (with

a plastic mallet) should dislodge the

sprocket.

6. Install two 5/16" - 18 x 4" bolts in camshaft bolt

holes then remove camshaft (fig. 6A3-30).

NOTICE: All camshaft journals are the same

diameter and care must be used in removing

camshaft to avoid damage to bearings.

Inspection

The camshaft bearing journals should be

measured with a micrometer for an out-of-round

condition. If the journals exceed

.001" out-of-round,

the camshaft should be replaced.

Installation

When a new camshaft is installed coat camshaft

lobes with "Molykote" or its equivalent. When a new

camshaft is installed, replacement of all valve lifters is

recommended to insure durability of the camshaft

lobes and lifter feet.

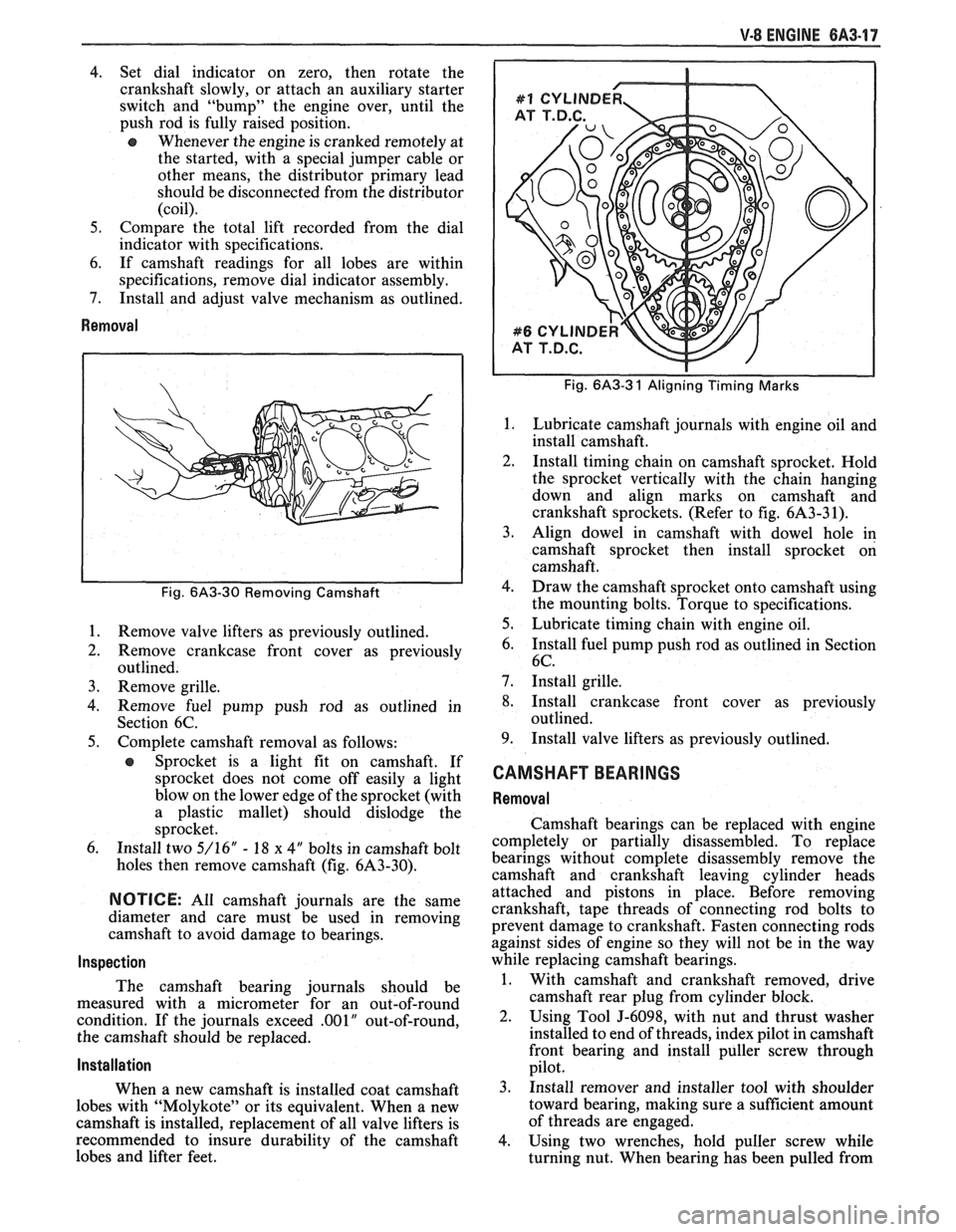

Fig. 6A3-3 1 Aligning Timing Marks

Lubricate camshaft journals with engine oil and

install camshaft.

Install timing chain on camshaft sprocket. Hold

the sprocket vertically with the chain hanging

down and align marks on camshaft and

crankshaft sprockets. (Refer to fig. 6A3-3 1).

Align dowel in camshaft with dowel hole in

camshaft sprocket then install sprocket on

camshaft.

Draw the camshaft sprocket onto camshaft using

the mounting bolts. Torque to specifications.

Lubricate timing chain with engine oil.

Install fuel pump push rod as outlined in Section

6C.

Install grille.

Install crankcase front cover as previously

outlined.

Install valve lifters as previously outlined.

CAMSHAFT BEARINGS

Removal

Camshaft bearings can be replaced with engine

completely or partially disassembled. To replace

bearings without complete disassembly remove the

camshaft and crankshaft leaving cylinder heads

attached and pistons in place. Before removing

crankshaft, tape threads of connecting rod bolts to

prevent damage to crankshaft. Fasten connecting rods

against sides of engine so they will not be in the way

while replacing camshaft bearings.

1. With camshaft and crankshaft removed, drive

camshaft rear plug from cylinder block.

2. Using Tool J-6098, with nut and thrust washer

installed to end of threads, index pilot in camshaft

front bearing and install puller screw through

pilot.

3. Install remover and installer tool with shoulder

toward bearing, making sure a sufficient amount

of threads are engaged.

4. Using two wrenches, hold puller screw while

turning nut. When bearing has been pulled from

Page 417 of 1825

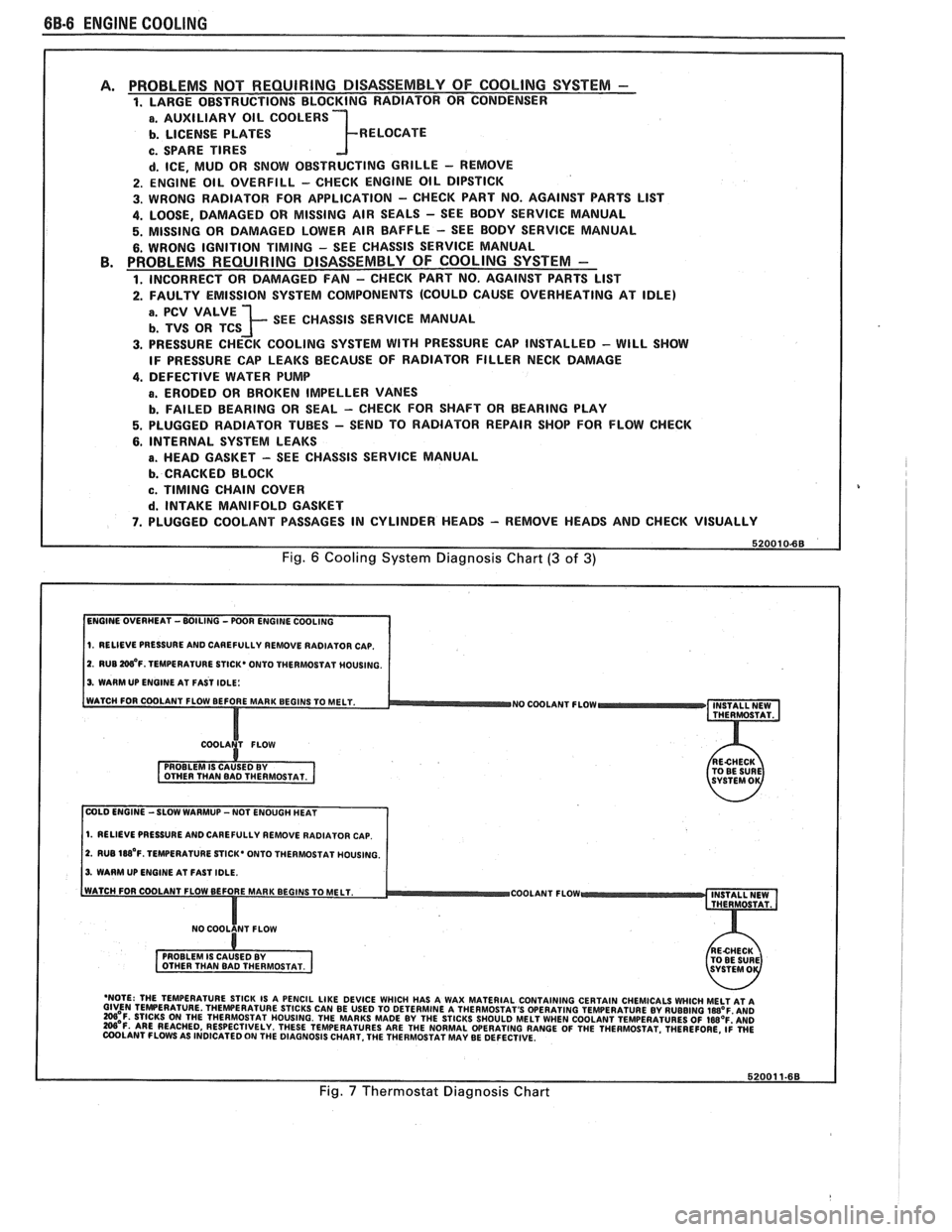

6B-8 ENGINE COOLING

PROBLEMS NOT REQUIRING DISASSEMBLY OF COOLING SYSTEM - 1. LARGE OBSTRUCTIONS BLOCKING RADIATOR OR CONDENSER

a. AUXILIARY OIL COOLERS

b. LICENSE PLATES R ELOCATE

c. SPARE TIRES

d. ICE, MUD OR SNOW OBSTRUCTING GRILLE - REMOVE

2. ENGINE OIL OVERFILL - CHECK ENGINE OIL DIPSTICK

3. WRONG RADIATOR FOR

APPLICATION - CHECK PART NO. AGAINST PARTS LlST

4. LOOSE, DAMAGED OR MISSING AIR SEALS - SEE BODY SERVICE MANUAL

5. MISSING OR DAMAGED LOWER AIR BAFFLE - SEE BODY SERVICE MANUAL

6. WRONG IGNITION TIMING - SEE CHASSIS SERVICE MANUAL PROBLEMS REQUIRING DISASSEMBLY OF COOLING SYSTEM -

1. INCORRECT OR DAMAGED FAN - CHECK PART NO. AGAINST PARTS LlST

2. FAULTY EMISSION SYSTEM COMPONENTS (COULD CAUSE OVERHEATING AT IDLE)

; SEE CHASSIS SERVICE MANUAL

3. PRESSURE CHECK COOLING SYSTEM WITH PRESSURE CAP INSTALLED - WILL SHOW

IF PRESSURE CAP LEAKS BECAUSE OF RADIATOR FILLER NECK DAMAGE

4. DEFECTIVE WATER PUMP

a. ERODED OR BROKEN IMPELLER VANES

b. FAILED BEARING OR SEAL - CHECK FOR SHAFT OR BEARING PLAY

5. PLUGGED RADIATOR TUBES - SEND TO RADIATOR REPAIR SHOP FOR FLOW CHECK

6. INTERNAL SYSTEM LEAKS

B. HEAD GASKET - SEE CHASSIS SERVICE MANUAL

b. CRACKED BLOCK

c. TIMING CHAIN COVER

d. INTAKE MANIFOLD GASKET

7. PLUGGED COOLANT PASSAGES IN CYLINDER HEADS - REMOVE HEADS AND CHECK VISUALLY

Fig. 6 Cooling System Diagnosis Chart (3 of 3)

1. RELIEVE PRESSURE AND CAREFULLY REMOVE RADIATOR CAP.

2. RUB W'F. TEMPERATURE STICK* ONTO THERMOSTAT MOUSING.

3. WARM UP ENGINE AT FAST IDLE:

WATCH FOR COOLANT FLOW BEFORE MAR

NO COOLANT FLOW INSTALL NEW

THERMOSTAT.

COLD ENGINE -SLOW WARMUP -NOT ENOUGH HEAT

1. RELIEVE PRESSURE AND CAREFULLY REMOVE RADIATOR CAP.

2. RUB 188'~. TEMPERATURE STICK' ONTO THERMOSTAT HOUSING.

3. WARM UP ENGINE AT FAST IDLE.

COOLANT FLOW

- 'NOTE: THE TEMPERATURE STICK IS A PENCIL LIKE DEVICE WHICH HAS A WAX MATERIAL CONTAINING CERTAIN CHEMICALS WHICH MELT AT A GIVEN TEMPERATURE THEWERATURE STICKS CAN BE USED TO DETERMINE A THERMOSTAT'S OPERATING TEMPERATURE BY RUBBING laB°F AN0 =OF. STICKS ON THE THERMOSTAT HOUSING. THE MARKS MADE BY THE STICKS SHOULD MELT WHEN COOLANT TEMPERATURES OF IWOF'AND W'F. ARE REACHED, RESPECTIVELY. THESE TEMPERATURES ARE THE NORMAL WERATING RANGE OF THE THERMOSTAT. THEREFORE, ~i WE COOLANT FLOWS AS INDICATED ON THE DIAGNOSIS CHART. THE THERMOSTAT MAY BE DEFECTIVE.

Fig. 7 Thermostat Diagnosis Chart

Page 447 of 1825

6D1-4 BATTERY

VOLTAGE

A. 16.0 or more

B. 14.0

- 15.9

C. 13.9 or less HOURS

1. Set parking brake and place automatic

Up to 4 Hours transmission in "PARK" (NEUTRAL for

Up to 8 Hours manual transmission.) Turn off the ignition,

Up to 16 Hours turn off lights, and all other electrical

If the charge current is still not

measurable

at the end of the above charging

times, the battery should be replaced.

If the charge current is measurable during

the charging time, the battery is considered to be

good and charging should be completed in the

normal manner.

5. It

is important to remember that a completely

discharged battery must be recharged for a

sufficient number of ampere hours (AH) to

restore it to a usable state. As a general rule of

thumb, using the reserve capacity rating (RC) of

the battery as the number of ampere hours of

charge will usually bring the green dot into view.

For example, if battery is rated at 75 RC minutes,

it would be completely recharged as follows:

10 ampere charge x 7-1/2 hours

= 75 AH

25 ampere charge x 3 hours = 75 AH, etc.

6. It

is recommended that any battery recharged by

this procedure be

LOAD TESTED to establish

serviceability.

JUMP STARTING IN CASE OF EMERGENCY

WITH AUXILIARY (BOOSTER) BAVEEWY

NOTICE: Do not push or tow the vehicle to start.

Damage to the emission system, or to other parts

of the vehicle may result.

Both booster and discharged battery should be

treated carefully when using jumper cables. Follow the

procedure outlined below, being careful not to cause

sparks:

CAUTION: Departure from these

conditions or the procedure below

could result in:

(1) Serious personal

injury (particularly to eyes) or property

damage from such causes as battery

explosion, battery acid, or electrical

burns; and/or

(2) damage to electronic

components of either vehicle.

Never expose battery to open flame or electric

spark

- batteries generate a gas which is flammable and

explosive.

Remove rings, watches, and other jewelry. Wear

approved eye protection.

Do not allow battery fluid to contact eyes, skin,

fabrics, or painted surfaces

- fluid is a corrosive acid.

Flush any contacted area with water immediately and

thoroughly. Be careful that metal tools or jumper

cables do not contact the positive battery terminal (or

metal in contact with it) and any other metal on the

car, because a short circuit could occur. Batteries

should always be kept out of the reach of children.

loads.

2. Check the built-in hydrometer. If it is clear or

light yellow, replace the battery.

3. Attach the end of one jumper cable to the positive

terminal of the booster battery and the other end

of the same cable to the positive terminal of the

discharged battery. Do not permit vehicles to

touch each other as this could cause a ground

connection and counteract the benefits of this

procedure. (Use 12-volt battery only to jump start

the engine).

4. Attach one end of the remaining negative cable

to the negative terminal of the booster battery,

and the other end to a solid engine ground (such

as

A/C compresser bracket or generator

mounting bracket) at least 18 inches from the

battery of the vehicle being started (DO NOT

CONNECT DIRECTLY TO THE NEGATIVE

TERMINAL OF THE DEAD BATTERY).

5. Start the engine of the vehicle that is providing

the jump start and turn off electrical accessories.

Then start the engine in the car with the

discharged battery.

6. Reverse these directions exactly when removing

the jumper cables. The negative cable must be

disconnected from the engine that was jump

started first.

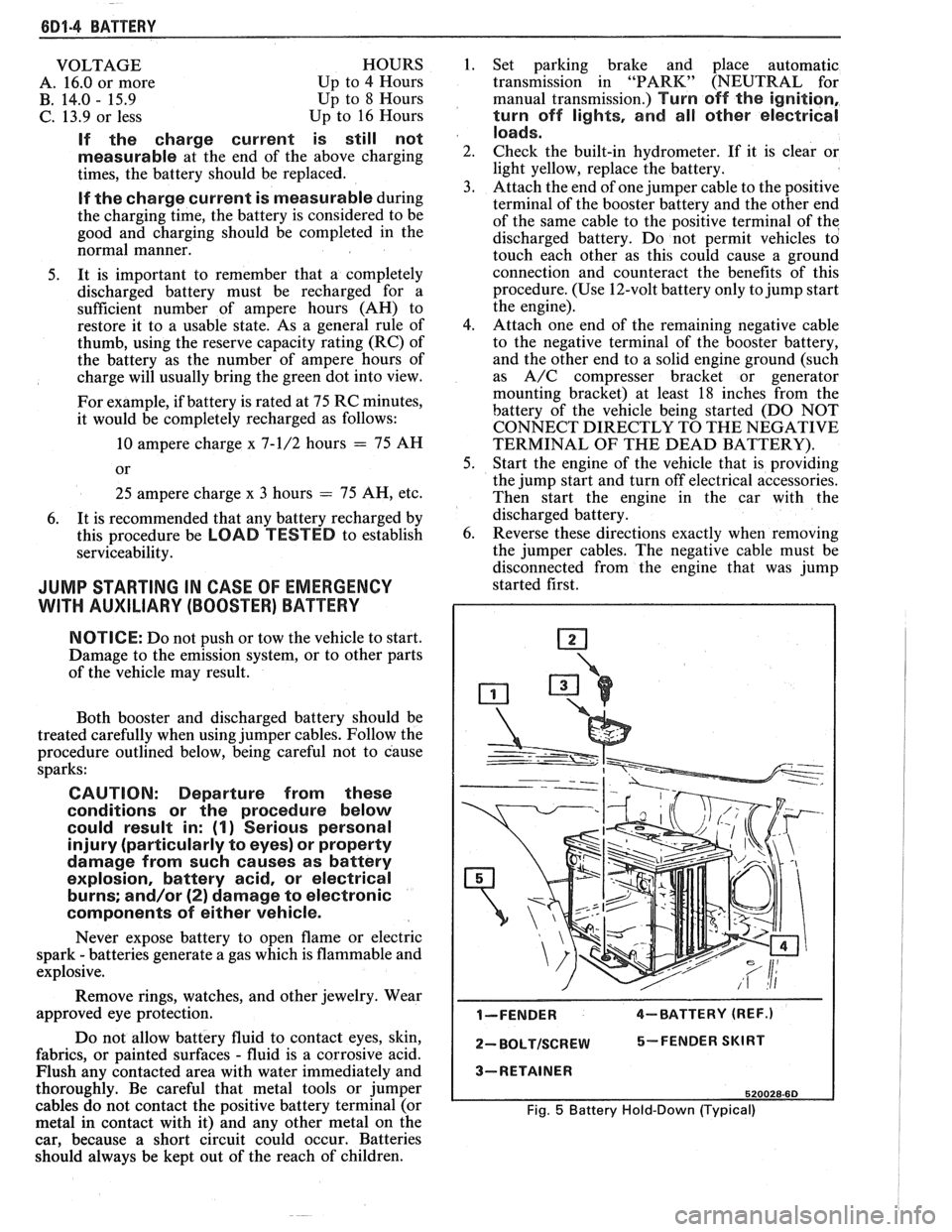

I-FENDER 4-BATTERY (REF.)

2- BOLTISCREW 5-FENDER SKIRT

3-RETAINER

520028-60

Fig. 5 Battery Hold-Down (Typical)

Page 1001 of 1825

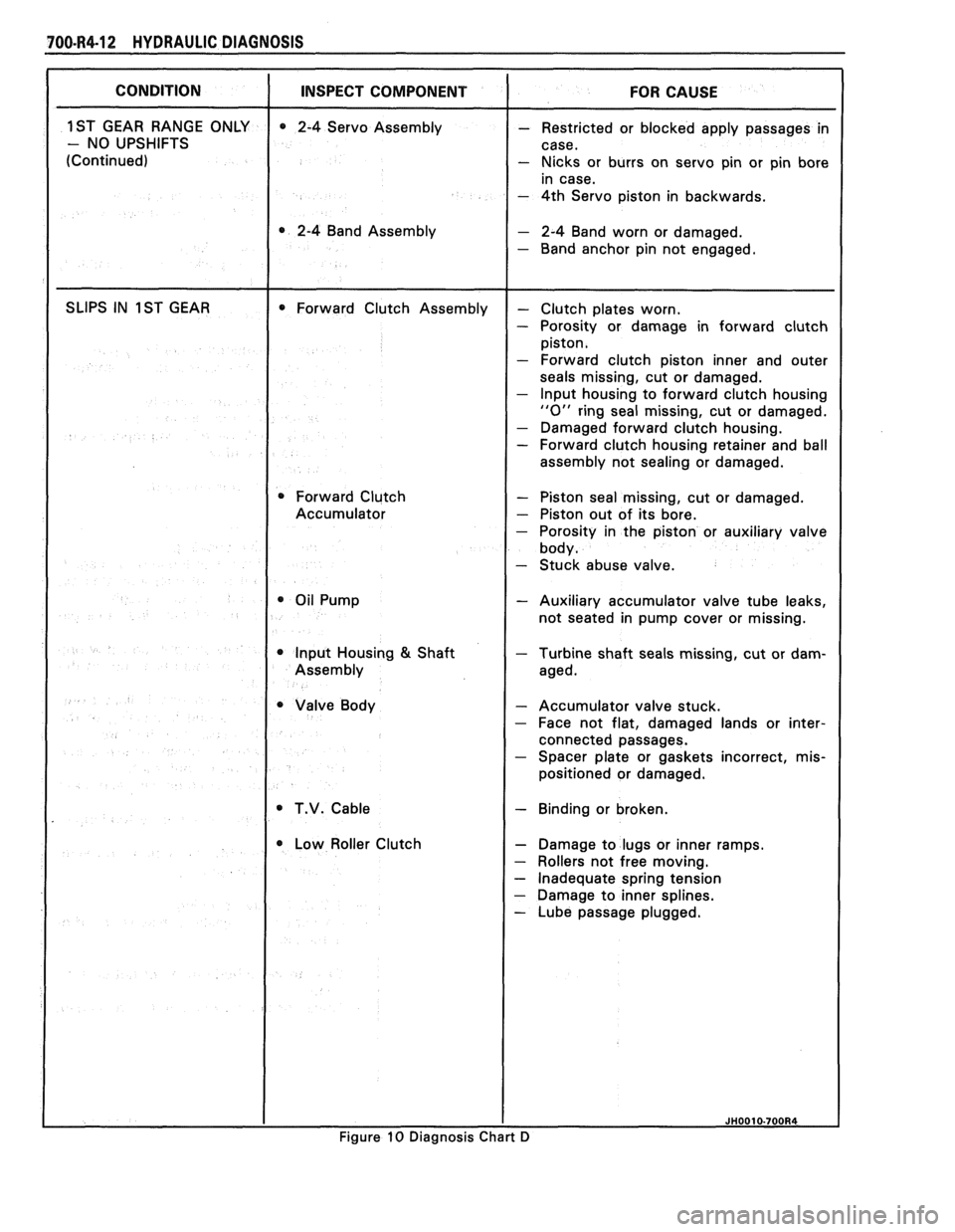

700-R4-12 HY DRAULlC DIAGNOSIS

- Nicks or burrs on servo pin or pin bore

- 4th Servo piston in backwards.

0 2-4 Band Assembly - 2-4 Band worn or damaged.

- Band anchor pin not engaged.

seals missing, cut or damaged.

- lnput housing to forward clutch housing

"0" ring seal missing, cut or damaged.

- Damaged forward clutch housing. - Forward clutch housing retainer and ball

assembly not sealing or damaged.

0 Forward Clutch - Piston seal missing, cut or damaged.

Accumulator

- Piston out of its bore.

- Stuck abuse valve.

- Auxiliary accumulator valve tube leaks,

not seated in pump cover or missing.

Input Housing

& Shaft - Turbine shaft seals missing, cut or dam-

- Accumulator valve stuck. - Face not flat, damaged lands or inter-

connected passages.

- Spacer plate or gaskets incorrect, mis-

positioned or damaged.

T.V. Cable - Binding or broken.

Low Roller Clutch

- Damage to lugs or inner ramps.

- Rollers not free moving.

- Inadequate spring tension

- Damage to inner splines.

- Lube passage plugged.

Figure

10 Diagnosis Chart D

Page 1005 of 1825

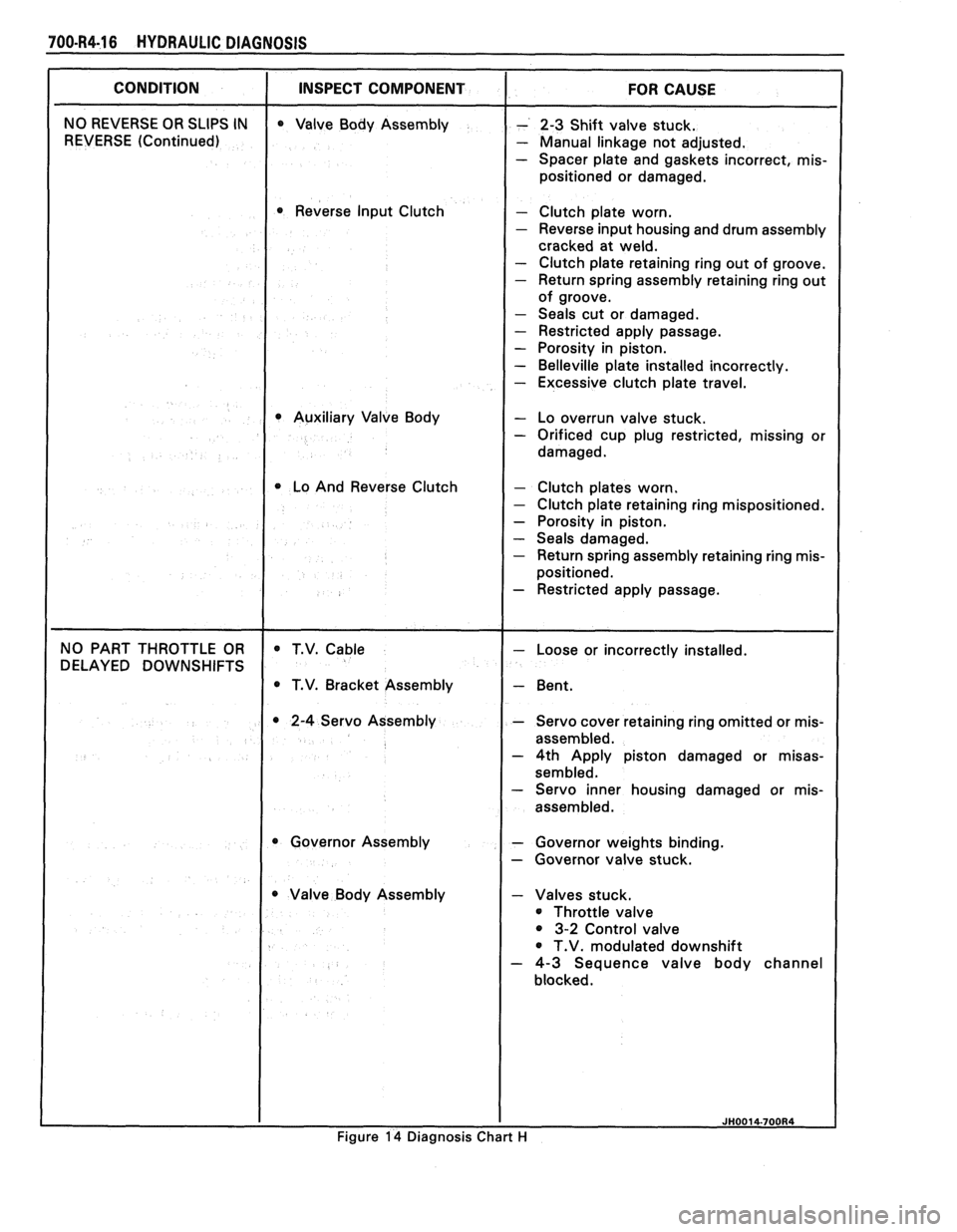

700-R4-16 HYDRAULIC DIAGNOSIS

I CONDITION I INSPECT COMPONENT I FOR CAUSE

NO REVERSE OR SLIPS IN

REVERSE (Continued) Valve

Body Assembly

Reverse Input Clutch

Auxiliary Valve Body

1 Lo And Reverse Clutch

- 2-3 Shift valve stuck.

- Manual linkage not adjusted.

- Spacer plate and gaskets incorrect, mis-

positioned or damaged.

Clutch plate worn.

Reverse input housing and drum assembly

cracked at weld.

Clutch plate retaining ring out of groove.

Return spring assembly retaining ring out

of groove.

Seals cut or damaged.

Restricted apply passage.

Porosity in piston.

Belleville plate installed incorrectly.

Excessive clutch plate travel.

- Lo overrun valve stuck. - Orificed cup plug restricted, missing or

damaged.

- Clutch plates worn. - Clutch plate retaining ring mispositioned.

- Porosity in piston.

- Seals damaged. - Return spring assembly retaining ring mis-

positioned.

- Restricted apply passage.

NO PART THROTTLE OR

DELAYED DOWNSHIFTS T.V.

Cable

T.V. Bracket Assembly

2-4 Servo Assembly

Governor Assembly

Valve Body Assembly

I

- Loose or incorrectly installed.

- Bent.

- Servo cover retaining ring omitted or mis-

assembled.

- 4th Apply piston damaged or misas-

sembled. - Servo inner housing damaged or mis-

assembled.

- Governor weights binding.

- Governor valve stuck.

- Valves stuck.

Throttle valve

3-2 Control valve

T.V. modulated downshift

- 4-3 Sequence valve body channel

blocked.

I I JH0014-700R4

Figure 14 Diagnosis Chart H

Page 1054 of 1825

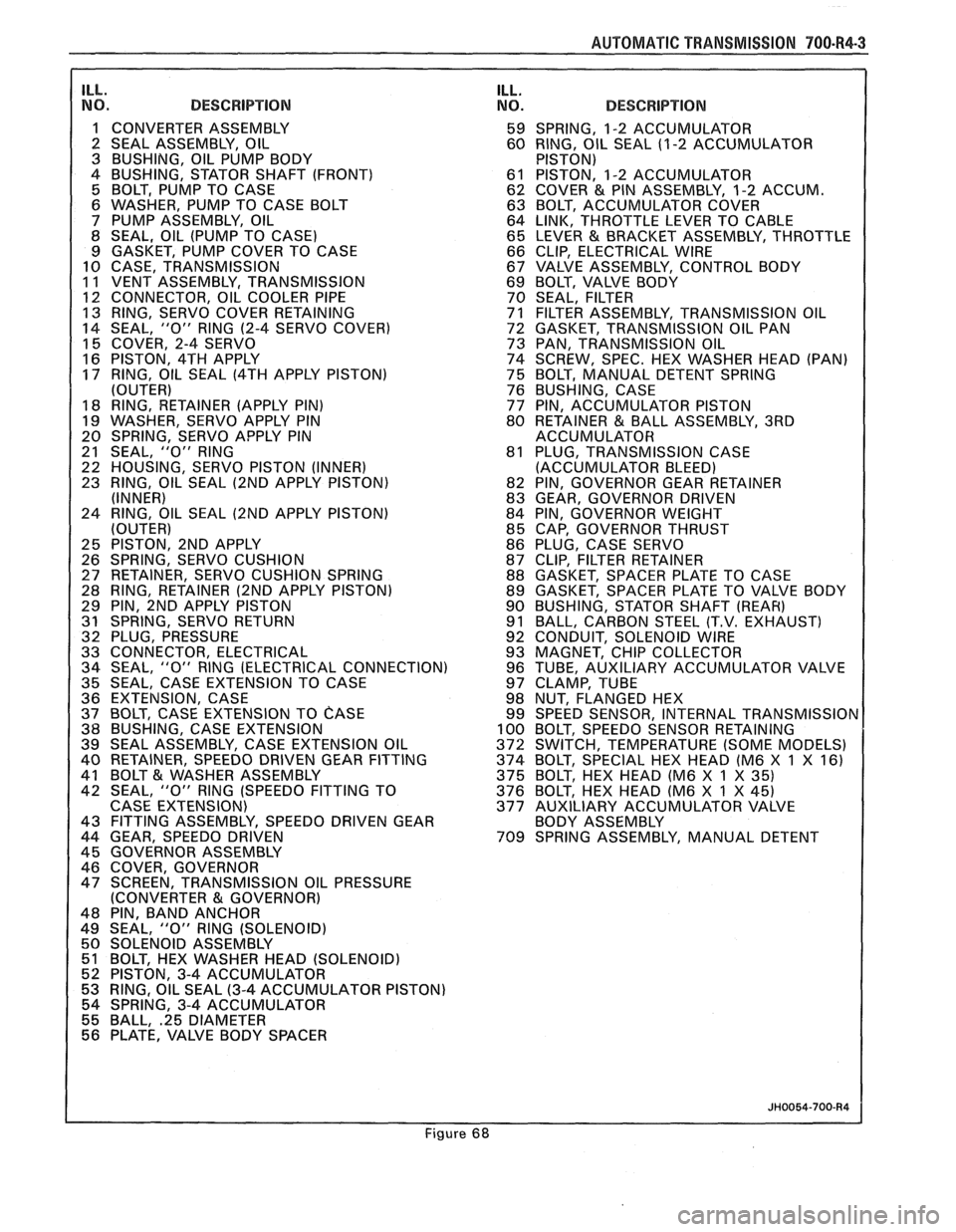

AUTOMAT lC TRANSMISSION 700-R4-3

ILL. NO. DESCRIPTION

1 CONVERTER ASSEMBLY

2 SEAL ASSEMBLY, OIL

3 BUSHING, OIL PUMP BODY

4 BUSHING, STATOR SHAFT (FRONT)

5 BOLT, PUMP TO CASE

6 WASHER, PUMP TO CASE BOLT

7 PUMP ASSEMBLY, OIL

8 SEAL, OIL (PUMP TO CASE)

9 GASKET, PUMP COVER TO CASE

10 CASE, TRANSMISSION

11 VENT ASSEMBLY, TRANSMISSION

1 12 CONNECTOR, OIL COOLER PIPE 13 RING, SERVO COVER RETAINING

14 SEAL, "0" RlNG

(2-4 SERVO COVER)

15 COVER, 2-4 SERVO

16 PISTON, 4TH APPLY

17 RING, OIL SEAL

(4TH APPLY PISTON)

(OUTER)

18 RING, RETAINER (APPLY PIN)

19 WASHER, SERVO APPLY PIN

20 SPRING, SERVO APPLY PIN

21 SEAL,

"0" RlNG

22 HOUSING, SERVO PISTON (INNER)

23 RING, OIL SEAL

(2ND APPLY PISTON)

(INNER)

24 RING, OIL SEAL

(2ND APPLY PISTON)

(OUTER)

25 PISTON, 2ND APPLY

26 SPRING, SERVO CUSHION

27 RETAINER, SERVO CUSHION SPRING

28 RING, RETAINER

(2ND APPLY PISTON)

29 PIN, 2ND APPLY PISTON

31 SPRING, SERVO RETURN

32 PLUG, PRESSURE

33 CONNECTOR, ELECTRICAL

34 SEAL,

"0" RlNG (ELECTRICAL CONNECTION)

35 SEAL, CASE EXTENSION TO CASE

36 EXTENSION, CASE

37 BOLT, CASE EXTENSION TO

CASE 38 BUSHING, CASE EXTENSION

39 SEAL ASSEMBLY, CASE EXTENSION OIL

40 RETAINER, SPEEDO DRIVEN GEAR FITTING

41 BOLT

& WASHER ASSEMBLY

42 SEAL, "0" RlNG (SPEEDO FITTING TO

CASE EXTENSION)

43 FITTING ASSEMBLY, SPEEDO DRIVEN GEAR

44 GEAR, SPEEDO DRIVEN

45 GOVERNOR ASSEMBLY

46 COVER, GOVERNOR

47 SCREEN, TRANSMISSION OIL PRESSURE

(CONVERTER

81 GOVERNOR)

48 PIN, BAND ANCHOR

49 SEAL,

"0" RlNG (SOLENOID)

50 SOLENOID ASSEMBLY

51 BOLT, HEX WASHER HEAD (SOLENOID)

52 PISTON, 3-4 ACCUMULATOR

53 RING, OIL SEAL

(3-4 ACCUMULATOR PISTON)

54 SPRING, 3-4 ACCUMULATOR

55 BALL,

.25 DIAMETER 56 PLATE, VALVE BODY SPACER

ILL. NO. DESCRIPTION

59 SPRING, 1-2 ACCUMULATOR

60 RING, OIL SEAL (1

-2 ACCUMULATOR

PISTON)

61 PISTON, 1-2 ACCUMULATOR

62 COVER

& PIN ASSEMBLY, 1-2 ACCUM.

63 BOLT, ACCUMULATOR COVER

64 LINK, THROTTLE LEVER TO CABLE

65 LEVER

& BRACKET ASSEMBLY, THROTTLE

66 CLIP, ELECTRICAL WIRE

67 VALVE ASSEMBLY, CONTROL BODY

69 BOLT, VALVE BODY

70 SEAL, FILTER

71 FILTER ASSEMBLY, TRANSMISSION OIL

72 GASKET, TRANSMISSION OIL PAN

73 PAN, TRANSMISSION OIL

74 SCREW, SPEC. HEX WASHER HEAD (PAN)

75 BOLT, MANUAL DETENT SPRING

76 BUSHING, CASE

77 PIN, ACCUMULATOR PISTON

80 RETAINER

& BALL ASSEMBLY, 3RD

ACCUMULATOR

81 PLUG, TRANSMISSION CASE

(ACCUMULATOR BLEED)

82 PIN, GOVERNOR GEAR RETAINER

83 GEAR, GOVERNOR DRIVEN

84 PIN, GOVERNOR WEIGHT

85 CAP, GOVERNOR THRUST

86 PLUG, CASE SERVO

87 CLIP, FILTER RETAINER

88 GASKET, SPACER PLATE TO CASE

89 GASKET, SPACER PLATE TO VALVE BODY

90 BUSHING, STATOR SHAFT

(REAR)

91 BALL, CARBON STEEL (T.V. EXHAUST)

92 CONDUIT, SOLENOID WIRE

93 MAGNET, CHIP COLLECTOR

96 TUBE, AUXILIARY ACCUMULATOR VALVE

97 CLAMP, TUBE

98 NUT, FLANGED HEX

99 SPEED SENSOR, INTERNAL

TRANSMISSIOr 100 BOLT, SPEEDO SENSOR RETAINING

372 SWITCH, TEMPERATURE (SOME MODELS)

374 BOLT, SPECIAL HEX HEAD (M6 X

1 X 16)

375 BOLT, HEX HEAD (M6 X 1 X

35) 376 BOLT, HEX HEAD (M6 X 1 X 45)

377 AUXILIARY ACCUMULATOR VALVE

BODY ASSEMBLY

709 SPRING ASSEMBLY, MANUAL DETENT

Figure 68

Page 1056 of 1825

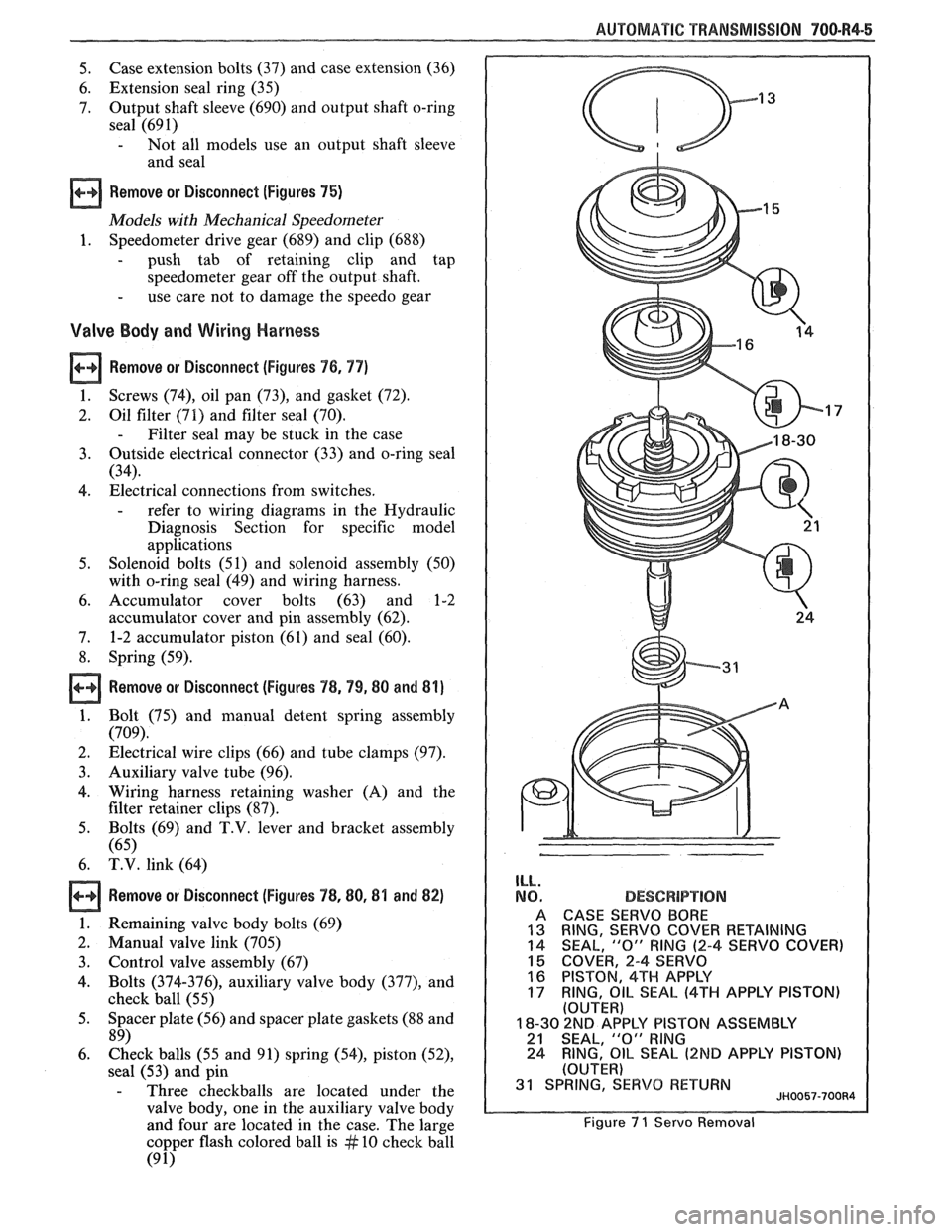

AUTOMA"PI&: TRANSMISSION 780-R4-5

5. Case extension bolts (37)

and case extension (36)

6. Extension seal ring (35)

7. Output

shaft sleeve (690) and output shaft o-ring

seal (691)

- Not all models use an output shaft sleeve

and seal

a Remove or Disconnect (Figures 75)

Models with Mechanical Speedometer

1. Speedometer drive gear

(689) and clip (688)

- push tab of retaining clip and tap

speedometer gear off the output shaft.

- use care not to damage the speedo gear

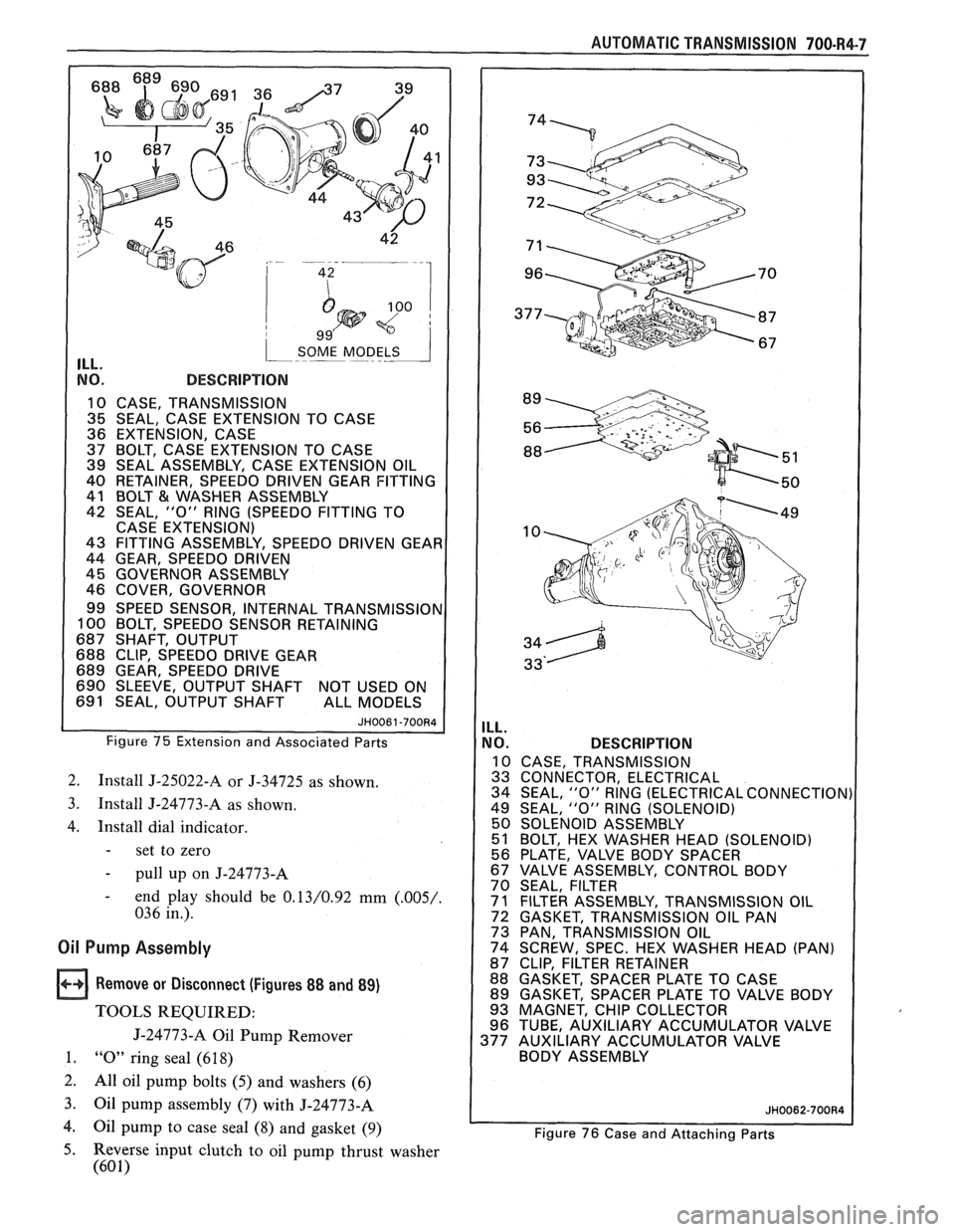

Valve Body and Wiring Harness

Remove or Disconnect (Figures 76, 77)

1. Screws (74), oil

pan (73), and gasket (72).

2. Oil filter

(71) and filter seal (70).

- Filter seal may be stuck in the case

3. Outside

electrical connector (33) and o-ring seal

(34).

4. Electrical connections from switches.

- refer to wiring diagrams in the Hydraulic

Diagnosis Section for specific model

applications

5. Solenoid bolts

(51) and solenoid assembly (50)

with o-ring seal (49) and wiring harness.

6. Accumulator cover bolts (63) and 1-2

accumulator cover and pin assembly (62).

7. 1-2 accumulator piston (61) and seal (60).

8. Spring (59).

Remove or Disconnect (Figures 78,99,88 and 81)

1. Bolt (75) and manual detent spring assembly

(709).

2. Electrical wire clips (66) and tube clamps (97).

3. Auxiliary valve tube (96).

4. Wiring harness retaining washer (A) and the

filter retainer clips

(87).

5. Bolts (69) and T.V. lever and bracket assembly

(65)

6. T.V. link (64)

Remove or Disconnect (Figures 78,88,8'1 and 82)

1. Remaining valve body bolts (69)

2. Manual valve link (705)

3. Control valve assembly (67)

4. Bolts

(374-376), auxiliary valve body (377), and

check

ball (55)

5. Spacer plate (56) and spacer plate gaskets (88 and

89)

6. Check balls (55 and 91) spring (54), piston (52),

sea1 (53) and pin

- Three checkballs are located under the

valve body, one in the auxiliary valve body

and four are located in the case. The large

copper flash colored ball is

# 10 check ball

(9 1)

ILL.

NO.

A

13 14

15 16

17

DESCBPlPT!ON

CASE SERVO BORE

RING,

SERVO COVER RETAINING

SEAL, "0" RING (2-4 SERVO COVER)

COVER, 2-4 SERVO

PISTON, 4TH APPLY

RING,

OIL SEAL (4TH APPLY PISTON) (OUTER)

18-30 2ND AP'PLY PISTON ASSEMBLY 21 SEAL, "0" RlNG

24 RING, OIL SEAL (2ND APPLY

PISTON)

(OUTER) 31 SPRING, SERVO RETURN JH0057-700R4

Figure 7 1 Servo Removal

Page 1058 of 1825

1 SOME MODELS 1 ILL.

NO. DESCRIPTION

10 CASE, TRANSMISSION

1 35 SEAL, CASE EXTENSION TO CASE

36 EXTENSION, CASE

37 BOLT,

CASE EXTENSION TO CASE

39 SEAL ASSEMBLY, CASE EXTENSION OIL

40 RETAINER, SPEEDO

DRIVEN GEAR FITTING

41 BOLT

& WASHER ASSEMBLY

42 SEAL,

"0" RlNG (SPEEDO FITTING TO

CASE EXTENSION)

43 FITTING ASSEMBLY, SPEEDO DRIVEN GEAI

44 GEAR, SPEEDO DRIVEN

45 GOVERNOR ASSEMBLY

46 COVER, GOVERNOR

99 SPEED SENSOR, INTERNAL

TRANSMISSIOI 100 BOLT, SPEEDO SENSOR RETAINING

687 SHAFT, OUTPUT

688 CLIP, SPEEDO DRIVE GEAR

689 GEAR, SPEEDO DRIVE

690 SLEEVE, OUTPUT SHAFT NOT USED ON

691 SEAL, OUTPUT SHAFT ALL MODELS

Figure 75 Extension and Associated Parts

2. Install J-25022-A or J-34725 as shown.

3. Install J-24773-A as shown.

4. Install dial indicator.

- set to zero

- pull up on J-24773-A

- end play should be 0.13/0.92 mm (.005/.

036 in.).

Oil Pump Assembly

Remove or Disconnect (Figures 88 and 89)

TOOLS REQUIRED:

J-24773-A Oil Pump Remover

1. "0" ring seal (6 18)

2.

All oil pump bolts (5) and washers (6)

3.

Oil pump assembly (7) with J-24773-A

4. Oil pump to case seal (8) and gasket (9)

AUTOMATIC TRANSMISSION 700-R4-7

ILL.

NO. DESCRIPTION

10 CASE, TRANSMISSION

33 CONNECTOR, ELECTRICAL

34 SEAL,

"0" RlNG (ELECTRICAL CONNECTION)

49 SEAL,

"0" RlNG (SOLENOID)

50 SOLENOID ASSEMBLY

51 BOLT, HEX WASHER HEAD (SOLENOID)

56 PLATE. VALVE BODY SPACER

/ 67 VALVE' ASSEMBLY, CONTROL BODY

70 SEAL, FILTER

1 71 FILTER ASSEMBLY, TRANSMISSION OIL

72 GASKET, TRANSMISSION OIL PAN

73 PAN, TRANSMISSION OIL

74 SCREW, SPEC. HEX WASHER HEAD (PAN)

87 CLIP, FILTER RETAINER

88 GASKET, SPACER PLATE TO CASE

89 GASKET, SPACER PLATE TO VALVE BODY

93 MAGNET, CHIP COLLECTOR

96 TUBE, AUXILIARY ACCUMULATOR VALVE

377 AUXILIARY ACCUMULATOR VALVE

BODY ASSEMBLY

Figure 76 Case and Attaching Parts

5. Reverse input clutch to oil pump thrust washer

(60 1)