light PONTIAC GRAND PRIX 2008 Owners Manual

[x] Cancel search | Manufacturer: PONTIAC, Model Year: 2008, Model line: GRAND PRIX, Model: PONTIAC GRAND PRIX 2008Pages: 450, PDF Size: 2.64 MB

Page 317 of 450

3. Turn off the ignition on both vehicles. Unplug

unnecessary accessories plugged into the cigarette

lighter or the accessory power outlet. Turn off the

radio and all lamps that are not needed. This will

avoid sparks and help save both batteries. And it

could save the radio!

4. Open the hood on the other vehicle and locate the

positive (+) and negative (−) terminal locations on

that vehicle.

You will not use your vehicle’s battery for jump

starting. It has a remote positive (+) jump starting

terminal, located on the underhood fuse block, for

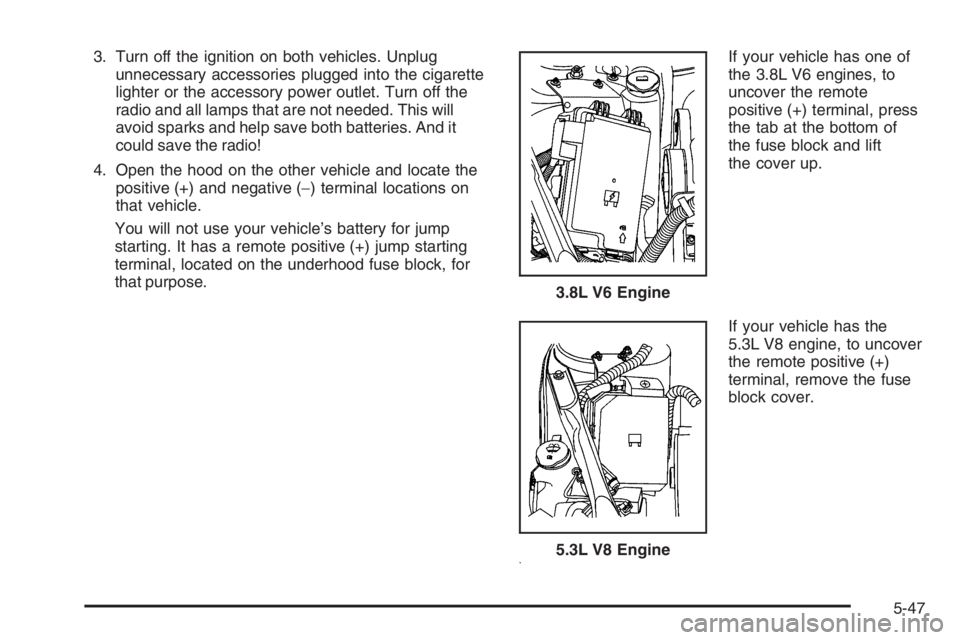

that purpose.If your vehicle has one of

the 3.8L V6 engines, to

uncover the remote

positive (+) terminal, press

the tab at the bottom of

the fuse block and lift

the cover up.

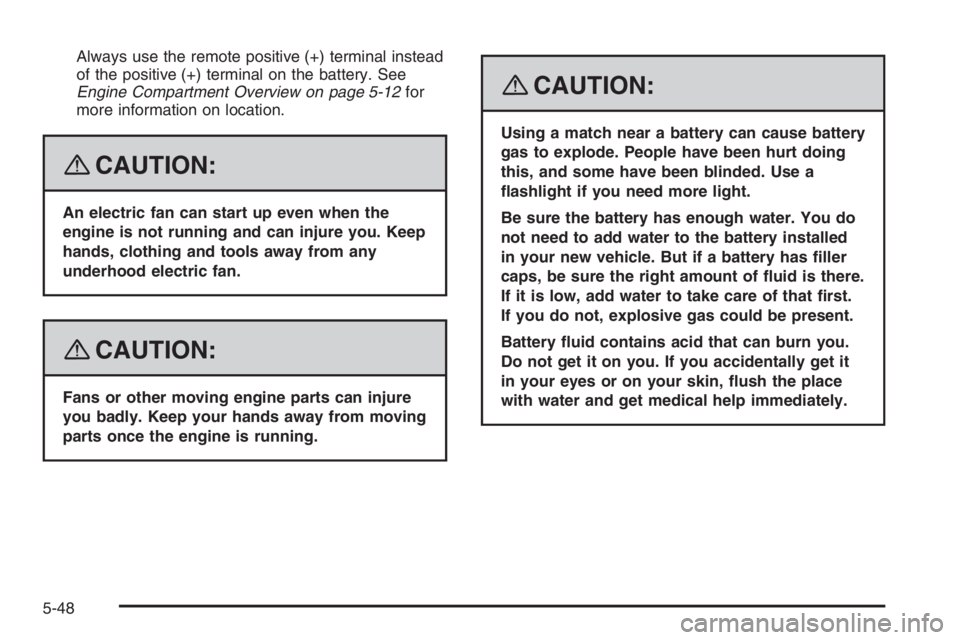

If your vehicle has the

5.3L V8 engine, to uncover

the remote positive (+)

terminal, remove the fuse

block cover. 3.8L V6 Engine

5.3L V8 Engine

5-47

Page 318 of 450

Always use the remote positive (+) terminal instead

of the positive (+) terminal on the battery. See

Engine Compartment Overview on page 5-12for

more information on location.

{CAUTION:

An electric fan can start up even when the

engine is not running and can injure you. Keep

hands, clothing and tools away from any

underhood electric fan.

{CAUTION:

Fans or other moving engine parts can injure

you badly. Keep your hands away from moving

parts once the engine is running.

{CAUTION:

Using a match near a battery can cause battery

gas to explode. People have been hurt doing

this, and some have been blinded. Use a

�ashlight if you need more light.

Be sure the battery has enough water. You do

not need to add water to the battery installed

in your new vehicle. But if a battery has �ller

caps, be sure the right amount of �uid is there.

If it is low, add water to take care of that �rst.

If you do not, explosive gas could be present.

Battery �uid contains acid that can burn you.

Do not get it on you. If you accidentally get it

in your eyes or on your skin, �ush the place

with water and get medical help immediately.

5-48

Page 321 of 450

Headlamp Aiming

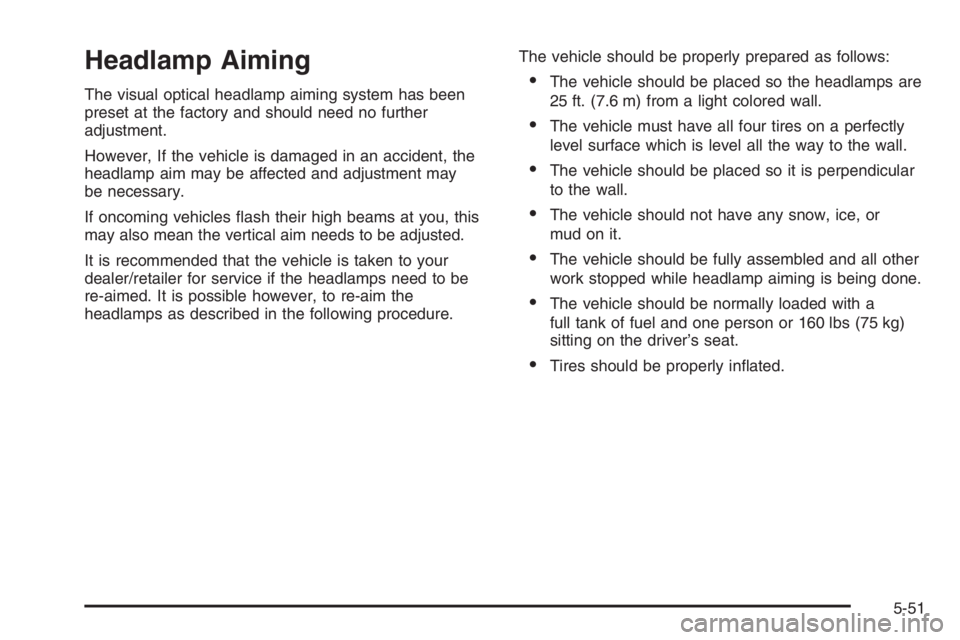

The visual optical headlamp aiming system has been

preset at the factory and should need no further

adjustment.

However, If the vehicle is damaged in an accident, the

headlamp aim may be affected and adjustment may

be necessary.

If oncoming vehicles �ash their high beams at you, this

may also mean the vertical aim needs to be adjusted.

It is recommended that the vehicle is taken to your

dealer/retailer for service if the headlamps need to be

re-aimed. It is possible however, to re-aim the

headlamps as described in the following procedure.The vehicle should be properly prepared as follows:The vehicle should be placed so the headlamps are

25 ft. (7.6 m) from a light colored wall.

The vehicle must have all four tires on a perfectly

level surface which is level all the way to the wall.

The vehicle should be placed so it is perpendicular

to the wall.

The vehicle should not have any snow, ice, or

mudonit.

The vehicle should be fully assembled and all other

work stopped while headlamp aiming is being done.

The vehicle should be normally loaded with a

full tank of fuel and one person or 160 lbs (75 kg)

sitting on the driver’s seat.

Tires should be properly in�ated.

5-51

Page 322 of 450

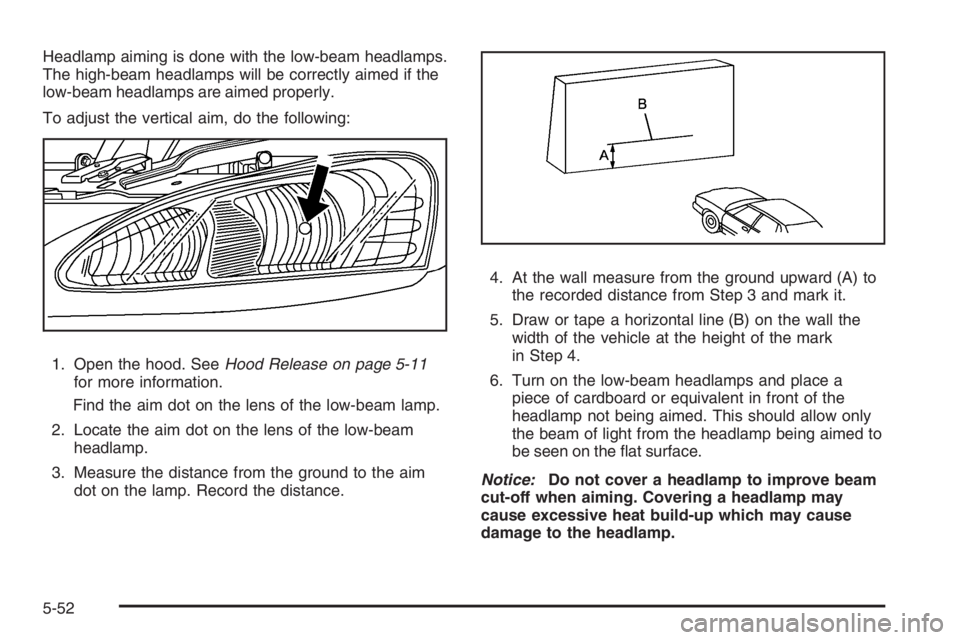

Headlamp aiming is done with the low-beam headlamps.

The high-beam headlamps will be correctly aimed if the

low-beam headlamps are aimed properly.

To adjust the vertical aim, do the following:

1. Open the hood. SeeHood Release on page 5-11

for more information.

Find the aim dot on the lens of the low-beam lamp.

2. Locate the aim dot on the lens of the low-beam

headlamp.

3. Measure the distance from the ground to the aim

dot on the lamp. Record the distance.4. At the wall measure from the ground upward (A) to

the recorded distance from Step 3 and mark it.

5. Draw or tape a horizontal line (B) on the wall the

width of the vehicle at the height of the mark

in Step 4.

6. Turn on the low-beam headlamps and place a

piece of cardboard or equivalent in front of the

headlamp not being aimed. This should allow only

the beam of light from the headlamp being aimed to

be seen on the �at surface.

Notice:Do not cover a headlamp to improve beam

cut-off when aiming. Covering a headlamp may

cause excessive heat build-up which may cause

damage to the headlamp.

5-52

Page 323 of 450

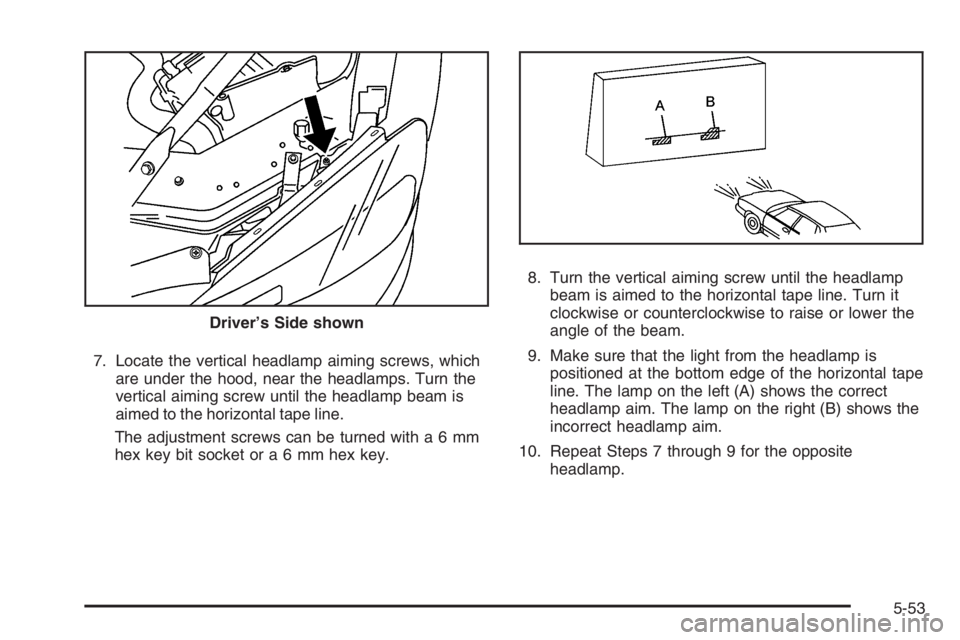

7. Locate the vertical headlamp aiming screws, which

are under the hood, near the headlamps. Turn the

vertical aiming screw until the headlamp beam is

aimed to the horizontal tape line.

The adjustment screws can be turned witha6mm

hex key bit socket ora6mmhexkey.8. Turn the vertical aiming screw until the headlamp

beam is aimed to the horizontal tape line. Turn it

clockwise or counterclockwise to raise or lower the

angle of the beam.

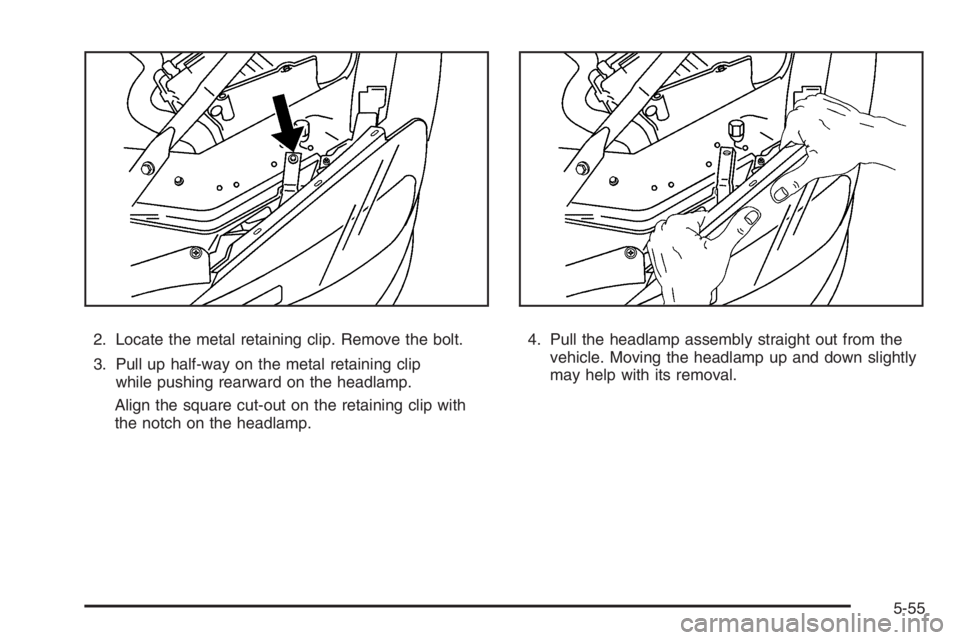

9. Make sure that the light from the headlamp is

positioned at the bottom edge of the horizontal tape

line. The lamp on the left (A) shows the correct

headlamp aim. The lamp on the right (B) shows the

incorrect headlamp aim.

10. Repeat Steps 7 through 9 for the opposite

headlamp. Driver’s Side shown

5-53

Page 325 of 450

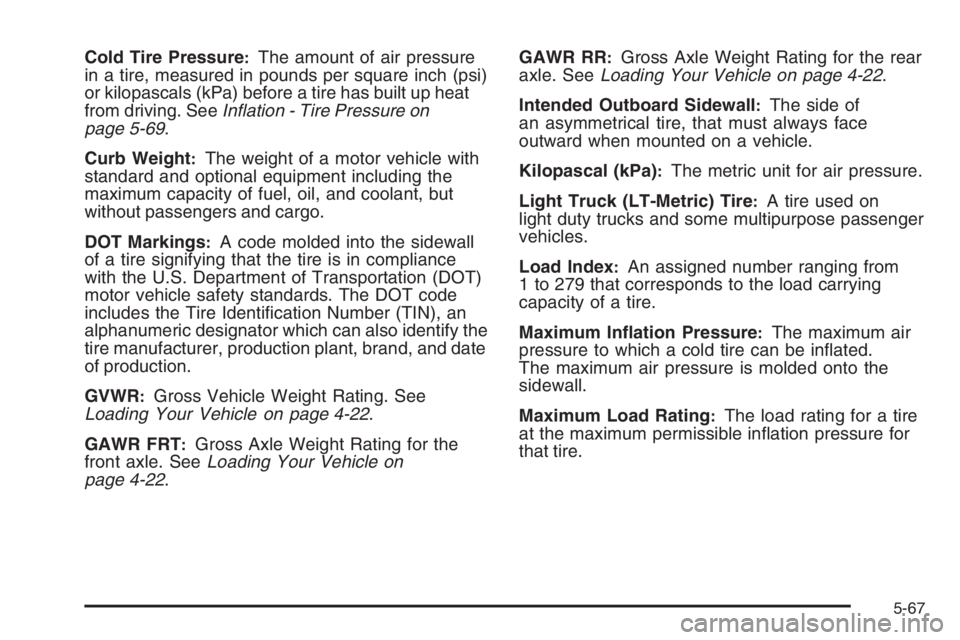

2. Locate the metal retaining clip. Remove the bolt.

3. Pull up half-way on the metal retaining clip

while pushing rearward on the headlamp.

Align the square cut-out on the retaining clip with

the notch on the headlamp.4. Pull the headlamp assembly straight out from the

vehicle. Moving the headlamp up and down slightly

may help with its removal.

5-55

Page 337 of 450

Cold Tire Pressure:The amount of air pressure

in a tire, measured in pounds per square inch (psi)

or kilopascals (kPa) before a tire has built up heat

from driving. SeeInflation - Tire Pressure on

page 5-69.

Curb Weight

:The weight of a motor vehicle with

standard and optional equipment including the

maximum capacity of fuel, oil, and coolant, but

without passengers and cargo.

DOT Markings

:A code molded into the sidewall

of a tire signifying that the tire is in compliance

with the U.S. Department of Transportation (DOT)

motor vehicle safety standards. The DOT code

includes the Tire Identi�cation Number (TIN), an

alphanumeric designator which can also identify the

tire manufacturer, production plant, brand, and date

of production.

GVWR

:Gross Vehicle Weight Rating. See

Loading Your Vehicle on page 4-22.

GAWR FRT

:Gross Axle Weight Rating for the

front axle. SeeLoading Your Vehicle on

page 4-22.GAWR RR

:Gross Axle Weight Rating for the rear

axle. SeeLoading Your Vehicle on page 4-22.

Intended Outboard Sidewall

:The side of

an asymmetrical tire, that must always face

outward when mounted on a vehicle.

Kilopascal (kPa)

:The metric unit for air pressure.

Light Truck (LT-Metric) Tire

:A tire used on

light duty trucks and some multipurpose passenger

vehicles.

Load Index

:An assigned number ranging from

1 to 279 that corresponds to the load carrying

capacity of a tire.

Maximum In�ation Pressure

:The maximum air

pressure to which a cold tire can be in�ated.

The maximum air pressure is molded onto the

sidewall.

Maximum Load Rating

:The load rating for a tire

at the maximum permissible in�ation pressure for

that tire.

5-67

Page 338 of 450

Maximum Loaded Vehicle Weight:The sum of

curb weight, accessory weight, vehicle capacity

weight, and production options weight.

Normal Occupant Weight

:The number of

occupants a vehicle is designed to seat multiplied

by 150 lbs (68 kg). SeeLoading Your Vehicle

on page 4-22.

Occupant Distribution

:Designated seating

positions.

Outward Facing Sidewall

:The side of an

asymmetrical tire that has a particular side that

faces outward when mounted on a vehicle.

The side of the tire that contains a whitewall, bears

white lettering, or bears manufacturer, brand,

and/or model name molding that is higher or

deeper than the same moldings on the other

sidewall of the tire.

Passenger (P-Metric) Tire

:A tire used on

passenger cars and some light duty trucks and

multipurpose vehicles.Recommended In�ation Pressure

:Vehicle

manufacturer’s recommended tire in�ation

pressure as shown on the tire placard. See

Inflation - Tire Pressure on page 5-69andLoading

Your Vehicle on page 4-22.

Radial Ply Tire

:A pneumatic tire in which the

ply cords that extend to the beads are laid at

90 degrees to the centerline of the tread.

Rim

:A metal support for a tire and upon which

the tire beads are seated.

Sidewall

:The portion of a tire between the tread

and the bead.

Speed Rating

:An alphanumeric code assigned to

a tire indicating the maximum speed at which a

tire can operate.

Traction

:The friction between the tire and the

road surface. The amount of grip provided.

Tread

:The portion of a tire that comes into

contact with the road.

5-68

Page 342 of 450

Federal Communications Commission

(FCC) and Industry and Science

Canada

The Tire Pressure Monitor System (TPMS) operates on

a radio frequency and complies with Part 15 of the

FCC Rules. Operation is subject to the following

two conditions:

1. This device may not cause harmful interference.

2. This device must accept any interference received,

including interference that may cause undesired

operation.

The Tire Pressure Monitor System (TPMS) operates on

a radio frequency and complies with RSS-210 of

Industry and Science Canada. Operation is subject to

the following two conditions:

1. This device may not cause interference.

2. This device must accept any interference received,

including interference that may cause undesired

operation of the device.

Changes or modi�cations to this system by other than

an authorized service facility could void authorization to

use this equipment.

Tire Pressure Monitor Operation

The Tire Pressure Monitor System (TPMS) is designed

to warn the driver when a low tire pressure condition

exists. TPMS sensors are mounted onto each tire and

wheel assembly, excluding the spare tire and wheel

assembly. The TPMS sensors monitor the air pressure in

the vehicle’s tires and transmits the tire pressure readings

to a receiver located in the vehicle.

When a low tire pressure

condition is detected, the

TPMS illuminates the low

tire pressure warning light,

located in the instrument

panel cluster.

5-72

Page 343 of 450

At the same time a message to check the pressure in a

speci�c tire appears on the Driver Information center

(DIC) display. The low tire pressure warning light and

the DIC warning message come on at each ignition cycle

until the tires are in�ated to the correct in�ation pressure.

Using the DIC buttons, tire pressure readings can be

viewed by the driver. For additional information and

details about the DIC operation and displays seeDIC

Operation and Displays (Uplevel DIC with Trip Computer)

on page 3-55orDIC Operation and Displays (Base Level

DIC) on page 3-62andDIC Warnings and Messages on

page 3-67.

The low tire pressure warning light may come on in cool

weather when the vehicle is �rst started, and then turn

off as you start to drive. This could be an early indicator

that the air pressure in the tire(s) are getting low and

need to be in�ated to the proper pressure.A tire and Loading Information label, attached to your

vehicle, shows the size of your vehicle’s original

equipment tires and the correct in�ation pressure for your

vehicle’s tires when they are cold. SeeLoading Your

Vehicle on page 4-22, for an example of the Tire and

Loading Information label and its location on your vehicle.

Also seeInflation - Tire Pressure on page 5-69.

Your vehicle’s TPMS system can warn you about a low

tire pressure condition but it does not replace normal

tire maintenance. SeeTire Inspection and Rotation on

page 5-75andTires on page 5-62.

Your vehicle, when new, may have included a

factory-installed Tire In�ator Kit. This kit uses a GM

approved liquid tire sealant. SeeTire Sealant and

Compressor Kit (GXP) on page 5-86.

Notice:Using non-approved tire sealants could

damage the Tire Pressure Monitor System (TPMS)

sensors. TPMS sensor damage caused by using

an incorrect tire sealant is not covered by the

vehicle warranty. Always use the GM approved tire

sealant available through your dealer/retailer.

5-73