light Ram 1500 2018 Repair Manual

[x] Cancel search | Manufacturer: RAM, Model Year: 2018, Model line: 1500, Model: Ram 1500 2018Pages: 372, PDF Size: 7.1 MB

Page 180 of 372

To Decrease Speed

When the Speed Control is set, you can de-

crease speed by pushing the SET (-) button.

The driver’s preferred units can be selected

through the instrument panel settings if

equipped. Refer to “Getting To Know Your

Instrument Panel” in the Owner’s Manual for

more information. The speed increment

shown is dependent on the selected speed

unit of U.S. (mph) or Metric (km/h):

U.S. Speed (mph)

• Pushing the SET (-) button once will resultin a 1 mph decrease in set speed. Each

subsequent tap of the button results in a

decrease of 1 mph.

• If the button is continually pushed, the set speed will continue to decrease until the

button is released, then the new set speed

will be established.

Metric Speed (km/h)

• Pushing the SET (-) button once will result in a 1 km/h decrease in set speed. Each

subsequent tap of the button results in a

decrease of 1 km/h. • If the button is continually pushed, the set

speed will continue to decrease until the

button is released, then the new set speed

will be established.

To Accelerate For Passing

Press the accelerator as you would normally.

When the pedal is released, the vehicle will

return to the set speed.

Using Speed Control On Hills

The transmission may downshift on hills to

maintain the vehicle set speed.

NOTE:

The Speed Control system maintains speed

up and down hills. A slight speed change on

moderate hills is normal.

On steep hills, a greater speed loss or gain

may occur so it may be preferable to drive

without Speed Control.

WARNING!

Speed Control can be dangerous where the

system cannot maintain a constant speed.

Your vehicle could go too fast for the con-

WARNING!

ditions, and you could lose control and

have an accident. Do not use Speed Con-

trol in heavy traffic or on roads that are

winding, icy, snow-covered or slippery.

To Resume Speed

To resume a previously set speed, push the

RES (+) button and release. Resume can be

used at any speed above 20 mph (32 km/h).

To Deactivate

A soft tap on the brake pedal, pushing the

CANCEL button, or normal brake pressure

while slowing the vehicle will deactivate the

Speed Control without erasing the set speed

from memory.

Pushing the ON/OFF button or turning the

ignition switch OFF erases the set speed from

memory.STARTING AND OPERATING

178

Page 183 of 372

REFUELING THE VEHICLE — GAS

ENGINE

The fuel filler cap (gas cap) is located behind

the fuel filler door, on the left side of the

vehicle. Open the fuel door and remove the

fuel cap by turning it counter-clockwise.

NOTE:

When removing the fuel filler cap, lay the cap

tether in the hook, located on the fuel filler

door.

WARNING!

• Never have any smoking materials lit inor near the vehicle when the gas cap is

removed or the tank is being filled.

• Never add fuel to the vehicle when the

engine is running.

• A fire may result if gasoline is pumped

into a portable container that is inside of

a vehicle. You could be burned. Always

place gas containers on the ground while

filling.

CAUTION!

• Damage to the fuel system or emissionscontrol system could result from using

an improper fuel tank filler tube cap.

• A poorly fitting fuel filler cap could let

impurities into the fuel system.

• A poorly fitting fuel filler cap may cause

the “Malfunction Indicator Light (MIL)”

to turn on.

• To avoid fuel spillage and overfilling, do

not “top off” the fuel tank after filling.

When the fuel nozzle “clicks” or shuts

off, the fuel tank is full.

NOTE:

• When the fuel nozzle “clicks” or shuts off, the fuel tank is full.

• Tighten the gas cap until you hear a “click- ing” sound. This is an indication that the

gas cap is tightened properly. The MIL in

the instrument cluster may turn on if the

gas cap is not secured properly. Make sure

that the gas cap is tightened each time the

vehicle is refueled.

WARNING!

Static electricity can cause an ignition of

flammable liquid, vapor or gas in any ve-

hicle or trailer. To reduce risk of serious

injury or death when filling containers:

• Always place container on the ground before filling.

• Keep the pump nozzle in contact with

the container when you are filling it.

• Use only approved containers for flam-

mable liquid.

• Do not leave container unattended while

filling.

• A static electric charge could cause a

spark and fire hazard.

181

Page 185 of 372

2. Insert funnel into same filler pipe openingas the fuel nozzle.

NOTE:

Ensure funnel is inserted fully to hold

flapper door open. 3. Pour fuel into funnel opening.

4. Remove funnel from filler pipe, clean off

prior to putting back in the jack kit.

WARNING!

• Never have any smoking materials lit inor near the vehicle when the fuel door is

open or the tank is being filled.

• Never add fuel when the engine is run-

ning. This is in violation of most state

and federal fire regulations and may

cause the “Malfunction Indicator Light”

to turn on.

• A fire may result if fuel is pumped into a

portable container that is inside of a

vehicle. You could be burned. Always

place fuel containers on the ground

while filling.

CAUTION!

To avoid fuel spillage and overfilling, do

not “top off” the fuel tank after filling.

Diesel Exhaust Fluid

Your vehicle is equipped with a Selective

Catalytic Reduction system to meet the very

stringent diesel emissions standards required

by the Environmental Protection Agency.

The purpose of the SCR system is to reduce

levels of NOx (oxides of nitrogen emitted from

engines) that are harmful to our health and

the environment to a near-zero level. Small

quantities of Diesel Exhaust Fluid (DEF) is

injected into the exhaust upstream of a cata-

lyst where, when vaporized, it converts smog-

forming nitrogen oxides (NOx) into harmless

nitrogen (N2) and water vapor (H2O), two

natural components of the air we breathe.

You can operate with the comfort that your

vehicle is contributing to a cleaner, healthier

world environment for this and generations to

come.

System Overview

This vehicle is equipped with a Diesel Ex-

haust Fluid (DEF) injection system and a

Selective Catalytic Reduction (SCR) catalyst

to meet the emission requirements.

Fill Locations And Funnel Useage

1 — Diesel Exhaust Fluid (DEF) Fill

Location

2 — Diesel Fuel Fill Location

3 — Emergency Diesel Fuel Fill Funnel

183

Page 189 of 372

2. Insert the fuel nozzle fully into the fillerpipe – the nozzle opens and holds the

flapper door while refueling.

3. Fill the vehicle with fuel – when the fuel nozzle “clicks” or shuts off the fuel tank is

full.

4. Remove the fuel nozzle and close the fuel door.

Emergency Fuel Can Refueling

Most fuel cans will not open the flapper door.

A funnel is provided to open the flapper door

to allow emergency refueling with a fuel can.

1. Retrieve fuel funnel from the jack kit located under the front passenger seat.

2. Insert funnel into same filler pipe opening as the fuel nozzle.

NOTE:

Ensure funnel is inserted fully to hold

flapper door open.

3. Pour fuel into funnel opening. 4. Remove funnel from filler pipe, clean off

prior to putting back in the jack kit.

WARNING!

• Never have any smoking materials lit inor near the vehicle when the fuel door is

open or the tank is being filled.

• Never add fuel when the engine is run-

ning. This is in violation of most state

and federal fire regulations and may

cause the “Malfunction Indicator Light”

to turn on.

• A fire may result if fuel is pumped into a

portable container that is inside of a

vehicle. You could be burned. Always

place fuel containers on the ground

while filling.

CAUTION!

To avoid fuel spillage and overfilling, do

not “top off” the fuel tank after filling.

Fill Locations And Funnel Useage

1 — Diesel Exhaust Fluid (DEF) Fill

Location

2 — Diesel Fuel Fill Location

3 — Emergency Diesel Fuel Fill Funnel

187

Page 195 of 372

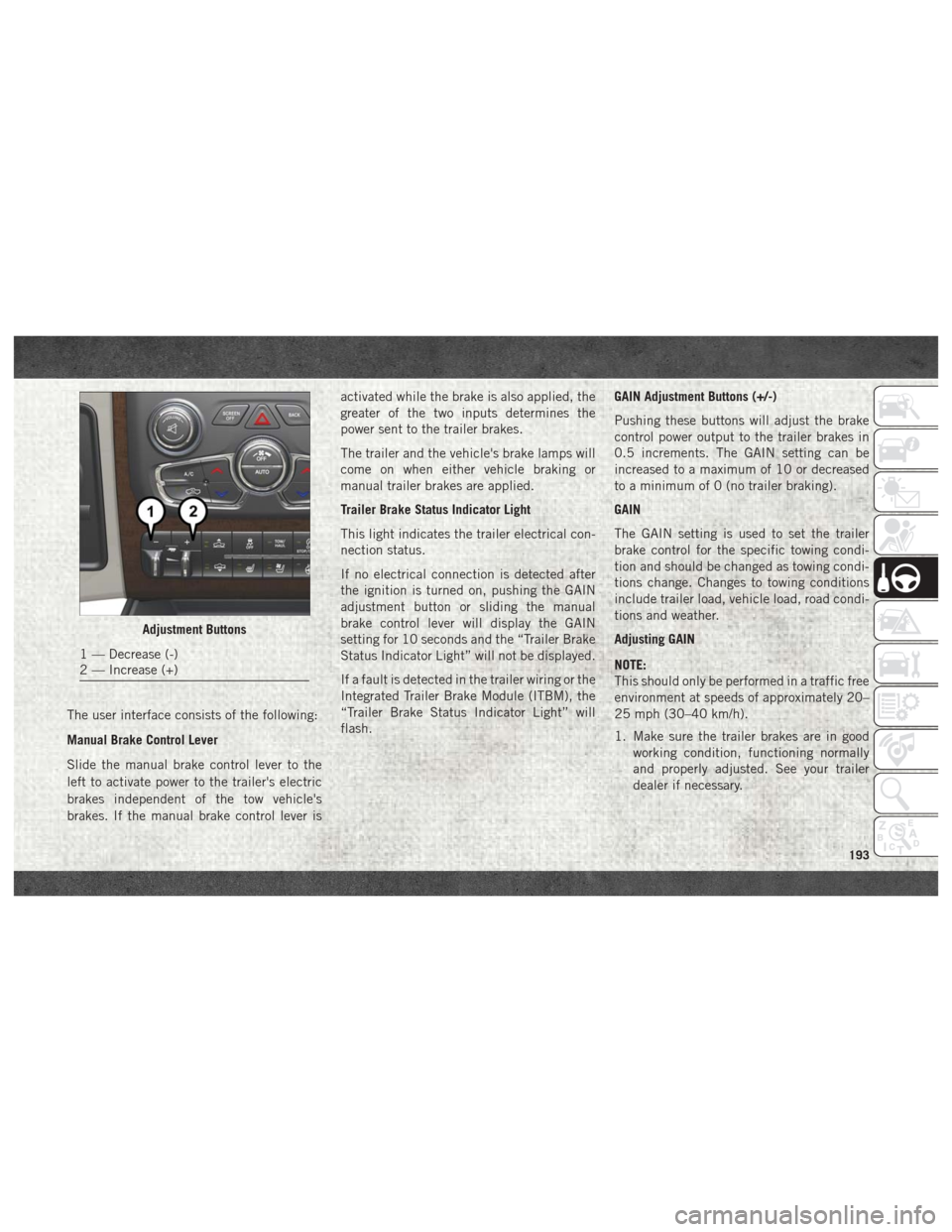

The user interface consists of the following:

Manual Brake Control Lever

Slide the manual brake control lever to the

left to activate power to the trailer's electric

brakes independent of the tow vehicle's

brakes. If the manual brake control lever isactivated while the brake is also applied, the

greater of the two inputs determines the

power sent to the trailer brakes.

The trailer and the vehicle's brake lamps will

come on when either vehicle braking or

manual trailer brakes are applied.

Trailer Brake Status Indicator Light

This light indicates the trailer electrical con-

nection status.

If no electrical connection is detected after

the ignition is turned on, pushing the GAIN

adjustment button or sliding the manual

brake control lever will display the GAIN

setting for 10 seconds and the “Trailer Brake

Status Indicator Light” will not be displayed.

If a fault is detected in the trailer wiring or the

Integrated Trailer Brake Module (ITBM), the

“Trailer Brake Status Indicator Light” will

flash.

GAIN Adjustment Buttons (+/-)

Pushing these buttons will adjust the brake

control power output to the trailer brakes in

0.5 increments. The GAIN setting can be

increased to a maximum of 10 or decreased

to a minimum of 0 (no trailer braking).

GAIN

The GAIN setting is used to set the trailer

brake control for the specific towing condi-

tion and should be changed as towing condi-

tions change. Changes to towing conditions

include trailer load, vehicle load, road condi-

tions and weather.

Adjusting GAIN

NOTE:

This should only be performed in a traffic free

environment at speeds of approximately 20–

25 mph (30–40 km/h).

1. Make sure the trailer brakes are in good

working condition, functioning normally

and properly adjusted. See your trailer

dealer if necessary.

Adjustment Buttons

1 — Decrease (-)

2 — Increase (+)

193

Page 196 of 372

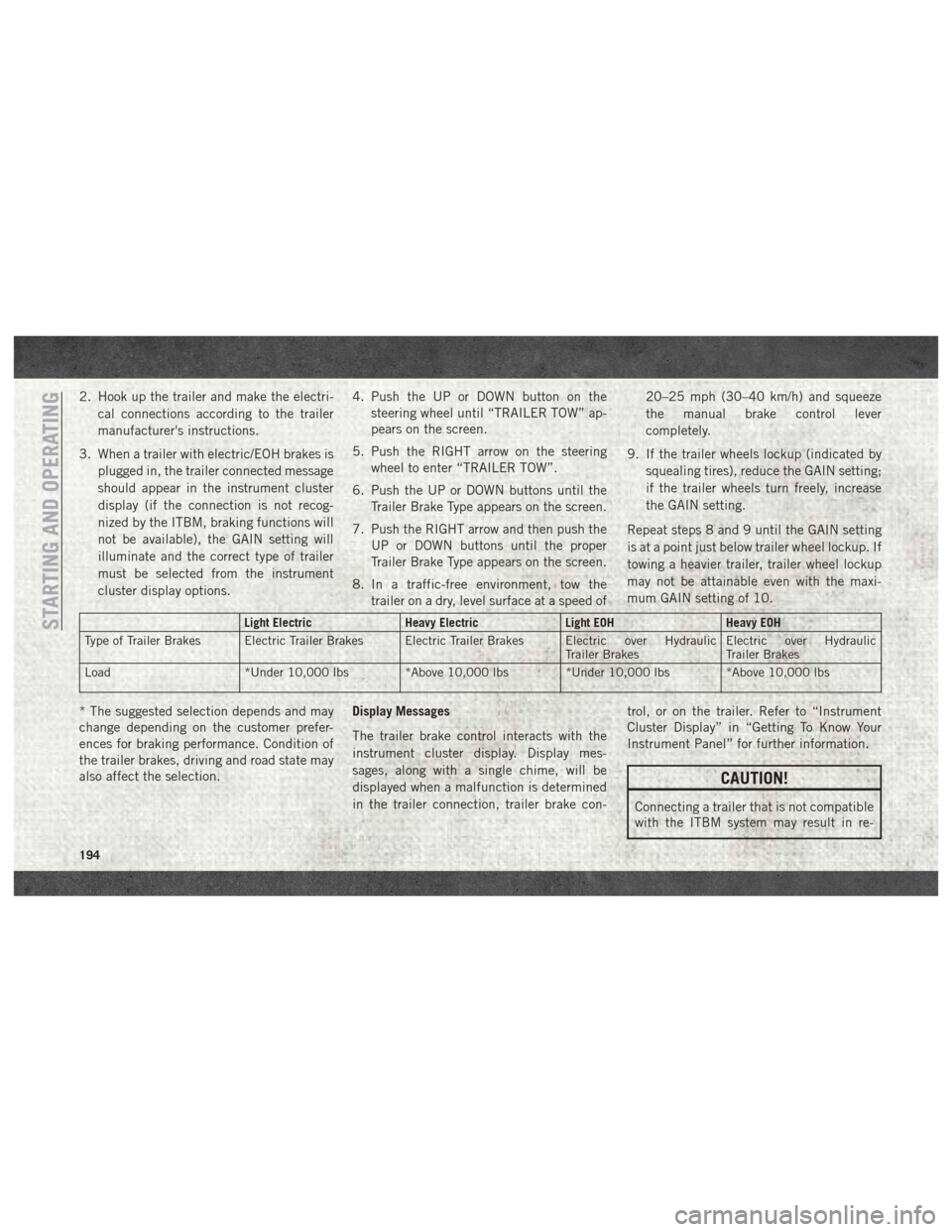

2. Hook up the trailer and make the electri-cal connections according to the trailer

manufacturer's instructions.

3. When a trailer with electric/EOH brakes is plugged in, the trailer connected message

should appear in the instrument cluster

display (if the connection is not recog-

nized by the ITBM, braking functions will

not be available), the GAIN setting will

illuminate and the correct type of trailer

must be selected from the instrument

cluster display options. 4. Push the UP or DOWN button on the

steering wheel until “TRAILER TOW” ap-

pears on the screen.

5. Push the RIGHT arrow on the steering wheel to enter “TRAILER TOW”.

6. Push the UP or DOWN buttons until the Trailer Brake Type appears on the screen.

7. Push the RIGHT arrow and then push the UP or DOWN buttons until the proper

Trailer Brake Type appears on the screen.

8. In a traffic-free environment, tow the trailer on a dry, level surface at a speed of 20–25 mph (30–40 km/h) and squeeze

the manual brake control lever

completely.

9. If the trailer wheels lockup (indicated by squealing tires), reduce the GAIN setting;

if the trailer wheels turn freely, increase

the GAIN setting.

Repeat steps 8 and 9 until the GAIN setting

is at a point just below trailer wheel lockup. If

towing a heavier trailer, trailer wheel lockup

may not be attainable even with the maxi-

mum GAIN setting of 10.

Light Electric Heavy ElectricLight EOHHeavy EOH

Type of Trailer Brakes Electric Trailer Brakes Electric Trailer Brakes Electric over Hydraulic Trailer BrakesElectric over Hydraulic

Trailer Brakes

Load *Under 10,000 lbs *Above 10,000 lbs *Under 10,000 lbs *Above 10,000 lbs

* The suggested selection depends and may

change depending on the customer prefer-

ences for braking performance. Condition of

the trailer brakes, driving and road state may

also affect the selection. Display Messages

The trailer brake control interacts with the

instrument cluster display. Display mes-

sages, along with a single chime, will be

displayed when a malfunction is determined

in the trailer connection, trailer brake con- trol, or on the trailer. Refer to “Instrument

Cluster Display” in “Getting To Know Your

Instrument Panel” for further information.

CAUTION!

Connecting a trailer that is not compatible

with the ITBM system may result in re-

STARTING AND OPERATING

194

Page 201 of 372

The NEUTRAL (N) indicator light will

blink while the shift is in progress. The

light will stop blinking (stay on solid)

when the shift to NEUTRAL (N) is com-

plete. After the shift is completed and

the NEUTRAL (N) light stays on, re-

lease the NEUTRAL (N) button.

6. Release the parking brake.

7. Shift the transmission into REVERSE.

8. Release the brake pedal (and clutch pedal on manual transmissions) for five seconds

and ensure that there is no vehicle

movement.

9. Repeat steps 7 and 8 with automatic transmission in DRIVE or manual trans-

mission in first gear.

10. Shift the transmission to NEUTRAL. Firmly apply the parking brake. Turn OFF

the engine. For vehicles with Keyless

Enter-N-Go, push and hold the ENGINE

START/STOP button until the engine

shuts off.

11. Shift the transmission into PARK or place manual transmission in gear (NOT in Neutral). On 8-speed transmissions

the shifter will automatically select

PARK when the engine is turned off.

12. Turn the ignition to the OFF mode, then cycle the ignition to the RUN mode and

back to the OFF mode. Remove the key

fob from the ignition.

13. Attach the vehicle to the tow vehicle using a suitable tow bar.

14. Release the parking brake.

NOTE:

With electronic shift transfer case:

• Steps 2 through 4 are requirements that must be met before pushing the NEUTRAL

(N) button, and must continue to be met

until the shift has been completed. If any of

these requirements are not met before

pushing the NEUTRAL (N) button or are no

longer met during the shift, the NEUTRAL

(N) indicator light will flash continuously

until all requirements are met or until the

NEUTRAL (N) button is released. • The ignition must be in the ON/RUN mode

for a shift to take place and for the position

indicator lights to be operable. If the igni-

tion is not in the ON/RUN mode, the shift

will not take place and no position indicator

lights will be on or flashing.

• A flashing NEUTRAL (N) position indicator light indicates that shift requirements have

not been met.

• If the vehicle is equipped with air suspen- sion, the engine should be started and left

running for a minimum of 60 seconds (with

all the doors closed) at least once every

24 hours. This process allows the air sus-

pension to adjust the vehicle’s ride height

to compensate for temperature effects.

Shifting Out Of NEUTRAL (N)

Use the following procedure to prepare your

vehicle for normal usage:

1. Bring the vehicle to a complete stop, leav-

ing it connected to the tow vehicle.

2. Firmly apply the parking brake.

3. Press and hold the brake pedal.

199

Page 202 of 372

4. Start the engine. Shift the transmissioninto NEUTRAL. Depress the clutch pedal

on a manual transmission.

• With manual shift transfer case, shift the transfer case lever to the desired

position.

• With electronic shift transfer case with rotary selector switch, push and hold

the transfer case NEUTRAL (N) button

until the NEUTRAL (N) indicator light

turns off. After the NEUTRAL (N) indi-

cator light turns off, release the NEU-

TRAL (N) button. After the NEUTRAL

(N) button has been released, the

transfer case will shift to the position

indicated by the selector switch.

• With electronic shift transfer case with push-button selector switch, push and

hold the switch for the desired transfer

case position, until the NEUTRAL (N)

indicator light turns off and the desired

position indicator light turns on. NOTE:

When shifting out of transfer case NEUTRAL

(N), turning the engine OFF is not required,

but may be helpful to avoid gear clash. With

the 8-speed automatic transmission, the en-

gine must remain running, since turning the

engine OFF will shift the transmission to

PARK (and the transmission must be in NEU-

TRAL for the transfer case to shift out of

NEUTRAL).

5. Turn the engine OFF. Shift automatic

transmission into PARK. On 8-speed

transmissions the shifter will automati-

cally select PARK when the engine is

turned off.

6. Release the brake pedal (and clutch pedal on a manual transmission).

7. Disconnect vehicle from the tow vehicle.

8. Start the engine.

9. Press and hold the brake pedal.

10. Release the parking brake.

11. Shift the transmission into gear, release the brake pedal (and clutch pedal on

manual transmissions), and check that

the vehicle operates normally. NOTE:

With electronic shift transfer case:

• Steps 3 and 4 are requirements that must

be met before pushing the button to shift

out of NEUTRAL (N), and must continue to

be met until the shift has been completed.

If any of these requirements are not met

before pushing the button or are no longer

met during the shift, the NEUTRAL (N)

indicator light will flash continuously until

all requirements are met or until the button

is released.

• The ignition must be in the ON/RUN mode for a shift to take place and for the position

indicator lights to be operable. If the igni-

tion is not in the ON/RUN mode, the shift

will not take place and no position indicator

lights will be on or flashing.

• A flashing NEUTRAL (N) position indicator light indicates that shift requirements have

not been met.

STARTING AND OPERATING

200

Page 204 of 372

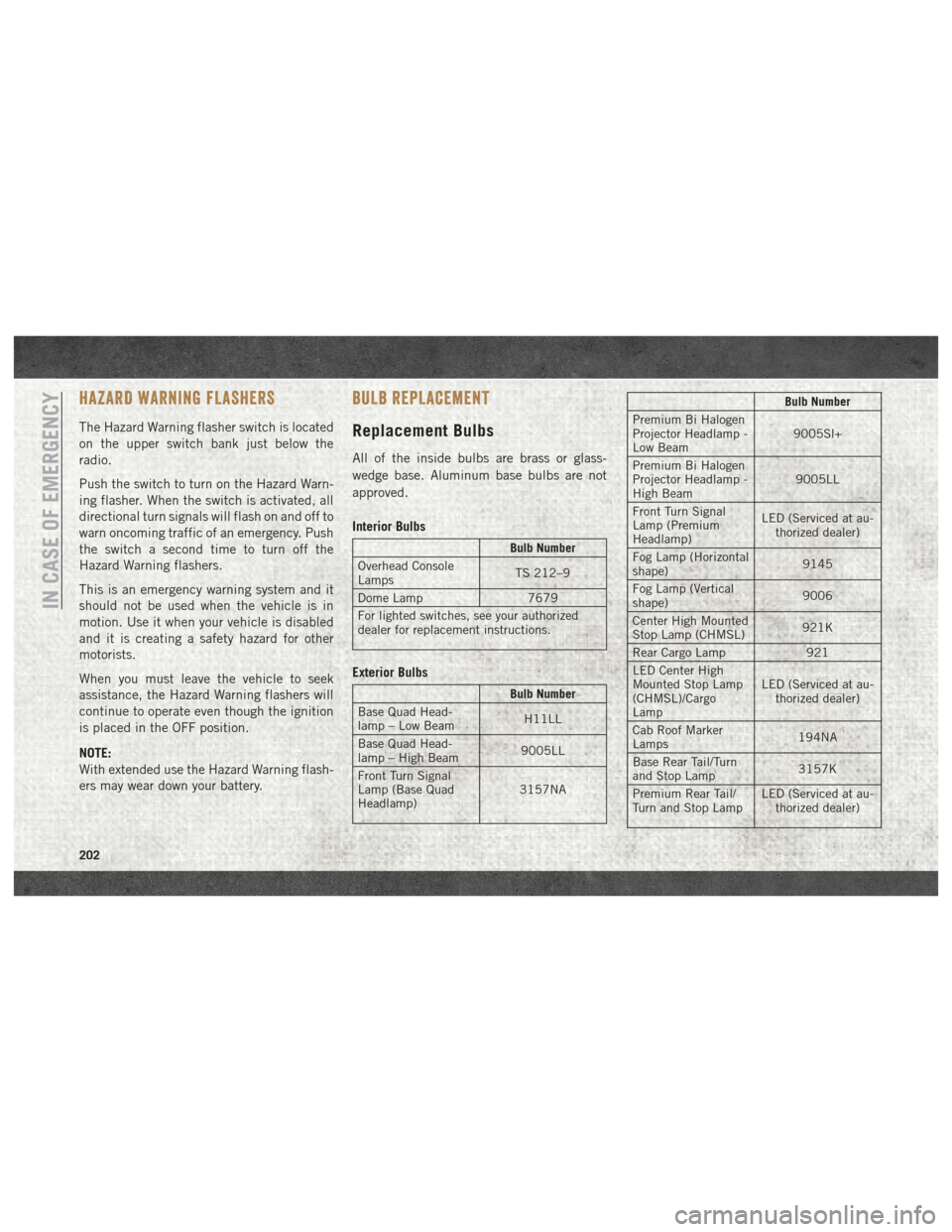

HAZARD WARNING FLASHERS

The Hazard Warning flasher switch is located

on the upper switch bank just below the

radio.

Push the switch to turn on the Hazard Warn-

ing flasher. When the switch is activated, all

directional turn signals will flash on and off to

warn oncoming traffic of an emergency. Push

the switch a second time to turn off the

Hazard Warning flashers.

This is an emergency warning system and it

should not be used when the vehicle is in

motion. Use it when your vehicle is disabled

and it is creating a safety hazard for other

motorists.

When you must leave the vehicle to seek

assistance, the Hazard Warning flashers will

continue to operate even though the ignition

is placed in the OFF position.

NOTE:

With extended use the Hazard Warning flash-

ers may wear down your battery.

BULB REPLACEMENT

Replacement Bulbs

All of the inside bulbs are brass or glass-

wedge base. Aluminum base bulbs are not

approved.

Interior Bulbs

Bulb Number

Overhead Console

Lamps TS 212–9

Dome Lamp 7679

For lighted switches, see your authorized

dealer for replacement instructions.

Exterior Bulbs

Bulb Number

Base Quad Head-

lamp – Low Beam H11LL

Base Quad Head-

lamp – High Beam 9005LL

Front Turn Signal

Lamp (Base Quad

Headlamp) 3157NA

Bulb Number

Premium Bi Halogen

Projector Headlamp -

Low Beam 9005Sl+

Premium Bi Halogen

Projector Headlamp -

High Beam 9005LL

Front Turn Signal

Lamp (Premium

Headlamp) LED (Serviced at au-

thorized dealer)

Fog Lamp (Horizontal

shape) 9145

Fog Lamp (Vertical

shape) 9006

Center High Mounted

Stop Lamp (CHMSL) 921K

Rear Cargo Lamp 921

LED Center High

Mounted Stop Lamp

(CHMSL)/Cargo

Lamp LED (Serviced at au-

thorized dealer)

Cab Roof Marker

Lamps 194NA

Base Rear Tail/Turn

and Stop Lamp 3157K

Premium Rear Tail/

Turn and Stop Lamp LED (Serviced at au-

thorized dealer)

IN CASE OF EMERGENCY

202

Page 206 of 372

CavityCartridge Fuse Micro Fuse Description

F07 40 Amp Green – Starter Solenoid

F08 20 Amp Blue (1500 LD/

Cummins Diesel) –

Emissions Diesel – If Equipped

F09 40 Amp Green (Special

Services Vehicle & Cum- mins Diesel) –

Diesel Fuel Heater – If Equipped

F10 40 Amp Green –Body Controller / Exterior Lighting #2

F10 50 Amp Red –Body Controller / Exterior Lighting #2 – If Equipped with

Stop/Start

F11 30 Amp Pink –Integrated Trailer Brake Module – If Equipped

F12 40 Amp Green –Body Controller #3 / Power Locks

F13 40 Amp Green – Blower Motor

F14 40 Amp Green –Body Controller #4 / Interior Lighting

F16 30 Amp Pink –Smart Bar – If Equipped

F19 20 Amp Blue (1500 LD

Diesel)

30 Amp Pink (Cummins Diesel) –

SCR – If Equipped

F20 30 Amp Pink –Passenger Door Module

F21 30 Amp Pink –Drive Train Control Module

F22 20 Amp Blue

30 Amp Pink (Cummins Diesel) –

Engine Control Module

F23 30 Amp Pink –Body Controller #1 / Interior Lighting

F24 30 Amp Pink –Driver Door Module

IN CASE OF EMERGENCY

204