height adjustment PONTIAC FIERO 1988 Service Repair Manual

[x] Cancel search | Manufacturer: PONTIAC, Model Year: 1988, Model line: FIERO, Model: PONTIAC FIERO 1988Pages: 1825, PDF Size: 99.44 MB

Page 109 of 1825

26-2 CHASSIS SHEET METAL

TO RAISE OR LOWER THE FRONT comers

for proper alignment, proceed as follows:

1. Close hood firmly.

2. Determine the amount of adjustment necessary.

3. Open hood.

4. Raise or lower the adjustable hood bumpers as

required.

FORE AND APT adjustment can be accom-

plished as follows:

1. Loosen hinge to fender attaching screws.

Remove or Disconnect

Open hood.

Scribe line on hood inner panel and fender panel

to indicate original hinge position.

Block hood on side where hinge is to be

removed.

Prop hood open.

Remove hinge-to-hood attaching screws and

hinge-to-fender attaching screws.

Carefully remove hinge and strut assembly.

- -

2. Reposition hinge assembly. install or Conned 3. Tighten hinge to fender attaching screws to

specifications. 1. Mount new hinge on fender using scribed line

4. If necessary, repeat procedure on opposite side for location,

and tighten attaching screws.

of hood. 2.

Position hinge to hood using scribed line for

location, install attaching screws and tighten.

3. Carefully close hood and check for proper

- - alignment.

4. If hood is misaligned, measure amount of

mis-

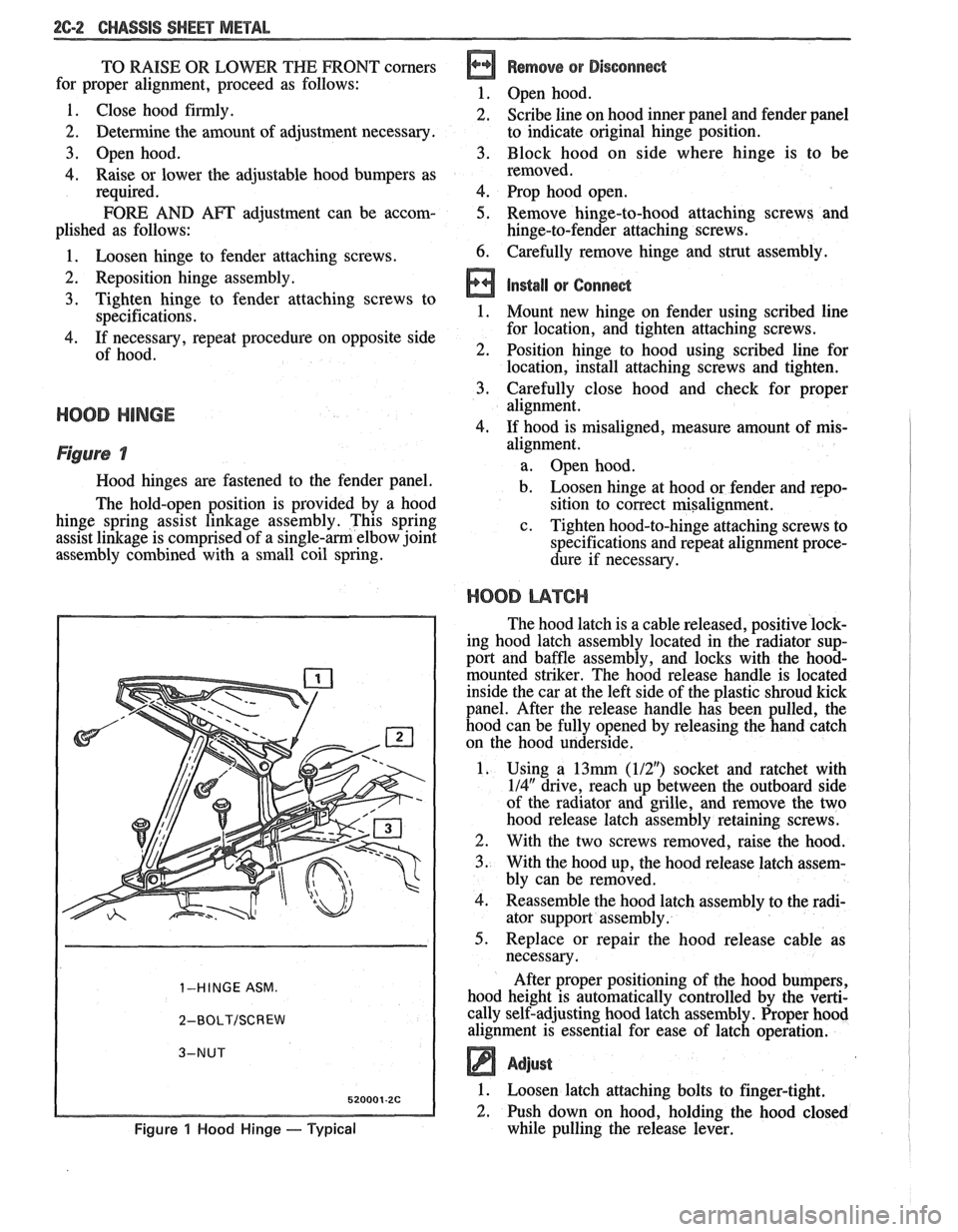

Figure 7

Hood hinges are fastened to the fender panel.

The hold-open position is provided by a hood

hinge spring assist linkage assembly. This spring

assist linkage is comprised of a

single-am elbow joint

assembly combined with a small coil spring.

1-HINGE ASM.

2-BOLT/SCREW

Figure 1 Hood Hinge - Typical

alignment.

a. Open hood.

b. Loosen hinge at hood or fender and repo-

sition to correct misalignment.

c. Tighten hood-to-hinge attaching screws to

specifications and repeat alignment proce-

dure if necessary.

HOOD L14TCI-I

The hood latch is a cable released, positive lock-

ing hood latch assembly located in the radiator sup-

port and baffle assembly, and locks with the

hood-

mounted striker. The hood release handle is located

inside the car at the left side of the plastic shroud kick

panel. After the release handle has been pulled, the

hood can be fully opened by releasing the hand catch

on the hood underside.

1. Using a

13mrn (112") socket and ratchet with

114" drive, reach up between the outboard side

of the radiator and grille, and remove the two

hood release latch assembly retaining screws.

2. With the two screws removed, raise the hood.

3. With the hood up, the hood release latch assem-

bly can be removed.

4. Reassemble the hood latch assembly to the radi-

ator support assembly.

5. Replace or repair the hood release cable as

necessary.

After proper positioning of the hood bumpers,

hood height is automatically controlled by the verti-

cally self-adjusting hood latch assembly. Proper hood

alignment is essential for ease of latch operation.

Adjust

1. Loosen latch attaching bolts to finger-tight.

2. Push down on hood, holding the hood closed

while pulling the release lever.

Page 127 of 1825

3-2 STEERING, SUSPENSION, TIRES AND WHEELS DIAGNOSIS

o Excessive wheel runout

e Blister or bump on tire

e Excessive loaded radial runout of tire and wheel

assembly

Hard Steering (Power)

lnspect

e Hydraulic system - Make test with gage J 5176

or J 25323

e Steering gear adjustment

e Bind or catch in steering gear

e Loose steering gear mounting

e Steering gear pressure port check valve (800

series)

Too Much Play In Steering

a lnspect

e Wheel bearings worn

e Loose steering gear mounting

e Joints from column to steering gear loose or worn

e Steering gear adjustment

Poor Returnability (Power)

Inspect

e Lack of lubrication - ball joints and tie rod ends

o Bind in ball joints

o Rind in steering column

e Front-wheel alignment

e Steering gear adjustment

e Sticking valve

o Steering gear adjustment

e Lower coupling binding on steering gear

Abnormal Noise, Front End

lnspect

Lubrication - ball joints and tie rod ends

Damaged suspension components

Worn control arm bushings or tie rod ends

Imose stabilizer shaft

Loose wheel nuts

Loose suspension bolts

Wheel covers

Steering gear adjustment

Worn strut dampener, shock absorbers or

n~ountings

Spring improperly positioned

Wander or Poor Steering Stability

Inspect

o Mismatched or uneven tires

e Lubrication - ball joints and tie rod ends

e Worn strut dampeners or shock absorbers

e Loose stabilizer shaft Broken

or sagging springs

e Steering gear adjustment

e Front-wheel or rear-wheel alignment

Erratic Steering When Braking

lnspect

e Wheel bearings worn

e Broken or sagging springs

e Leaking wheel cylinder or caliper

Warped rotors

e Incorrect or uneven caster

Low Or Uneven Trim Height

e Broken or sagging springs

@ Overloaded car

e Incorrect or weak springs

Ride Too Soft

Inspect

e Worn strut dampeners or shock absorbers

e Incorrect or sagging springs

Ride Too Harsh

lnspect -

e Incorrect strut dampeners or shock absorbers

e Incorrect springs

Body Leans Or Sways In Corners

lnspect

e Loose stabilizer shaft

e Worn strut dampeners, shock absorbers or

mounting

a Broken or sagging springs

e Overloaded car

Suspension Bottoms

lnspect

a Overloaded car

e Worn strut dampeners or shock absorbers

e Incorrect, broken or sagging spring

"Dog" Tracking

lnspect

e Damaged rear suspension arm or worn bushings

e Bent rear axle

e Frame or underbody alignment incorrect

Page 139 of 1825

3-14 STEERING, SUSPENSION, TIRES AND WHEELS DIAGNOSIS

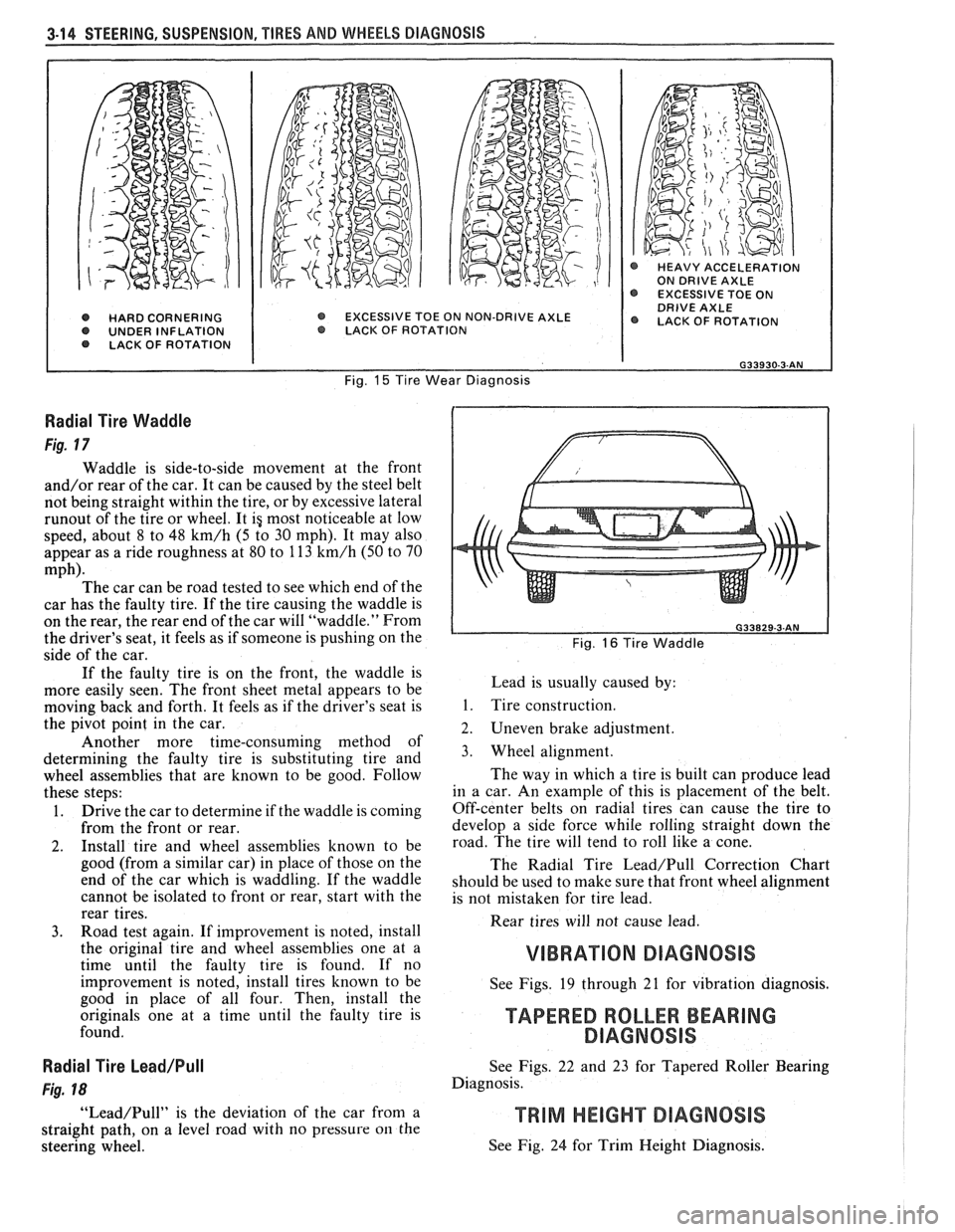

@ HARD CORNERING O UNDER INFLATION LACK OF ROTATION

@ HEAVY ACCELERATION ON DRIVE AXLE EXCESSIVE TOE ON DRIVE AXLE EXCESSIVE TOE ON NON-DRIVE AXLE @ LACK OF ROTATION O LACK. OF ROTAT ION

Fig. 15 Tire Wear Diagnosis

Radial Tire Waddle

Fig. 17

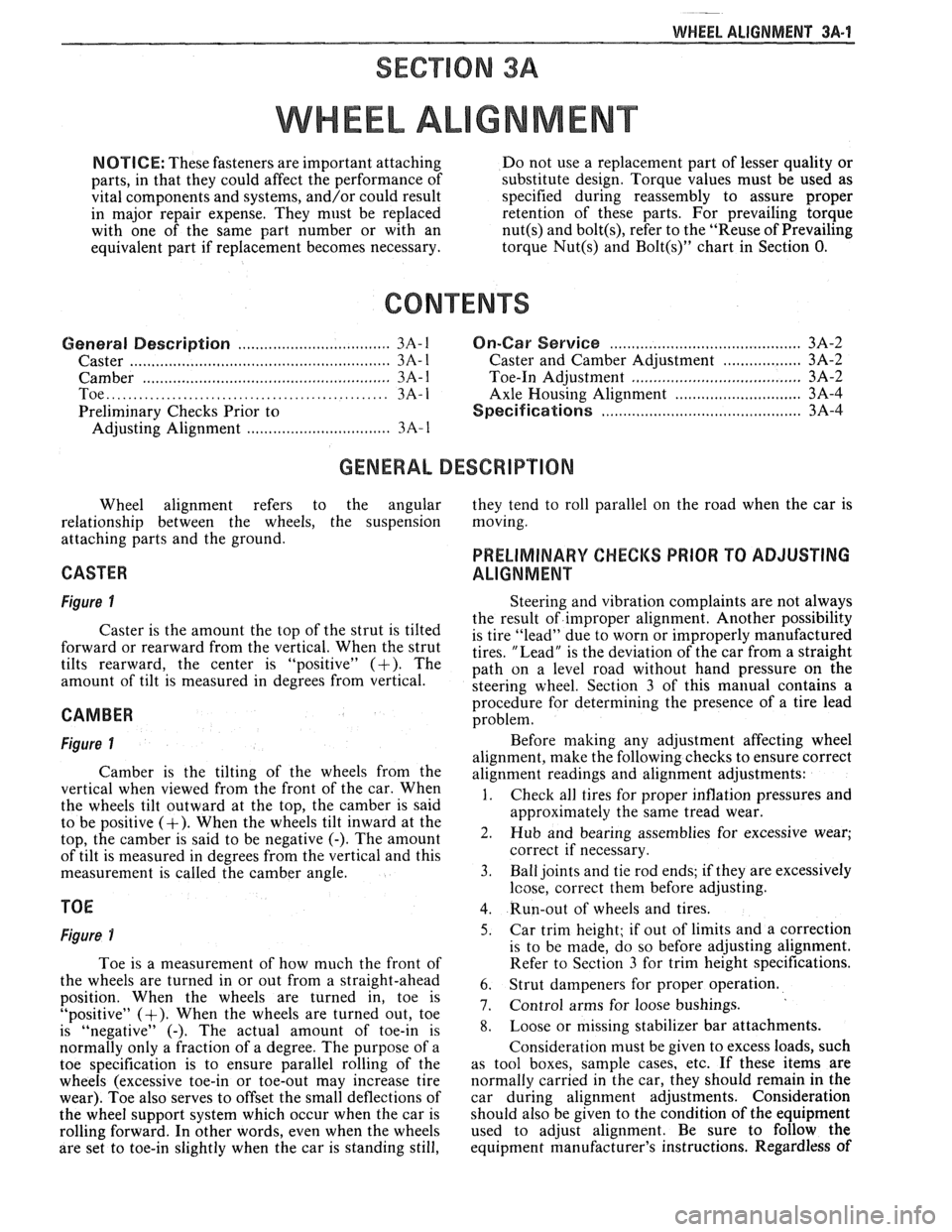

Waddle is side-to-side movement at the front

and/or rear of the car. It can be caused by the steel belt

not being straight within the tire, or by excessive lateral

runout of the tire or wheel. It ig most noticeable at low

speed, about 8 to 48

km/h (5 to 30 mph). It may also

appear as a ride roughness at 80 to 113

km/h (50 to 70

mph). The car can be road tested to see which end of the

car has the faulty tire. If the tire causing the waddle is

on the rear, the rear end of the car will "waddle." From

the driver's seat, it feels as if someone is pushing on the

side of the car.

If the faulty tire is on the front, the waddle is

more easily seen. The front sheet metal appears to be

moving back and forth. It feels as if the driver's seat is

the pivot point in the car.

Another more time-consuming method of

determining the faulty tire is substituting tire and

wheel assemblies that are known to be good. Follow

these steps:

1. Drive the car to determine if the waddle is coming

from the front or rear.

2. Install tire and wheel assemblies known to be

good (from a similar car) in place of those on the

end of the car which is waddling. If the waddle

cannot be isolated to front or rear, start with the

rear tires.

3. Road test again. If improvement is noted, install

the original tire and wheel assemblies one at a

time until the faulty tire is found. If no

improvement is noted, install tires known to be

good in place of all four. Then, install the

originals one at a time until the faulty tire is

found.

Radial Tire Lead/Pull

Fig. 18

"Lead/Pull" is the deviation of the car from a

straight path, on a level road with no pressure

on the

steering wheel.

L Fig. 16 Tire Waddle

Lead is usually caused by:

1. Tire construction.

2. Uneven brake adjustment.

3. Wheel alignment.

The way in which a tire is built can produce lead

in a car. An example of this is placement of the belt.

Off-center belts on radial tires can cause the tire to

develop a side force while rolling straight down the

road. The tire will tend to roll like a cone.

The Radial Tire

Lead/Pull Correction Chart

should be used to make sure that front wheel alignment

is not mistaken for tire lead.

Rear tires will not cause lead.

VIBRATION DIAGNOSIS

See Figs. 19 through 21 for vibration diagnosis.

TAPERED ROLLER BEARING

DlAGNOSlS

See Figs. 22 and 23 for Tapered Roller Bearing

Diagnosis.

See Fig. 24 for Trim Height Diagnosis.

Page 148 of 1825

-

WHEEL. ALIGNMENT 3A-1

SECTION 3A

WHEEL AL GNMENT

NOTICE: These fasteners are important attaching Do not use a replacement part of lesser quality or

parts, in that they could affect the performance of substitute

design. Torque values must be used as

vital components and systems, and/or could result specified during reassembly to assure proper

in major repair expense. They must be replaced retention of these parts. For prevailing torque

with one of the same part number or with an

nut(s) and bolt(s), refer to the "Reuse of Prevailing

equivalent part if replacement becomes necessary. torque

Nut(s) and Bolt(s)" chart in Section 0.

General Description ...................... .. ...... 3A- 1 On-Car Service ........................ .. ........... 3A-2

Caster .................... .. ............................ 3A- 1 Caster and Camber Adjustment .................. 3A-2

..................................... Camber ................... .. .............................. 3A-I Toe-In Adjustment 3A-2

Toe.. ................................................. 3A- 1 Axle Housing Alignment ......................... .... 3A-4

Preliminary Checks Prior to Specifications ....................... ... ............... 3A-4

Adjusting Alignment ..................... ...... 3A- 1

GENERAL DESCRIPmIOMI

Wheel alignment refers to the angular they tend to roll parallel on the road when the car is

relationship between the wheels, the suspension moving.

attaching parts and the ground.

PRELIMINARY CHECKS PRIOR TO ADJUSTING

CASTER ALIGNMENT

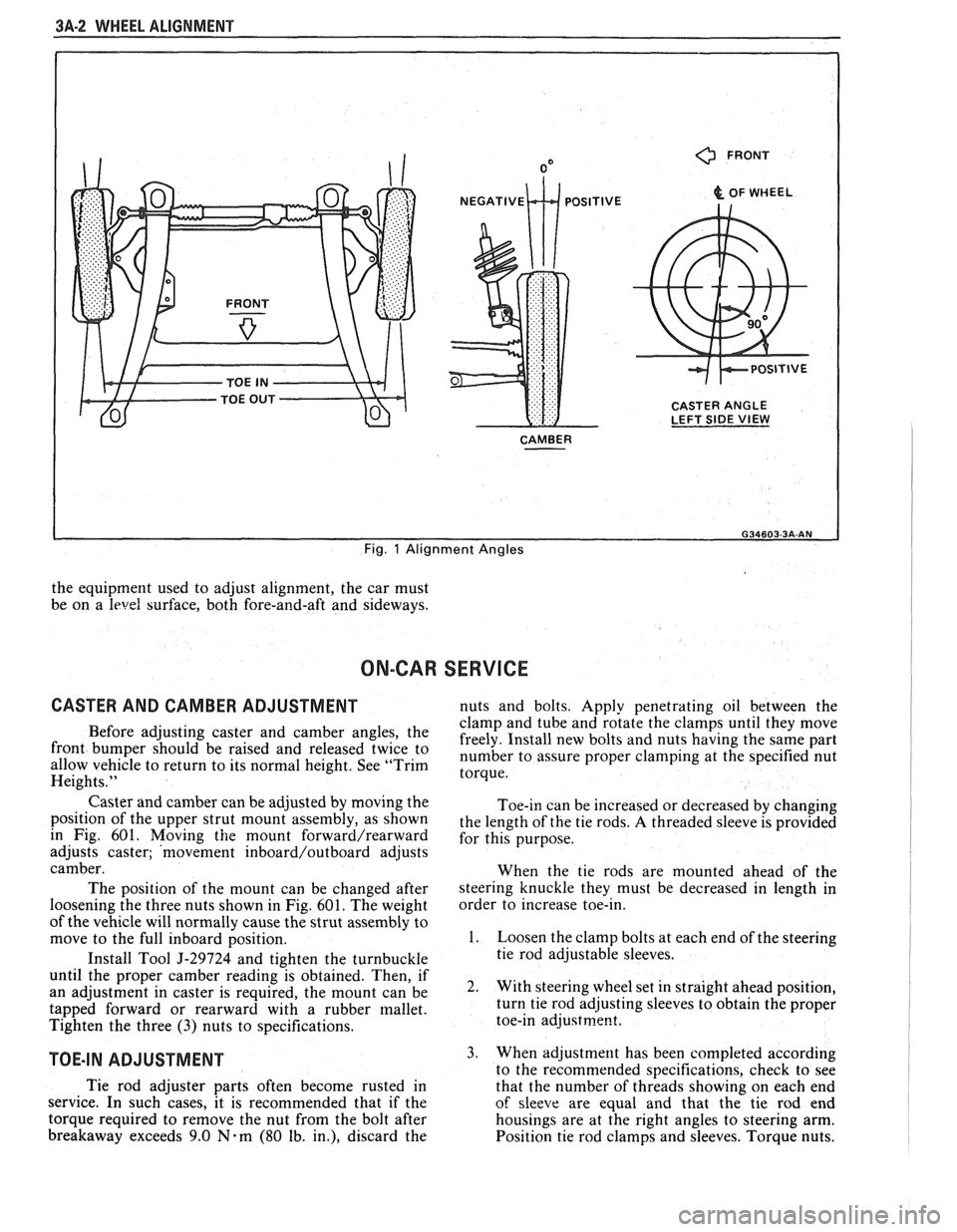

Figure 1

Caster is the amount the top of the strut is tilted

forward or rearward from the vertical. When the strut

tilts rearward, the center is "positive"

(+). The

amount of tilt is measured in degrees from vertical.

CAMBER

Figure 1

Camber is the tilting of the wheels from the

vertical when viewed from the front of the car. When

the wheels tilt outward at the top, the camber is said

to be positive

(+). When the wheels tilt inward at the

top, the camber is said to be negative

(-). The amount

of tilt is measured in degrees from the vertical and this

measurement is called the camber angle.

TOE

Figure i

Toe is a measurement of how much the front of

the wheels are turned in or out from a straight-ahead

position. When the wheels are turned in, toe is

"positive"

(+). When the wheels are turned out, toe

is "negative"

(-). The actual amount of toe-in is

normally only a fraction of a degree. The purpose of a

toe specification is to ensure parallel rolling of the

wheels (excessive toe-in or toe-out may increase tire

wear). Toe also serves to offset the small deflections of

the wheel support system which occur when the car is

rolling forward. In other words, even when the wheels

are set to toe-in slightly when the car is standing still, Steering

and vibration complaints are not always

the result of improper alignment. Another possibility

is tire "lead" due to worn or improperly manufactured

tires. "Lead" is the deviation of the car from a straight

path on a level road without hand pressure on the

steering wheel. Section

3 of this manual contains a

procedure for determining the presence of a tire lead

problem.

Before making any adjustment affecting wheel

alignment, make the following checks to ensure correct

alignment readings and alignment adjustments:

1. Check all tires for proper inflation pressures and

approximately the same tread wear.

2. Hub and bearing assemblies for excessive wear;

correct if necessary.

3. Ball joints and tie rod ends; if they are excessively

lcose, correct them before adjusting.

4. Run-out of wheels and tires.

5. Car trim height; if out of limits and a correction

is to be made, do so before adjusting alignment.

Refer to Section

3 for trim height specifications.

6. Strut dampeners for proper operation.

7. Control arms for loose bushings.

8. Loose or missing stabilizer bar attachments.

Consideration must be given to excess loads, such

as tool boxes, sample cases, etc. If these items are

normally carried in the car, they should remain in the

car during alignment adjustments. Consideration

should also be given to the condition of the equipment

used to adjust alignment. Be sure to follow the

equipment manufacturer's instructions. Regardless

of

Page 149 of 1825

3A-2 WHEEL ALIGNMENT

0 FRONT

& OF WHEEL

CASTER ANGLE

LEFT SIDE

VIEW

CAMBER

I

Fig. 1 Alignment Angles

the equipment used to adjust alignment, the car must

be on a

level surface, both fore-and-aft and sideways.

ON-CAR SERVICE

CASTER AND CAMBER ADJUSTMENT nuts and bolts. Apply penetrating oil between the

clamp and tube and rotate the clamps until they move

Before adjusting caster and camber the freely. Install new bolts and nuts having the same part front be 'aised and twice to number to assure proper at the specified nut allow vehicle to return to its normal height. See "Trim torque. Heights."

Caster and camber can be adjusted by moving the

position of the upper strut mount assembly, as shown

in Fig. 601. Moving

the mount forward/rearward

adjusts caster; 'movement inboard/outboard adjusts

camber.

The position of the mount can be changed after

loosening the three nuts shown in Fig.

601. The weight

of the vehicle will normally cause the strut assembly to

move to the full inboard position.

Install Tool

5-29724 and tighten the turnbuckle

until the proper camber reading is obtained. Then, if

an adjustment in caster is required, the mount can be

tapped forward or rearward with a rubber mallet.

Tighten the three

(3) nuts to specifications.

TOE-IN ADJUSTMENT

Toe-in can be increased or decreased by changing

the length of the tie rods.

A threaded sleeve is provided

for this purpose.

When the tie rods are mounted ahead of the

steering knuckle they must be decreased in length in

order to increase toe-in.

1. Loosen the clamp bolts at each end of the steering

tie rod adjustable sleeves.

2. With steering wheel set in straight ahead position,

turn tie rod adjusting sleeves to obtain the proper

toe-in

adjustrne~t.

3. When adjustment has been completed according

to the recommended snecifications. check to see

Tie rod adjuster parts often become rusted in

that the number of thrkads showing on each end

service. In such cases, it is recommended that if the

of sleeve are equal and that the tie rod end

torque required to remove the nut from the bolt after housings are at the right angles to steering arm.

breakaway exceeds 9.0

Nam (80 lb. in.), discard the

Position tie rod clamps and sleeves. Torque nuts.

Page 151 of 1825

3A-4 WHEEL ALIGNMENT

AXLE HOUSING ALIGNMENT 2. If a tram is used for checking toe out, it will still

be necessary to perform Steps

1 and 2 in order to If rear tire wear indicates that the axle housing

check camber.

may be bent, the alignment can be checked as follows:

The necessary straightening operations may be

1. Back the car squarely onto an alignment performed using frame straightening equipment

machine, ~h~ actual toe-out will be read on the without removing the axle housing from the car. This

scale as toe-in. However, if the toe-out is checked procedure will allow checks during the straightening

with a tram gage, disregard this notice. operation

to determine when the housing is within the

prescribed limits.

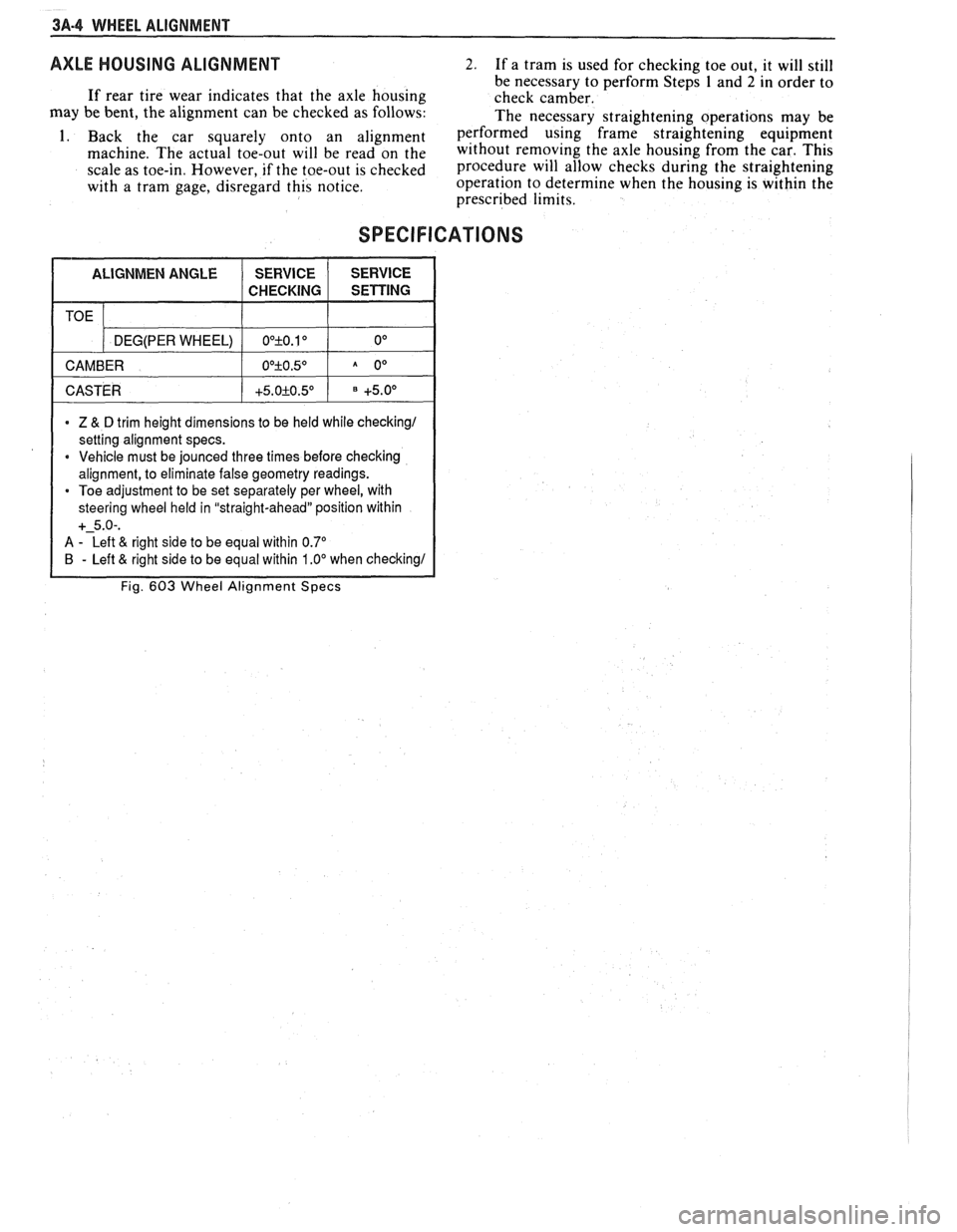

SPECIFICATIONS

1 CASTER 1 +5.0+0.5O 1 +5.0° 1

TOE

* Z & D trim height dimensions to be held while checking1

setting alignment specs.

* Vehicle must be jounced three times before checking

alignment, to eliminate false geometry readings.

Toe adjustment to be set separately per wheel, with

steering wheel held in "straight-ahead" position within

+-5.0-.

A - Left & right side to be equal within 0.7"

B - Left & right side to be equal within 1 .OO when checking1

Fig. 603 Wheel Alignment Specs

DEG(PER WHEEL)

CAMBER OO+O.10 0°

O0+O.5O A 0°

Page 188 of 1825

STEERING LINKAGE 3B6-1

SECTION 3B6

STEERING LINKAGE

The following notice applies to one or more steps in the assembly

procedure of components in this portion of the manual as Notice indicated at

appropriate locations by the terminology "See Caution on Page

1 of this

Section

" .

NOTICE: These fasteners are important attaching parts in that they

could affect the performance of vital components and systems,

andlor could

result in major repair expense. They must be replaced with one of the same

part number or with an equivalent part if replacement becomes necessary. Do

not use a replacement part of lesser quality or substitute design. Torque

values must be used as specified during reassembly to assure proper retention

of these parts. For prevailing torque

nut(s) and bolt(s), refer to the "Reuse of

Prevailing Torque

Nut(s) and Bolt(s)" chart in Section 10.

CONTENTS

General Description ........................................... 3B6- 1 Relay Rod ............................................................ 3B6-3

Maintenance and Adjustments ............................... 3B6- I Idler Arm ............................................................. 3B6-4

On-Car Service ........................................................ 3B6-2 Pitman Arm ......................................................... 3B6-5

Tie Rods .............................................................. 3B6-2 Specifications ........................................................... 3B6-6

GENERAL DESCRIPTION

A parallelogram type steering linkage connects both

steering gear. The right end of the relay rod is supported by

front wheels to the steering gear through the

pitman arm,

the idler arm which pivots on a support attached to the

The right and left tie rods are attached to the steering arms

frame rail. The

pitman arm and idler arm remain parallel to

and to the relay rod by ball studs. The left end of the relay

each other while they move through symmetrical arcs. See

rod is supported by the

pitman arm, which is driven by the Fig. 3B6-2.

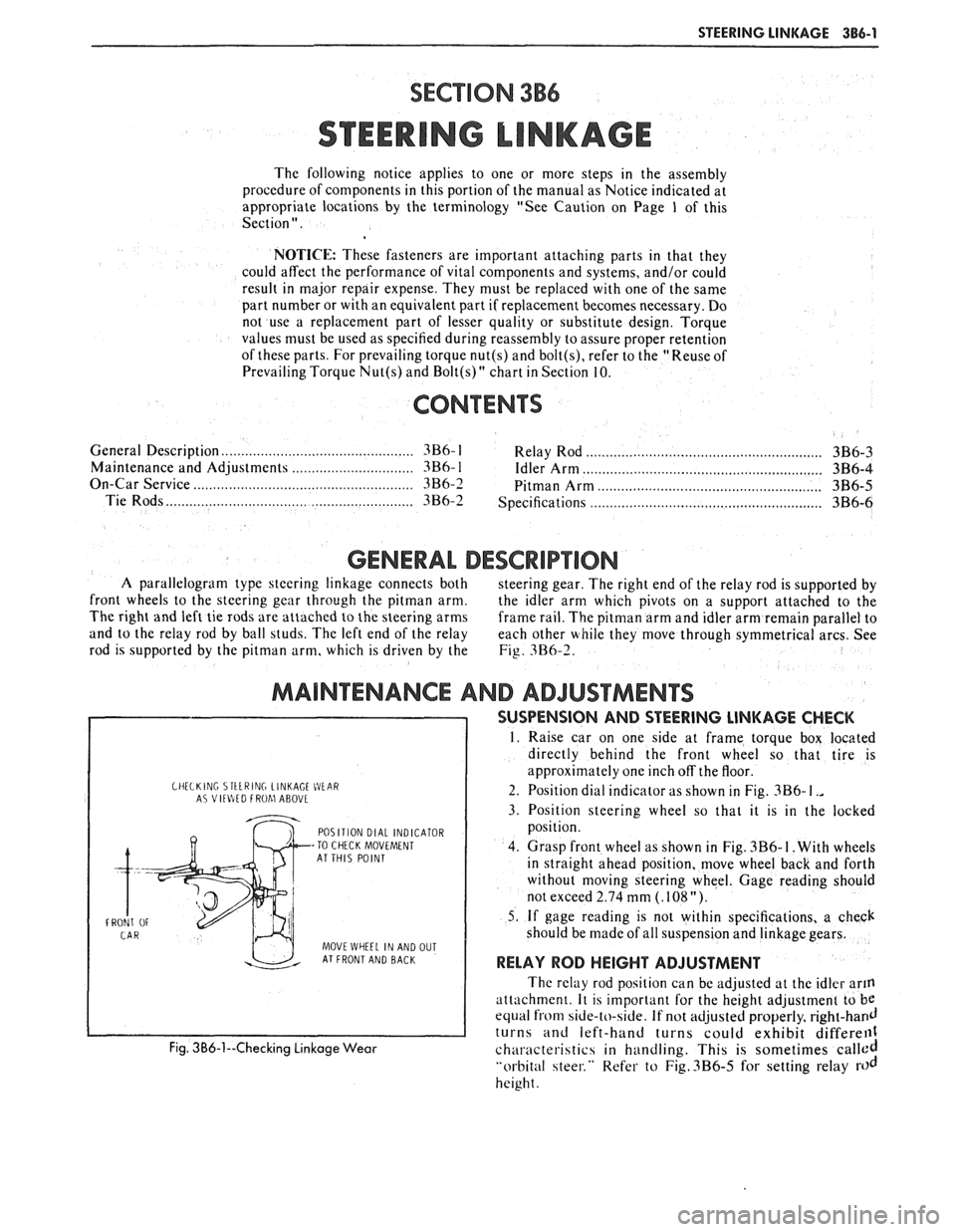

MAONTENANCE AND ADJUSTMENTS

CHELKlNC STtLRING LINKAGE WEIR A? VltlItD FROhl ABOVL

POSITION DIAL INDICATOR

-TO CHECK MOVEMENT

AT THIS POINT

FRONT

OF

MOVE WHEEL IN AND OUT AT FRONT AND BACK

Fig. 3B6-1--Checking Linkage Wear

SUSPENSION AND STEERING LINKAGE CHECK

1. Raise car on one side at frame torque box located

directly behind the front wheel so that tire is

approximately one inch off the floor.

2. Position dial indicator as shown in Fig.

3B6- I .,

3. Position steering wheel so that it is in the locked

position.

4. Grasp front wheel as shown in Fig.

3B6- I. With wheels

in straight ahead position, move wheel back and forth

without moving steering wheel. Gage reading should

not exceed 2.74 mm

(. 108 ").

5. If gage reading is not within specifications, a check

should be made of all suspension and linkage gears.

RELAY ROD HEIGHT ADJUSTMENT

The relay rod position can be adjusted at the idler arm

attach men^. It is important for the height adjustment to be

equal from side-to-side. If not adjusted properly, right-hand

turns and left-hand turns could exhibit differell1

characteristics in handling. This is sometimes called

"orbital steer." Refer to Fig.3B6-5 for setting relay rod

height.

Page 190 of 1825

STEERING LINKAGE 386-3

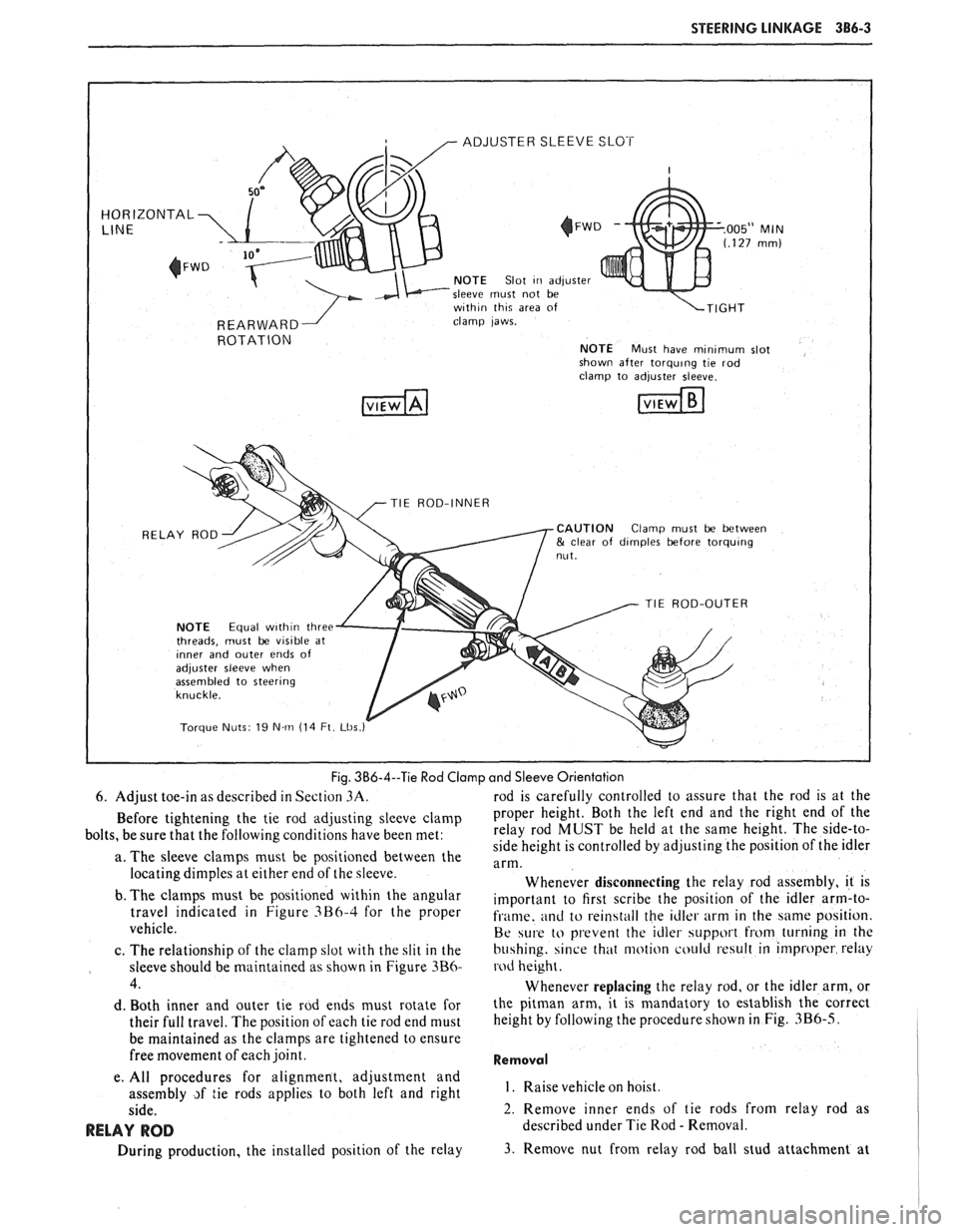

ADJUSTER SLEEVE SLOT

HORIZONTAL

NOTE Slot Iri adjuster

sleeve must not be

w~th~n th~q area of

clamp laws.

ROTATION NOTE Must have mlnlmum slot

shown after torqulng tie rod

TIE ROD-INNER

RELAY ROD

CAUTION Clamp must be between & clear of d~mples before torqulng

TIE ROD-OUTER

NOTE Equal w~th~n three

threads, must be vis~ble at Inner and outer ends of adjuster sleeve when

assembled to steerlng

Torque Nuts 19 N m (14 Ft Lbs

Fig. 3B6-4--Tie Rod Clamp and Sleeve Orientation

6. Adjust toe-in as described in Section

3A. rod is carefully controlled to assure that the rod is at the

Before tightening the tie rod adjusting sleeve clamp Proper height. Both the left end and the right end of the

bolts, be sure that the following conditions have been met: relay

rod MUST be held at the same height. The side-to-

side height is controlled by adjusting the position of the idler

a. The sleeve clamps must be positioned between the

arm. locating dimples at either end of the sleeve.

Whenever disconnecting the relay rod assembly, it is

b. The

clalnps must be positioned within the angular important to first scribe the position of the idler arm-to- travel indicated in Figure 3B6-4 for the Proper fi.ame. and to rein4tall the idler arm in the same position.

vehicle.

Be w1.e to prevent the idler support hom turning in the

c. The relationship of the clamp slot with the slit in the

bu4hing. since that motion could result in improper relay

sleeve should be maintained as shown in Figure

3B6- rod height.

4. Whenever replacing the relay rod, or the idler arm, or

d. Both inner and outer tie rod ends must rotate for the pitman arm, it is mandatory to establish the correct

their full travel. The position of each tie rod end must height

by following the procedure shown

in Fig. 3B6-5.

be maintained as the clamps are tightened to ensure

free movement of each joint.

Removal

e. All procedures for alignment, adjustment and

assembly

~f tie rods applies to both left and right I. Raise vehicle hoist.

side. 2. Remove inner ends of tie rods from relay rod as

RELAY ROD described under Tie Rod - Removal.

During production, the installed position of the relay

3. Remove nut from relay rod ball stud attachment at

Page 1158 of 1825

CLUTCH 7C-4

SECTION 76

CLUTCH

CONTENTS

GENERAL DESCRIPTION .......................... .. ............................................................. 7C-I

DIAGNOSIS ...................................................................................................................... 7C-3

Preliminary Checks ....................... ... ............................................................................ 7C-2

Bleeding Hydraulic Clutch System ................... .. .......................................................... 7C-2

ON-VEHICLE SERVICE ................................................................................................. 7C-5

Clutch Hydraulic System ................................................................................................. 7C-5

..................... Pressure Plate and Disc .. ........................................................................... 7C-6

Clutch Pedal ..................................................................................................................... 7C-6

Pilot Bearing .................................................................................................................. 7C-6

....................................................................................................... SPECIFICATIONS 7C-8

............................................................................................................ SPECIAL TOOLS 7C-8

GENERAL DESCRIPTION

COMPONENTS

The principal parts of a clutch system are: the

driving member and the operating members. Figure

7C-1 shows an exploded view of the clutch system.

DRIVEN MEMBERS (FIGURES 7C-1 AND 7C-2)

The driven member is the clutch disc with a

splined hub which is free to slide lengthwise along the

splines of the input shaft, but which drives the input

shaft through these same splines.

The driving and driven members are held in

contact by spring pressure. This pressure is exerted by

a diaphragm spring in the pressure plate assembly.

HYDRAULIC CLUTCH (FIGURE 7C-3)

A hydraulic clutch operating mechanism is used

on all models. The

mechanism consist of a remote

reservoir, clutch master cylinder and slave cylinder.

The remote reservoir is mounted to a bracket which

bolts to the power brake booster. The clutch master

cylinder is mounted on the cowl panel and the slave

cylinder is mounted on the bell housing. The clutch

master cylinder is operated directly off the clutch

pedal.

When the clutch pedal is pressed down, hydraulic

fluid under pressure from the clutch master cylinder

flows into the slave cylinder. Since the piston is also

connected to the clutch fork this lever moves the

release bearing into contact with the clutch cover

release fingers to disengage the clutch. The hydraulic

clutch system locates the clutch pedal height and

provides automatic clutch adjustment. No adjustment

of clutch linkage or pedal position is required.

OPERATING MEMBERS (FIGURE 7C-3)

HYDRAULIC CLUTCH FLUID

When adding fluid to or refilling the system after

The clutch release system is operated by service operations use GM Delco Supreme No. 11 hydraulic pressure and consists of the clutch pedal, brake fluid or an equivalent fluid that meets DOT 3 clutch master cylinder, clutch slave cylinder, clutch specifications. fork and clutch release bearing.

NOTICE: Do not use mineral or paraffin base oil in

the Clutch Hydraulic System. These fluids will

damage the rubber parts in the cylinders.

Page 1746 of 1825

procedure or glass breakage and

personal injury could occur.

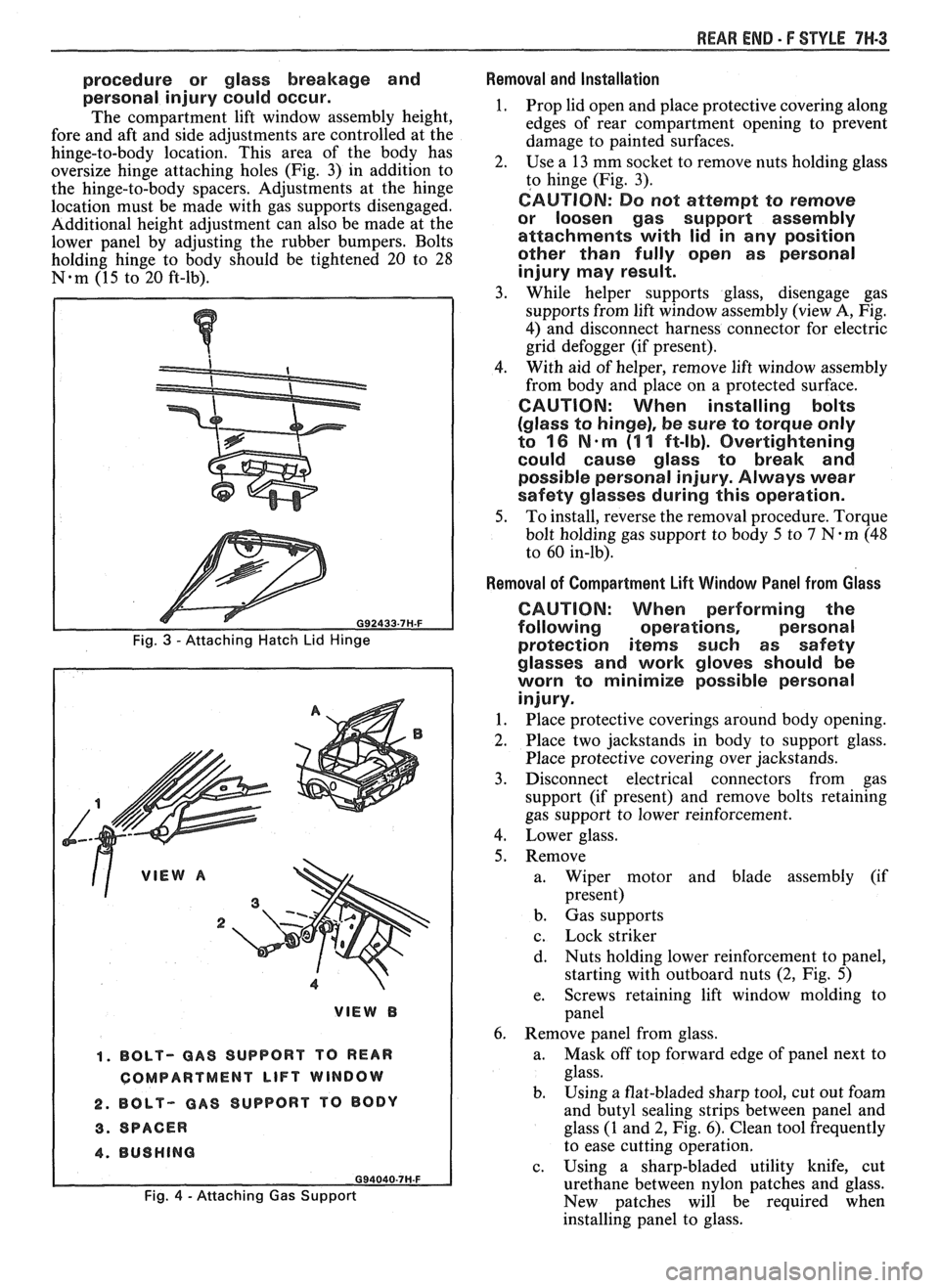

The compartment lift window assembly height,

fore and aft and side adjustments are controlled at the

hinge-to-body location. This area of the body has

oversize hinge attaching holes (Fig. 3) in addition to

the hinge-to-body spacers. Adjustments at the hinge

location must be made with gas supports disengaged.

Additional height adjustment can also be made at the

lower panel by adjusting the rubber bumpers. Bolts

holding hinge to body should be tightened 20 to 28

N-m (15 to 20 ft-lb).

, ,' VIEW A

2

1. BOLT- GAS SUPPORT TO REAR

COMPARTMENT

LIFT WINDOW

2. BOLT- GAS SUPPORT

TO BODY

3. SPACER

4. BUSHING

Fig. 4 - Attaching Gas Support

REAR END - F STYLE 7W-3

Removal and Installation

1. Prop lid open and place protective covering along

edges of rear compartment opening to prevent

damage to painted surfaces.

2. Use

a 13 mm socket to remove nuts holding glass

to hinge (Fig. 3).

CAUTION: Do not attempt to remove

or loosen gas support assembly

attachments with lid in any position

other than fully open as personal

injury may result.

3. While helper supports glass, disengage gas

supports from lift window assembly (view A, Fig.

4) and disconnect harness connector for electric

grid defogger (if present).

4. With

aid of helper, remove lift window assembly

from body and place on a protected surface.

CAUTION: When installing bolts

(glass to hinge), be sure to torque only

to

16 N-m (1 1 ft-lb). Overtightening

could cause glass to break and

possible personal injury. Always wear

safety glasses during this operation.

5. To install, reverse the removal procedure. Torque

bolt holding gas support to body 5 to

7 N-m (48

to 60 in-lb).

Removal of Compartment Lift Window Panel from Glass

CAUTION: When performing the

following operations, personal

protection

iterns such as safety

glasses and work gloves should be

worn to minimize possible personal

injury.

1. Place protective coverings around body opening.

2. Place two jackstands in body to support glass.

Place protective covering over jackstands.

3. Disconnect electrical connectors from gas

support (if present) and remove bolts retaining

gas support to lower reinforcement.

4. Lower glass.

5. Remove a. Wiper motor and blade assembly (if

present)

b. Gas supports

c. Lock striker

d. Nuts

holding lower reinforcement to panel,

starting with outboard nuts

(2, Fig. 5)

e. Screws

retaining lift window molding to

panel

6. Remove panel from glass.

a. Mask

off top forward edge of panel next to

glass.

b. Using

a flat-bladed sharp tool, cut out foam

and butyl sealing strips between panel and

glass (1 and 2, Fig. 6). Clean tool frequently

to ease cutting operation.

c. Using a sharp-bladed utility knife, cut

urethane between nylon patches and glass.

New patches will be required when

installing panel to glass.