recommended oil PONTIAC FIERO 1988 Service Repair Manual

[x] Cancel search | Manufacturer: PONTIAC, Model Year: 1988, Model line: FIERO, Model: PONTIAC FIERO 1988Pages: 1825, PDF Size: 99.44 MB

Page 5 of 1825

OA-2 GENERAL INFORMATION

VIN NUMBER PLATE

LOCATION

Fig. 2 Vehicle Identification Number Plate Location

marking indicating the strength of the material in the

fastener as outlined below. Metric cross recess screws

are identified by a Posidriv or Type

1A cross recess as

shown in Figure 8. Either a Phillips head or Type

1A

cross recess screwdriver can be used in Posidriv recess

screw heads, but Type

1A cross recess screwdrivers

will perform better.

NOTICE: Most metric fasteners have a blue color

coating. However, this should not be used as a

positive way of identifying as some metric fasteners

are not color coated.

General Motors Engineering Standards, along

with other North American Industries, have adopted

a portion of the standard metric fastener sizes defined

by

IS0 (International Standards Organization). This

was done to reduce the number of fastener sizes used

and yet retain the best strength qualities in each thread

size. For example, the customary 1/4-20 and 1/4-28

screws are replaced by the metric

M6.0 X 1 screw

which has nearly the same diameter and

25.4 threads

per inch. The thread pitch is in between the customary

coarse and fine thread pitches.

Metric and customary thread notation differ

slightly. The difference is shown in Figure 9.

FASTENER STRENGTH ODENTIFIGATION

Most commonly used metric fastener strength

property classes are 9.8 and 10.9 with the class

identification embossed on the head of each bolt.

Customary (inch) strength classes range from grade 2

to 8 with radial line identification embossed on each

bolt head

(i.e., grade 7 bolt will exhibit 5 embossed

radial lines on the bolt head). Some metric nuts will be

marked with single digit strength identification

numbers on the nut face. Figure 12 shows the different

strength markings.

When replacing metric fasteners, be careful to use

bolts and nuts of the same strength or greater than the

original fasteners (the same number marking or higher)

.It is also important to select replacement fasteners of

the correct size. Correct replacement bolts and nuts are

available through the parts division. Many metric

fasteners available in the after-market parts channels

were designed to metric standards of countries other

than the United States. These fasteners may be of a

lower strength, different thread pitch and may not have the

numbered head marking system. The metric

fasteners used on GM products are designed to new,

international standards that may not be used by some

nondomestic bolt and nut suppliers. In general, except

for special applications, the common sizes and pitches

are:

M 6.0

X 1

M 8 x 1.25

M 10 X 1.5 M 12 X 1.75

M 14x2 I

PREVAILING TORQUE FASTENERS

A prevailing torque nut is designed to develop an

interference between the nut and bolt threads. This is

most often accomplished by distortion of the top of an

all-metal nut or by using a nylon patch on the threads

in the middle of the hex flat.

A nylon insert may also

be used as a method of interference between nut and

bolt threads (Fig. 11).

A prevailing torque bolt is designed to develop an

interference between bolt and nut threads, or the

threads of a tapped hole. This is accomplished by

distorting some of the threads or by using a nylon patch

or adhesive (Fig. 11).

RECOMMENDATIONS FOR FASTENER REUSE: I

Clean, unrusted prevailing torque nuts and bolts

may be reused as follows:

a. Clean dirt and other foreign material off nut

or bolt.

b. Inspect nut or bolt to insure there are no

cracks, elongation, or other signs of abuse

or overtightening. (If there is any doubt,

replace with a new prevailing torque

fastener of equal or greater strength.)

c. Lightly coat bolt

& nut with engine oil.

Assemble parts and hand start nut or bolt.

d. Observe that before fastener seats, it

develops torque per the chart in Figure

10.

(If there is any doubt, replace with a new

prevailing torque fastener of equal or

greater strength.)

e. Tighten fastener to torque specified in

appropriate section of this manual.

Bolts and nuts which are rusty or damaged

should be replaced with new parts of equal or

greater strength.

VEHICLE LIF"TING PROCEDURES

NOTICE: When jacking or lifting vehicle from

frame side rails, be certain lift pads do not contact

catalytic converter as damage to converter will

result.

Many dealer service facilities and service stations

are equipped with a type of automotive hoist which

must bear upon some part of the frame in order to lift

the vehicle. Figures 14 and 15 indicate the

recommended areas for hoist contact for Pontiac

Sunbird models.

If any other hoist methods are used, special care

must be used not to damage the fuel tank, filler neck,

I

exhaust system or underbody. I

Page 18 of 1825

MAINTENANCE AND LUBRICATION OB-1

SECTION OB

NTENANCE AND LUBR

CONTENTS

Maintenance Schedule, Gasoline .............................................. OB-l

Maintenance Schedules I and 11 .............................................. OB-2

Owner Inspections

......................................................... OB-3

Recommended Fluids and Lubricants ......................................... OB-6

PASSENGER CAR MAINTENANCE SCHEDULE

VEHICLES

WITH GASOLINE ENGINE

NORMAL CAR USE ITEM 4

The maintenance services contained in Schedules I Carburetor or Throttle Body Mounting Bolt

and 11 are based on the assumption that your car will be Torque* used as designed:

Check torque of mounting bolts and/or nuts. @ To carry passengers and cargo within the limits

shown on the Tire Placard located on the edge of the ITEM 5 driver's door.

@ On reasonable road surfaces within legal driving Engine Idle Speed Adjustment*

limits. (Engines

without Idle Speed Control or Idle Air

Control) - Adjust to specifications shown on the under- @ On unleaded gasoline.

hood label. If no specifications are shown on the label, no

adjustment is necessary. Calibrated test equipment must

EXPLANATION OF SCHEDULED MAINTENANCE be used. SERVICES

The services listed in Maintenance Scheduies I and ITEM 6

11 are further explained below. When the following main- ~i~~ and wheel aotation tenance services are performed, make sure all parts are

replaced and all necessary repairs are done before driving To equalize wear and obtain maximum tire life,

your car. Be sure to use the proper fluid and lubricants as rotate in accordance with patterns shown in Owner's

shown in Figure OB-2. Manual.

ITEM 1

Engine Oil and Oil Filter Change*

ALWAYS USE SFICC OR SF/CD ENERGY CON-

SERVING OILS OF PROPER VISCOSITY

- Also.

always change oil and filter as soon as possible after

driving in a dust storm. See your Owner's Manual for

further details.

ITEM 2

Chassis Lubrication

Lubricate all grease fittings in suspension and steer-

ing linkage. Lubricate

transmissionltransaxle shift

linkage, parking brake cable guides, underbody contact

points and linkage. Also lubricate clutch cross shaft lever

every

30,000 miles (50 000 km) on rear-wheel-drive cars

only.

ITEM 3

Carburetor Choke and Hoses*

If your car is equipped with a carburetor, verify that

choke and vacuum break work properly and are within

specifications. Correct any binding caused by damage or

gum on the choke shaft. Inspect hoses for proper hookup,

cracks, chafing or decay. Correct as necessary.

Vacuum or A.I.R. Pump Drive Belt Inspection*

When a separate belt is used to drive the vacuum or

A.I.R.

pump, inspect it for cracks, fraying, wear and

proper tension. Adjust or replace as needed.

ITEM 8

Cooling System Service*

Drain, flush and refill system with new coolant. See

your Owner's Manual

for further details.

ITEM 9

Wheel Bearing Repack (Rear-Wheel-Drive Cars

Only Except Corvette)

Clean and repack front wheel bearings at each brake

relining or 15,000 miles

(25 000 km), whichever comes

first, when car is used in such service as police, taxi or

door-to-door delivery. If you do not use your car in such

service, clean and repack bearings at each brake relining

or 30,000 miles

(50 000 km), whichever comes first.

Corvette models do not require wheel bearing repack.

Page 22 of 1825

MAINTENANCE AND LUBRICATION OB-5

Throttle linkage inspection -- Inspect for inter-

ference, binding, damaged or missing parts.

Engine drive belts inspection - Inspect all

belts for cracks, fraying and wear. Adjust or replace as

needed.

Rear axle service (if equipped) - Check gear

lubricant level and add if needed. For cars equipped with a

limited slip rear axle, fluid does not require changing

(except Caprice and Corvette

- change fluid and required

additive at first

7,500 miles (12 500 km). See your

Owner's Manual or "Recommended Fluids

& Lubricants

Chart" in this section.

IF YOU USE YOUR GAR TO PULL A TRAILER,

CHANGE GEAR LUBRICANT EVERY 7,500 MILES

(12 500 KM).

NOTICE: A large loss in this system may indicate a

problem. Have it inspected and repaired at once.

Power antenna - Clean and then lubricate power

antenna mast. The proper lubricant as shown in Figure

OB-2 should be used.

AT LEAST ONCE A YEAR

Lap and shoulder belts condition and opera-

tion

- Inspect belt system, including webbing, buckles,

latch plates, retractors, guide loops and anchors.

Moveable head restraint operation - On cars

with moveable restraints, make sure restraints stay in the

desired position. (See adjustment instructions in your

Owner's Manual.)

Seatback latch and recliner operation on

cars equipped

with recliner seat --- Be sure seat-

backs latch on those cars with folding seats using mechan-

ical latches. Make sure the recliner is holding by pushing

and pulling on the top of the

seatback while it is reclined.

See your Owner's Manual for seat operating information.

Spare tire and jack storage- Be alert to rattles

in rear of car. Make sure the space tire, all jacking equip-

ment, any tire inflator and any covers or doors are securely

stowed at all times. Oil jack ratchet or screw mechanism

after each use.

Key lock service - Lubricate key lock cylinder at

least annually.

Body lubrication service - Lubricate all body

door hinges including the tailgate or hatchback lid (if

equipped). Also lubricate the body hood, fuel door and

rear compartment hinges and latches including interior

glove box and counsel doors, and any folding seat

hardware.

"Fansmissionltransaxle neutral or clutch

starl switch operation

CAUnON: Before pedorming the follow-

ing safety switch check, be sure to have

enough room around the car. Then, firmly

apply both the parking brake (see your

Owner's Manual for procedure) and the

regular brakes. Do not use the accelerator pedal.

If the engine

starls, be ready to turn

off the ignition promptly. Take these pre-

cautions because the car could move

without warning and possibly cause per-

sonal injury or properly damage. On auto-

matic transmissionltransaxle cars, try to

starl the engine in each gear. The starler

should crank only in "Park" or "Neutral."

On manual transmissionltransaxle cars,

place the

shiR lever in "Neutral," push the

clutch halfway and try to starl. The starler

should crank only when the clutch is fully

depressed.

Steering column lock operation

- While

parked, try to turn key to "Lock" in each gear range. The

key should turn to "Lock" only when gear is in "Park" on

automatic or "Reverse" on manual

transmissionltransax-

le. On cars with key release lever, try to turn key toULock"

without depressing the lever. The key should turn to

"Lock" only with the key lever depressed. On all vehicles,

the key should come out only in "Lock."

Parking brake and transmissionltransaxle

"Park" mechanism operation

CAUT1ON:Before checking the holding

ability of the parking brake and automatic

transmissionltransaxle "Park" mecha-

nism, park on a fairly steep hill with

enough room for movement in the down-

hill direction. To reduce the risk of person-

al injury or property damage, be prepared

to apply the regular brakes promptly if the

car begins to move.

To check the parking brake, with the engine running and

transmission/transaxle in "Neutral." slowly remove foot

pressure from the regular brake pedal (until the car is held

by only the parking brake).

To check the automatic transmissionltransaxle "Park"

mechanism holding ability, release all brakes after shift-

ing the transmissionltransaxle to "Park."

ljnderbody flushing - At least every spring,

tlush from the underbody with plain water any corrosive

materials used for ice and snow removal and dust control.

Take care to thoroughly clean any areas where mud and

other debris can collect.

Sediment packed in closed areas

of the vehicle should be loosened before being flushed.

Engine cooling system service - Inspect

coolant and freeze protection. If dirty or rusty, drain, flush

and refill with new coolant. Keep coolant

at the proper

mixture as specified in your Owner's Manual. This pro-

vides proper freeze protection. corrosion inhibitor level

and engine operating temperature. Inspect hoses and re-

place if cracked. swollen or deteriorated. Tighten hose

clamps. Clean outside of radiator and air conditioning

condensor. Wash radiator filler cap and neck.

To help

ensure proper operation. a pressure test of both the cooling

system and cap is also recommended. (See maintenance

schedule charts in Figure

OB-l for the recommended

coolant change interval.)

Page 23 of 1825

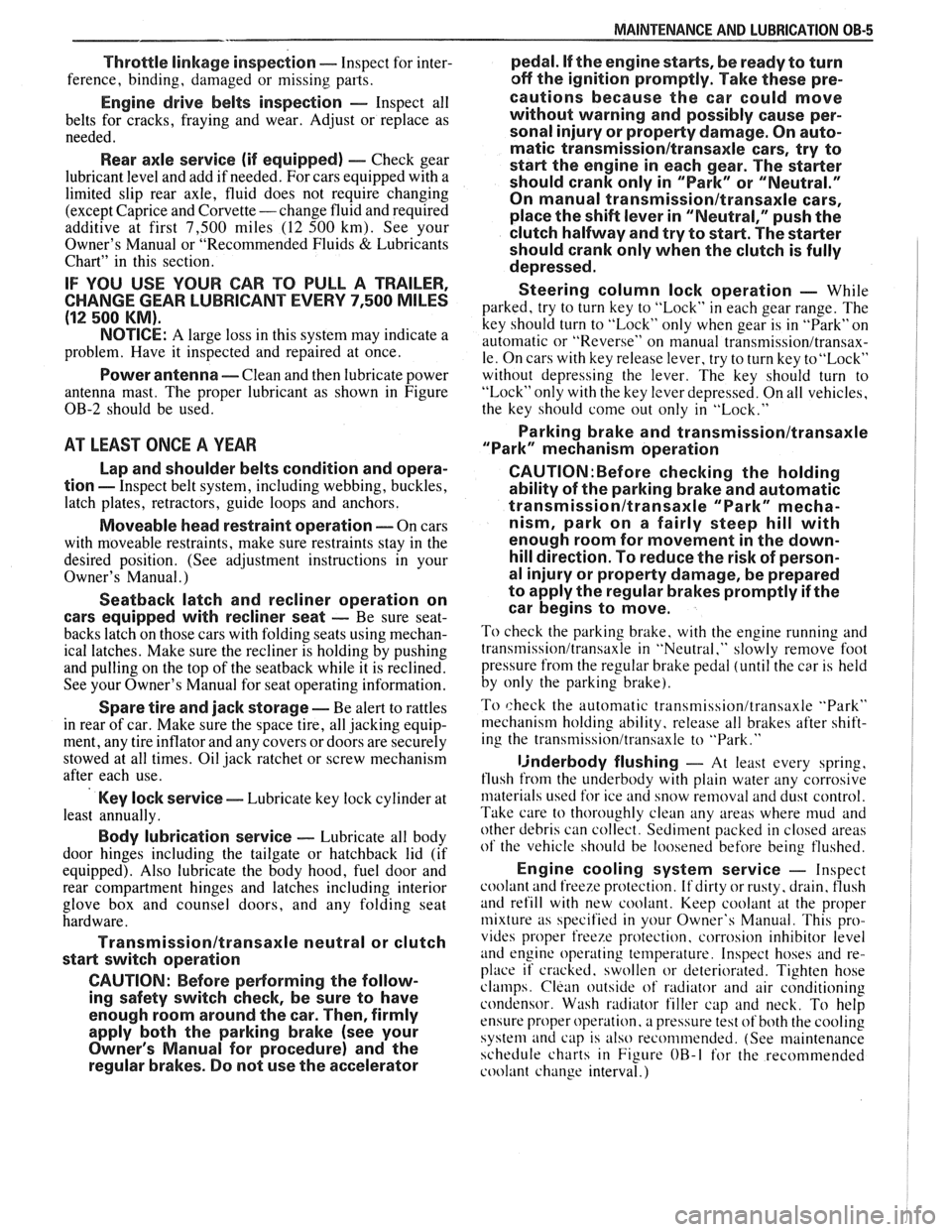

NOTE: Fluids and lubricants identified below by name, part number or specification may be obtained from your GM dealer.

Figure 00-2 Recommended Fluids and Lubricants

USAGE

Engine

Oil

Engine Coolant

Brake and

Hydraul~c Clutch Systems

Parking Brake Cables

Power Steering System

Manual

Steerlng Gear (reclrculat~ng ball)

Automatic

Transrn~ssionRransaxle and 5 Speed Manual Transm~ss~ons

Manual Transm~ssion (rear-wheel-drive) 4 Speed

Manual

Transm~ss~onRransaxle Shin Linkage

Key Lock Cylinders

Automatic Transmlss~onfrransaxle Shlft Llnkage

Clutch Llnkage Plvot Po~nts

Floor Sh~n L~nkage

Power Antenna Mast (3-mast sect~on-type only)

Chass~s Lubr~cation

Standard D~fferent~al Rear Axle

L~m~ted-Sl~p D~flerent~al Rear Axle

W~ndsh~eld.Washer Solvent

Hood Latch Assembly

a)

Plvots and Sprlng Anchor

b) Release Pawl

Front Wheel Bearings

(rearqwheel-drive)

Hood and door hlnges, statlon wagon tailgate hlnge or hatchback Ild and Ilnkage, headl~ght door assembl~es, statlon wagon rear foldrng seat, fuel door hlnge, rear compartment Ihd hlnges

Weatherstr~ps

FLUlDlLUBRlCANT

GM Goodwrench Motor 011 or equivalent for API Se~lce, SFICC or SFICD of the

recommended v~scos~ty

M~xture of water and good qual~ty ethylene glycol base antllreeze conforming to GM spec 1825M (GM Part No 1052753)

Delco Supreme 11

Fluld (GM Part No 1052535) or DOT-3 Fluld

Chass~s grease meetlng requirements of GM-6031M (GM Part No 1052497)

GM power

steerlng flu~d, Part No 1052884 or equivalent

Use lubricant meetlng requirements of GM-4673M (GM Part No 1052182)

DEXR0N'-II Automat~c Transm~ss~on Flu~d (GM Part No 1051855) Camaro and Flreblrd (5 Speed)

Corvette overdr~ve unlt - DEXRON a.II All others SAE-80W-90 GL-5 gear lubr~cant (GM Part No 1052271)

Chass~s grease meetlng requirements of GM-6031M (GM Part No 1052497)

Black Key Lock

Cyl~nders - light oil (GM Par1 No. 1052949)

All other Key Lock Cyl~nders - sllicone lubrlcant (GM Part No 1052277)

Eng~ne 011

Eng~ne 011

Eng~ne 011

Llght 011 (GM Part No 1052949)

Chass~s grease meetlng requirements of GM-6031M (GM Part No 1052497)

SAE

80W or SAE 80W-90 GL-5 (SAE 80W GL-5 In Canada) gear lubricant (GM Part No

1052271)

For Camaro only

- Use SAE BOW190 GL-5+ Hypold 011 (GM Part No 1050010), 11 equ~pped wl5 7L (L98) Englne or 5 OL (LB9) engine wmpeed manual transm~ss~on and disc brakes

All other applications - Use SAE 80W or SAE 80W-90 GL-5 Gear Lubr~cant (GM Part No

1052271)

GM

Opt~kleen Washer Solvent (GM Part No 1051515) or equ~valent

a) Eng~ne 011 b) Chass~s grease meet~ng requirements of GM.6031M (GM Part No 1052497)

Lubricant GM Part No 1051344 grease or equivalent

Eng~ne 011

S~l~cone Grease (GM Part No 1052863) or equivalent

Page 55 of 1825

18-12 AIR CONDITIONING

ELEGTRICAWACUUM SYSTEM

DIAGNOSIS

When diagnosing problems in the electrical sys-

tems of the air conditioning system, consult section

8A.

LEAK TESTING THE REFRIGERANT

SYSTEM

Whenever a refrigerant leak is suspected in the

system or a service operation performed which results

in disturbing lines or connections, it is advisable to

test for leaks.

Liquid Leak Detectors

There are a number of locations (fittings,

valves, etc.) on the air conditioning system where a

liquid leak detector solution may be used to pinpoint

refrigerant leaks.

By applying test solution to the area in question

with the swab that is attached to the bottle cap, bub-

bles will form within seconds if there is a leak.

For restricted access areas, such as sections of

the evaporator and condenser, an electronic leak

detector, such as

5-29547 or equivalent, is more prac-

tical for determining and locating leaks.

3-LOW BATTERY

INDICATOR

2-HI-LOW SWITCH

4-BALANCE CONTROL

Figure 12 Electronic Leak Detector J-29547

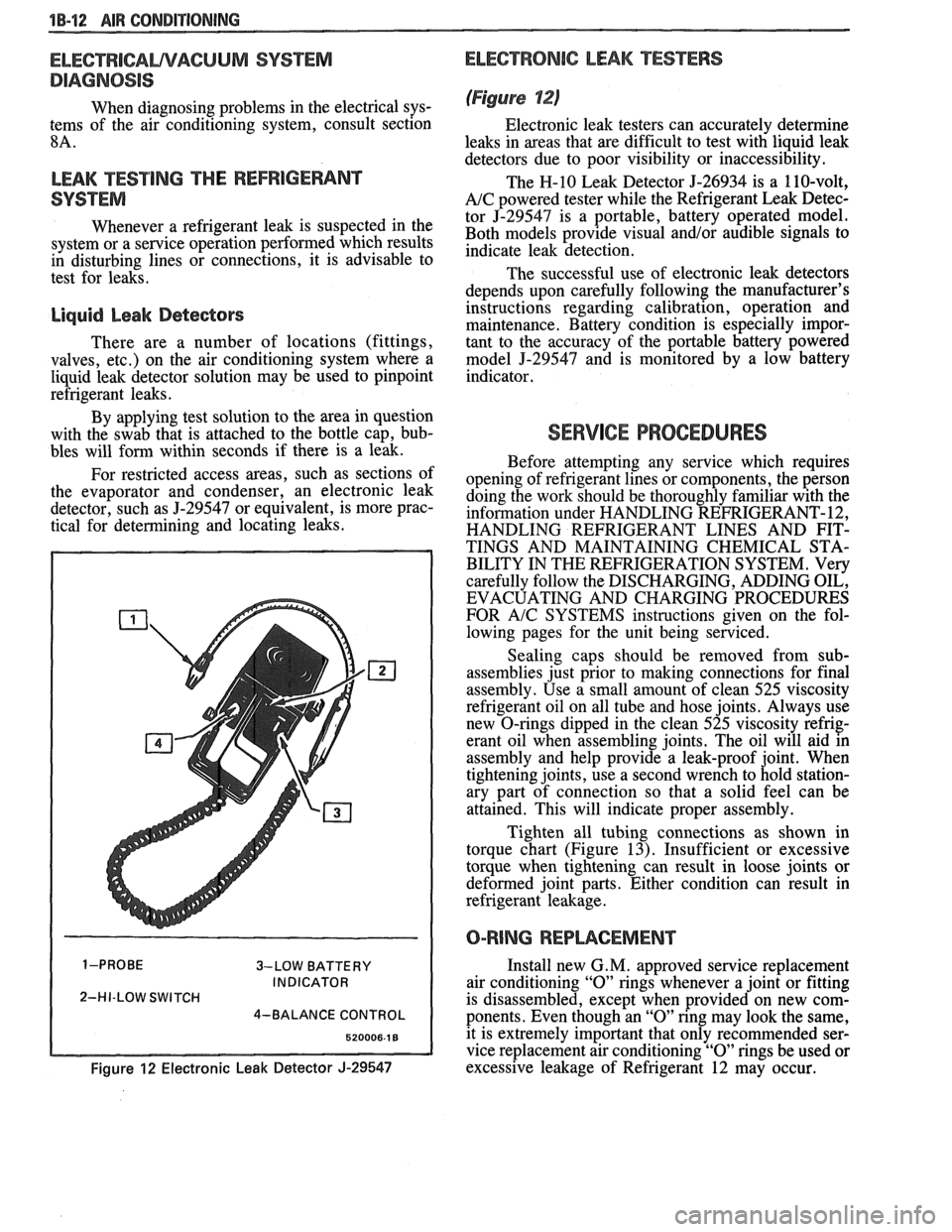

ELECTRONIC LEAK TESTERS

(Figure 12)

Electronic leak testers can accurately determine

leaks in areas that are difficult to test with liquid leak

detectors due to poor visibility or inaccessibility.

The H-10 Leak Detector 5-26934 is a 110-volt,

A/C powered tester while the Refrigerant Leak Detec-

tor J-29547 is a portable, battery operated model.

Both models provide visual

and/or audible signals to

indicate leak detection.

The successful use of electronic leak detectors

depends upon carefully following the manufacturer's

instructions regarding calibration, operation and

maintenance. Battery condition is especially impor-

tant to the accuracy of the portable battery powered

model

5-29547 and is monitored by a low battery

indicator.

SERVICE PROCEDURES

Before attempting any service which requires

opening of refrigerant lines or components, the person

doing the work should be thoroughly familiar with the

information under HANDLING REFRIGERANT- 12,

HANDLING REFRIGERANT LINES AND FIT-

TINGS AND MAINTAINING CHEMICAL STA-

BILITY IN THE REFRIGERATION SYSTEM. Very

carefully follow the DISCHARGING, ADDING OIL,

EVACUATING AND CHARGING PROCEDURES

FOR

A/C SYSTEMS instructions given on the fol-

lowing pages for the unit being serviced.

Sealing caps should be removed from sub-

assemblies just prior to making connections for final

assembly. Use a small amount of clean 525 viscosity

refrigerant oil on all tube and hose joints. Always use

new O-rings dipped in the clean 525 viscosity refrig-

erant oil when assembling joints. The oil will aid in

assembly and help provide a leak-proof joint. When

tightening joints, use a second wrench to hold station-

ary part of connection so that

a solid feel can be

attained. This will indicate proper assembly.

Tighten all tubing connections as shown in

torque chart (Figure

13). Insufficient or excessive

torque when tightening can result in loose joints or

deformed joint parts. Either condition can result in

refrigerant leakage.

O-RING REPWCEMENT

Install new G. M. approved service replacement

air conditioning

"0" rings whenever a joint or fitting

is disassembled, except when provided on new com-

ponents. Even though an

"0" ring may look the same,

it is extremely important that only recommended ser-

vice replacement air conditioning

"0" rings be used or

excessive leakage of Refrigerant 12 may occur.

Page 149 of 1825

3A-2 WHEEL ALIGNMENT

0 FRONT

& OF WHEEL

CASTER ANGLE

LEFT SIDE

VIEW

CAMBER

I

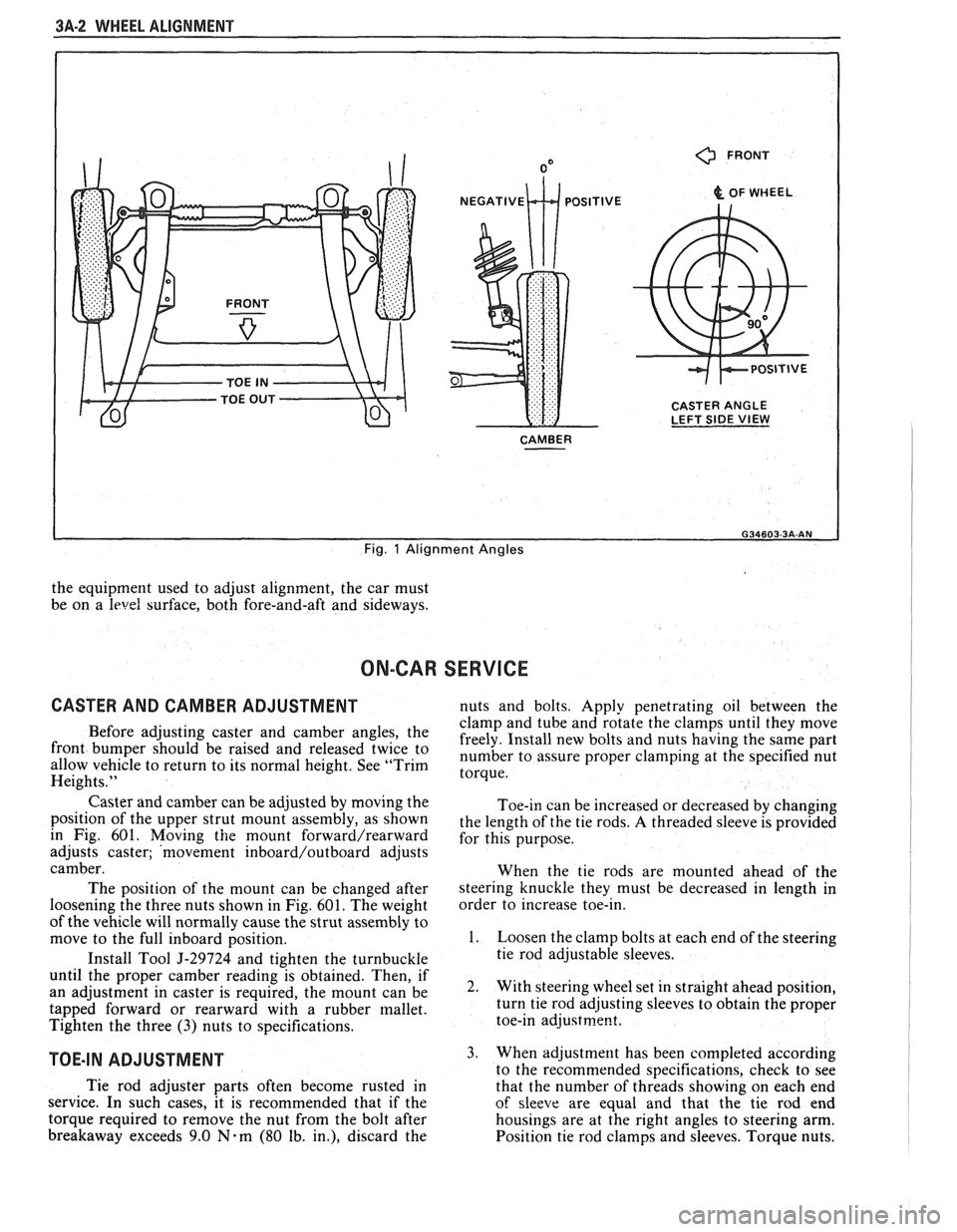

Fig. 1 Alignment Angles

the equipment used to adjust alignment, the car must

be on a

level surface, both fore-and-aft and sideways.

ON-CAR SERVICE

CASTER AND CAMBER ADJUSTMENT nuts and bolts. Apply penetrating oil between the

clamp and tube and rotate the clamps until they move

Before adjusting caster and camber the freely. Install new bolts and nuts having the same part front be 'aised and twice to number to assure proper at the specified nut allow vehicle to return to its normal height. See "Trim torque. Heights."

Caster and camber can be adjusted by moving the

position of the upper strut mount assembly, as shown

in Fig. 601. Moving

the mount forward/rearward

adjusts caster; 'movement inboard/outboard adjusts

camber.

The position of the mount can be changed after

loosening the three nuts shown in Fig.

601. The weight

of the vehicle will normally cause the strut assembly to

move to the full inboard position.

Install Tool

5-29724 and tighten the turnbuckle

until the proper camber reading is obtained. Then, if

an adjustment in caster is required, the mount can be

tapped forward or rearward with a rubber mallet.

Tighten the three

(3) nuts to specifications.

TOE-IN ADJUSTMENT

Toe-in can be increased or decreased by changing

the length of the tie rods.

A threaded sleeve is provided

for this purpose.

When the tie rods are mounted ahead of the

steering knuckle they must be decreased in length in

order to increase toe-in.

1. Loosen the clamp bolts at each end of the steering

tie rod adjustable sleeves.

2. With steering wheel set in straight ahead position,

turn tie rod adjusting sleeves to obtain the proper

toe-in

adjustrne~t.

3. When adjustment has been completed according

to the recommended snecifications. check to see

Tie rod adjuster parts often become rusted in

that the number of thrkads showing on each end

service. In such cases, it is recommended that if the

of sleeve are equal and that the tie rod end

torque required to remove the nut from the bolt after housings are at the right angles to steering arm.

breakaway exceeds 9.0

Nam (80 lb. in.), discard the

Position tie rod clamps and sleeves. Torque nuts.

Page 189 of 1825

386-2 STEERING LINKAGE

LUBRICATION ADJUSTMENTS

The steering linkage should be lubricated with any

water resistant

EP type chassis lubricant at specified Toeein

intervals. Lubrication points and additional information on Adjust

the steering linkage for proper toe-in setting as

chassis lubrication can be found in Section

OB. outlined in Section 3A.

ON-CAR SERVICE 3. To remove outer ball stud, use a tool such as

RELAY ROD

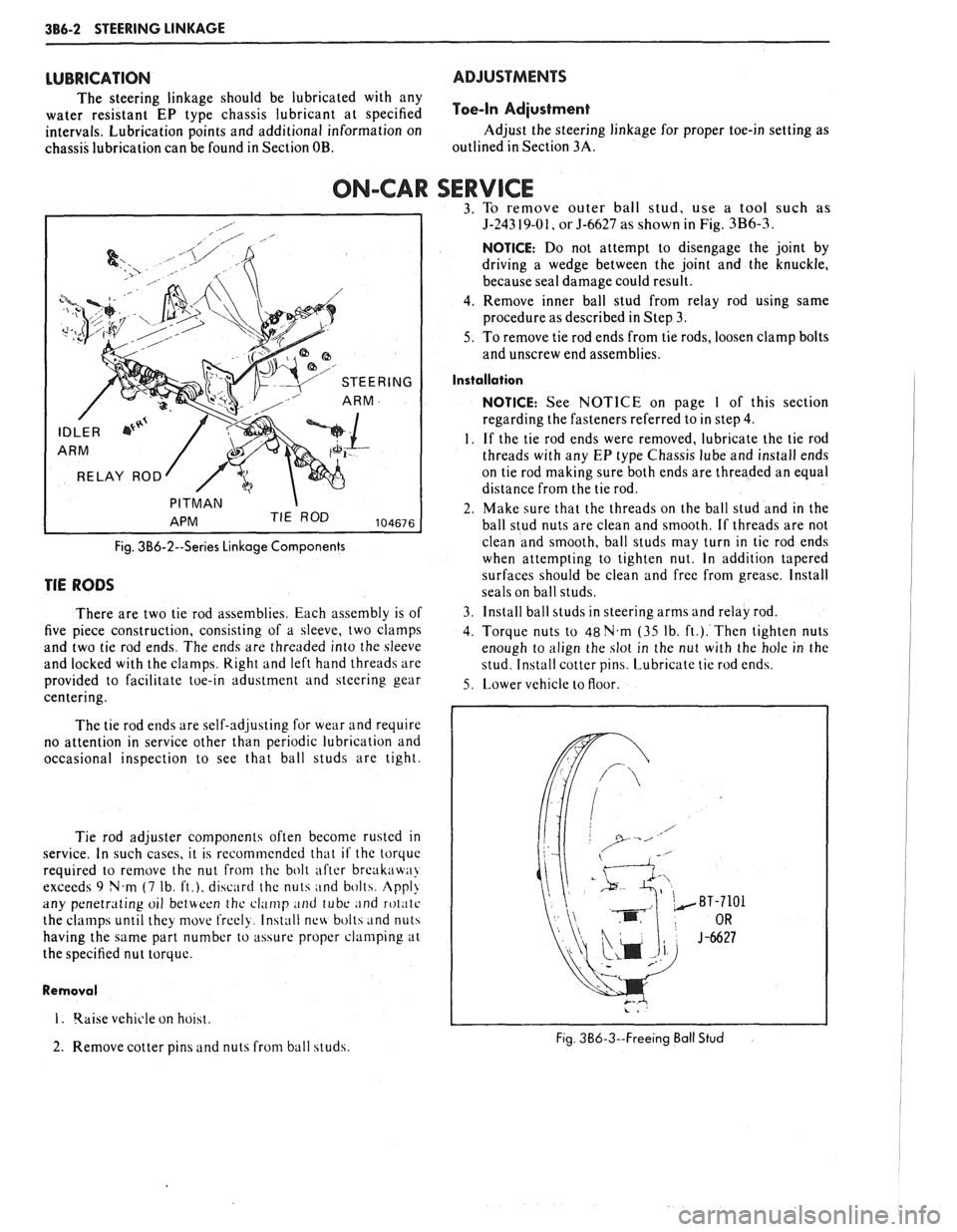

Fig. 3B6-2--Series Linkage Components

TIE RODS

There are two tie rod assemblies. Each assembly is of

five piece construction, consisting of a sleeve, two clamps

and two tie rod ends. The ends are threaded into the sleeve

and locked with the clamps.

Right and left hand threads are

provided to facilitate toe-in adustment and steering gear

centering.

The tie rod ends are self-adjusting for wear and require

no attention in service other than periodic lubrication and

occasional inspection to see that ball studs are tight.

Tie rod adjuster components often become rusted

in

service. In such cases, it is recommended that if the torquc

required to remove the nut from thc bolt after break:iw:~>

exceeds 9 N.m (7 Ib, ft.), discard the nuts and bolth. Appl!

any penetrating oil betwoon thc clamp and tube ;~nd roliitc

the clamps until they movt. frcely. Install nc\4 bolts and nuts

having the same part number to assure proper clamping at

the specified nut torque.

Removal

I. qaise vehicle on hoiht.

2. Remove cotter pins and nuts from ball studs.

5-243 19-01, or 5-6627 as shown in Fig. 3B6-3

NOTICE: Do not attempt to disengage the joint by

driving a wedge between the joint and the knuckle,

because seal damage could result.

4. Remove inner ball stud from relay rod using same

procedure as described in Step 3.

5. To remove tie rod ends from tie rods, loosen clamp bolts

and unscrew end assemblies.

Installation

NOTICE: See NOTICE on page I of this section

regarding the fasteners referred to in step

4.

1. If the tie rod ends were removed, lubricate the tie rod

threads with any

EP type Chassis lube and install ends

on tie rod making sure both ends are threaded an equal

distance from the tie rod.

2. Make sure that the threads on the ball stud and in the

ball stud nuts are clean and smooth. If threads are not

clean and smooth, ball studs may turn in tie rod ends

when attempting to tighten nut. In addition tapered

surfaces should be clean and free from grease. Install

seals on ball studs.

3. Install ball studs in steering arms and relay rod.

4. Torque nuts to 48N.m (35 Ib. ft.). Then tighten nuts

enough to align the slot in the nut with the hole in the

stud. Install cotter pins. Lubricate tie rod

end\.

5. Lower vehicle to floor.

Fig. 3B6-3--Freeing Ball Stud

Page 235 of 1825

3E.4 TIRES AND WHEELS

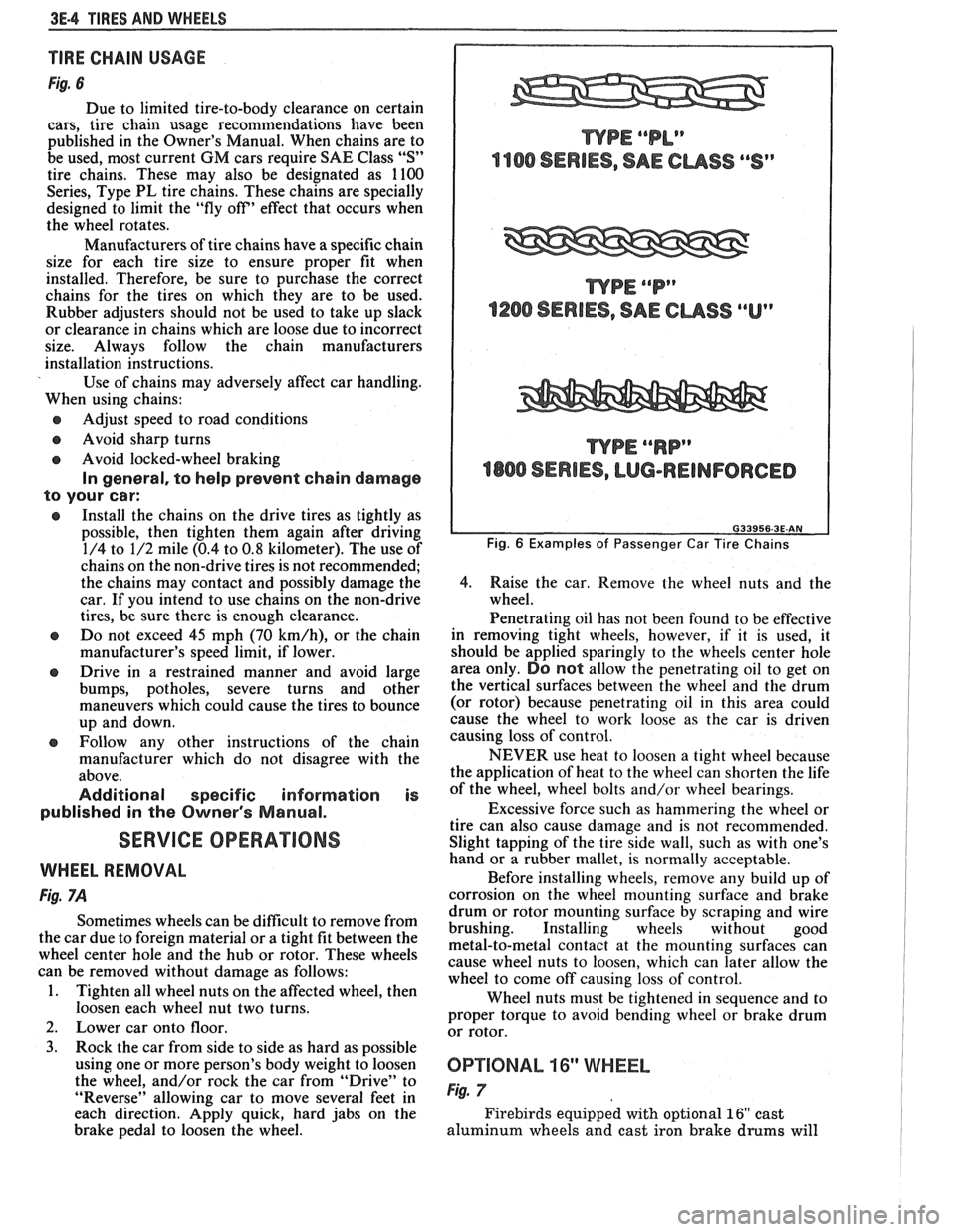

TIRE CHAIN USAGE

Fig. 6

Due to limited tire-to-body clearance on certain

cars, tire chain usage recommendations have been

published in the Owner's Manual. When chains are to

be used, most current

GM cars require SAE Class "S"

tire chains. These may also be designated as 1100

Series, Type PL tire chains. These chains are specially

designed to limit the "fly off' effect that occurs when

the wheel rotates.

Manufacturers of tire chains have a specific chain

size for each tire size to ensure proper fit when

installed. Therefore, be sure to purchase the correct

chains for the tires on which they are to be used.

Rubber adjusters should not be used to take up slack

or clearance in chains which are loose due to incorrect

size. Always follow the chain manufacturers

installation instructions.

Use of chains may adversely affect car handling.

When using chains:

@ Adjust speed to road conditions

@ Avoid sharp turns

@ Avoid locked-wheel braking

In general, to help prevent chain damage

to your car:

@ Install the chains on the drive tires as tightly as

possible, then tighten them again after driving

1/4 to 1/2 mile (0.4 to

0.8 kilometer). The use of

chains on the non-drive tires is not recommended;

the chains may contact and possibly damage the

car. If you intend to use chains on the non-drive

tires, be sure there is enough clearance.

e Do not exceed 45 mph (70 km/h), or the chain

manufacturer's speed limit, if lower.

@ Drive in a restrained manner and avoid large

bumps, potholes, severe turns and other

maneuvers which could cause the tires to bounce

up and down.

e Follow any other instructions of the chain

manufacturer which do not disagree with the

above.

Additional specific information is

published in the Owner's Manual.

SERVICE OPERATIONS

WHEEL REMOVAL

Fig. 7A

Sometimes wheels can be difficult to remove from

the car due to foreign material or a tight fit between the

wheel center hole and the hub or rotor. These wheels

can be removed without damage as follows:

1. Tighten all wheel nuts on the affected wheel, then

loosen each wheel nut two turns.

2. Lower car onto floor.

3. Rock the car from side to side as hard as possible

using one or more person's body weight to loosen

the wheel, and/or rock the car from

"Drive" to

"Reverse" allowing car to move several feet in

each direction. Apply quick, hard jabs on the

brake pedal to loosen the wheel.

WPE ""P"

1200 SERIES, SAE CUSS ""Up

WPE ""RP"

4800 SERIES, LUG-REINFORCED

Fig. 6 Examples of Passenger Car Tire Chains

4.

Raise the car. Remove the wheel nuts and the

wheel.

Penetrating oil has not been found to be effective

in removing tight wheels, however,

if it is used, it

should be applied sparingly to the wheels center hole

area only.

DO not allow the penetrating oil to get on

the vertical surfaces between the wheel and the drum

(or rotor) because penetrating oil in this area could

cause the wheel to work loose as the car is driven

causing loss of control.

NEVER use heat to loosen a tight wheel because

the application of heat to the wheel can shorten the life

of the wheel, wheel bolts and/or wheel bearings.

Excessive force such as hammering the wheel or

tire can also cause damage and is not recommended.

Slight tapping of the tire side wall, such as with one's

hand or a rubber mallet, is normally acceptable.

Before installing wheels, remove any build up of

corrosion on the wheel mounting surface and brake

drum or rotor mounting surface by scraping and wire

brushing. Installing wheels without good

metal-to-metal contact at the mounting surfaces can

cause wheel nuts to loosen, which can later allow the

wheel to come off causing loss of control.

Wheel nuts must be tightened in sequence and to

proper torque to avoid bending wheel or brake drum

or rotor.

0P"FIONAL 16" WHEEL

Fig. 7

Firebirds equipped with optional 16" cast

aluminum wheels and cast iron brake

drums will

Page 302 of 1825

BRAKES 5-9

TUBE hlUST BE

SUBMERGED IN

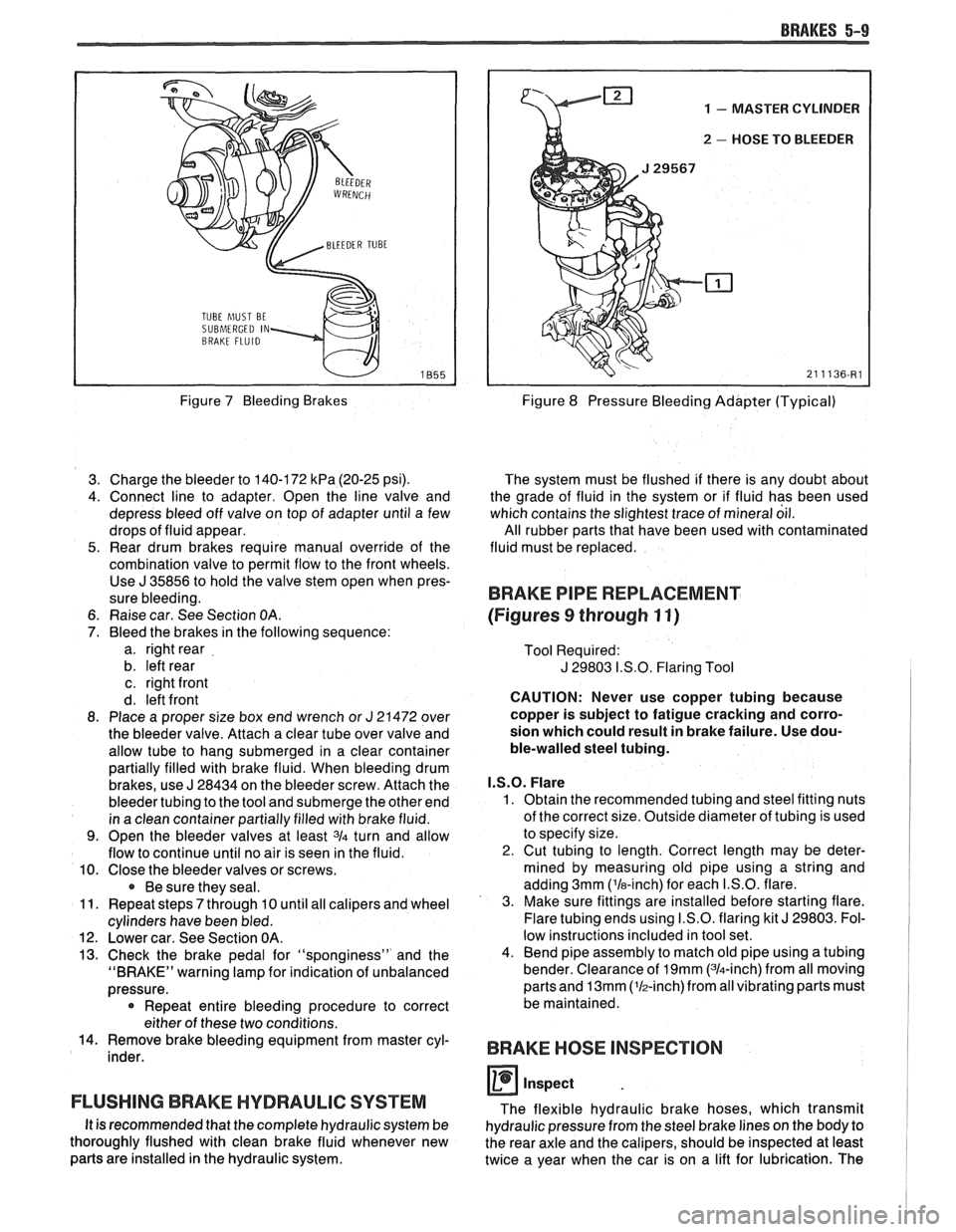

Figure 7 Bleeding Brakes

3. Charge the bleeder to 140-172

kPa (20-25 psi).

4. Connect line to adapter. Open the line valve and

depress bleed off valve on top of adapter until a few

drops of fluid appear.

5. Rear drum brakes require manual override of the

combination valve to permit flow to the front wheels. Use

J 35856 to hold the valve stem open when pres-

sure bleeding.

6. Raise car. See Section

OA.

7. Bleed the brakes in the following sequence:

a. right rear

b. left rear

c. right front

d. left front

8. Place a proper size box end wrench or

J 21472 over

the bleeder valve. Attach a clear tube over valve and

allow tube to hang submerged in a clear container

partially filled with brake fluid. When bleeding drum

brakes, use

J 28434 on the bleeder screw. Attach the

bleeder tubing to the tool and submerge the other end

in a clean container partially filled with brake fluid.

9. Open the bleeder valves at least 3/4 turn and allow

flow to continue until no air is seen in the fluid.

10. Close the bleeder valves or screws.

Be sure they seal.

11. Repeat steps

7 through 10 until all calipers and wheel

cylinders have been bled.

12. Lower car. See Section OA.

13. Check the brake pedal for "sponginess" and the

"BRAKE" warning lamp for indication of unbalanced

pressure.

* Repeat entire bleeding procedure to correct

either of these two conditions.

14. Remove brake bleeding equipment from master cyl-

inder.

FLUSHING BRAKE HYDRAULIC SYSTEM

It is recommended that the complete hydraulic system be

thoroughly flushed with clean brake fluid whenever new

parts are installed in the hydraulic system.

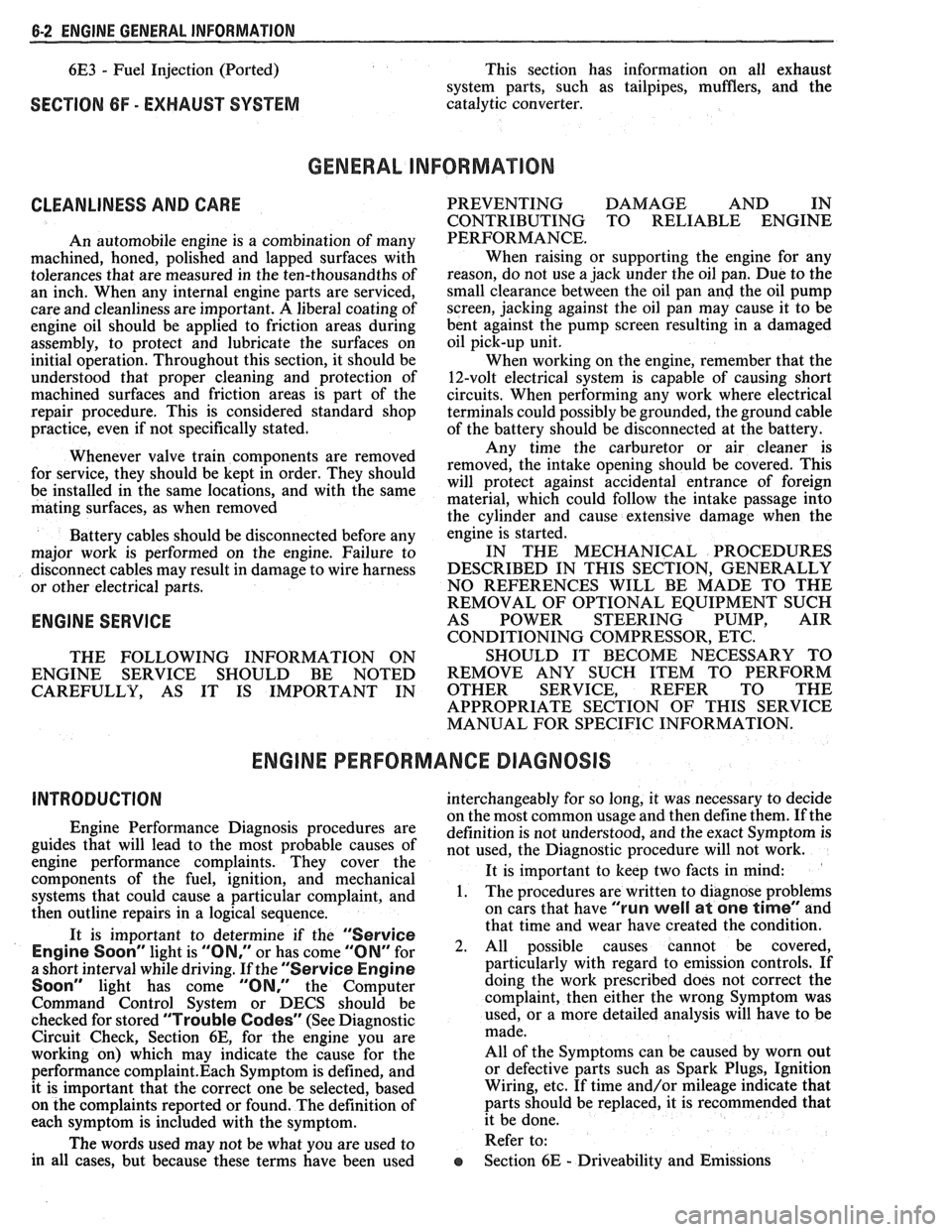

1 - MASTER CYLINDER

u 2 - HOSE TO BLEEDER

Figure 8 Pressure Bleeding Adapter (Typical)

The system must be flushed if there is any doubt about

the grade of fluid in the system or if fluid has been used

which contains the slightest trace of mineral oil.

All rubber parts that have been used with contaminated

fluid must be replaced.

BRAKE PIPE REPLACEMENT

(Figures

9 through 11)

Tool Required:

J 29803 I.S.O. Flaring Tool

CAUTION: Never use copper tubing because

copper is subject to fatigue cracking and corro-

sion which could result in brake failure. Use dou-

ble-walled steel tubing.

I.S.O. Flare

1. Obtain the recommended tubing and steel fitting nuts

of the correct size. Outside diameter of tubing is used

to specify size.

2. Cut tubing to length. Correct length may be deter-

mined by measuring old pipe using a string and

adding 3mm ('la-inch) for each I.S.O. flare.

3. Make sure fittings are installed before starting flare.

Flare tubing ends using I.S.O. flaring kit

J 29803. Fol-

low instructions included in tool set.

4. Bend pipe assembly to match old pipe using a tubing

bender. Clearance of

19mm (314-inch) from all moving

parts and

13mm (lh-inch)from all vibrating parts must

be maintained.

BRAKE HOSE INSPECTION

0 inspect

The flexible hydraulic brake hoses, which transmit

hydraulic pressure from the steel brake lines on the body to

the rear axle and the calipers, should be inspected at least

twice a year when the car is on a lift for lubrication. The

Page 347 of 1825

6-2 ENGINE GENERAL INFORMATION

6E3 - Fuel Injection (Ported) This section has information

on all exhaust

system parts, such as tailpipes, mufflers, and the

SECTION 6F - EXHAUST SYSTEM catalytic converter.

GENERAL INFORMAflION

CLEANLINESS AND CARE

An automobile engine is a combination of many

machined, honed, polished and lapped surfaces with

tolerances that are measured in the ten-thousandths of

an inch. When any internal engine parts are serviced,

care and cleanliness are important. A liberal coating of

engine oil should be applied to friction areas during

assembly, to protect and lubricate the surfaces on

initial operation. Throughout this section, it should be

understood that proper cleaning and protection of

machined surfaces and friction areas is part of the

repair procedure. This is considered standard shop

practice, even if not specifically stated. PREVENTING

DAMAGE AND IN

CONTRIBUTING TO RELIABLE ENGINE

PERFORMANCE.

When raising or supporting the engine for any

reason, do not use a jack under the oil pan. Due to the

small clearance between the oil pan and the oil pump

screen, jacking against the oil pan may cause it to be

bent against the pump screen resulting in a damaged

oil pick-up unit.

When working on the engine, remember that the

12-volt electrical system is capable of causing short

circuits. When performing any work where electrical terminals could possibly be grounded, the ground cable

of the battery should be disconnected at the battery.

Any time the carburetor or air cleaner is

train components are removed removed, the intake opening should be covered. This for service, they should be in order' will protect against entrance of foreign be installed in the same locations, and with the same material, which could follow the intake passage into mating surfaces, as when removed

the cylinder and cause extensive damage when the -

Battery cables should be disconnected before any engin; is started.

major work is performed on the engine. Failure to IN THE MECHANICAL PROCEDURES

disconnect cables may result in damage to wire harness DESCRIBED IN THIS SECTION, GENERALLY

or other electrical parts. NO

REFERENCES WILL BE MADE TO THE

REMOVAL OF OPTIONAL EQUIPMENT SUCH

ENGINE SERVICE AS POWER STEERING PUMP, AIR

CONDITIONING COMPRESSOR, ETC.

THE FOLLOWING INFORMATION ON SHOULD IT BECOME NECESSARY TO

ENGINE SERVICE SHOULD BE NOTED REMOVE ANY SUCH ITEM TO

PERFORM

CAREFULLY, AS IT IS IMPORTANT IN OTHER SERVICE, REFER TO THE

APPROPRIATE SECTION OF THIS SERVICE

MANUAL FOR SPECIFIC INFORMATION.

ENGINE PERFORMANCE DIAGNOSIS

INTRODUCTION interchangeably for so long, it was necessary to decide

on the most common usage and then define them. If the

Engine Performance procedures are definition is not understood, and the exact Symptom is

guides that will lead to the most probable causes of not used, the Diagnostic procedure will not work. engine performance complaints. They cover the

components of the fuel, ignition, and mechanical It

is important to keep two facts in mind:

systems that could cause a particular

complaint, and 1. The procedures are written to diagnose problems

then outline repairs in a logical sequence. on cars

that have

"run well at one time" and

that time and wear have created the condition.

It is important to determine if the

"Service ~~~i~~ soon- light is "ON,~' or has come for 2. All possible causes cannot be covered,

a short interval while driving. If the

"Service Engine particularly with regard to emission controls. If

Soon" light has come "ON," the Computer doing the work prescribed does not correct the

Command Control System or DECS should be complaint, then either the wrong Symptom was

checked for stored

"Trouble Codes" (See Diagnostic used, or a more detailed analysis will have to be

Circuit Check, Section 6E, for the engine you are made.

working on) which may indicate the cause for the All of the Symptoms can be caused by worn out

performance

complaint.Each Symptom is defined, and or defective parts such as Spark Plugs, Ignition

it is important that the correct one be selected, based Wiring, etc. If time and/or mileage indicate that

on the complaints reported or found. The definition of parts should be replaced, it is recommended that

each symptom is included with the symptom. it

be done.

The words used may not be what you are used to Refer to:

in all cases, but because these terms have been used

@ Section 6E - Driveability and Emissions