Engine PONTIAC GRAND AM 2003 Manual Online

[x] Cancel search | Manufacturer: PONTIAC, Model Year: 2003, Model line: GRAND AM, Model: PONTIAC GRAND AM 2003Pages: 354, PDF Size: 16.3 MB

Page 270 of 354

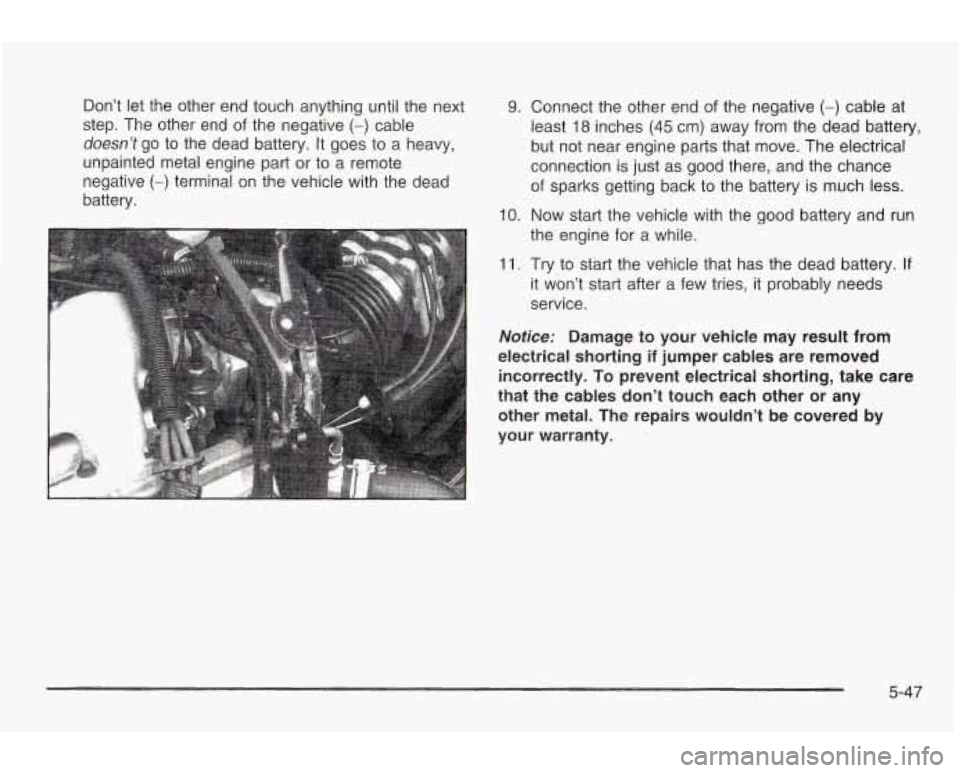

Don’t let the other end touch anything until the next

step. The other end of the negative

(-) cable

doesn’t go to the dead battery. It goes to a heavy,

unpainted metal engine part or to a remote

negative

(-) terminal on the vehicle with the dead

battery.

9.

10.

11.

Connect the other end of the negative (-) cable at

least 18 inches

(45 cm) away from the dead battery,

but not near engine parts that move. The electrical

connection is

just as good there, and the chance

of sparks getting back to the battery

is much less.

Now start the vehicle with the good battery and run

the engine for a while.

Try to start the vehicle that has the dead battery. If

it won’t start after a few tries, it probably needs

service.

Notice: Damage to your vehicle may result from

electrical shorting if jumper cables are removed

incorrectly.

To prevent electrical shorting, take care

that the cables don’t touch each other or any

other metal. The repairs wouldn’t be covered by

your warranty.

5-47

Page 271 of 354

r

B

I1

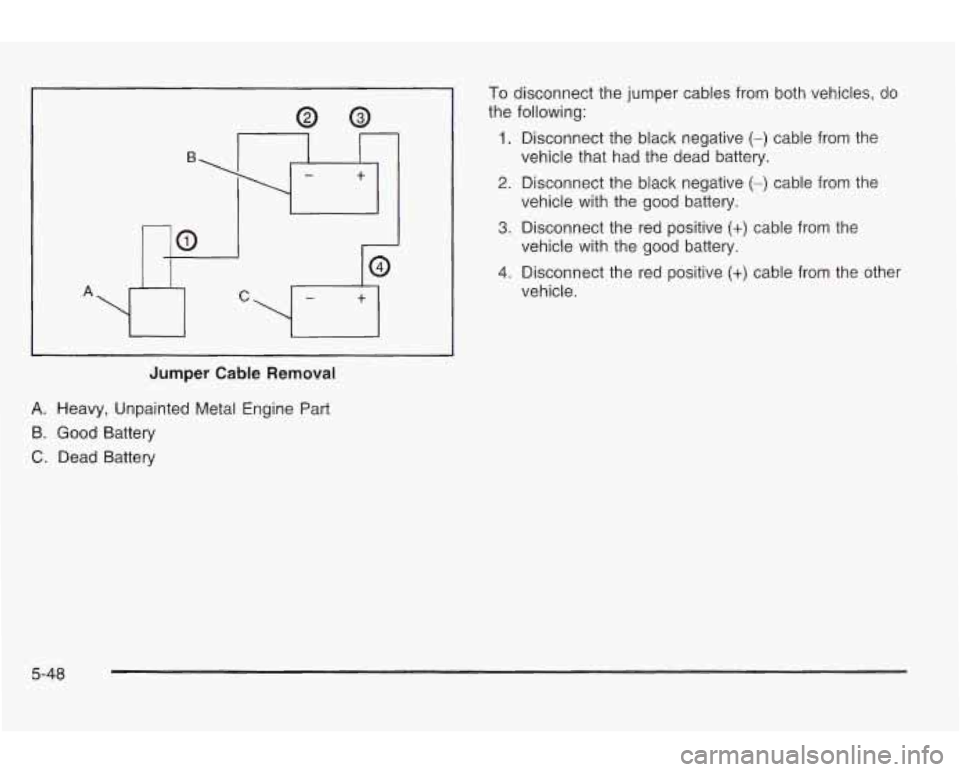

Jumper Cable Removal

A. Heavy, Unpainted Metal Engine Part

B. Good Battery

C. Dead Battery

To disconnect the jumper cables from both vehicles, do

the following:

1. Disconnect the black negative (-) cable from the

2. Disconnect the black negative (-) cable from the

3. Disconnect the red positive (+) cable from the

4. Disconnect the red positive (+) cable from the other

vehicle that

had the dead battery.

vehicle with the good battery.

vehicle with the good battery.

vehicle.

5-48

Page 285 of 354

Changing a Flat Tire

If a tire goes flat, avoid further tire and wheel damage

by driving slowly to

a level place. Turn on your

hazard warning flashers.

Changing a tire can cause an injury. The

vehicle can slip

off the jack and roll over you

or other people. You and they could be badly

injured. Find a level place to change your tire.

To help prevent the vehicle from moving:

1. Set the parking brake firmly.

2. Put an automatic transaxle shift lever in

PARK (P), or shift a manual transaxle to

FIRST

(1) or REVERSE (R).

3. Turn off the engine.

To be even more certain the vehicle won’t move, you can put blocks at

the front and

rear

of the tire farthest away from the one

being changed. That would be the tire on other side of the vehicle, at the The following steps

will tell you how to use the jack and

change a tire.

5-62

Page 303 of 354

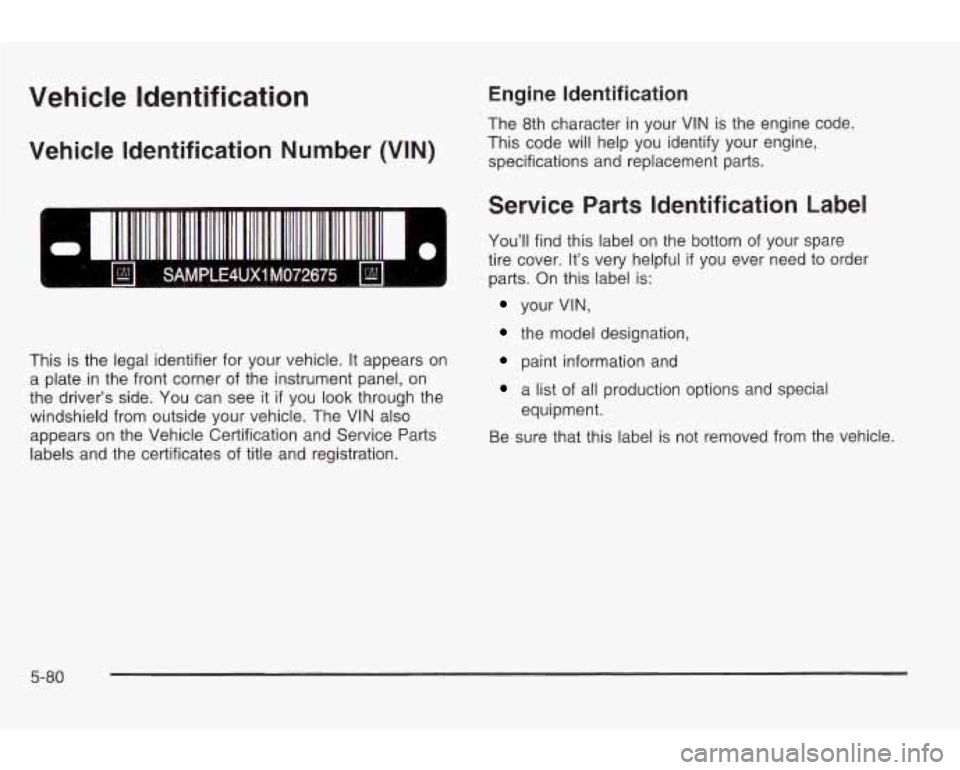

Vehicle Identification

Vehicle Identification Number (VIN)

This is the legal identifier for your vehicle. It appears on

a plate in the front corner

of the instrument panel, on

the driver’s side. You can see

it if you look through the

windshield from outside your vehicle. The VIN also

appears on the Vehicle Certification and Service Parts

labels and the certificates of title and registration.

Engine Identification

The 8th character in your VIN is the engine code.

This code will help you identify your engine,

specifications and replacement parts.

Service Parts Identification Label

You’ll find this label on the bottom of your spare

tire cover. It’s very helpful

if you ever need to order

parts. On this label is:

your VIN,

the model designation,

paint information and

a list of all production options and special

equipment.

Be sure that this label is not removed from the vehicle.

5-80

Page 304 of 354

Electrical System

Add-On Electrical Equipment

Notice: Don’t add anything electrical to your

vehicle unless you check with your dealer first.

Some electrical equipment can damage your vehicle

and the damage wouldn’t be covered by your

warranty. Some add-on electrical equipment can

keep other components from working as they

should.

Your vehicle has an air bag system. Before attempting

to add anything electrical to your vehicle, see

Servicing Your Air Bag-Equipped Vehicle on page 1-59.

Windshield Wiper Fuses

The windshield wiper motor is protected by a circuit

breaker and a fuse. If the motor overheats due to heavy

the overload is caused by some electrical problem, have

it fixed.

SXLY, ek., the vvipec vviii Sup urliii iikle I~IIU~WI cuuis. ii

Power Windows and Qther Power

Options

A circuit breaker in the fuse panel protects the power

windows. When the current load is

too heavy, the circuit

breaker opens and closes, protecting the circuit until

the problem is fixed.

Fuses and Circuit Breakers

The wiring circuits in your vehicle are protected from

short circuits by a combination

of fuses, circuit breakers

and fusible links. This greatly reduces the chance of

damage caused by electrical problems.

Look at the silver-colored band inside the fuse.

If the

band is broken or melted, replace the fuse. Be sure

to

replace a bad fuse with a new one of the identical

size and rating.

There are three fuse blocks in your vehicle: two

instrument panel fuse blocks and the engine

rmpsrtment !LE? h!r\Ck.

There are four spare fuses located in the driver’s side

instrument panel end cap for your use.

Instrument Panel Fuse Blocks

There are two fuse panels for your vehic!~. One Is

located on the driver’s side of the instrument panel

the other

is located on the passenger’s side. and

5-81

Page 307 of 354

Engine Compartment Fuse Block

The engine compartment fuse block is located on the

driver’s side

of the engine compartment, near the

battery.

.

Fuse

1

2

Usage

Ignition Switch

Right Electrical Center-Fog Lamps,

Radio, Body Function Control

Module, Interior Lamps Fuse

3

4

5

6

7

8

Relays

9

10

11

12

13

14

15 Usage

Left Electrical Center-Stop Lamps,

Hazard Lamps, Body Function

Control Module, Cluster, Climate

Control System

Anti-Lock Brakes

Left Electrical Center-Power Seats,

Power Mirrors, Door Locks, Trunk

Release, Audio Amplifier, Remote

Keyless Entry

Not Used Ignition Switch

Cooling Fan

#I

Usage

Rear Defog

Not Used

Starter

Cooling Fan #1

HVAC Blower (Climate Control)

Cooling Fan #2

Cooling Fan

5-84

Page 309 of 354

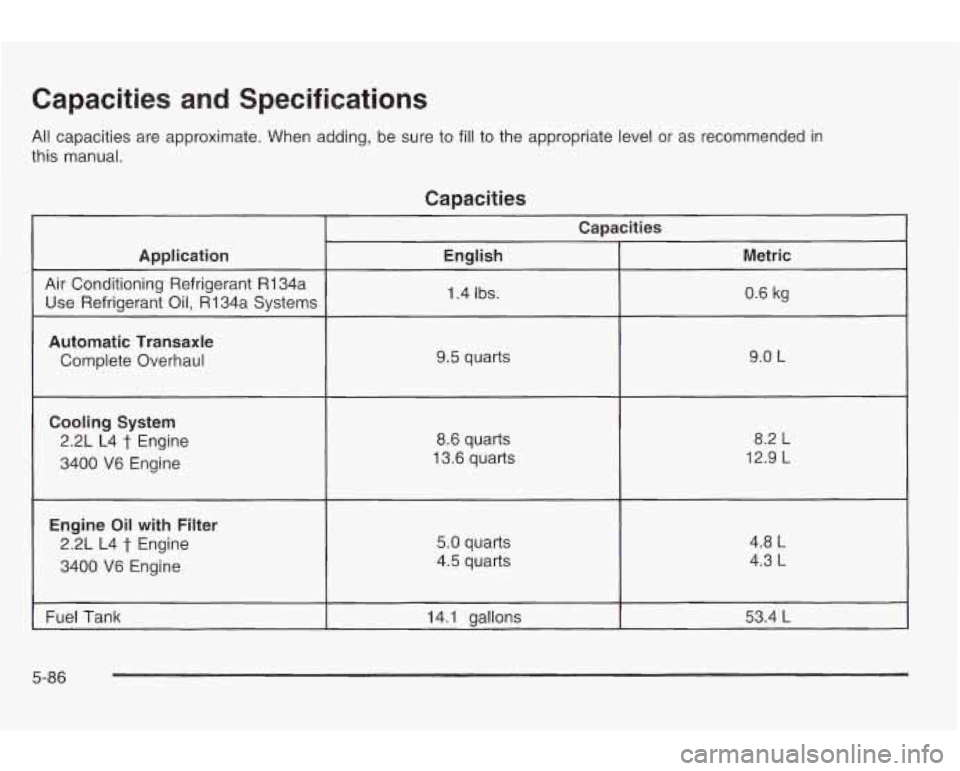

Capacities and Specifications

All capacities are approximate. When adding, be sure to fill to the appropriate level or as recommended in

this manual.

Capacities

I Capacities

Application

0.6 kg 1.4

Ibs.

Metric

English

Air Conditioning Refrigerant R134a

Use Refrigerant Oil, R134a Systems

Automatic Transaxle

Complete Overhaul

9.0 L

9.5 quarts

Cooling System

2.2L

L4 t Engine

3400 V6 Engine 8.6 quarts

13.6 quarts 8.2

L

12.9 L

Engine Oil with Filter

2.2L L4

t Engine

3400 V6 Engine 5.0 quarts

4.5 quarts 4.8 L

4.3 L

Fuel Tank

53.4 L 14.1

gallons

5-86

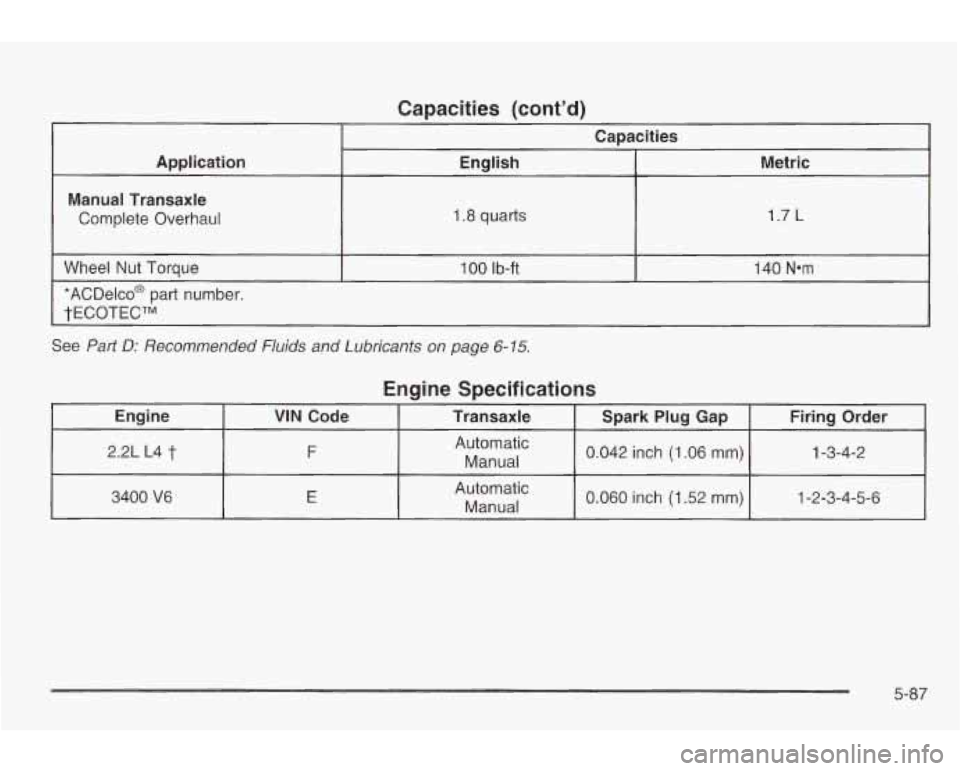

Page 310 of 354

Capacities (cont’d)

Manual Transaxle

Complete Overhaul 1.7 L

See Part D: Recommended Fluids and Lubricants on page 6-15.

Engine SDecifications -

42 inch (1.06 rnrn

5-87

Page 311 of 354

Normal Maintenance Replacement Parts

Part

Engine Air Cleaner/Filter

2.2 L L4t Engine

3400 V6

Engine

Oil Filter

2.2 L L4t Engine

3400 V6

PCV Valve Spark Plugs 2.2

L L4 t Engine

3400 V6

Windshield Wiper Blades

Type Passenger’s Side

Driver’s Side

*ACDelco@ part number. Number

AI 172C*

AI 279C*

PF2244G* PF47*

CV892C*

41-981

* (Platinum Plug)

41-1

01 * (Platinum Plug)

Shepherd’s

Hook

17.0 inches (43.0 cm)

22.0 inches (56.0 cm)

tECOTECTM

5-88

Page 312 of 354

Section 6 Maintenance Schedule

Maintenance Schedule ...................................... 6.2

Introduction

................................................... 6.2

Your Vehicle and the Environment

.................... 6-2

Maintenance Requirements

.............................. 6-2

How This Section is Organized

......................... 6-3

Part A: Scheduled Maintenance Services

........... 6-4

Using Your Maintenance Schedule

.................... 6-4

Scheduled Maintenance

................................... 6-5

Part

6: Owner Checks and Services ................. 6-9

At Each Fuel Fill ............................................ 6-9

At Least Once a Month

................................... 6-9

At Least Twice a Year

................................... 6-10 At

Least Once a Year

................................... 6.10

Part

C: Periodic Maintenance Inspections ......... 6.13

Steering, Suspension and Front Drive Axle

Boot and Seal Inspection ............................ 6-13

Exhaust System Inspection

............................ 6.13

Fuel System Inspection

.................................. 6.13

Engine Cooling System Inspection

................... 6.14

Throttle System Inspection

............................. 6.14

Brake System Inspection

................................ 6.14

Part

D: Recommended Fluids and Lubricants .... 6-15

Part

E: Maintenance Record ........................... 6.16

6-1