instrument panel PONTIAC FIERO 1988 Service Repair Manual

[x] Cancel search | Manufacturer: PONTIAC, Model Year: 1988, Model line: FIERO, Model: PONTIAC FIERO 1988Pages: 1825, PDF Size: 99.44 MB

Page 2 of 1825

1988

SER

This manual applies to the 1988 Pontiac Firebird Models.

It contains the latest product information available at the

time of publication approval. lnformation pertaining to

the operation of the vehicle is contained in the Owner's

Manual which accompanies each vehicle. The right is

reserved to make changes at any time without notice.

Any references to brand names in this manual is intended

merely as an example of the types of

lubricant% tools,

materials, etc, recommended for use in servicing 1988

Pontiac Models. In all cases, an equivalent may be used.

PONTIAC DIVISION

GENERAL

MOTORS CORPORATION

PONTIAC, MICHIGAN 48053

1987 General Motors Corp. All Rights Reserved.

No part of this publication may be reproduced, stored in any

retrieval system or transmitted in any form or by any means,

including but not limited to electronic, mechanical,

photocopying, recording or otherwise, without the prior written

permission of General Motors Corp. This includes all text,

illustrations, tables and charts.

S-881 OF 9-87 Printed in Canada

TABLE OF CONTENTS

SECTION NAME

GENERAL INFORMATION

OA. General lnformation

OB. Maintenance & Lubrication

1 SECT.

HEATING AND AIR CONDITIONING

1A. Heating and Ventilation

1 B. Air Conditioning

1D1. R-4 AIC Com~ressor Overhaul

FRAME AND BUMPERS

2B. Bumpers 2C. Chassis Sheet Metal

STEERING, SUSPENSION, WHEELS

AND TIRES

3. Diagnosis

3A. Wheel Alignment

3B5. Steering Wheels and Columns 3B6. Steering Linkage 3B7. Power Steering Gear and Pump

3C. Front Suspension

3D. Rear Suspension

3E. Tires and Wheels

FINAL DRIVE

4A. Propeller Shaft

4B. Rear Axle

4B1. Bora-Warner Axle

BRAKES 5. Brakes 5A3. Comoosite Master Cvlinder 5B1. Disc r rake Caliper ~ssembly - 300013100 Series 5B6. Disc Brake Caliper Assembly - 3548

Series

5C3. Direct Torque Drum Brake Assembly 5D2. Power Head Assembly - Tandem Diaohraam 5F. ~~ecifications and Special Tools

ENGINE 6. Engine General lnformation 6A2. 2.8L 6A3. 5.OL & 5.7L 6B. Engine Cooling

6C. En~ine Fuel

6D. ~ngine Electrical 6D1. Battery 6D2. Cranking System 6D3. Charging System 6D4. Ignition System 6D5. Engine Wiring

6E. Driveabilitv and Emissions

6E2. ~missions' 6E3. Emissions - PFI

6F. Engine Exhaust

TRANSMISSION 7A. Automatic Transmission - General

lnformation

7A1. Automatic Transmission - On-Car

Service

700R4. Automatic Transmission Hydraulic Diagnosis

700R4. Automatic Transmission Unit Repair

76. 5-Speed Manual Transmission

7C. Clutch

CHASSIS ELECTRICAL 8A. Electrical Diagnosis

8B. Lighting and Horns

8C. Instrument

Panel, Gages

& Console

8E. Windshield Wiper &Washer System

ACCESSORIES 9A. Radio Systems and Antennas 9B. Cruise Control 9G. Miscellaneous Accessories

I BODY SERVICE MANUAL END

OF

MANUAL

Page 4 of 1825

GENERAL INFORMATION OA-1

SECTION (DA

GENERAL NFORMAT

CONTENTS

................................... General Description OA- 1 Prevailing Torque Fasteners ......................... OA-2

...................................... Body Number Plate OA- 1 Recommendations For Fastener Reuse ........ OA-2

..................... Vehicle Identification Number OA- 1 Vehicle Lifting Procedures ............ ., ............. OA-2

......................................... Metric Fasteners OA- 1 Precautions Against Tipping ........................ OA-7

................... Fastener Strength Identification OA-2 Automotive Abbreviations ................... .... 0.4- 1 1

GENERAL DESCRIPTION

Only general information appears in this section. left

of the windshield, see Figure 2. Refer to Figure 3

Detailed specifications on major units are given at the for detailed "VIN" code information.

For Engine V.I.

end of each respective section of this manual. N. Location, refer to Figure

4.

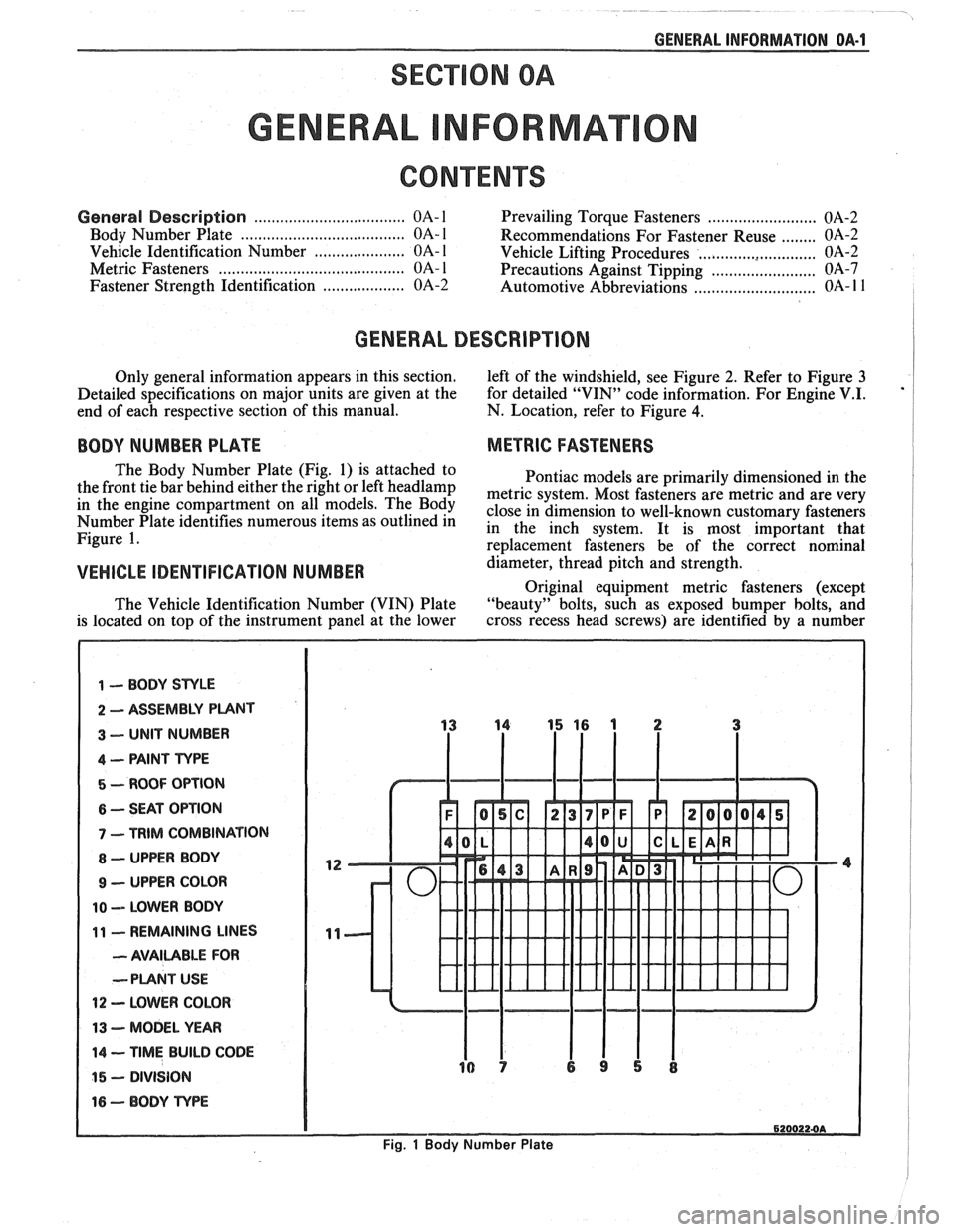

BODY NUMBER PLATE METRIC FASTENERS

The Body Number Plate (Fig. 1) is attached to

Pontiac models are primarily dimensioned in the

the front tie bar behind either the right or left

headlamp metric system, Most fasteners are metric and are very in the engine On The close in dimension to well-known customary fasteners Number Plate identifies numerous items as outlined in in the inch system. It is most important that Figure 1. re~lacement fasteners be of the correct nominal

VEHICLE IDENTIFICATION NUMBER d&meter, thread pitch and strength.

Original equipment metric fasteners (except

The Vehicle Identification Number (VIN) Plate "beauty" bolts, such

as exposed bumper bolts, and

is located on top of the instrument panel at the lower cross

recess head screws) are identified by a number

1 -- BODY STYLE

2 ASSEMBLY PUNT

3 -- UNIT NUMBER

4 -- PAINT TYPE

5 - ROOF OPTION

6 -- SEAT OPTION

7 - TRIM COMBINATION

8 - UPPER BODY

9 - UPPER COLOR

10 -- LOWER BODY

11 - REMAINING LINES

- AVAILABLE FOR

--PLANT

USE

12 - LOWER COLOR

13 - MODEL YEAR

14 -- TIME BUILD CODE

15 - DIVISION

16 - BODY TvPE

6200224A

Fig. 1 Body Number Plate

Page 16 of 1825

- -

GENERAL INFORMATION OA-13

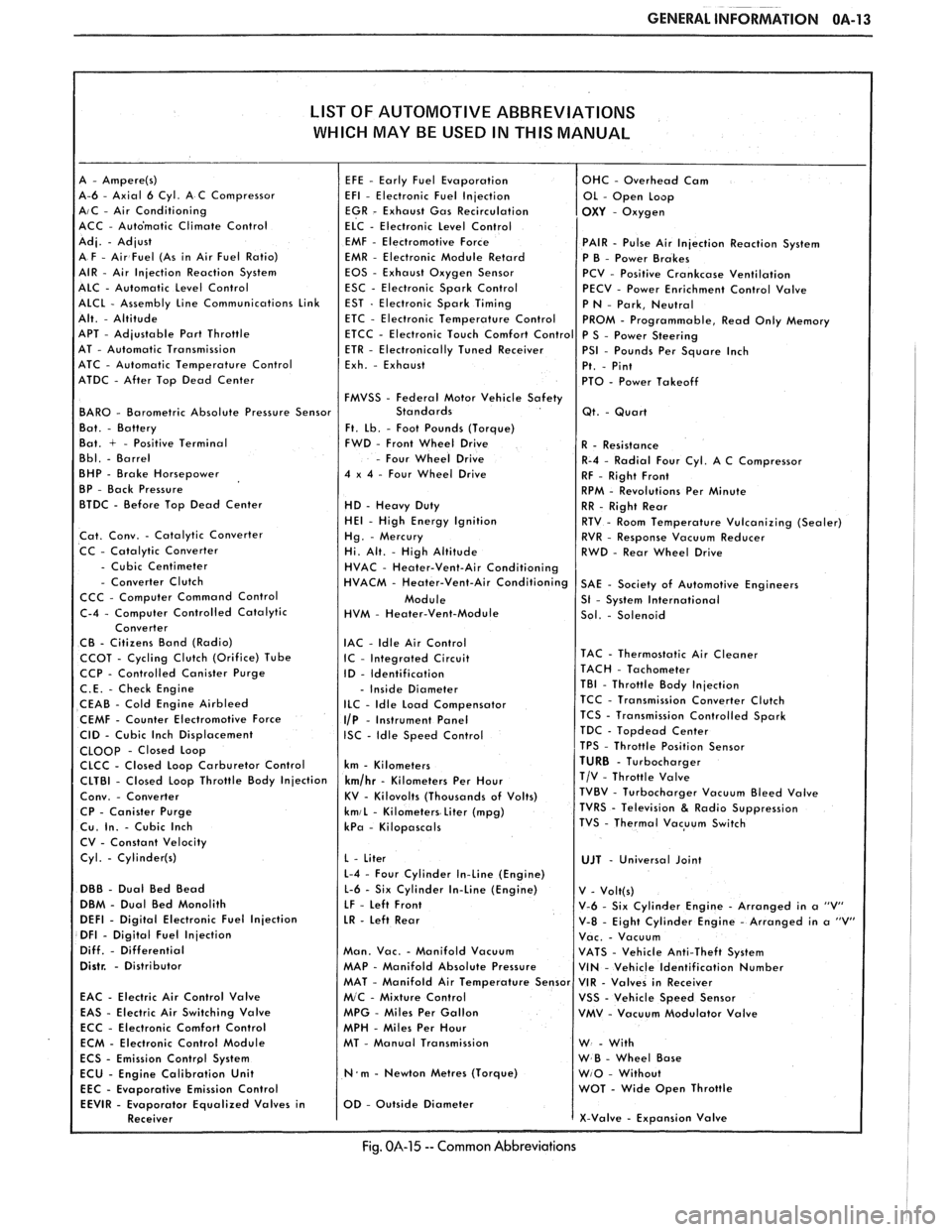

LIST OF AUTOMOTIVE ABBREVIATIONS

WHICH MAY

BE USED IN THIS MANUAL

A-6 - Axial 6 Cyl. A C Compressor AIC - Air Conditioning

ACC - Auto'matic Climate Control

EMF

- Electromotive Force PAIR - Pulse Air Injection Reaction System

EMR - Electronic Module Retard

P B - Power Brakes

EOS - Exhaust Oxygen Sensor

PCV - Positive Crankcase Ventilation

ESC - Electronic Spark Control

PECV - Power Enrichment Control Valve

APT

- Adjustable Part Throttle

AT - Automatic Transmission

ATC - Automatic Temperature Control

ATDC

- After Top Dead Center

FMVSS

- Federal Motor Vehicle Safety BAR0 - Barometric Absolute Pressure Sensor

Ft. Lb. - Foot Pounds (Torque)

Bat. + - Positive Terminal FWD - Front Wheel Drive

- Four Wheel Drive

BHP - Brake Horsepower 4 x 4 - Four Wheel Drive

BP - Back Pressure

BTDC - Before Top Dead Center

HD - Heavy Duty HE1 - High Energy Ignition

Cat. Conv. - Catalytic Converter

CC - Catalytic Converter

- Cubic Centimeter - Converter Clutch

CCC - Computer Command Control

HVM

- Heater-Vent-Module

IAC

- ldle Air Control CCOT - Cycling Clutch (Orifice) Tube IC - Integrated Circuit CCP - Controlled Canister Purge

ID - Identification

C.E. - Check Engine - Inside Diameter

CEAB - Cold Engine Airbleed ILC - Idle Load Compensator

CEMF - Counter Electromotive Force I/P - Instrument Panel

CID - Cubic Inch Displacement ISC - Idle Speed Control CLOOp - Closed Loop

CLCC - Closed Loop Carburetor Control km - Kilometers

CP

- Canister Purge kmiL - Kilometers Liter (mpg) Cu. In. - Cubic Inch kPa - Kilopascals

CV - Constant Velocity

Cyl.

- Cylinder(s)

L-4 - Four Cylinder In-Line (Engine)

DBB - Dual Bed Bead L-6 - Six Cylinder In-Line (Engine)

DBM - Dual Bed Monolith

LF - Left Front DEFl - Digital Electronic Fuel Injection LR - Left Rear DFI - Digital Fuel Injection

Diff. - Differential Man. Vac. - Manifold Vacuum Distr. - Distributor MAP - Manifold Absolute Pressure

EAC

- Electric Air Control Valve

EAS - Electric Air Switching Valve MPG - Miles Per Gallon

ECC - Electronic Comfort Control

MPH - Miles Per Hour

ECM - Electronic Control Module MT - Manual Transmission

N.m - Newton Metres (Torque)

Emission Control

Fig. 014-15 -- Common Abbreviations

Page 21 of 1825

OB-4 MAINTENANCE AND LUBRICATION

Tire and wheel operation - Be alert to a vibra-

tion of the steering wheel or seat at normal highway

speeds. This may mean a wheel balance is needed. Also, a

pull right or left on a straight, level road may show the

need for

a tire pressure adjustment or wheel alignment.

Steering system operation - Be alert to

changes in steering action. An inspection is needed when

the steering wheel is harder to turn or has too much free

play or if unusual sounds are noted when turning or

parking.

Headlight aim operation - Take note of light

pattern occasionally. If beam aim doesn't look right,

headlights should be adjusted.

AT EACH FUEL FILL

Engine oil level check - Check engine oil level

and add if necessary. See your Owner's

Manual for further

details.

NOTICE: A large loss in this system may indicate a

problem. Have it inspected and repaired at once.

Engine coolant level and condition - Check

engine coolant level in coolant reservoir tank and add if

necessary. Replace if dirty or rusty. See your Owner's

Manual for further details.

NOTICE: A large loss in this system may indicate a

problem. Have it inspected and repaired at once.

Windshield washer fluid level check -- Check

washer fluid level in container and add if necessary.

Hood latch operation - When opening hood on

cars equipped with hoods that open from the front, note

the operation of secondary latch. It should keep hood from

opening all the way when primary latch is released. Make

sure that hood closes firmly.

AT LEAST MONTI-ILY

Tire and wheel inspection and pressure

check--

Check tires for abnormal wear or damage. Also,

check for damaged wheels. Keep pressures as shown on

Tire Placard on the driver's door (include spare unless it is

a stowaway). Pressure should b\: checked when tires are

"cold". See "Tires" in Owner's Manual for further

infomation.

Light operation check - Check operation of

license plate light, side-marker lights, headlights includ-

ing high beams, parking lights, taillights, brake lights.

turn signals, backup lights, instrument panel and interior

lights and hazard warning flashers.

Fluid leak check - After the car has been parked

for a while, inspect the surface beneath the car for water,

oil, fuel or other fluids. Water dripping from the air

conditioning system after use is normal. If you notice fuel

leaks or fumes, the cause should be found and corrected at

once.

AT LEAST TWICE A YEAR (FOR EXAMPLE,

EVERY SPRING AND FALL)

Power steering pump fluid level check --

Check power steering pump fluid level in accordance with

Owner's Manual instructions and keep at proper level.

NOTICE: A large loss in this system may indicate a

problem. Have it inspected and repaired at once.

Brake master cylinder reservoir fluid level

check ---- Check fluid and keep at proper level. Note: It is

normal for the brake fluid level to go down slightly as the

brake pads wear

- so be sure to keep reservoir filled.

NOTICE: A large loss in this system may indicate a

problem. Have

it inspected and repaired at once.

Clutch system service --- manual transmis-

sionltransaxle --- For cars equipped with hydraulic

clutch system, check the reservoir fluid level and add fluid

as required. All others, check clutch pedal free travel and

adjust as necessary. See your Owner's Manual for further

details.

~

NOTICE: A large loss in this system may indicate a

problem. Have it inspected and repaired at once.

Weatherstrip Lubrication - Clean surface and

then apply a thin film of silicone grease with a clean cloth.

EACH TIME OIL IS CHANGED

Automatic and manual transmissionltrans-

axle fluid level check - Check transmission/transaxle

fluid level and add as required. (Corvette only) if equipped

with manual transmission

- check fluid in the overdrive

unit and add as required.

NOTICE: A large loss in this system may indicate a

problem. Have

it inspected and repaired at once.

Brake systems inspection - For convenience,

the following should be done when wheels are removed

for rotation: Inspect lines and hoses for proper hookup,

binding, leaks, cracks, chafing, etc. Inspect disc brake

pads for wear and rotors for surface condition. Also in-

spect drum brake linings for wear and cracks. Inspect

other brake parts, including drums, wheel cylinders, park-

ing brake, etc. at the same time. Check parking brake

adjustment.

INSPECT BRAKES MORE OFTEN IF DRIVING

HABITS OR CONDITIONS RESULT IN FREQUENT

BRAKING.

Steering, suspension and front drive axle

boot and seal inspection

- Inspect front and rear

suspension and steering system for damaged, loose or

missing parts, signs of wear or lack of lubrication. Inspect

power steering lines and hoses for proper hookup, bind-

ing, leaks, cracks, chafing, etc. (On cars equipped with

manual steering gear, check for seal leakage.) On

front-

wheel-drive cars, clean then inspect drive axle boot seals

for damage, tears or leakage. Replace seals if necessary.

Exhaust system inspection - Inspect complete

system. Inspect body near the exhaust system. Look for

broken, damaged, missing or out-of-position parts as well

as open seams, holes, loose connections or other condi-

tions which could cause a heat buildup in the tloor pan or

could let exhaust fumes seep into the trunk or passenger

compartment.

Page 24 of 1825

HEATING AND VENTILATION 1A-1

SECTION 1A

NG AND VENT

CONTENTS

General Description ................................. 1A-1

Diagnosis - Heater Trouble ...................... 1A-5

Insufficient Heating or Defrosting .............. 1A-5

Blower Electrical ......................................... 1A-7

....... Improper Air DeliveryINo Mode Shift 1 A-8

Too Much Heat .......................................... 1A-9 ....................................................... Controls 1A-10 ............................................... Blower Noise 1A-11

....................................... On-Vehicle Sewice 1A-13

.......................... Heater Control Assembly 1 A- 13

....................................... Blower Switch 1A- 13

.................................. Temperature Cable

1 A- 13

.......................................... Heater Core 1 A- 13

................................. Vent Control Cable 1 A- 13

Lower Heater Outlet

................................ 1A-14

........................................ Blower Motor 1A-14

GENERAL DESCRIPTION

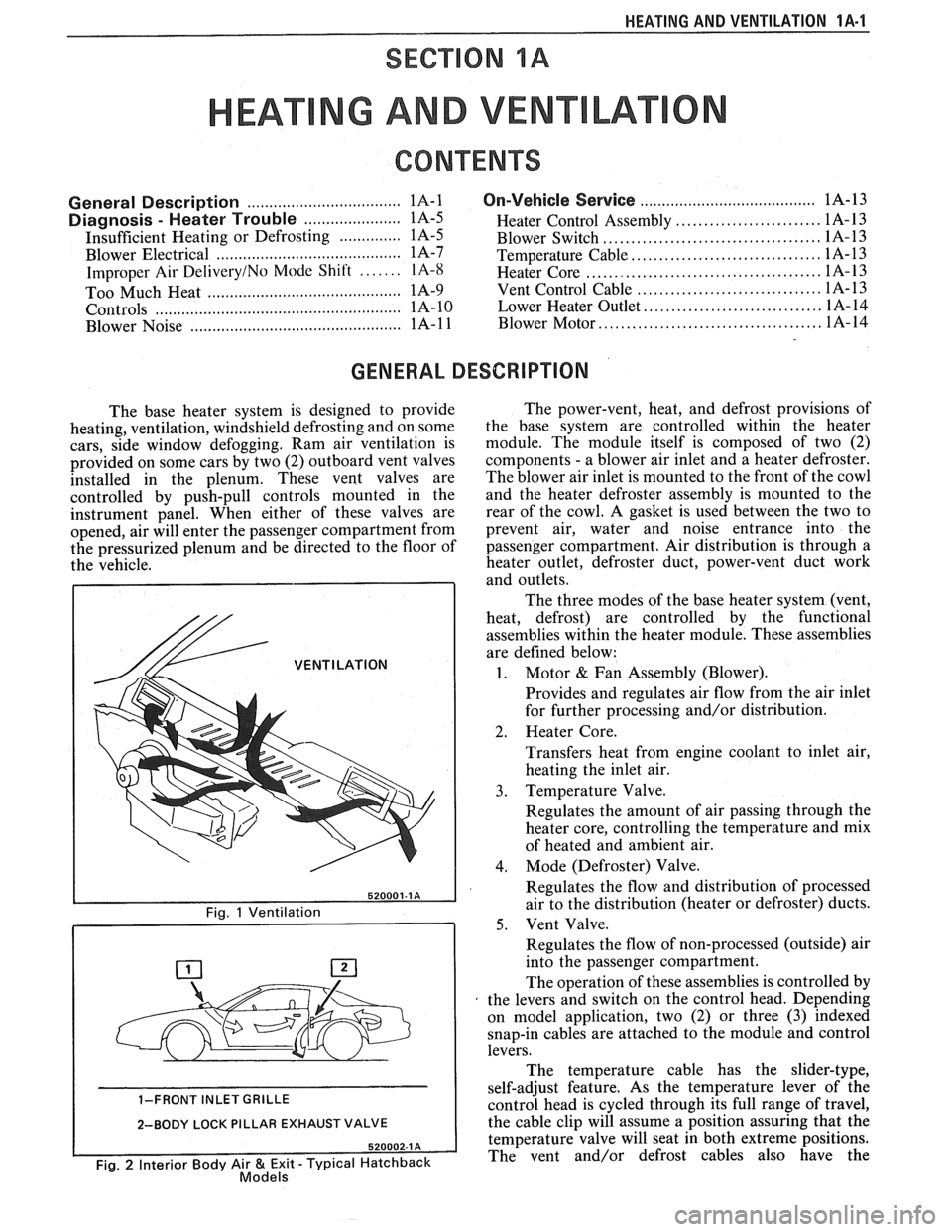

The base heater system is designed to provide

heating, ventilation, windshield defrosting and on some

cars, side window defogging. Ram air ventilation is

provided on some cars by two (2) outboard vent valves

installed in the plenum. These vent valves are

controlled by push-pull controls mounted in the

instrument panel. When either of these valves are

opened, air will enter the passenger compartment from

the pressurized plenum and be directed to the floor of

the vehicle.

/& VENTILATION

1-FRONT INLET GRILLE

2-BODY LOCK PILLAR EXHAUST VALVE

Fig. 2 Interior Body Air & Exit - Typical Hatchback Models

The power-vent, heat, and defrost provisions of

the base system are controlled within the heater

module. The module itself is composed of two (2)

components

- a blower air inlet and a heater defroster.

The blower air inlet is mounted to the front of the cowl

and the heater defroster assembly is mounted to the

rear of the cowl. A gasket is used between the two to

prevent air, water and noise entrance into the

passenger compartment. Air distribution is through a

heater outlet, defroster duct, power-vent duct work

and outlets.

The three modes of the base heater system (vent,

heat, defrost) are controlled by the functional

assemblies within the heater module. These assemblies

are defined below:

1. Motor & Fan Assembly (Blower).

Provides and regulates air flow from the air inlet

for further processing and/or distribution.

2. Heater Core.

Transfers heat from engine coolant to inlet air,

heating the inlet air.

3. Temperature Valve.

Regulates the amount of air passing through the

heater core, controlling the temperature and mix

of heated and ambient air.

4. Mode (Defroster) Valve.

Regulates the flow and distribution of processed

air to the distribution (heater or defroster) ducts.

5. Vent Valve.

Regulates the flow of non-processed (outside) air

into the passenger compartment.

The operation of these assemblies is controlled by

the levers and switch on the control head. Depending

on model application, two (2) or three

(3) indexed

snap-in cables are attached to the module and control

levers.

The temperature cable has the slider-type,

self-adjust feature. As the temperature lever of the

control head is cycled through its full range of travel,

the cable clip will assume a position assuring that the

temperature valve will seat in both extreme positions.

The vent and/or defrost cables also have the

Page 25 of 1825

1A-2 HEATING AND VENTILATION

520003-1 A

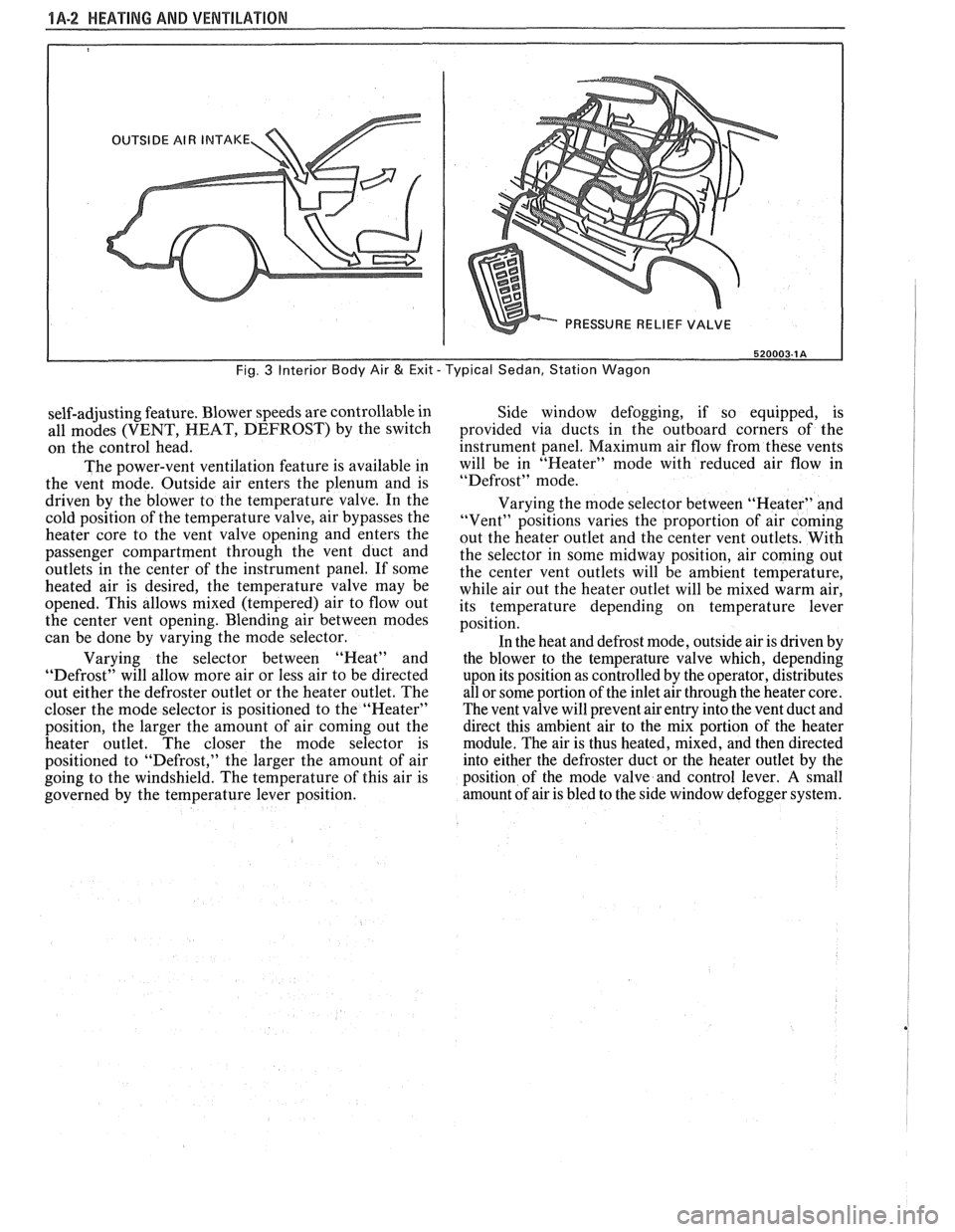

Fig. 3 Interior Body Air & Exit - Typical Sedan, Station Wagon

self-adjusting feature. Blower speeds are controllable in

all modes (VENT, HEAT, DEFROST) by the switch

on the control head.

The power-vent ventilation feature is available in

the vent mode. Outside air enters the plenum and is

driven by the blower to the temperature valve. In the

cold position of the temperature valve, air bypasses the

heater core to the vent valve opening and enters the

passenger compartment through the vent duct and

outlets

in the center of the instrument panel. If some

heated air is desired, the temperature valve may be

opened. This allows mixed (tempered) air to flow out

the center vent opening. Blending air between modes

can be done by varying the mode selector.

Varying the selector between "Heat" and

"Defrost" will allow more air or less air to be directed

out either the defroster outlet or the heater outlet. The

closer the mode selector is positioned to the "Heater"

position, the larger the amount of air coming out the

heater outlet. The closer the mode selector is

positioned to "Defrost," the larger the amount of air

going to the windshield. The temperature of this air is

governed by the temperature lever position. Side window

defogging, if so equipped, is

provided via ducts in the outboard corners of the

instrument panel. Maximum air flow from these vents

will be in "Heater" mode with reduced air flow in

"Defrost" mode.

Varying the mode selector between "Heater" and

"Vent" positions varies the proportion of air coming

out the heater outlet and the center vent outlets. With

the selector in some midway position, air coming out

the center vent outlets will be ambient temperature,

while air out the heater outlet will be mixed warm air,

its temperature depending on temperature lever

position.

In the heat and defrost mode, outside air is driven by

the blower to the temperature valve which, depending

upon its position as controlled by the operator, distributes

all or some portion of the inlet air through the heater core.

The vent valve will prevent air entry into the vent duct and

direct this ambient air to the mix portion of the heater

module. The air is thus heated, mixed, and then directed

into either the defroster duct or the heater outlet by the

position of the mode valve and control lever.

A small

amount of air is bled to the side window defogger system.

Page 26 of 1825

HEAPING AND VENTILA"T0N 1A-3

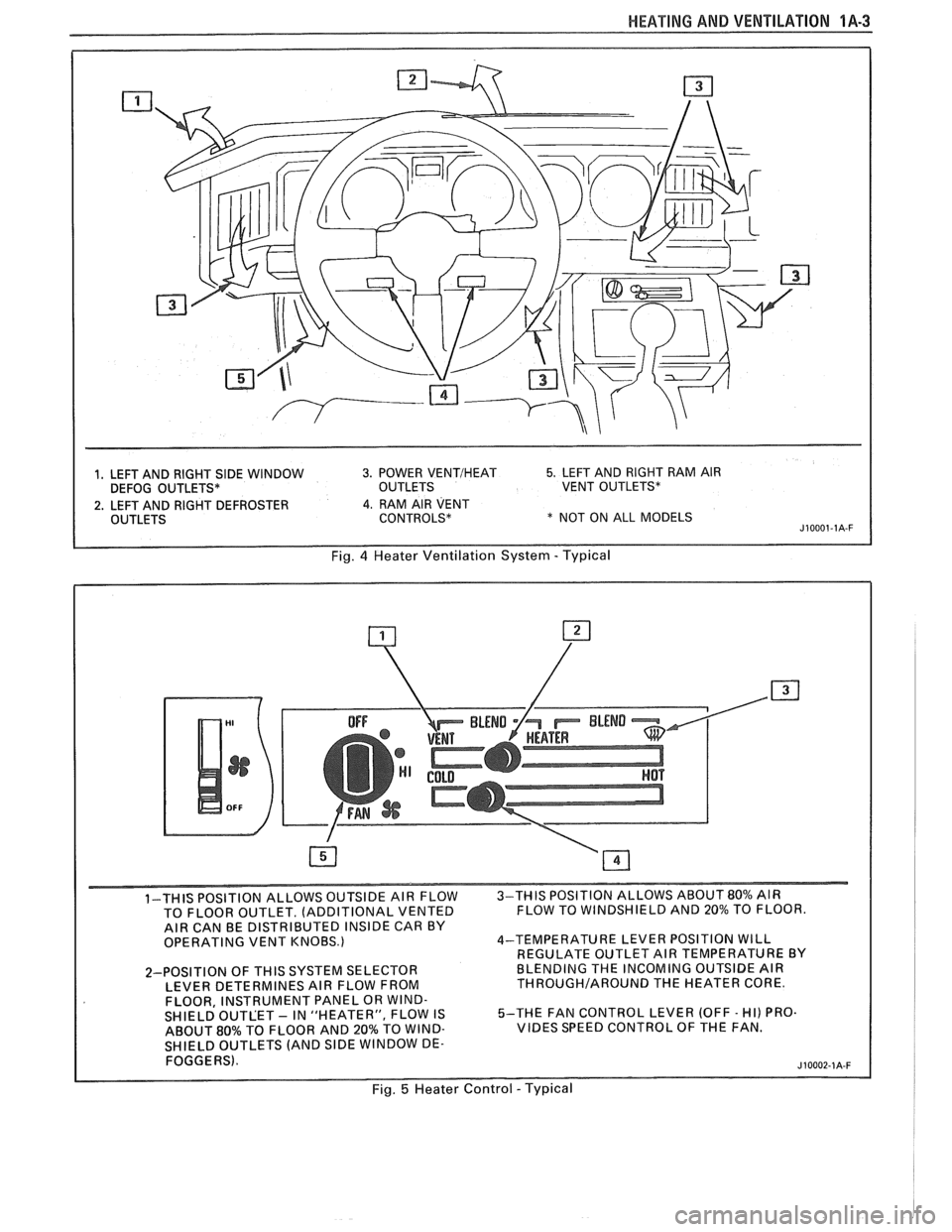

1, LEFT AND RIGHT SIDE WINDOW 3. POWER VENTIHEAT 5. LEFT AND RIGHT RAM AIR

DEFOG OUTLETS* OUTLETS VENT OUTLETS*

2. LEFT AND RIGHT DEFROSTER 4. RAM AIR VENT

OUTLETS CONTROLS* * NOT ON ALL MODELS J10001-1A-F

Fig. 4 Heater Ventilation System - Typical

1-THIS POSITION ALLOWS OUTSIDE AIR FLOW 3-THIS

POSITION ALLOWS ABOUT 80% AIR

TO FLOOR OUTLET. (ADDITIONAL VENTED FLOW

TO WINDSHIELD AND 20% TO FLOOR.

AIR CAN BE DISTRIBUTED INSIDE CAR BY

OPERATING VENT KNOBS.) 4-TEMPERATURE

LEVER POSITION WILL

REGULATE OUTLET AIR TEMPERATURE BY

2-POSITION OF

THIS SYSTEM SELECTOR BLENDING

THE INCOMING OUTSIDE AIR

LEVER DETERMINES AIR FLOW FROM THROUGHIAROUND THE HEATER CORE.

FLOOR, INSTRUMENT PANEL OR WIND-

SHIELD OUTLET - IN "HEATER", FLOW IS 5-THE

FAN CONTROL LEVER (OFF - HI) PRO.

ABOUT

80% TO FLOOR AND 20% TO WIND- VIBES SPEED CONTROL OF THE FAN.

SHIELD OUTLETS (AND

SlDE WINDOW DE-

FOGGERS).

Fig. 5 Heater Control - Typical

Page 33 of 1825

----

1A-10 HEATING AND VENTILATION

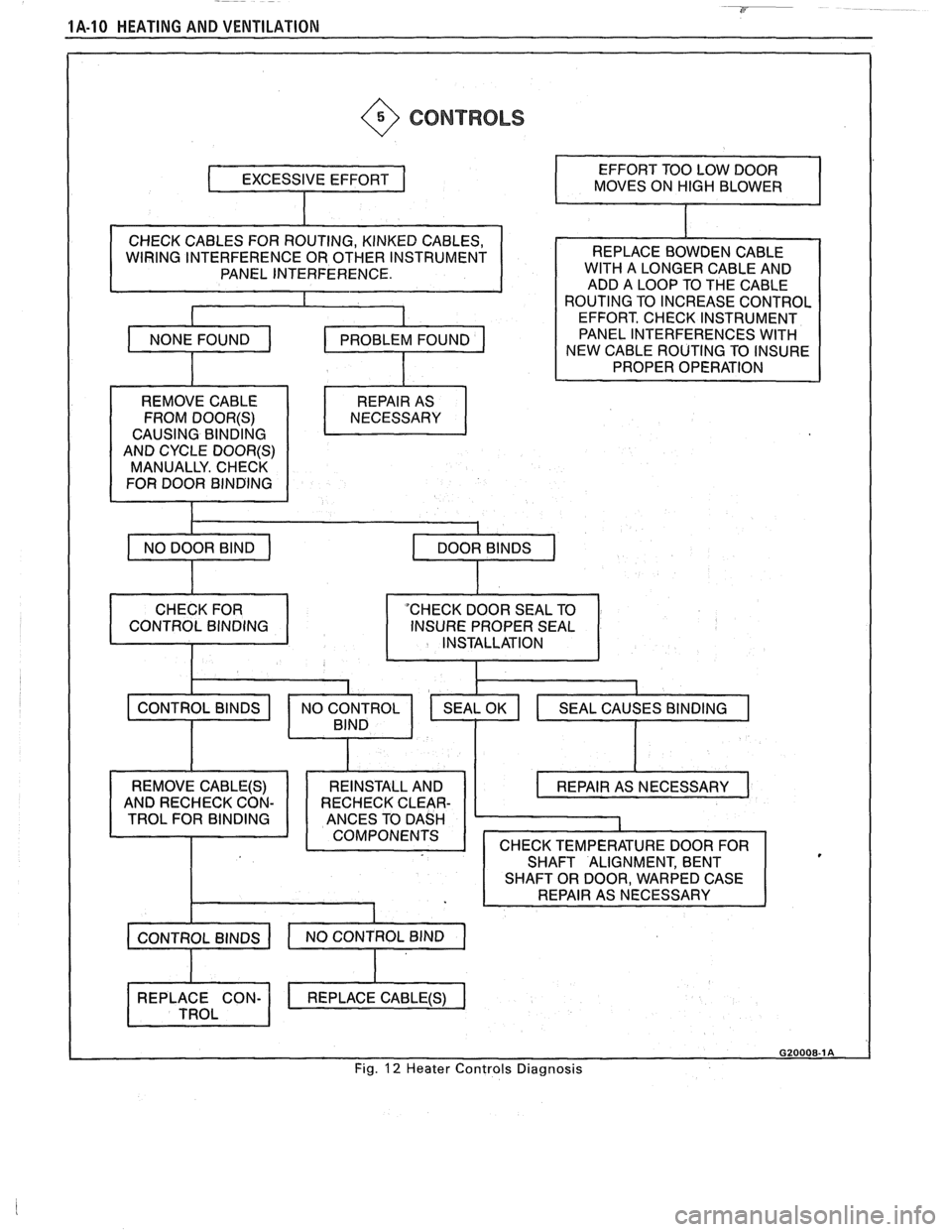

@ CONTROLS

CHECK CABLES FOR ROUTING, KINKEC CABLES,

WIRING INTERFERENCE OR OTHER INSTRUMENT

PANEL INTERFERENCE.

REMOVE CABLE FROM

DOOR(S)

CAUSING BINDING

AND CYCLE

DOOR(§)

MANUALLY. CHECK

FOR DOOR BINDING MOVES

ON

HIGH BLOWER

WlTH A LONGER CABLE AND

ADD A LOOP TO THE CABLE

ROUTING TO INCREASE CONTROL

EFFORT, CHECK INSTRUMENT

PANEL INTERFERENCES

WlTH

NEW CABLE ROUTING TO INSURE

PROPER

OPERATI

INSTALLATION

I

SEAL OK

SHAFT ALIGNMENT, BENT

Fig. 12 Heater Controls Diagnosis

Page 38 of 1825

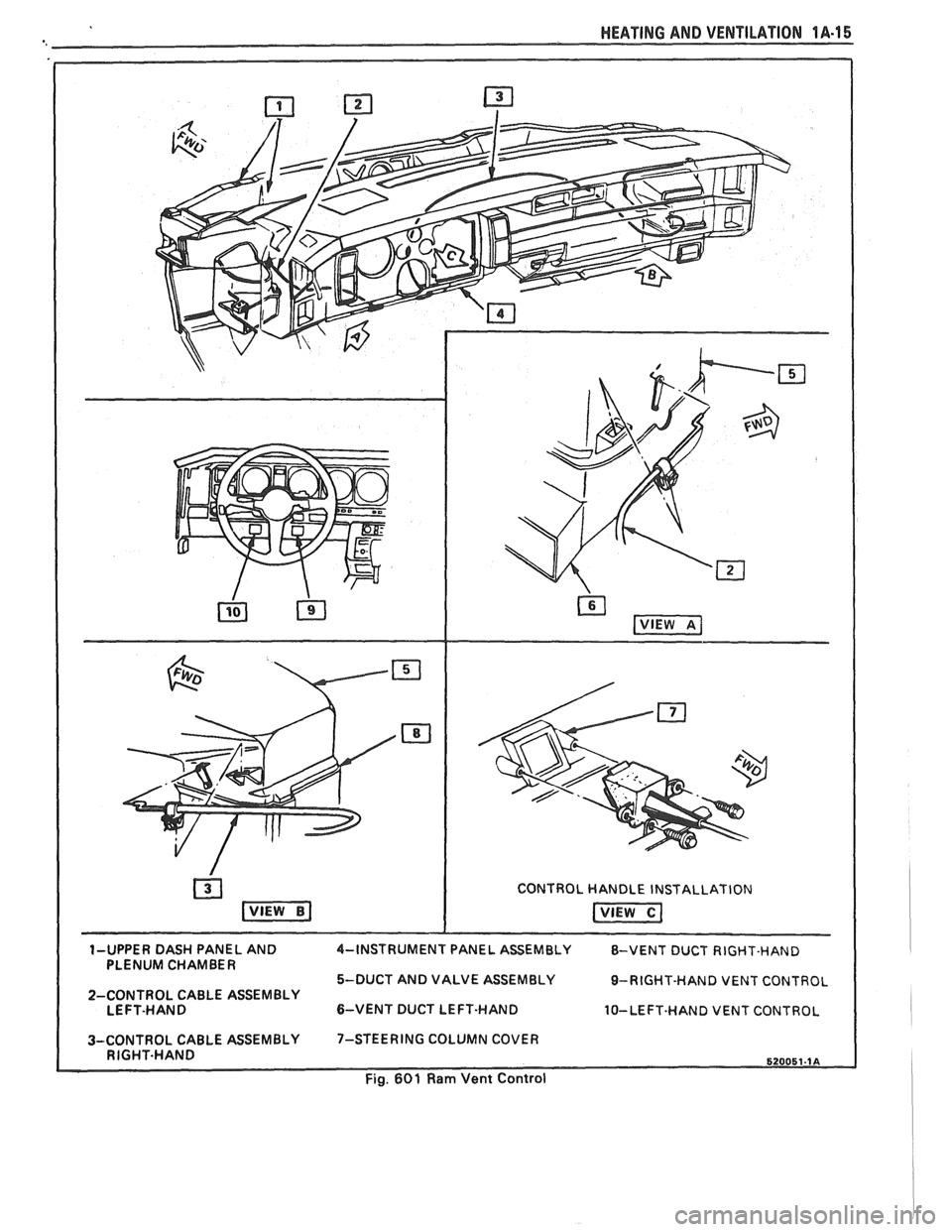

CONTROL HANDLE INSTALLATION

1-UPPER DASH PANEL AND 4-INSTRUMENT PANEL ASSEMBLY 8-VENT DUCT RIGHT-HAND

PLENUM CHAMBER

5-DUCT AND VALVE ASSEMBLY

9-RIGHT-HAND VENT CONTROL

2-CONTROL CABLE ASSEMBLY

LEFT-HAND

&VENT DUCT LEFT-HAND 10-LEFT-HAND VENT CONTROL

3-CONTROL CABLE ASSEMBLY 7-STEERING COLUMN

COVER

RIGHT-HAND

Page 39 of 1825

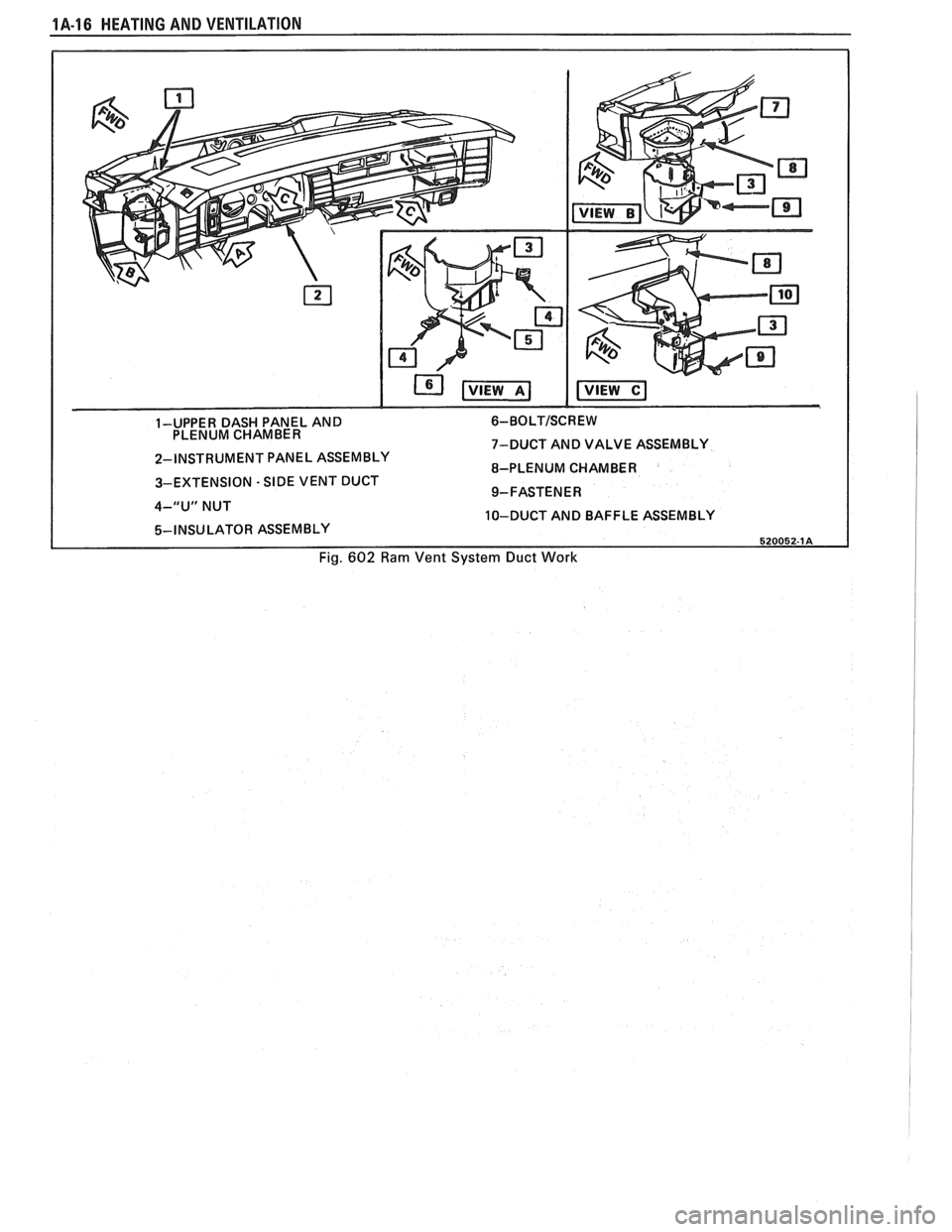

1A-16 HEATING AND VENTILATION

1-UPPER DASH PANEL AND 6- BO LT/SC R E W PLENUM CHAMBER

7-DUCT AND VALVE ASSEMBLY

2-INSTRUMENT PANEL ASSEMBLY

8-PLENUM CHAMBER

3-EXTENSION

- SIDE VENT DUCT

9-FASTENER

4-"U" NUT

10-DUCT AND BAFFLE ASSEMBLY

5-INSU LATOR ASSEMBLY 520052-1A

Fig. 602 Ram Vent System Duct Work