ECU PONTIAC FIERO 1988 Service Repair Manual

[x] Cancel search | Manufacturer: PONTIAC, Model Year: 1988, Model line: FIERO, Model: PONTIAC FIERO 1988Pages: 1825, PDF Size: 99.44 MB

Page 22 of 1825

MAINTENANCE AND LUBRICATION OB-5

Throttle linkage inspection -- Inspect for inter-

ference, binding, damaged or missing parts.

Engine drive belts inspection - Inspect all

belts for cracks, fraying and wear. Adjust or replace as

needed.

Rear axle service (if equipped) - Check gear

lubricant level and add if needed. For cars equipped with a

limited slip rear axle, fluid does not require changing

(except Caprice and Corvette

- change fluid and required

additive at first

7,500 miles (12 500 km). See your

Owner's Manual or "Recommended Fluids

& Lubricants

Chart" in this section.

IF YOU USE YOUR GAR TO PULL A TRAILER,

CHANGE GEAR LUBRICANT EVERY 7,500 MILES

(12 500 KM).

NOTICE: A large loss in this system may indicate a

problem. Have it inspected and repaired at once.

Power antenna - Clean and then lubricate power

antenna mast. The proper lubricant as shown in Figure

OB-2 should be used.

AT LEAST ONCE A YEAR

Lap and shoulder belts condition and opera-

tion

- Inspect belt system, including webbing, buckles,

latch plates, retractors, guide loops and anchors.

Moveable head restraint operation - On cars

with moveable restraints, make sure restraints stay in the

desired position. (See adjustment instructions in your

Owner's Manual.)

Seatback latch and recliner operation on

cars equipped

with recliner seat --- Be sure seat-

backs latch on those cars with folding seats using mechan-

ical latches. Make sure the recliner is holding by pushing

and pulling on the top of the

seatback while it is reclined.

See your Owner's Manual for seat operating information.

Spare tire and jack storage- Be alert to rattles

in rear of car. Make sure the space tire, all jacking equip-

ment, any tire inflator and any covers or doors are securely

stowed at all times. Oil jack ratchet or screw mechanism

after each use.

Key lock service - Lubricate key lock cylinder at

least annually.

Body lubrication service - Lubricate all body

door hinges including the tailgate or hatchback lid (if

equipped). Also lubricate the body hood, fuel door and

rear compartment hinges and latches including interior

glove box and counsel doors, and any folding seat

hardware.

"Fansmissionltransaxle neutral or clutch

starl switch operation

CAUnON: Before pedorming the follow-

ing safety switch check, be sure to have

enough room around the car. Then, firmly

apply both the parking brake (see your

Owner's Manual for procedure) and the

regular brakes. Do not use the accelerator pedal.

If the engine

starls, be ready to turn

off the ignition promptly. Take these pre-

cautions because the car could move

without warning and possibly cause per-

sonal injury or properly damage. On auto-

matic transmissionltransaxle cars, try to

starl the engine in each gear. The starler

should crank only in "Park" or "Neutral."

On manual transmissionltransaxle cars,

place the

shiR lever in "Neutral," push the

clutch halfway and try to starl. The starler

should crank only when the clutch is fully

depressed.

Steering column lock operation

- While

parked, try to turn key to "Lock" in each gear range. The

key should turn to "Lock" only when gear is in "Park" on

automatic or "Reverse" on manual

transmissionltransax-

le. On cars with key release lever, try to turn key toULock"

without depressing the lever. The key should turn to

"Lock" only with the key lever depressed. On all vehicles,

the key should come out only in "Lock."

Parking brake and transmissionltransaxle

"Park" mechanism operation

CAUT1ON:Before checking the holding

ability of the parking brake and automatic

transmissionltransaxle "Park" mecha-

nism, park on a fairly steep hill with

enough room for movement in the down-

hill direction. To reduce the risk of person-

al injury or property damage, be prepared

to apply the regular brakes promptly if the

car begins to move.

To check the parking brake, with the engine running and

transmission/transaxle in "Neutral." slowly remove foot

pressure from the regular brake pedal (until the car is held

by only the parking brake).

To check the automatic transmissionltransaxle "Park"

mechanism holding ability, release all brakes after shift-

ing the transmissionltransaxle to "Park."

ljnderbody flushing - At least every spring,

tlush from the underbody with plain water any corrosive

materials used for ice and snow removal and dust control.

Take care to thoroughly clean any areas where mud and

other debris can collect.

Sediment packed in closed areas

of the vehicle should be loosened before being flushed.

Engine cooling system service - Inspect

coolant and freeze protection. If dirty or rusty, drain, flush

and refill with new coolant. Keep coolant

at the proper

mixture as specified in your Owner's Manual. This pro-

vides proper freeze protection. corrosion inhibitor level

and engine operating temperature. Inspect hoses and re-

place if cracked. swollen or deteriorated. Tighten hose

clamps. Clean outside of radiator and air conditioning

condensor. Wash radiator filler cap and neck.

To help

ensure proper operation. a pressure test of both the cooling

system and cap is also recommended. (See maintenance

schedule charts in Figure

OB-l for the recommended

coolant change interval.)

Page 80 of 1825

W-4 AIR CONDITIONING COMPRESSOR OVERHAUL 1 Dl-l

SECTION 1 Dl

R COND NG COMPRESSOR

OVERHAUL

For Compressor REMOVAL AND INSTALLATION, see Air Conditioning Section 1B. For

DISCHARGING, ADDING OIL, EVACUATING AND CHARGING PROCEDURES FOR

A/C

SYSTEMS, see Air Conditioning Section 1B.

CONTENTS

General Description ............................... 1D1-1

Service Procedures .................................. 1D1-4

Minor Repair Procedures ....................... 1D1-4

Clutch Plate and Hub Assembly ............... 1D1-4

Clutch Rotor and Bearing: Four-Pole

Clutch

..................................................... 1D1-5

Clutch Rotor and Bearing: Six-Pole

Clutch

.......................... ... ....................... 1 D 1-7

Clutch Coil and Pulley Rim ...................... 1 D 1 - 10

Major Repair Procedures ....................... 1D1-12

Shaft Seal .................................................. 1Dl-12

Seal Leak Detection ........................... .... 1D1-12

Replacement (On Car) ........................... 1 D 1- 12

Replacement (Off Car)

........................... 1 D 1 - 13

Pressure Relief Valve

................................. 1 D 1 - 13

Nigh Pressure Cut-Off Switch

................... 1 D 1 - 13

Front Head and 0-Ring

............................ 1 D 1 - 14

Thrust and Belleville Washers

................... 1 D 1 - 16

Main Bearing

.............................................. 1 D 1- 16

Shell and 0-Ring

....................................... 1D 1- 17

Discharge Valve Plate and Retainer

......... 1 D 1 - 18

Cylinder and Shaft Assembly

.................... 1 D 1 - 19

Leak Testing (External and Internal)

........ 1D1- 19

Special Tools ..................................... ... .. 1D1-21

GENERAL DESCRIPTION

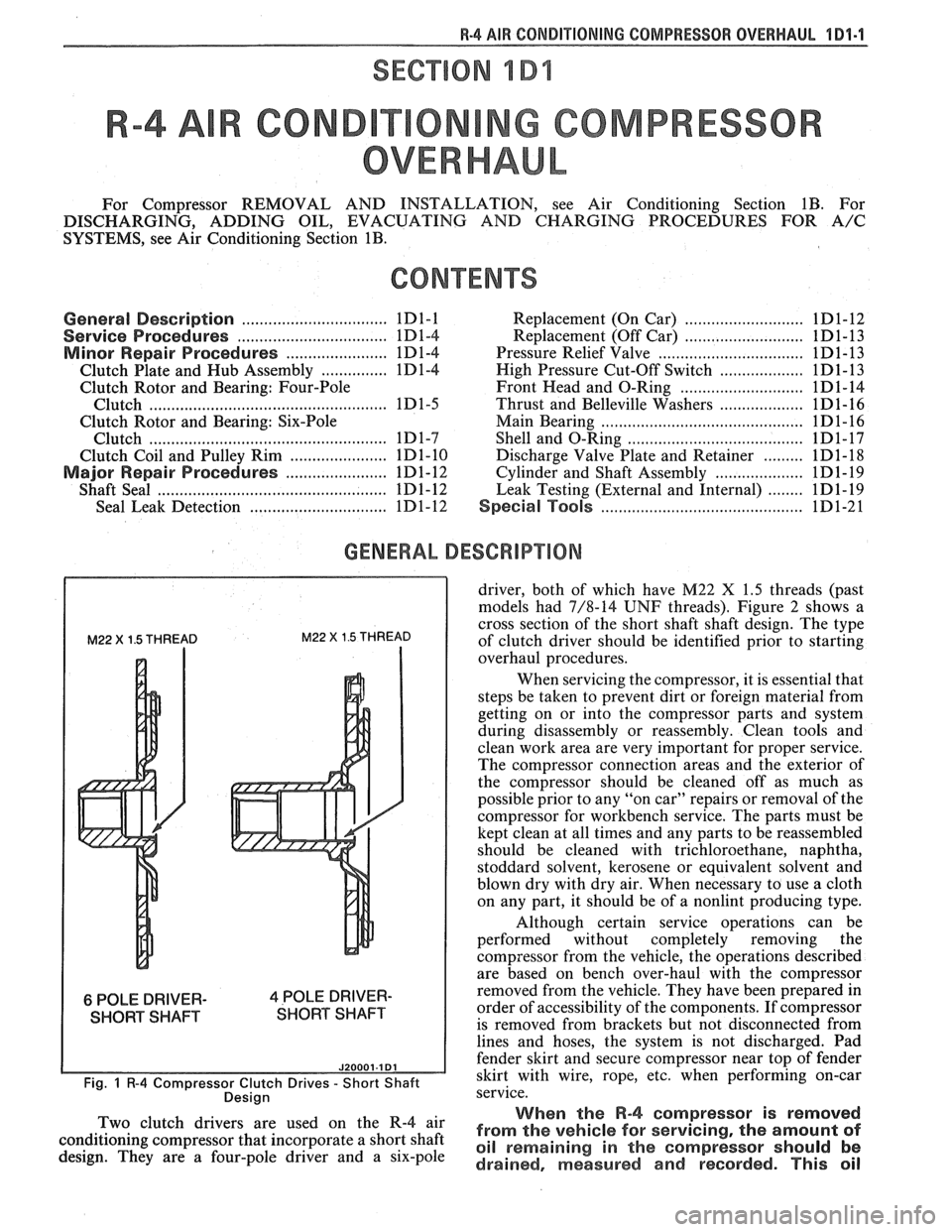

M22 X 1.5 THREAD M22 X 1.5 THREAD

6 POLE DRIVER- 4 POLE DRIVER-

SHORT SHAFT SHORT SHAFT

J20001.1 Dl

Fig. 1 R-4 Compressor Clutch Drives - Short Shaft

Desian

driver, both of which have M22 X 1.5 threads (past

models had 7/8-14

UNF threads). Figure 2 shows a

cross section of the short shaft shaft design. The type

of clutch driver should be identified prior to starting

overhaul procedures.

When servicing the compressor, it is essential that

steps be taken to prevent dirt or foreign material from

getting on or into the compressor parts and system

during disassembly or reassembly. Clean tools and

clean work area are very important for proper service.

The compressor connection areas and the exterior of

the compressor should be cleaned off as much as

possible prior to any "on car" repairs or removal of the

compressor for workbench service. The parts must be

kept clean at all times and any parts to be reassembled

should be cleaned with trichloroethane, naphtha,

stoddard solvent, kerosene or equivalent solvent and

blown dry with dry air. When necessary to use a cloth

on any part, it should be of a nonlint producing type.

Although certain service operations can be

performed without completely removing the

compressor from the vehicle, the operations described

are based on bench over-haul with the compressor

removed from the vehicle. They have been prepared in

order of accessibility of the components. If compressor

is removed from brackets but not disconnected from

lines and hoses, the system is not discharged. Pad

fender skirt and secure compressor near top of fender

skirt with wire, rope,

etc, when performing on-car

service.

., When the R-4 compressor is removed Two 'lutch drivers are wed On the R-4 air from the vehicle for servicing, the amount of conditioning compressor that incorporate a short shaft oil remaining in the should be design. They are a four-pole driver and a six-pole drained, measured and recorded. This oil

Page 85 of 1825

1 D1-6 R-4 AIR CONDITIONING COMPRESSOR OVERHAUL

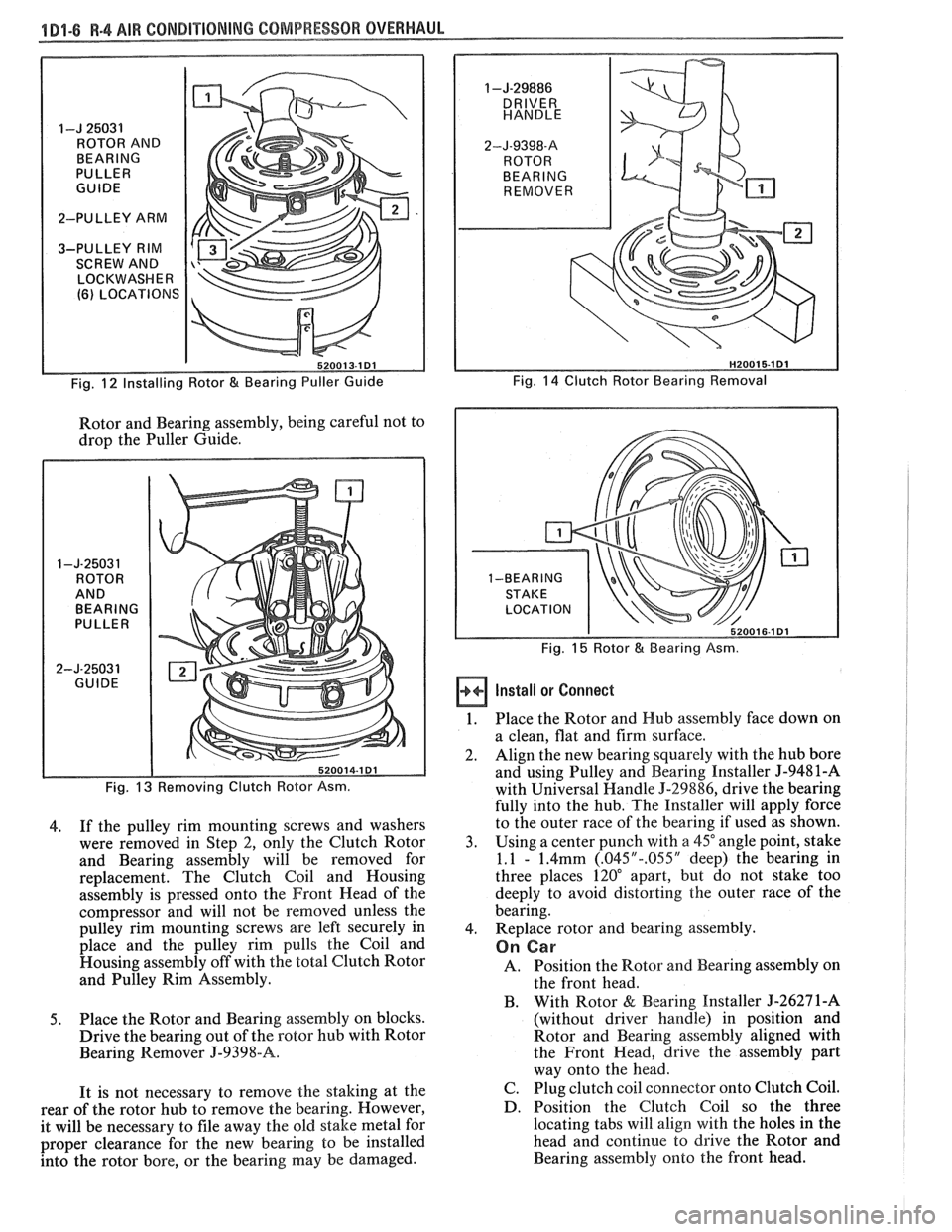

I-J 25031

ROTOR AND

BEARING

PULLER

GUIDE

2-PULLEY ARM

3-PULLEY RIM SCREW AND

LOCKWASHER

(6) LOCATIONS

Fig.

12 Installing Rotor & Bearing Puller Guide

Rotor and Bearing assembly, being careful not to

drop the Puller Guide.

1 -J-2503 1 ROTOR

AND BEARING

PULLER

2-J-25031 GUIDE

Fig.

13 Removing Clutch Rotor Asm.

4. If

the pulley rim mounting screws and washers

were removed in Step 2, only the Clutch Rotor

and Bearing assembly will be removed for

replacement. The Clutch Coil and Housing

assembly is pressed onto the Front Head of the

compressor and will not be removed unless the

pulley rim mounting screws are left securely in

place and the pulley rim pulls the Coil and

Housing assembly off with the total Clutch Rotor

and Pulley Rim Assembly.

5. Place the Rotor and Bearing assembly on blocks.

Drive the bearing out of the rotor hub with Rotor

Bearing Remover

J-9398-A.

It is not necessary to remove the staking at the

rear of the rotor hub to remove the bearing. However,

it will be necessary to file away the old stake metal for

proper clearance for the new bearing to be installed

into the rotor bore, or the bearing may be damaged.

1 -J-29886

2-J-9398-8

REMOVER

Fig.

14 Clutch Rotor Bearing Removal

Fig.

15 Rotor & Bearing Asm.

Install or Connect

1. Place the Rotor and Hub assembly face down on

a clean, flat and firm surface.

2. Align

the new bearing squarely with the hub bore

and using Pulley and Bearing Installer

5-9481-A

with Universal Handle 5-29886, drive the bearing

fully into the hub. The Installer will apply force

to the outer race of the bearing if used as shown.

3. Using

a center punch with

a 45" angle point, stake

1.1

- 1.4mm (.045"-.055" deep) the bearing in

three places 120" apart, but do not stake too

deeply to avoid distorting the outer race of the

bearing.

4. Replace

rotor and bearing assembly.

On Car

A. Position the Rotor and Bearing assembly on

the front head.

B. With Rotor

& Bearing Installer J-26271-A

(without driver handle) in position and

Rotor and Bearing assembly aligned with

the Front Head, drive the assembly part

way onto the head.

C. Plug clutch coil connector onto Clutch Coil.

D. Position the Clutch Coil so the three

locating tabs will

align with the holes in the

head and continue to drive the Rotor and

Bearing assembly onto the front head.

Page 91 of 1825

4 Dl-I 2 R-4 AIR CONDITIONING COMPRESSOR OVERHAUL

MAJOR REPAIR PROCEDURES

Service repair procedures to the

Compressor Shaft Seal,

Pressure Relief Valve

or disassembly

of the Internal Compressor

Cylinder and Shaft Assembly are considered

"MAJOR" SINCE THE REFRIGERATION

SYSTEM MUST BE DISCHARGED,

EVACUATED AND RECHARGED to complete

service and/or because major internal

operating and sealing components of the

compressor are being disassembled and

serviced.

When replacing the shaft seal assembly or

pressure relief valve, even if the compressor remains on

the vehicle during the operation, it will be necessary to

discharge the system of refrigerant (see Section

1B).

Other than clutch repair procedures, the same holds

true for any disassembly of the compressor.

If the compressor shell, front head or cylinder

and shaft assembly are to be serviced or replaced, the

oil in the compressor must be drained, measured and

replaced (see Section

1B) to determine addition of

proper oil quantity to new assembly.

A clean workbench, preferably covered with a

sheet of clean paper, orderliness in the work area and

a place for all parts being removed and replaced is of

great importance, as is the use of the proper, clean

service tools.

NOTICE: Any attempt to use make-shift or

inadequate equipment may result in damage

and/or improper compressor operation.

All parts required for servicing the internal

compressor are protected by a preservation process and

packaged in a manner which will eliminate the

necessity of cleaning, washing or flushing of the parts.

The parts can be used in the internal assembly just as

they are removed from the service package.

Seals and

protective packaging should be left in tact un

ti1 just

prior to installation.

SI-IAFT SEAL

Fig. 35 thru 40

Shaft Seal Design

The shaft seal is a one piece design.

Seal Leak Detection

A shaft seal should not be changed because of an

oil-line on the hood insulator. The Seal is designed to

seep some oil for lubrication purposes. Only change a

Shaft Seal when a leak is detected by evidence of oil

sprayed in large amounts and then only after actual

refrigerant leakage is found by using an approved leak

Detector such as J-29547 or equivalent.

Should an R-4 compressor shaft seal ever have to

be replaced, the accumulator in this R-4 system must

also be removed from the vehicle. The oil in the

accumulator then must be drained, measured and

replaced according to the directions in Section

1B to

determine oil loss.

On-Car

Remove

or Disconnect

1. Discharge A/C system

2. Loosen and reposition compressor in mounting

brackets

3. Clutch Plate and Hub assembly

4. Shaft seal seat retainer ring, using Snap Ring

Pliers J-5403-A

5. Thoroughly clean inside of compressor neck area

and O-ring groove surrounding the shaft, the

exposed portion of the seal seat and the shaft

itself. Any dirt or foreign material getting into

compressor may cause damage.

6. Remove Lip Seal:

e Fully engage the knurled tangs of Seal

Remover-Installer J-23 128-A into the

recessed portion of the Seal by turning the

handle clockwise. Remove the Seal from the

compressor with a rotary-pulling motion.

Discard the Seal. The handle must be

hand-tightened securely. Do not use a

wrench or pliers.

7. Discard the seal seat O-ring from the compressor

neck using 0-Ring Remover J-9553-01.

8. Recheck the shaft and inside of the compressor

neck and O-ring groove for dirt or foreign

material and be sure these areas are perfectly

clean before installing new parts.

Inspection

Seals should not be reused. Always use a new

specification service seal kit on rebuild. Care should be

taken to prevent damage to the lip of the one piece seal.

Make sure that the Seal Seat and Seal Lip are free of

lint and dirt that could damage the seal surface or

prevent sealing.

On-Car

Install

or Connect

1. Dip

the new seal O-ring in clean 525 viscosity

refrigerant oil and assemble onto 0-Ring

Installer J-33011.

2. Insert

the 0-Ring Installer

5-3301 1 completely

down into the compressor neck until the Installer

"bottoms." Lower the moveable slide of the

0-Ring Installer to release the 0-Ring into the

seal seat O-ring lower groove. (The compressor

neck top groove is for the shaft seal retainer ring.)

Rotate the Installer to seat the O-ring and remove

the Installer.

3. Prepare Lip Seal:

Assemble seal to Seal Installer J-23128-A,

by turning handle clockwise, and then push

Seal Protector J-34614, into seal lip. The

stamped steel case side of the lip seal must

be engaged with knurled tangs of installer so

that flared-out side of lip seal is facing and

installed towards the compressor.

4. Install Lip Seal:

Page 110 of 1825

CHASSIS SHEET METAL 2C-3

3. Allow hood to open, and tighten latch bolts in

new location.

FENDER PANEL

An outer fender panel with a plastic inner panel

is used. Care should be used in handling raw fenders

due to the lack of fender rigidity prior to installation.

Body surfaces at molding areas must be cleaned

thoroughly with suitable organic solvent immediately

prior to installation to ensure adhesion. Do not allow

adhesive surface of molding to come in contact with

wet solvent, dirt, or foreign matter.

NO"FICE: If heat source is used to condition

moldings prior to installation, the source is to

provide

uniform heating, not to exceed 85°F.

Application is to be made in a clean area with

ambient and body surface temperatures of at least

65°F.

The moldings are to be secured with two appli-

cations of a force of 20 pounds for the full length of

each section using a roller or other suitable tool.

Any section of molding removed once in contact

with the body surface must be replaced.

ALUMINUM PANEL REPAIR PROCEDURES

An aluminum hood (inner and outer panel) is

used on some vehicles. An aluminum panel can be

identified by checking it with a magnet, preferably in

the front corners to avoid any possible damage to the

paint. Aluminum will not attract a magnet.

Aluminum panels can be repaired successfully

with only slight changes of materials and techniques

commonly used to refinish steel panels. The necessary

modifications fall into two categories: 1) metal

preparation; and 2) painting.

Metal Preparation

1. Because aluminum is relatively easy to grind,

care must be taken not to use overly coarse abra-

sive discs or excessive grinder speeds (greater

than 2,000 rpm), both of which will cause

excessive heat and unnecessary metal removal.

2. Surface scratches should normally be removed

with 180 or 120 grit paper with scalloped edges.

Hand sanding with 80 grit paper will usually be

sufficient to remove excessive body filler or

heavy scratches, again followed with 180 grit

paper.

NOTICE: Avoid scratching aluminum when

sanding with 80 grit paper by hand.

3. Foam backed pads are recommended for

grinders used on aluminum, rather than the

stiffer rubber pads used for mounting abrasive

discs used on steel. The foam pad helps to

reduce heat build-up and improves blending for

feathering.

4. Localized heat, generated by grinding, can be

minimized by the use of a grease stick, such as

Formax F-160 or equivalent. This does, how-

ever, tend to load up the grinding discs quickly,

which should be periodically cleaned by rotating

them against a brush wetted with solvent.

5. If out-dings or minor convex defects need to be

filed, it is recommended to use a round edge,

double cut, flexible file with 22 teeth per inch

overlaid with 52 teeth per inch (such as

Nicholson

#50-412 or equivalent).

NOTICE: Keep file clean so that chips do not

scratch aluminum.

The use of heat is not recommended, since the

structural characteristics of aluminum are noticeably

affected by heat. A bent or buckled aluminum hood,

which exhibits strain cracks either before or after

straightening, should be replaced.

Both steel and aluminum panels can be metal

prepped and repaired with two-part polyester filler

materials in the same number of operations. The only

differences are that less aggressive type files and abra- sive discs should be used, with care being taken not to

overheat the aluminum.

Painting

Painting procedures for aluminum panels differ

very little from those used on steel panels. Two pre-

cautions should, however, be observed:

1. Alkaline base paint removers are not recom-

mended and should not be used.

2. Aluminum also requires a chemical cleaner such

as

DuPont 2253, Ditzler DX-533, or equivalent

be used on bare metal to remove contaminants

and corrosion. After cleaning, a conversion

coating such as DuPont

226S, Ditzler DX-503

or equivalent should be applied to promote

adhesion.

Beyond these considerations, painting alumi-

num panels should present no increases in difficulty or

changes in procedure and technique.

PAINTING AND REPAIRING NONMETAL

EXTERIOR PARTS 1

FiberglassIABS Plastic Panel Repair ~

A Plastic Solder Repair Kit can be used to repair

cracks, dents, or pits in fiberglass or ABS panels. A

Glass Woven Cloth should be installed on the under

side of a crack in the panel to structurally reinforce the

panel. The following procedure can be used to repair

the panels:

1. With a lacquer removing solvent, remove paint

from damaged area down to the fiberglass or

, ABS material. I

2. Scuff-sand area surrounding damaged area to

provide a good bonding surface.

Page 153 of 1825

385-2 STEERING WHEELS AND COLUMNS

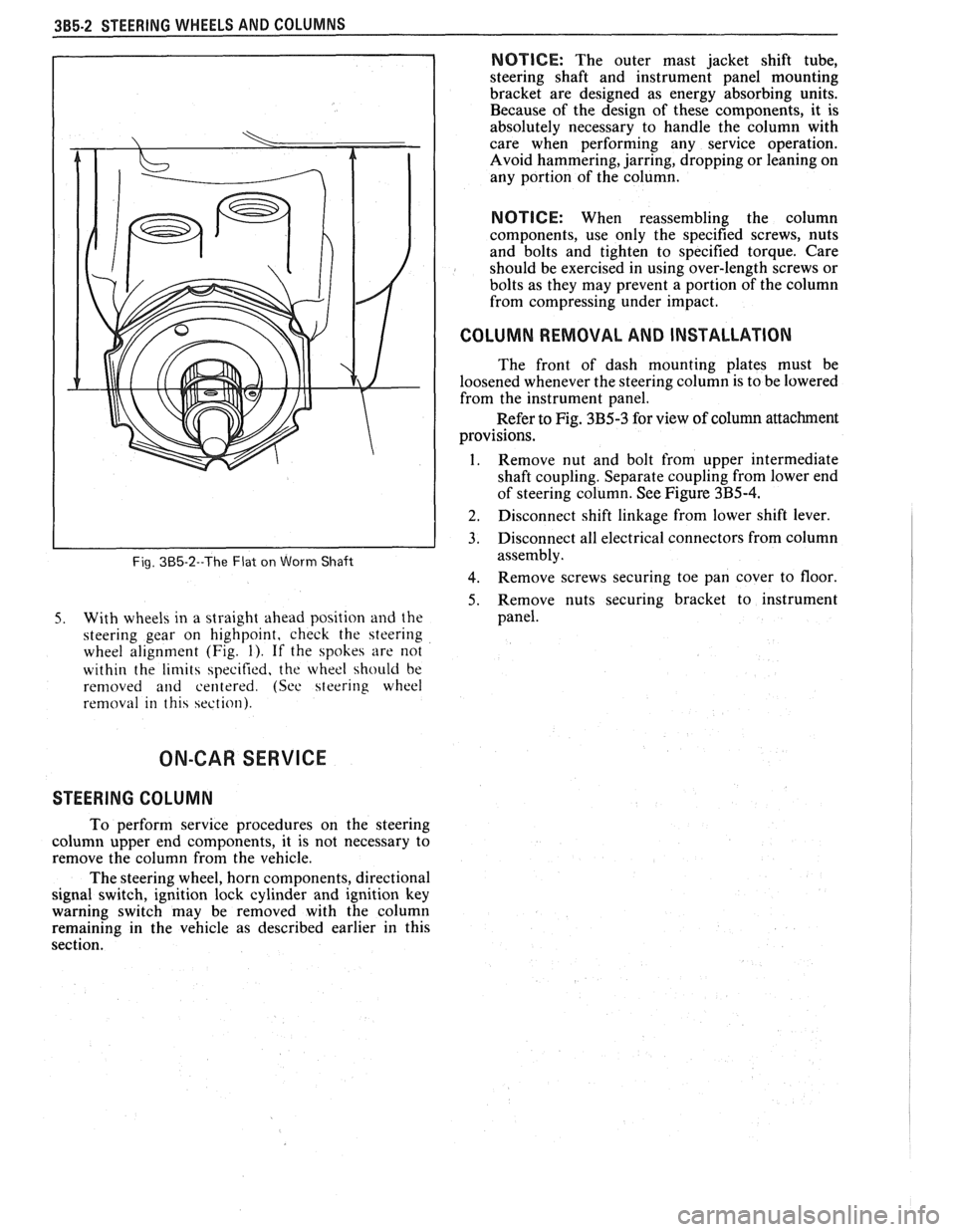

Fig. 385-2--The Flat on Worm Shaft

5. With wheels in a straight ahead position and the

steering gear on highpoint, check the steering

wheel alignment (Fig.

1). If the spokes are not

within the

limits specified, the wheel should be

removed

and centered. (See steering wheel

removal in this section).

NOTICE: The outer mast jacket shift tube,

steering shaft and instrument panel mounting

bracket are designed as energy absorbing units.

Because of the design of these components, it is

absolutely necessary to handle the column with

care when performing any service operation.

Avoid hammering, jarring, dropping or leaning on

any portion of the column.

NOTICE: When reassembling the column

components, use only the specified screws, nuts

and bolts and tighten to specified torque. Care

should be exercised in using over-length screws or

bolts as they may prevent a portion of the column

from compressing under impact.

I COLUMN REMOVAL AND INSTALLATION

The front of dash mounting plates must be

loosened whenever the steering column is to be lowered

from the instrument panel.

Refer to Fig. 3B5-3 for view of column attachment

provisions.

1. Remove nut and bolt from upper intermediate

shaft coupling. Separate coupling from lower end

of steering column. See Figure

3B5-4.

] 2. Disconnect shift linkage from lower shift lever.

3. Disconnect all electrical connectors from column

assembly.

4. Remove screws securing toe pan cover to floor

5. Remove nuts securing bracket to instrument

panel.

ON-CAR SERVICE

STEERING COLUMN

To perform service procedures on the steering

column upper end components, it is not necessary to

remove the column from the vehicle.

The steering wheel, horn components, directional

signal switch, ignition lock cylinder and ignition key

warning switch may be removed with the column

remaining in the vehicle as described earlier in this

section.

Page 166 of 1825

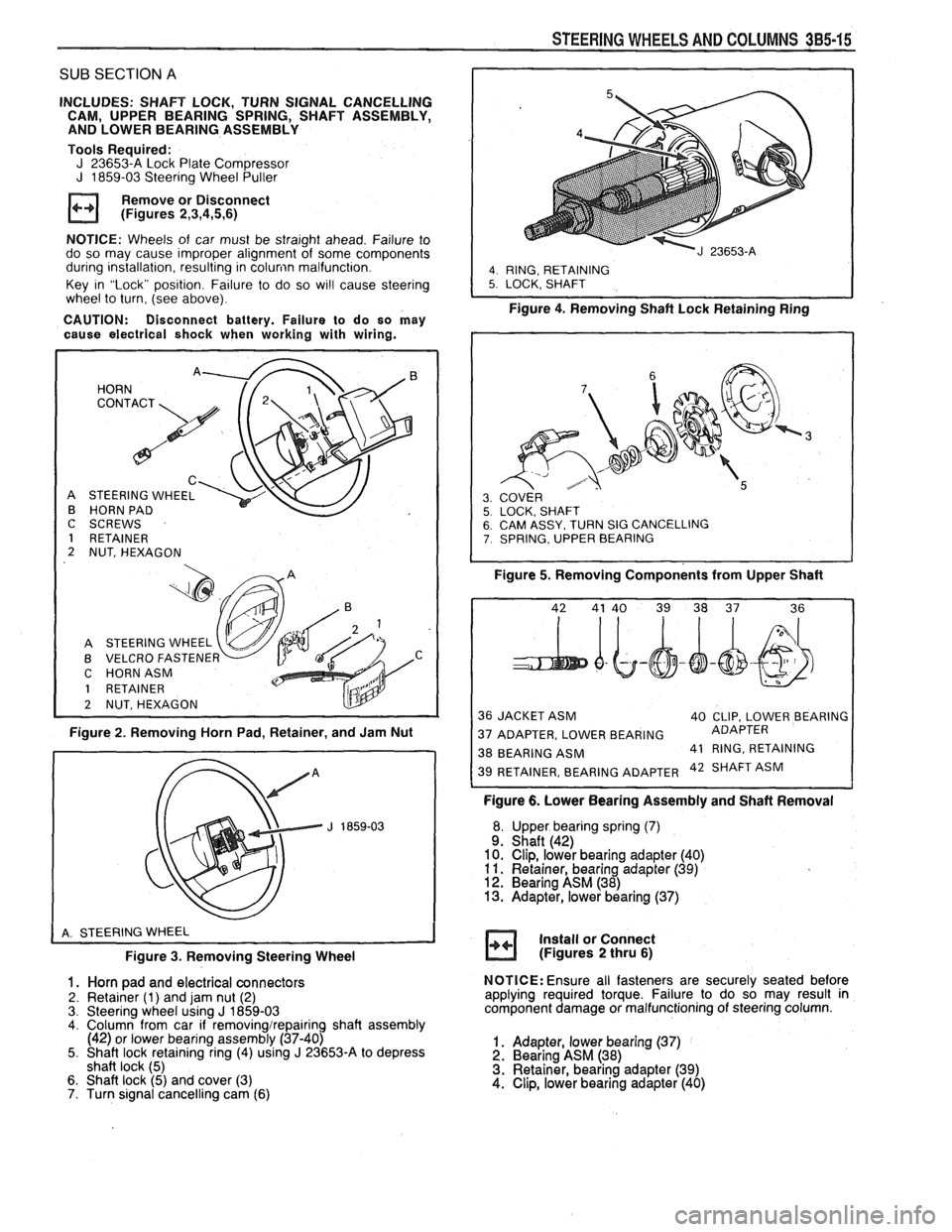

SUB SECTION A

INCLUDES: SHAFT LOCK, TURN SIGNAL CANCELLING

CAM, UPPER BEARING SPRING, SHAFT ASSEMBLY,

AND LOWER BEARING ASSEMBLY

Tools Required:

J 23653-A Lock Plate Compressor J 1859-03 Steering Wheel Puller

Remove or Disconnect

(Figures

2,3,4,5,6)

NOTICE: Wheels of car must be straight ahead. Failure to

do so may cause improper alignment of some components

during installation, resulting in

colunin malfunction.

Key in "Lock" position. Failure to do so

wi!l cause steering

wheel to turn, (see above).

CAUTION: Disconnect battery. Failure to do so may

cause electrical shock when working with wiring.

HORN

C

STEERING WHEEL

HORN PAD

I

C SCREWS

1 RETAINER

2 NUT, HEXAGON

A STEERING WHEEL

B VELCRO

FASTENEF v C HORNASM

1 RETAINER

2 NUTSHEXAGON

Figure 2. Removing Horn Pad, Retainer, and Jam Nut

Figure

3. Removing Steering Wheel

1. Horn pad and electrical connectors

2. Retainer (1) and jam nut (2)

3. Steering wheel using J 1859-03 4. Column from car if removingirepairing shaft assembly

(42) or lower bearing assembly (37-40)

5. Shaft lock retaining ring (4) using

J 23653-A to depress

shaft lock (5)

6. Shaft lock (5) and cover (3)

7. Turn signal cancelling cam (6)

STEERING WHEELS AND COLUMNS 385-15

I

4. RING, RETAINING 5. LOCK. SHAFT

Figure 4. Removing Shaft Lock Retainingain;

SY. TURN SIG CANCELLING , UPPER BEARING

Figure 5. Removing Components from Upper Shaft

36 JACKET ASM

40 CLIP, LOWER BEARING

37 ADAPTER, LOWER BEARING ADAPTER

38 BEARING

ASM 41

RING, RETAINING 42 SHAFT ASM

Figure 6. Lower Bearing Assembly and Shaft Removal

Upper bearing spring

(7) Shaft (42)

Clip, lower bearing adapter (40)

Retainer, bearing adapter

(39) Bearing ASM (38) Adapter, lower bearing (37)

Install or Connect

(Figures

2 thru 6)

NOTICE: Ensure all fasteners are securely seated before

applying required torque. Failure to do so may result in

component damage or malfunctioning of steering column.

1. Adapter, lower bearing (37) 2. Bearing ASM (38)

3. Retainer, bearing adapter (39)

4. Clip, lower bearing adapter (40)

Page 167 of 1825

385-16 STEERING WHEELS AND COLUMNS

5. Shaft assembly (42) to column 6. Bearing spring (7)

7. Turn signal cancelling cam (6)

8. Shaft lock (5) and cover (3) 9. Shaft lock retaining ring (4) using J 23653-A to depress

shaft lock (5) 10. Column to dash 1 1. Steering wheel 12. Jam nut (2) 13. Retainer (1) 14. Horn pad

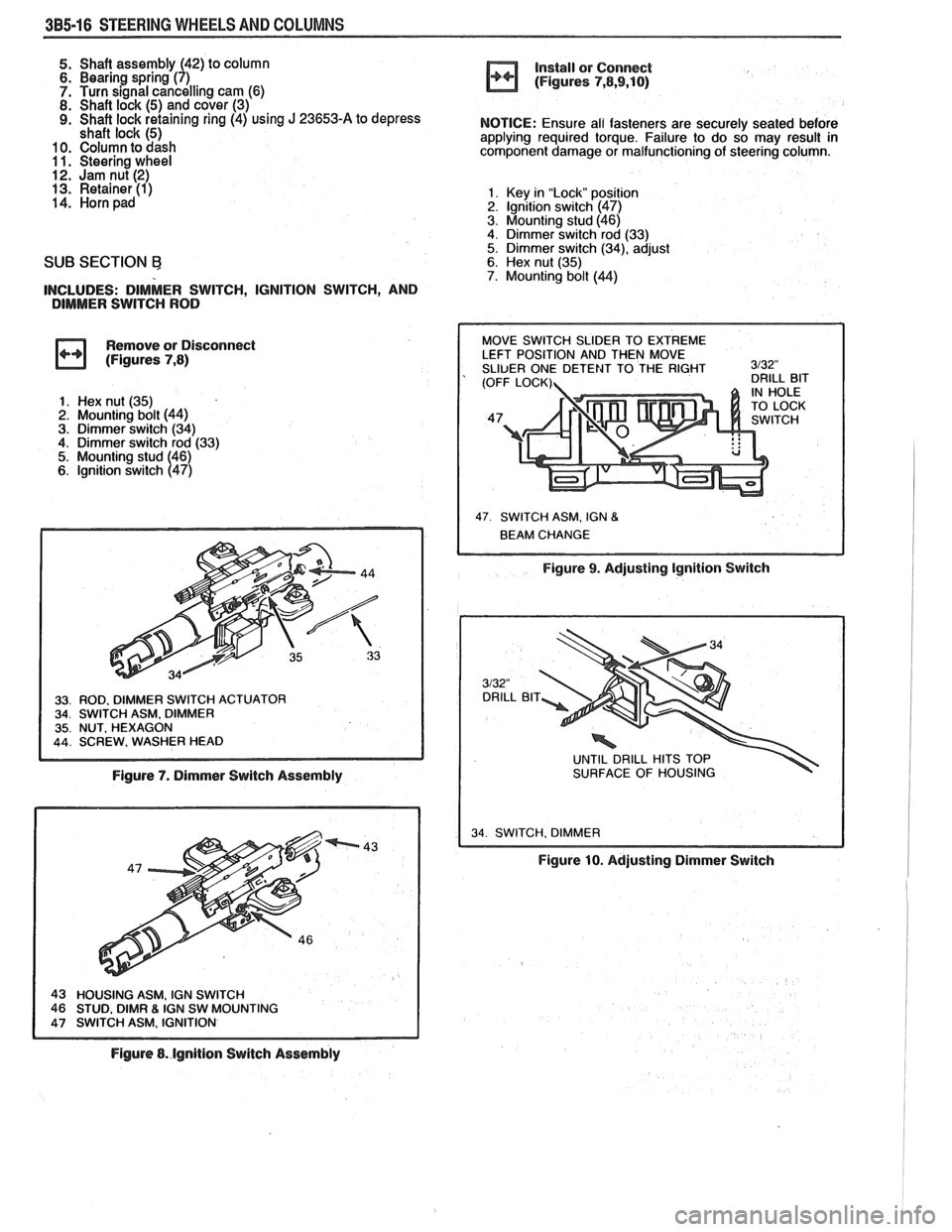

SUB SECTION Ej

INCLUDES: DIMMER SWITCH, IGNITION SWITCH, AND

DIMMER SWITCH ROD

Remove or Disconnect

(Figures

7,8)

1. Hex nut (35)

2. Mounting bolt (44)

3. Dimmer switch (34) 4. Dimmer switch rod (33)

5. Mounting stud (46)

6. lgnition switch (47)

Figure 7. Dimmer Switch Assembly

IGN SW MOUNTING

Figure 8. lgnition Switch Assembly install

or Connect

(Figures

7,8,9,10)

NOTICE: Ensure all fasteners are securely seated before

applying required torque. Failure to do so may result in

component damage or malfunctioning of steering column.

1. Key in "Lock" posit~sn 2. lgnltion switch (47)

3. Mounting stud (46)

4. Dimmer switch rod (33)

5. Dimmer switch (34), adjust 6. Hex nut (35) 7. Mounting bolt (44)

47 SWITCH ASM. IGN 8

Figure 9. Adjusting Ignition Switch

UNTIL DRILL HITS TOP

SURFACE OF HOUSING

34 SWITCH. DIMMER I

Figure 10. Adjusting Dimmer Switch

Page 168 of 1825

STEERING WHEELS AND COLUMNS 385-17

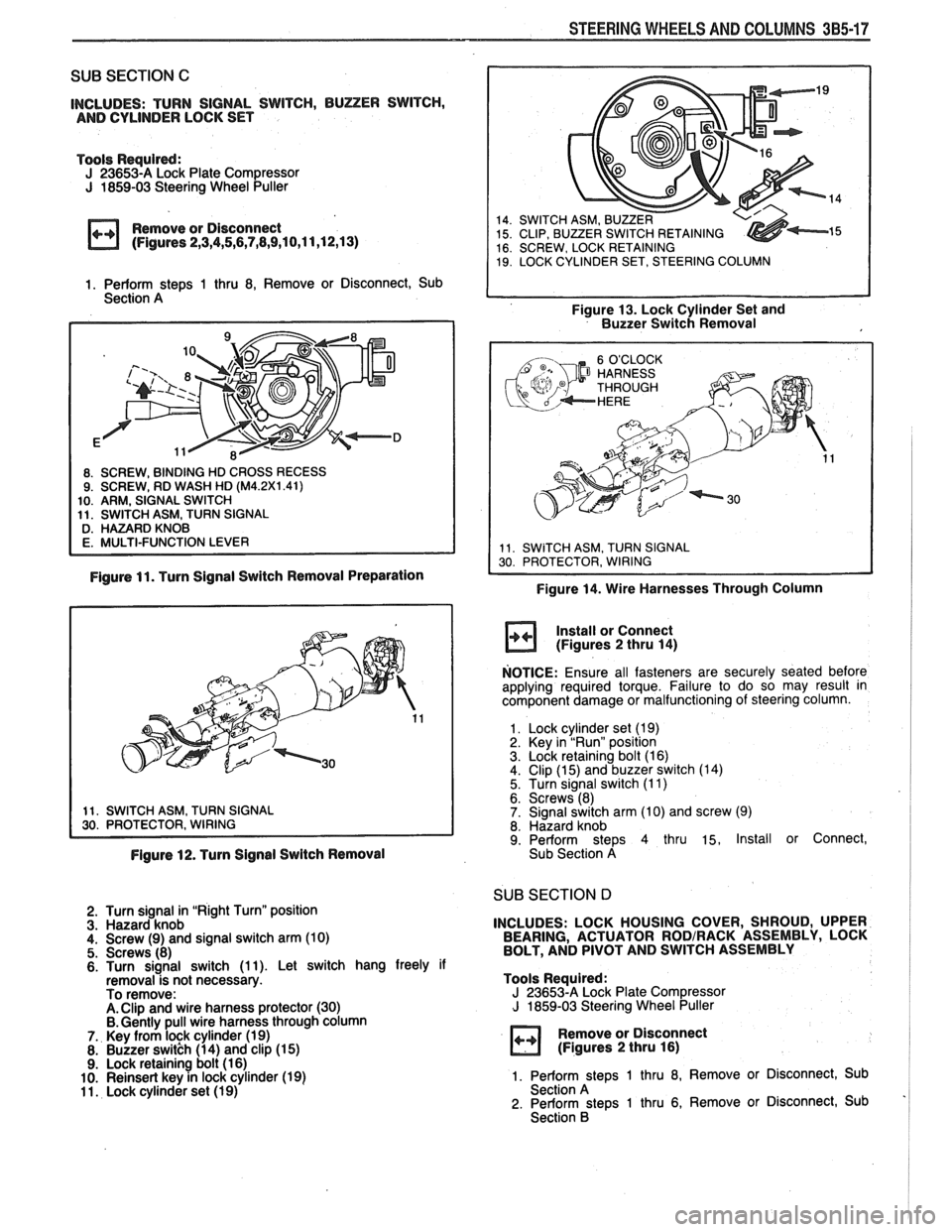

SUB SECTION C

INCLUDES: TURN SIGNAL SWITCH, BUZER SWITCH,

AND CYLINDER LOCK SET

Tools Required:

J 23653-A Lock Plate Compressor J 1859-03 Steering Wheel Puller

Remove or Disconnect

(Figures

2,3,4,5,6,7,8,9,10,11,12,13)

1. Perform ste~s 1 thru 8, Remove or Disconnect, Sub

Section A

, STEERING COLUMN

Figure 13. Lock Cylinder Set and

Buzzer Switch Removal

Figure 11. Turn Signal Switch Removal Preparation

Figure 14. Wire Harnesses Through Column

Install or Connect

(Figures

2 thru 14)

NOTICE: Ensure all fasteners are securely seated before

applying required torque. Failure to do so may result In

component damage or malfunctioning of steering column.

1. Lock cylinder set (1 9)

2. Key in "Run" position 3. Lock retaining bolt (16) 4. Clip (15) and buzzer switch (14)

5. Turn signal switch (1 1) 6. Screws (8) 7. Signal switch arm (1 0) and screw (9) 8. Hazard knob 9. Perform steps 4 thru 15, Install or Connect,

Figure 12. Turn Signal Switch Removal Sub

Section A

SUB SECTION D I 2. Turn signal in "Right Turn" position 3. Hazard knob

4. Screw (9) and signal switch arm (10) 5. Screws (8)

6. Turn signal switch (1 1). Let switch hang freely if

removal-is not necessary.

To remove:

A. Clip and wire harness protector (30) B. Gently pull wire harness through column 7.. Key from lock cylinder (19)

8. Buzzer switkh (14) and clip (1 5) 9. Lock retaining bolt (1 6)

10. Reinsert key in lock cylinder (19) 1 1. Lock cylinder set (19)

INCLUDES: LOCK HOUSING COVER, SHROUD, UPPER

BEARING, ACTUATOR RODIRACK ASSEMBLY, LOCK

BOLT, AND PIVOT AND SWITCH ASSEMBLY

Tools Required:

J 23653-A Lock Plate Compressor J 1859-03 Steering Wheel Puller

Remove or Disconnect

(Figures 2 thru 16)

1. Perform stem 1 thru 8, Remove or Disconnect, Sub

Section A ' 2. Perform steps 1 thru 6, Remove or Disconnect, Sub

Section B

Page 169 of 1825

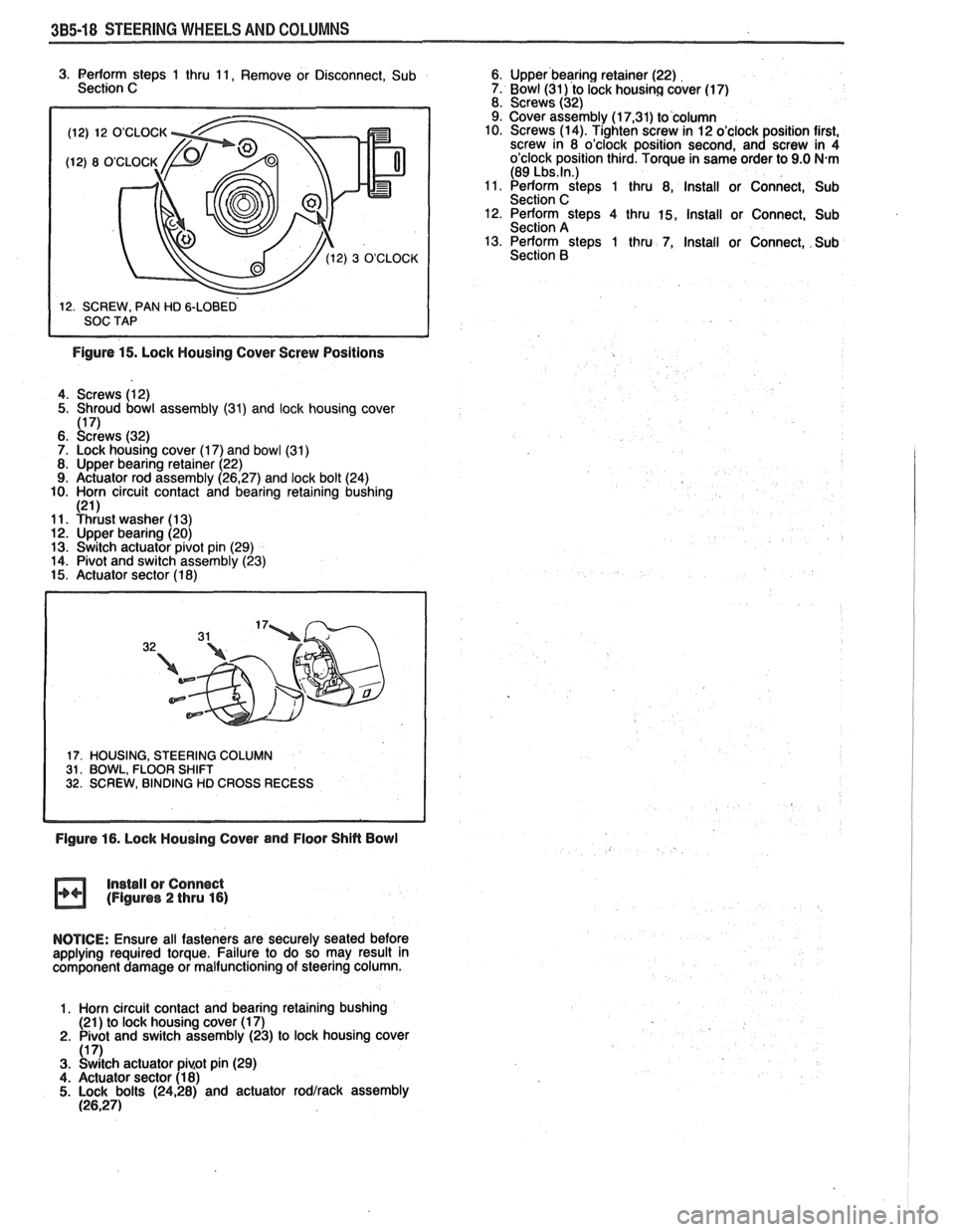

385-18 STEERING WHEELS AND COLUMNS

(12) 12 O'CLOCK

3. Perform steps 1 thru 11, Remove or Disconnect, Sub 6. Upper bearing retainer (22)

Section C 7. Bowl (31) to lock housing cover (17)

8. Screws (32)

9. Cover assembly (1

7,31) to column

10. Screws (14). Tighten screw in 12 o'clock position first,

screw in 8 o'clock position second, and screw in 4

o'clock position third. Torque in same order to 9.0

N.m (89 Lbs.ln.) 11. Perform steps 1 thru 8, Install or Connect, Sub

Section C 12. Perform steps 4 thru 15, Install or Connect, Sub

Section A

13. Perform steps 1 thru 7, Install or Connect, Sub

Section

B

Figure 15. Lock Housing Cover Screw Positions

4. Screws (12)

5. Shroud bowl assembly

(31) and lock housing cover 1171 6. ~c:dr'ews (32)

7. Lock housing cover (1 7) and bowl (31)

8. Upper bearing retainer (22)

9. Actuator rod assembly (26,27) and lock bolt (24)

10. Horn circuit contact and bearing retaining bushing

121 1 11. Yhiust washer (1 3) 12. Upper bearing (20)

13. Switch actuator pivot pin (29)

14. Pivot and switch assembly (23)

15. Actuator sector (1 8)

17. HOUSING, STEERING COLUMN 31. BOWL, FLOOR SHIFT 32. SCREW, BINDING HD CROSS RECESS

Figure 16. Lock Housing Cover and Floor Shin Bowl

Install

or Connect (Figures 2 thru 16)

NOTICE: Ensure all fasteners are securely seated before

applying required torque. Failure to do so may result in

component damage or malfunctioning of steering column.

1. Horn circuit contact and bearing retaining bushing

(21 ) to lock housing cover (1 7)

2. Pivot and switch assembly (23) to lock housing cover

(1 7) 3. Switch actuator pi~ot pin (29)

4. Actuator sector (1 8) 5. Lock bolts (2428) and actuator rodlrack assembly (26,271