PORSCHE 911 CARRERA 2005 5.G Owners Manual

Manufacturer: PORSCHE, Model Year: 2005, Model line: 911 CARRERA, Model: PORSCHE 911 CARRERA 2005 5.GPages: 282, PDF Size: 4.34 MB

Page 241 of 282

Practical Tips, Emergency Service

241

Installing the battery 1. Put battery in and push it all the way to the

stop.

2. Screw in fastening screw B.

Danger!

Risk of short circuit and explosion.

fImportant: connect the positive (+) cable first, and then the negative (–) ground wire.

3. Push on central vent hose C.

4. Fit plastic lid. Lock turn-locks A.

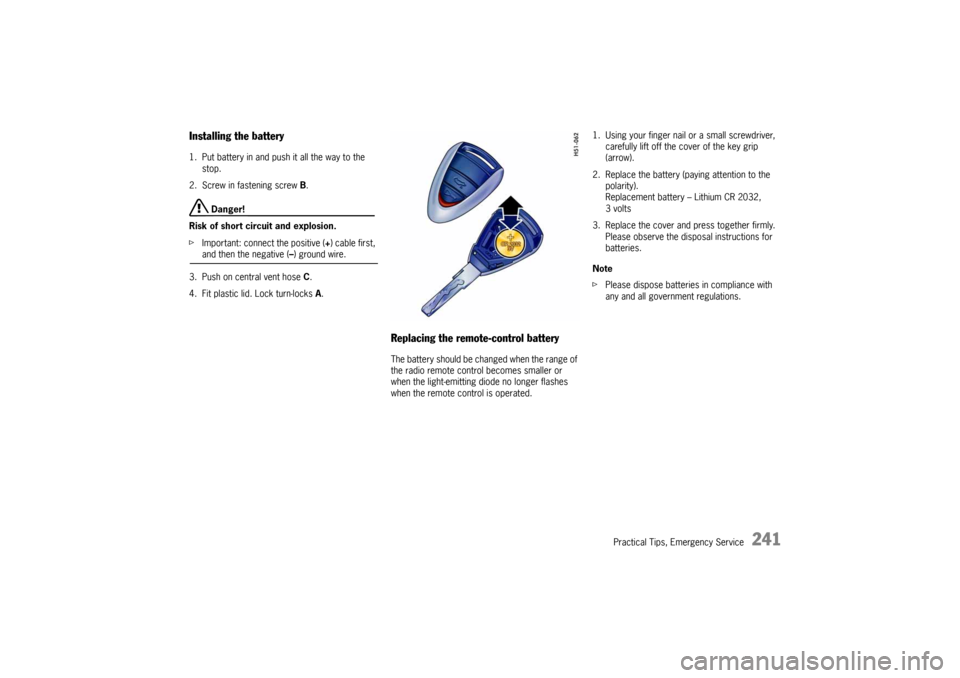

Replacing the remote-control battery The battery should be changed when the range of

the radio remote control becomes smaller or

when the light-emitting diode no longer flashes

when the remote control is operated.1. Using your finger nail or a small screwdriver,

carefully lift off the cover of the key grip

(arrow).

2. Replace the battery (paying attention to the

polarity).

Replacement battery – Lithium CR 2032,

3volts

3. Replace the cover and press together firmly.

Please observe the disposal instructions for

batteries.

Note

fPlease dispose batteries in compliance with

any and all government regulations.

Page 242 of 282

242

Practical Tips, Emergency Service

Emergency Starting with Jumper

Cables If the battery is discharged, e.g. in winter or after

the car has been parked for a long time, the bat-

tery of another car can be used for starting with

the help of jumper cables.

Make sure the voltage of both batteries is the

same. Both batteries must be 12 volt types.

The capacity (Ampere hours, Ah) of the booster

battery must not be substantially less than that of

the discharged battery.

The discharged battery must be correctly con-

nected to the vehicle’s electrical system.

fPlease observe the chapter “BATTERY” on

Page 236.

fPlease observe the chapter “EMERGENCY UN-

LOCKING OF THE LUGGAGE COMPARTMENT

LID” on Page 235.

Note

fDo not try to start the car by pushing or tow-

ing. Damage to the catalytic converters and

other components of the car may result.

Warning!

Risk of damage and serious personal injury

due to short circuit.

fUse only jumper cables of adequate diameter

cross-section and fitted with completely insu-

lated alligator clips.

fFollow all warnings and instructions of the

jumper cable manufacturer.

fWhen connecting jumper cables, make sure

that they cannot get caught in any moving

parts in the engine compartment.

The jumper cables must be long enough so

that neither vehicles nor cables touch another.

fThe vehicles must not be in contact, otherwise

current might flow as soon as the positive ter-

minals are connected.

fThe cable clamps must not be allowed to con-

tact each other when one end of the jumper ca-

bles are connected to a battery.

fEnsure that tools or conductive jewelery (rings,

chains, watch straps) do not come into contact

with the positive jumper cable or the positive

battery post.

fImproper hook-up of jumper cables can ruin

the alternator. Danger of caustic burns.

fDo not lean over the battery.

Danger of gas explosion.

fImproper use of booster battery to start a

vehicle may cause an explosion, resulting in

severe personal injuries.

fKeep sources of ignition away from the bat-

tery, e.g. open flame, burning cigarettes or

sparking due to cable contact or welding work.

fA discharged battery can freeze even at

23°F/–5°C.

Before connecting jumper cables, a frozen bat-

tery must be thawed out.

Page 243 of 282

Practical Tips, Emergency Service

243

Connect jumper cables in the following

sequence:

Always observe the sequence below:

1. Connect the positive lead (red) to the

positive terminal of the discharged battery

first, then connect it to the positive terminal of

the donor battery.

2. First connect the negative cable (black) to

the negative terminal of the donor battery, then

connect it to a suitable grounding point on the

vehicle with the discharged battery.

This grounding point must lie as far as possible

from the battery.

For example, a solid metal part or the engine

block are suitable grounding points.

If no suitable grounding points are to be found

on either vehicle, the negative cable must

carefully be connected directly to the negative

terminal of the battery.

If a suitable grounding point is to be found only

on the donor vehicle, the negative cable must

first be connected to the terminal of the

discharged battery, then to the grounding point

of the donor vehicle.

3. Run the engine of the donor car at a higher

speed.4. Start the engine.

An attempted start using jumper cables should

not last more than 15 seconds. Then allow a

waiting period of at least one minute.

Note

Before disconnecting the jumper cables, electrical

loads such as the heated rear window and the

heating fan blower should be switched on (the ve-

hicle’s lights must not be switched on). This reduc-

es voltage peaks which may occur when discon-

necting the jumper cables.

With the engine running, remove both jumper ca-

bles in reverse order.

Page 244 of 282

244

Practical Tips, Emergency Service

Lights, Replacing Bulbs

Warning!

Risk of short circuit.

fAlways switch off the relevant consumer when

changing bulbs.

Risk of injury. The Bi Xenon headlights are

under high voltage when installed.

fBe careful during all work in the area of the Bi

Xenon headlights.

Risk of damage. Bulbs of a higher wattage

can damage the lamp housing.

fOnly the bulbs shown in the chart may be used.

fNew bulbs must be clean and free from oil,

grease and fingerprints. Therefore, never

touch bulbs with your bare hands.

Use a cloth or soft paper while replacing bulbs.

Caution!

Risk of damage to headlights due to exces-

sive temperatures and abrasion.

fAttach no coverings (e.g. films, “stone

guards”) in the area of the headlights.

fUse soapy water only to clean light lenses and

plastic headlight lenses.

In no case may chemical cleaners or other vol-

atile cleaning fluids be used.

fTo prevent scratches, do not rub with a dry or merely moist cloth, tissue or insect sponges.

Page 245 of 282

Practical Tips, Emergency Service

245

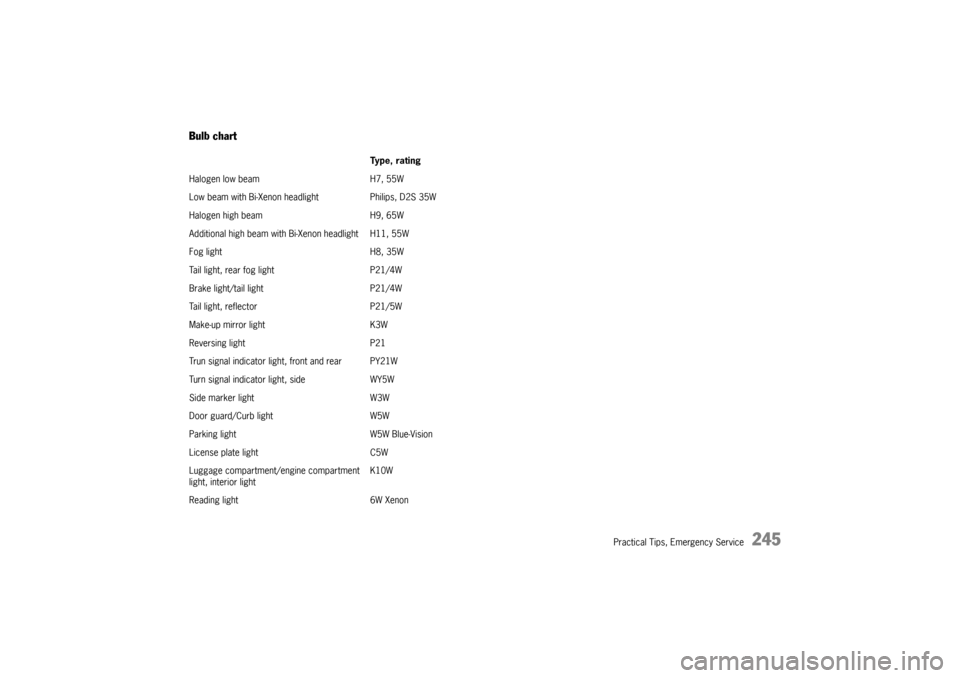

Bulb chart

Ty p e , r a t i n g

Halogen low beam H7, 55W

Low beam with Bi-Xenon headlight Philips, D2S 35W

Halogen high beam H9, 65W

Additional high beam with Bi-Xenon headlight H11, 55W

Fog light H8, 35W

Tail light, rear fog light P21/4W

Brake light/tail light P21/4W

Tail light, reflector P21/5W

Make-up mirror light K3W

Reversing light P21

Trun signal indicator light, front and rear PY21W

Turn signal indicator light, side WY5W

Side marker light W3W

Door guard/Curb light W5W

Parking light W5W Blue-Vision

License plate light C5W

Luggage compartment/engine compartment

light, interior lightK10W

Reading light 6W Xenon

Page 246 of 282

246

Practical Tips, Emergency Service

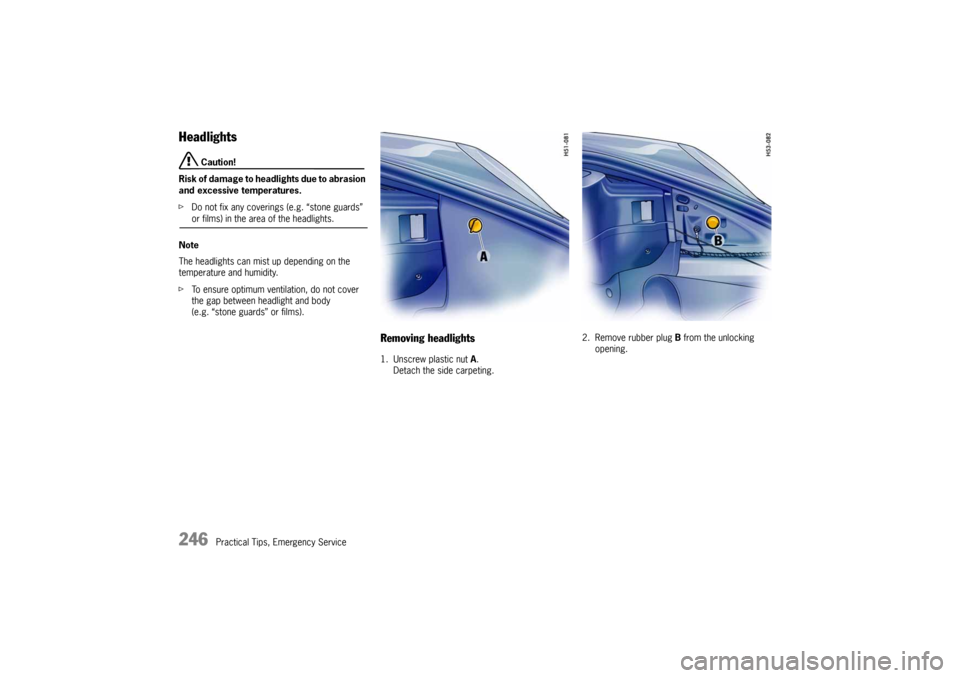

Headlights

Caution!

Risk of damage to headlights due to abrasion

and excessive temperatures.

fDo not fix any coverings (e.g. “stone guards” or films) in the area of the headlights.

Note

The headlights can mist up depending on the

temperature and humidity.

fTo ensure optimum ventilation, do not cover

the gap between headlight and body

(e.g. “stone guards” or films).

Removing headlights1. Unscrew plastic nut A.

Detach the side carpeting.2. Remove rubber plug B from the unlocking

opening.

Page 247 of 282

Practical Tips, Emergency Service

247

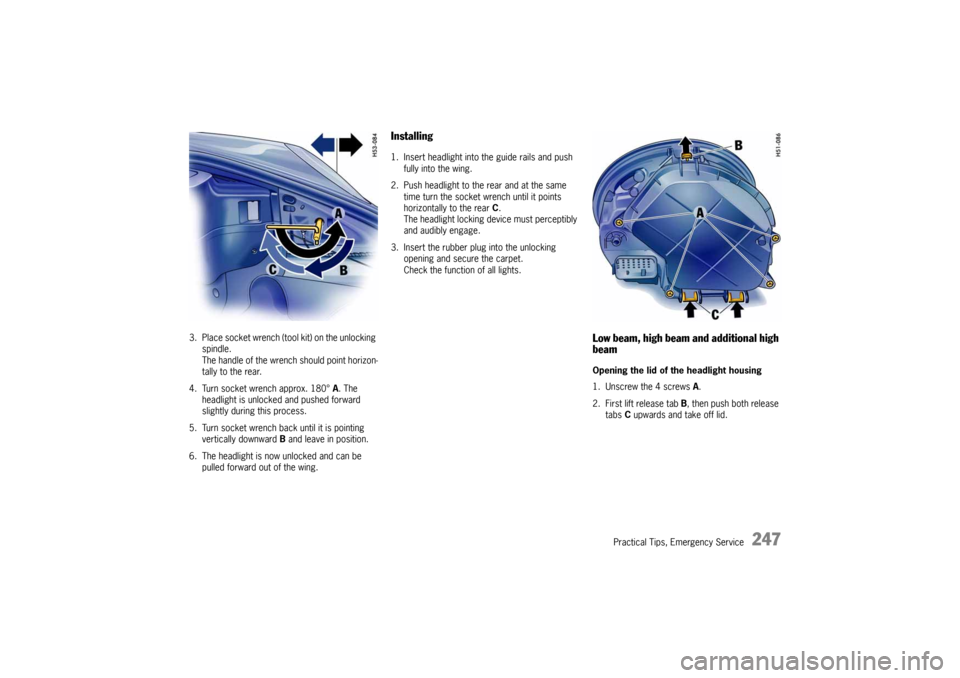

3. Place socket wrench (tool kit) on the unlocking

spindle.

The handle of the wrench should point horizon-

tally to the rear.

4. Turn socket wrench approx. 180° A. The

headlight is unlocked and pushed forward

slightly during this process.

5. Turn socket wrench back until it is pointing

vertically downward B and leave in position.

6. The headlight is now unlocked and can be

pulled forward out of the wing.

Installing1. Insert headlight into the guide rails and push

fully into the wing.

2. Push headlight to the rear and at the same

time turn the socket wrench until it points

horizontally to the rear C.

The headlight locking device must perceptibly

and audibly engage.

3. Insert the rubber plug into the unlocking

opening and secure the carpet.

Check the function of all lights.

Low beam, high beam and additional high

beamOpening the lid of the headlight housing

1. Unscrew the 4 screws A.

2. First lift release tab B, then push both release

tabs C upwards and take off lid.

Page 248 of 282

248

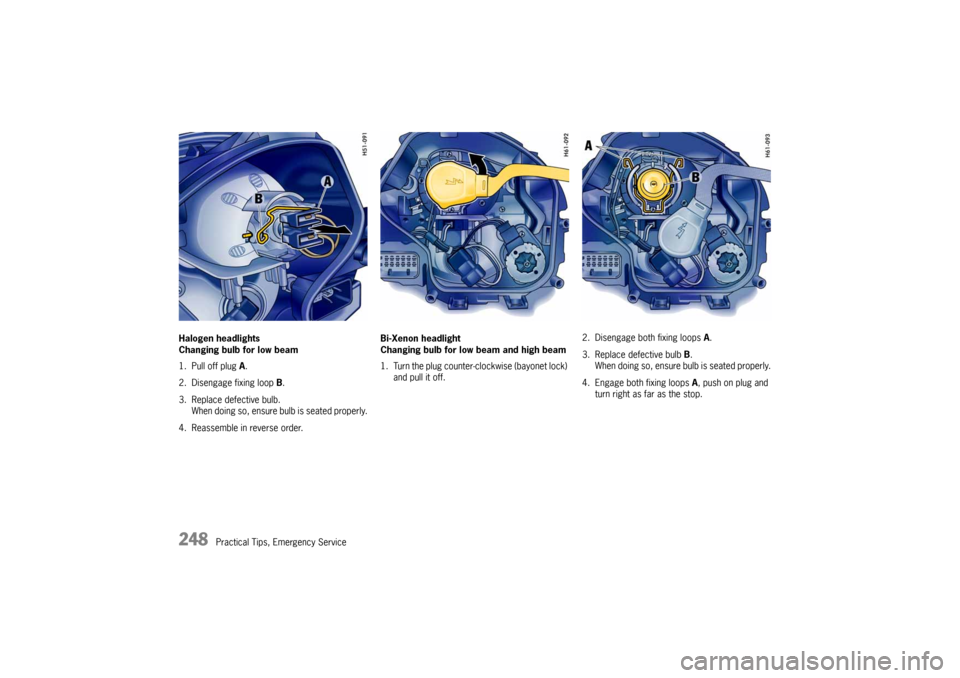

Practical Tips, Emergency Service Halogen headlights

Changing bulb for low beam

1. Pull off plug A.

2. Disengage fixing loop B.

3. Replace defective bulb.

When doing so, ensure bulb is seated properly.

4. Reassemble in reverse order.Bi-Xenon headlight

Changing bulb for low beam and high beam

1. Turn the plug counter-clockwise (bayonet lock)

and pull it off.2. Disengage both fixing loops A.

3. Replace defective bulb B.

When doing so, ensure bulb is seated properly.

4. Engage both fixing loops A, push on plug and

turn right as far as the stop.

Page 249 of 282

Practical Tips, Emergency Service

249

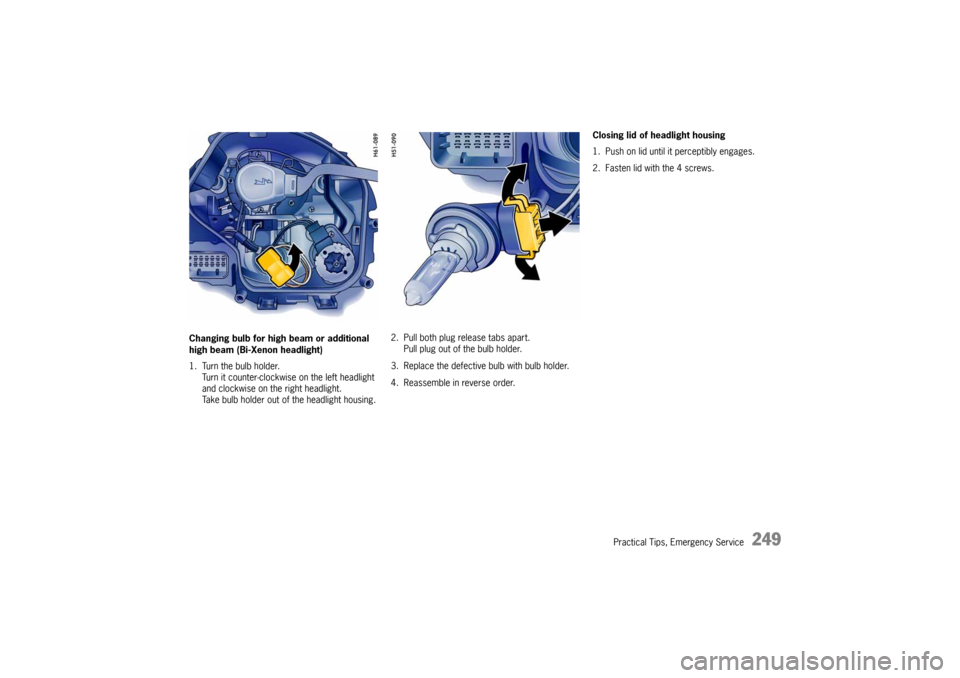

Changing bulb for high beam or additional

high beam (Bi-Xenon headlight)

1. Turn the bulb holder.

Turn it counter-clockwise on the left headlight

and clockwise on the right headlight.

Take bulb holder out of the headlight housing.2. Pull both plug release tabs apart.

Pull plug out of the bulb holder.

3. Replace the defective bulb with bulb holder.

4. Reassemble in reverse order.Closing lid of headlight housing

1. Push on lid until it perceptibly engages.

2. Fasten lid with the 4 screws.

Page 250 of 282

250

Practical Tips, Emergency Service

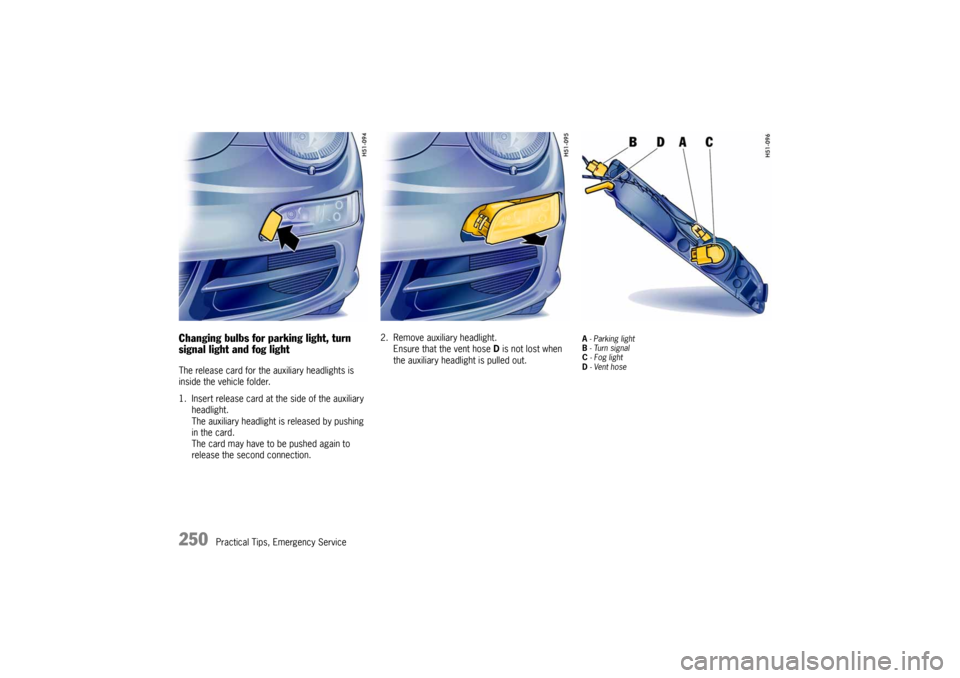

Changing bulbs for parking light, turn

signal light and fog lightThe release card for the auxiliary headlights is

inside the vehicle folder.

1. Insert release card at the side of the auxiliary

headlight.

The auxiliary headlight is released by pushing

in the card.

The card may have to be pushed again to

release the second connection.2. Remove auxiliary headlight.

Ensure that the vent hose D is not lost when

the auxiliary headlight is pulled out.

A - Parking light

B - Turn signal

C - Fog light

D - Vent hose