brake pads PONTIAC FIERO 1988 Service Repair Manual

[x] Cancel search | Manufacturer: PONTIAC, Model Year: 1988, Model line: FIERO, Model: PONTIAC FIERO 1988Pages: 1825, PDF Size: 99.44 MB

Page 21 of 1825

OB-4 MAINTENANCE AND LUBRICATION

Tire and wheel operation - Be alert to a vibra-

tion of the steering wheel or seat at normal highway

speeds. This may mean a wheel balance is needed. Also, a

pull right or left on a straight, level road may show the

need for

a tire pressure adjustment or wheel alignment.

Steering system operation - Be alert to

changes in steering action. An inspection is needed when

the steering wheel is harder to turn or has too much free

play or if unusual sounds are noted when turning or

parking.

Headlight aim operation - Take note of light

pattern occasionally. If beam aim doesn't look right,

headlights should be adjusted.

AT EACH FUEL FILL

Engine oil level check - Check engine oil level

and add if necessary. See your Owner's

Manual for further

details.

NOTICE: A large loss in this system may indicate a

problem. Have it inspected and repaired at once.

Engine coolant level and condition - Check

engine coolant level in coolant reservoir tank and add if

necessary. Replace if dirty or rusty. See your Owner's

Manual for further details.

NOTICE: A large loss in this system may indicate a

problem. Have it inspected and repaired at once.

Windshield washer fluid level check -- Check

washer fluid level in container and add if necessary.

Hood latch operation - When opening hood on

cars equipped with hoods that open from the front, note

the operation of secondary latch. It should keep hood from

opening all the way when primary latch is released. Make

sure that hood closes firmly.

AT LEAST MONTI-ILY

Tire and wheel inspection and pressure

check--

Check tires for abnormal wear or damage. Also,

check for damaged wheels. Keep pressures as shown on

Tire Placard on the driver's door (include spare unless it is

a stowaway). Pressure should b\: checked when tires are

"cold". See "Tires" in Owner's Manual for further

infomation.

Light operation check - Check operation of

license plate light, side-marker lights, headlights includ-

ing high beams, parking lights, taillights, brake lights.

turn signals, backup lights, instrument panel and interior

lights and hazard warning flashers.

Fluid leak check - After the car has been parked

for a while, inspect the surface beneath the car for water,

oil, fuel or other fluids. Water dripping from the air

conditioning system after use is normal. If you notice fuel

leaks or fumes, the cause should be found and corrected at

once.

AT LEAST TWICE A YEAR (FOR EXAMPLE,

EVERY SPRING AND FALL)

Power steering pump fluid level check --

Check power steering pump fluid level in accordance with

Owner's Manual instructions and keep at proper level.

NOTICE: A large loss in this system may indicate a

problem. Have it inspected and repaired at once.

Brake master cylinder reservoir fluid level

check ---- Check fluid and keep at proper level. Note: It is

normal for the brake fluid level to go down slightly as the

brake pads wear

- so be sure to keep reservoir filled.

NOTICE: A large loss in this system may indicate a

problem. Have

it inspected and repaired at once.

Clutch system service --- manual transmis-

sionltransaxle --- For cars equipped with hydraulic

clutch system, check the reservoir fluid level and add fluid

as required. All others, check clutch pedal free travel and

adjust as necessary. See your Owner's Manual for further

details.

~

NOTICE: A large loss in this system may indicate a

problem. Have it inspected and repaired at once.

Weatherstrip Lubrication - Clean surface and

then apply a thin film of silicone grease with a clean cloth.

EACH TIME OIL IS CHANGED

Automatic and manual transmissionltrans-

axle fluid level check - Check transmission/transaxle

fluid level and add as required. (Corvette only) if equipped

with manual transmission

- check fluid in the overdrive

unit and add as required.

NOTICE: A large loss in this system may indicate a

problem. Have

it inspected and repaired at once.

Brake systems inspection - For convenience,

the following should be done when wheels are removed

for rotation: Inspect lines and hoses for proper hookup,

binding, leaks, cracks, chafing, etc. Inspect disc brake

pads for wear and rotors for surface condition. Also in-

spect drum brake linings for wear and cracks. Inspect

other brake parts, including drums, wheel cylinders, park-

ing brake, etc. at the same time. Check parking brake

adjustment.

INSPECT BRAKES MORE OFTEN IF DRIVING

HABITS OR CONDITIONS RESULT IN FREQUENT

BRAKING.

Steering, suspension and front drive axle

boot and seal inspection

- Inspect front and rear

suspension and steering system for damaged, loose or

missing parts, signs of wear or lack of lubrication. Inspect

power steering lines and hoses for proper hookup, bind-

ing, leaks, cracks, chafing, etc. (On cars equipped with

manual steering gear, check for seal leakage.) On

front-

wheel-drive cars, clean then inspect drive axle boot seals

for damage, tears or leakage. Replace seals if necessary.

Exhaust system inspection - Inspect complete

system. Inspect body near the exhaust system. Look for

broken, damaged, missing or out-of-position parts as well

as open seams, holes, loose connections or other condi-

tions which could cause a heat buildup in the tloor pan or

could let exhaust fumes seep into the trunk or passenger

compartment.

Page 330 of 1825

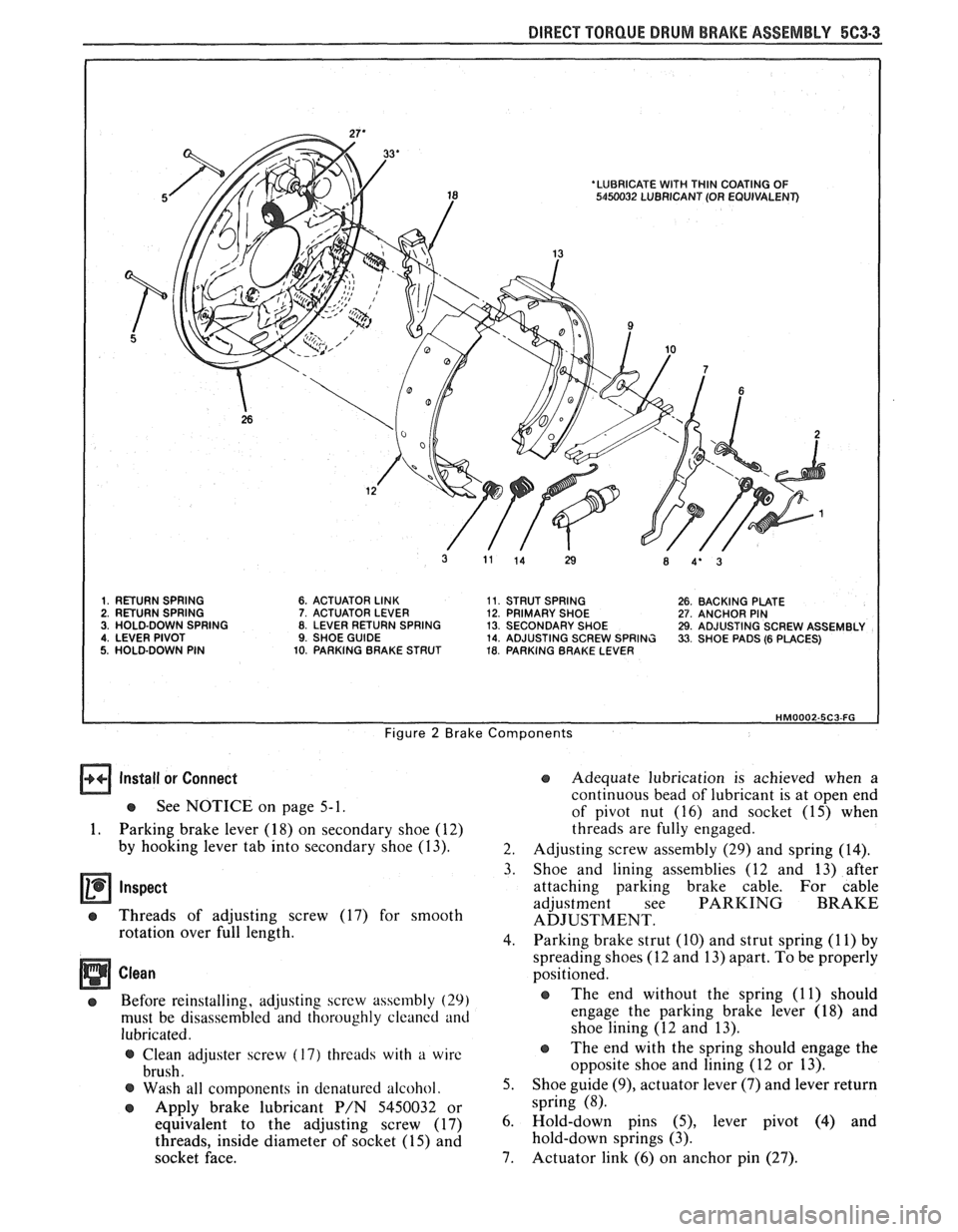

DIRECT TORQUE DRUM BRAKE ASSEMBLY 5C3-3

1. RETURN SPRING 6. ACTUATOR LINK 11. STRUT SPRING 26. BACKING PLATE 2. RETURN SPRING 7. ACTUATOR LEVER 12. PRIMARY SHOE 27. ANCHOR PIN 3. HOLD-DOWN SPRING 8. LEVER RETURN SPRING 13. SECONDARY SHOE 29. ADJUSTING SCREW ASSEMBLY 4. LEVER PIVOT 9. SHOE GUIDE 14. ADJUSTING SCREW SPRING 37 SHOE PADS (6 PLACES) 5. HOLD-DOWN PIN 10. PARKING BRAKE STRUT 18. PARKING BRAKE LEVER

Figure 2 Brake Components

Install or Connect

e See NOTICE on page 5-1.

1. Parking brake lever (18) on secondary shoe (12)

by hooking lever tab into secondary shoe (13).

o Threads of adjusting screw (17) for smooth

rotation over full length.

Clean

e Before reinstalling, adjusting screw asse~nbly (29)

must be disassembled and thoroughly cleaned and

lubricated.

@ Clean adjuster screw ( 17) threads with a wire

brush.

@ Wash all components in denatured alcohol.

o Apply brake lubricant P/N 5450032 or

equivalent to the adjusting screw (17)

threads, inside diameter of socket (15) and

socket face.

e Adequate lubrication is achieved when a

continuous bead of lubricant is at open end

of pivot nut (16) and socket (15) when

threads are fully engaged.

2. Adjusting screw assembly (29) and spring

(14).

3. Shoe and lining assemblies (12 and 13) after

attaching parking brake cable. For cable

adjustment see

PARKING BRAKE

ADJUSTMENT.

4. Parking brake strut (10) and strut spring

(1 1) by

spreading shoes (12 and 13) apart. To be properly

positioned.

o The end without the spring (11) should

engage the parking brake lever (18) and

shoe lining (12 and 13).

e~ The end with the spring should engage the

opposite shoe and lining (12 or 13).

5. Shoe guide

(9), actuator lever (7) and lever return

spring

(8).

6. Hold-down pins (5), lever pivot (4) and

hold-down springs (3).

7. Actuator link (6) on anchor pin (27).