RAM 1500 2021 Owners Manual

Manufacturer: RAM, Model Year: 2021, Model line: 1500, Model: RAM 1500 2021Pages: 496, PDF Size: 20.89 MB

Page 461 of 496

SERVICING AND MAINTENANCE459

(Continued)

(Continued)

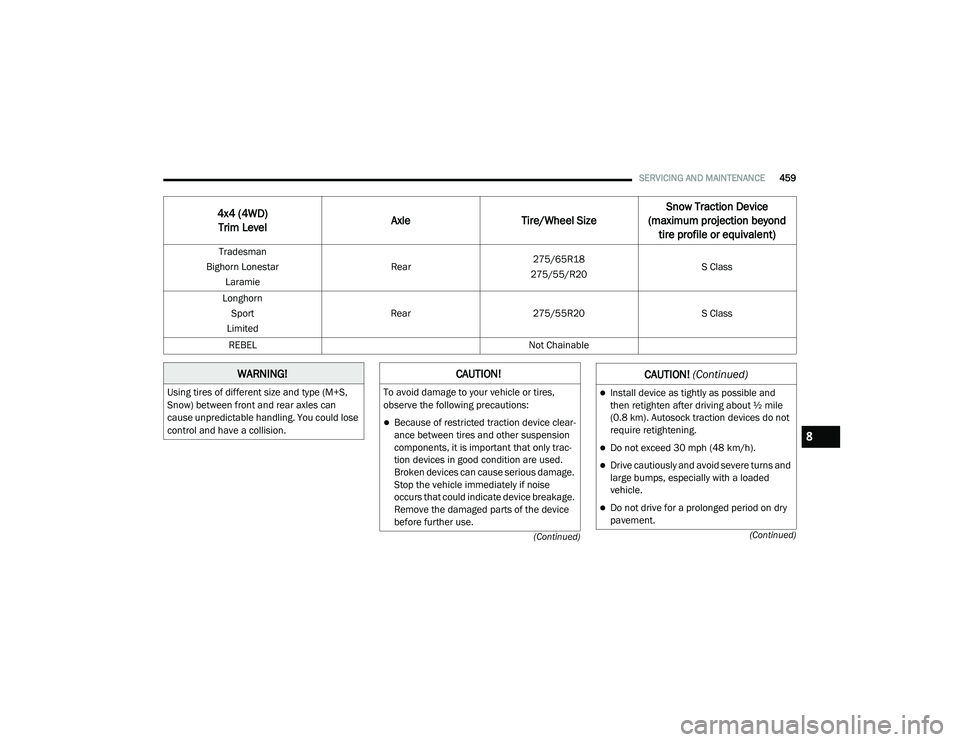

4x4 (4WD)

Trim Level Axle

Tire/Wheel Size Snow Traction Device

(maximum projection beyond tire profile or equivalent)

Tradesman

Bighorn Lonestar Laramie Rear

275/65R18

275/55/R20 S Class

Longhorn Sport

Limited Rear

275/55R20 S Class

REBEL Not Chainable

WARNING!

Using tires of different size and type (M+S,

Snow) between front and rear axles can

cause unpredictable handling. You could lose

control and have a collision.

CAUTION!

To avoid damage to your vehicle or tires,

observe the following precautions:

Because of restricted traction device clear-

ance between tires and other suspension

components, it is important that only trac-

tion devices in good condition are used.

Broken devices can cause serious damage.

Stop the vehicle immediately if noise

occurs that could indicate device breakage.

Remove the damaged parts of the device

before further use.

Install device as tightly as possible and

then retighten after driving about ½ mile

(0.8 km). Autosock traction devices do not

require retightening.

Do not exceed 30 mph (48 km/h).

Drive cautiously and avoid severe turns and

large bumps, especially with a loaded

vehicle.

Do not drive for a prolonged period on dry

pavement.

CAUTION! (Continued)

8

21_DT_OM_EN_USC_t.book Page 459

Page 462 of 496

460SERVICING AND MAINTENANCE

TIRE ROTATION RECOMMENDATIONS

Tires on the front and rear axles of vehicles

operate at different loads and perform different

steering, driving, and braking functions. For

these reasons, they wear at unequal rates.

These effects can be reduced by timely rotation

of tires. The benefits of rotation are especially

worthwhile with aggressive tread designs such

as those on all season type tires. Rotation will

increase tread life, help to maintain mud, snow

and wet traction levels and contribute to a

smooth, quiet ride.

For the proper maintenance intervals

Úpage 395. More frequent rotation is

permissible if desired. The reasons for any rapid or unusual wear should be corrected prior to

rotation being performed.

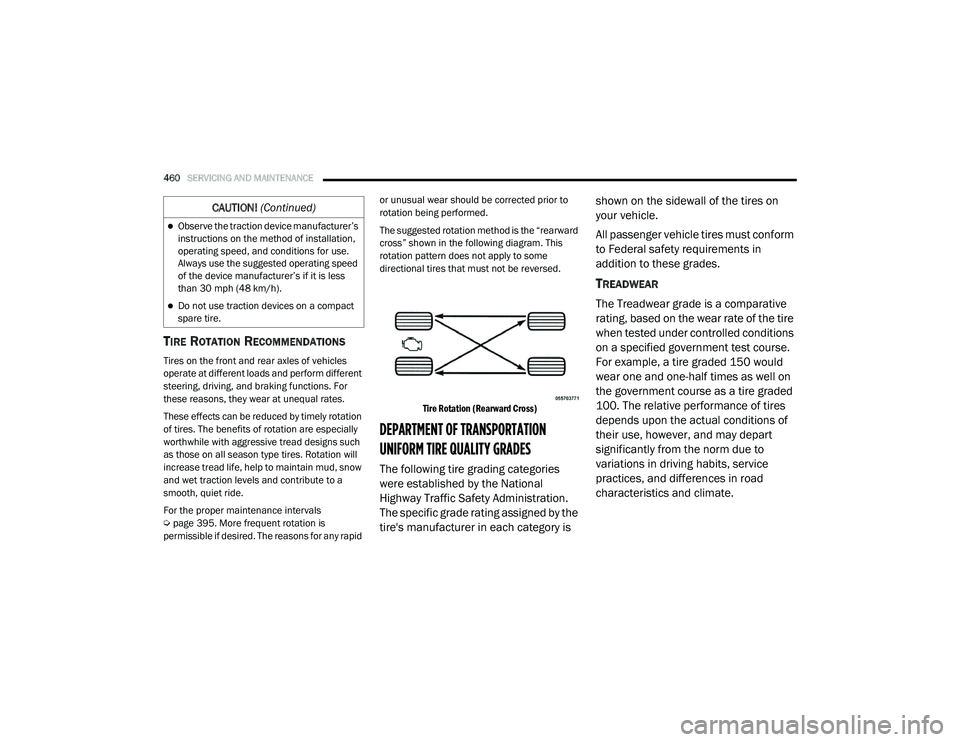

The suggested rotation method is the “rearward

cross” shown in the following diagram. This

rotation pattern does not apply to some

directional tires that must not be reversed.

Tire Rotation (Rearward Cross)

DEPARTMENT OF TRANSPORTATION

UNIFORM TIRE QUALITY GRADES

The following tire grading categories

were established by the National

Highway Traffic Safety Administration.

The specific grade rating assigned by the

tire's manufacturer in each category is shown on the sidewall of the tires on

your vehicle.

All passenger vehicle tires must conform

to Federal safety requirements in

addition to these grades.

TREADWEAR

The Treadwear grade is a comparative

rating, based on the wear rate of the tire

when tested under controlled conditions

on a specified government test course.

For example, a tire graded 150 would

wear one and one-half times as well on

the government course as a tire graded

100. The relative performance of tires

depends upon the actual conditions of

their use, however, and may depart

significantly from the norm due to

variations in driving habits, service

practices, and differences in road

characteristics and climate.

Observe the traction device manufacturer’s

instructions on the method of installation,

operating speed, and conditions for use.

Always use the suggested operating speed

of the device manufacturer’s if it is less

than 30 mph (48 km/h).

Do not use traction devices on a compact

spare tire.

CAUTION!

(Continued)

21_DT_OM_EN_USC_t.book Page 460

Page 463 of 496

SERVICING AND MAINTENANCE461

TRACTION GRADES

The Traction grades, from highest to

lowest, are AA, A, B, and C. These grades

represent the tire's ability to stop on wet

pavement, as measured under

controlled conditions on specified

government test surfaces of asphalt and

concrete. A tire marked C may have poor

traction performance.

TEMPERATURE GRADES

The Temperature grades are A (the

highest), B, and C, representing the tire's

resistance to the generation of heat and

its ability to dissipate heat, when tested

under controlled conditions on a

specified indoor laboratory test wheel. Sustained high temperature can cause

the material of the tire to degenerate

and reduce tire life, and excessive

temperature can lead to sudden tire

failure. The grade C corresponds to a

level of performance, which all

passenger vehicle tires must meet

under the Federal Motor Vehicle Safety

Standard No. 109. Grades B and A

represent higher levels of performance

on the laboratory test wheel, than the

minimum required by law.

STORING THE VEHICLE

If you are storing your vehicle for more than

three weeks, we recommend that you take the

following steps to minimize the drain on your

vehicle's battery:

Disconnect the negative cable from battery.

Any time you store your vehicle or keep it out

of service (i.e., vacation) for two weeks or

more, run the air conditioning system at idle

for about five minutes in the fresh air and

high blower setting. This will ensure

adequate system lubrication to minimize the

possibility of compressor damage when the

system is started again.

BODYWORK

PROTECTION FROM ATMOSPHERIC

A

GENTS

Vehicle body care requirements vary according

to geographic locations and usage. Chemicals

that make roads passable in snow and ice and

those that are sprayed on trees and road

surfaces during other seasons are highly

corrosive to the metal in your vehicle. Outside

parking, which exposes your vehicle to airborne

WARNING!

The traction grade assigned to this tire is

based on straight-ahead braking traction

tests, and does not include acceleration, cor -

nering, hydroplaning, or peak traction charac -

teristics.

WARNING!

The temperature grade for this tire is

established for a tire that is properly inflated

and not overloaded. Excessive speed,

underinflation, or excessive loading, either

separately or in combination, can cause heat

buildup and possible tire failure.

8

21_DT_OM_EN_USC_t.book Page 461

Page 464 of 496

462SERVICING AND MAINTENANCE

contaminants, road surfaces on which the

vehicle is operated, extreme hot or cold weather

and other extreme conditions will have an

adverse effect on paint, metal trim, and

underbody protection.

The following maintenance recommendations

will enable you to obtain maximum benefit from

the corrosion resistance built into your vehicle.

What Causes Corrosion?

Corrosion is the result of deterioration or

removal of paint and protective coatings from

your vehicle.

The most common causes are:

Road salt, dirt and moisture accumulation.

Stone and gravel impact.

Insects, tree sap and tar.

Salt in the air near seacoast localities.

Atmospheric fallout/industrial pollutants.

BODY AND UNDERBODY MAINTENANCE

Cleaning Headlights

Your vehicle is equipped with plastic headlights

and fog lights that are lighter and less susceptible to stone breakage than glass

headlights.

Plastic is not as scratch resistant as glass and

therefore different lens cleaning procedures

must be followed.

To minimize the possibility of scratching the

lenses and reducing light output, avoid wiping

with a dry cloth. To remove road dirt, wash with

a mild soap solution followed by rinsing.

Do not use abrasive cleaning components,

solvents, steel wool or other aggressive

material to clean the lenses.

Tri-Fold Soft Tonneau Cover Care

For cleaning and protecting the vinyl Tri-Fold

Tonneau cover, use Mopar Whitewall & Vinyl

Top Cleaner and Mopar Leather and Vinyl

Conditioner/Protectant.

PRESERVING THE BODYWORK

Washing

Wash your vehicle regularly. Always wash

your vehicle in the shade using Mopar Car

Wash, or a mild car wash soap, and rinse the

panels completely with water.

If insects, tar, or other similar deposits have

accumulated on your vehicle, use Mopar

Super Kleen Bug and Tar Remover to

remove.

Use a high quality cleaner wax, such as

Mopar Cleaner Wax to remove road film,

stains and to protect your paint finish. Use

precautions to not scratch the paint.

Avoid using abrasive compounds and power

buffing that may diminish the gloss or thin

out the paint finish.

CAUTION!

Do not use abrasive or strong cleaning

materials such as steel wool or scouring

powder that will scratch metal and painted

surfaces.

Use of power washers exceeding 1,200 psi

(8,274 kPa) can result in damage or

removal of paint and decals.

21_DT_OM_EN_USC_t.book Page 462

Page 465 of 496

SERVICING AND MAINTENANCE463

(Continued)

Bumper Care

The customer is responsible to clean and

maintain the chrome components of the

vehicle. Washing away road debris and salt

using an automotive soap. Fascia/bumpers

should be cleaned regularly using mild (neutral

Ph) soap and water to maintain their luster and

to prevent corrosion.

Your fascia/bumpers are susceptible to

deterioration caused by salt, sodium chloride,

magnesium chloride, calcium chloride, etc., and

other road chemicals used to melt ice or control

dust on dirt roads. Do not use harsh chemicals

or a stiff brush. They can stain or damage the

protective coating that helps keep them from

corroding and tarnishing.

Special Care

If you drive on salted or dusty roads or if you

drive near the ocean, hose off the undercar -

riage at least once a month.

It is important that the drain holes in the

lower edges of the doors, rocker panels, and

trunk be kept clear and open.

If you detect any stone chips or scratches in

the paint, touch them up immediately.

If your vehicle is damaged due to a collision

or similar cause that destroys the paint and

protective coating, have your vehicle repaired

as soon as possible.

If you carry special cargo such as chemicals,

fertilizers, de-icer salt, etc., be sure that such

materials are well packaged and sealed.

If a lot of driving is done on gravel roads,

consider mud or stone shields behind each

wheel.

Use Mopar Touch Up Paint on scratches as

soon as possible. An authorized dealer has

touch up paint to match the color of your

vehicle.

Spray-On Bedliner – If Equipped

During ownership, the shine and luster of the

Spray-On Bedliner can fade from oxidation, road

dirt, heavy-duty hauling and hard water stains.

Weathering and UV exposure will lead to fading.

To help maintain the appearance of your

Spray-On Bedliner, the manufacturer

recommends you periodically rinse all loose dirt

from your truck bed and clean your truck at

least twice per year using the Mopar Spray-On

Bedliner Conditioner available at a local

authorized dealer.

CAUTION!

Do not use scouring pads, steel wool, a

bristle brush, metal polishes, or oven

cleaner. These products may damage the

bumper’s protective finish. Such damage is

not covered by the New Vehicle Limited

Warranty. Only car wash soap, Mopar

Chrome Cleaner, or equivalent is recom -

mended.

Avoid products or automatic car washes

that use acidic solutions, strong alkaline

additives, or harsh brushes. Many after -

market cleaners and automatic car washes

may damage the bumper’s protective

finish. Such damage is not covered by the

New Vehicle Limited Warranty. Only car

wash soap, Mopar Chrome Cleaner, or

equivalent is recommended.

CAUTION! (Continued)

8

21_DT_OM_EN_USC_t.book Page 463

Page 466 of 496

464SERVICING AND MAINTENANCE

To Help Maintain The Appearance Of Your

Spray-On Bedliner, Follow The Steps Below:

1. Rinse your truck bed out with water to remove any loose dirt and debris.

2. Mix a mild soap or detergent with water. Then apply solution with a soft cloth or

brush.

3. Rinse bedliner with water.

4. Once dry, apply a small amount of Mopar Spray-On Bedliner Conditioner to a moist

towel or sponge and wipe over the entire

surface of the truck bedliner.

Spray-On Bedliners are chemically-resistant to

many different types of chemicals (including

gasoline, oil, hydraulic fluids) for short periods

of time. If a spill occurs on your Spray-On

Bedliner, rinse the truck out as soon as possible

to avoid permanent damage. Repairing The Spray-On Bedliner

While extremely tough, it is possible to damage

a Spray-On Bedliner. One common condition is

when loading a heavy pallet and dragging that

pallet across the floor of the bed. If a nail or

sharp point is exposed under the weight of the

pallet a scratch or tear is possible. While not

covered by your new vehicle warranty, a

cosmetic fix to cover the metal exposed by the

scratch is required. To repair a tear or gouge,

follow the directions provided in the Mopar

Quick Repair Kit.

INTERIORS

SEATS AND FABRIC PARTS

Use Mopar Total Clean to clean fabric

upholstery and carpeting.

Stain Repel Fabric Cleaning Procedure — If

Equipped

Stain Repel seats may be cleaned in the

following manner:

Remove as much of the stain as possible by

blotting with a clean, dry towel.

Blot any remaining stain with a clean, damp

towel.

For tough stains, apply Mopar Total Clean, or

a mild soap solution to a clean, damp cloth

and remove stain. Use a fresh, damp towel to

remove soap residue.

For grease stains, apply Mopar Multi-Purpose

Cleaner to a clean, damp cloth and remove

stain. Use a fresh, damp towel to remove

soap residue.

Do not use any harsh solvents or any other

form of protectants on Stain Repel products.

WARNING!

Do not use silicon-based protection products

to clean your bedliner. Silicon-based products

can become slippery and may result in

personal injury.

WARNING!

Do not use volatile solvents for cleaning

purposes. Many are potentially flammable,

and if used in closed areas they may cause

respiratory harm.

21_DT_OM_EN_USC_t.book Page 464

Page 467 of 496

SERVICING AND MAINTENANCE465

Seat Belt Maintenance

Do not bleach, dye or clean the belts with

chemical solvents or abrasive cleaners. This will

weaken the fabric.

If the belts need cleaning, use a mild soap

solution or lukewarm water. Do not remove the

belts from the vehicle to wash them. Dry with a

soft cloth.

Sun damage can also weaken the fabric.

Replace the belts if they appear frayed or worn

or if the buckles do not work properly.

NOTE:

If the belts retract slowly, inspect the upper

turning loop for soiling. If soiling is present,

clean with a wet soft cloth until all residue is

removed.

PLASTIC AND COATED PARTS

Use Mopar Total Clean to clean vinyl upholstery.

Cleaning Plastic Instrument Cluster

Lenses

The lenses in front of the instruments in this

vehicle are molded in clear plastic. When

cleaning the lenses, care must be taken to

avoid scratching the plastic.

Clean with a wet soft cloth. A mild soap solution

may be used, but do not use high alcohol

content or abrasive cleaners. If soap is used,

wipe clean with a clean damp cloth. Dry with a

soft cloth.

LEATHER SURFACES

Mopar Total Clean is specifically recommended

for leather upholstery.

Your leather upholstery can be best preserved

by regular cleaning with a damp soft cloth.

Small particles of dirt can act as an abrasive

and damage the leather upholstery and should

be removed promptly with a damp cloth.

Stubborn soils can be removed easily with a soft

cloth and Mopar Total Clean. Care should be

taken to avoid soaking your leather upholstery

with any liquid. Please do not use polishes, oils,

cleaning fluids, solvents, detergents, or

ammonia-based cleaners to clean your leather

upholstery.

WARNING!

A frayed or torn belt could rip apart in a

collision and leave you with no protection.

Inspect the belt system periodically, checking

for cuts, frays, or loose parts. Damaged parts

must be replaced immediately. Do not

disassemble or modify the system. Seat belt

assemblies must be replaced after a collision

if they have been damaged (i.e., bent

retractor, torn webbing, etc.).

CAUTION!

Direct contact of air fresheners, insect

repellents, suntan lotions, or hand sani -

tizers to the plastic, painted, or decorated

surfaces of the interior may cause perma -

nent damage. Wipe away immediately.

Damage caused by these type of products

may not be covered by your New Vehicle

Limited Warranty.

8

21_DT_OM_EN_USC_t.book Page 465

Page 468 of 496

466SERVICING AND MAINTENANCE

NOTE:

If equipped with light colored leather, it tends to

show any foreign material, dirt, and fabric dye

transfer more so than darker colors. The leather

is designed for easy cleaning, and FCA recom -

mends Mopar Total Clean leather cleaner

applied on a cloth to clean the leather seats as

needed.GLASS SURFACES

All glass surfaces should be cleaned on a

regular basis with Mopar Glass Cleaner, or any

commercial household-type glass cleaner.

Never use an abrasive type cleaner. Use caution

when cleaning the inside rear window equipped

with electric defrosters or windows equipped

with radio antennas. Do not use scrapers or

other sharp instruments that may scratch the

elements.

When cleaning the rear view mirror, spray

cleaner on the towel or cloth that you are using.

Do not spray cleaner directly on the mirror.

CAUTION!

Do not use Alcohol and Alcohol-based and/or

Ketone based cleaning products to clean

leather upholstery, as damage to the

upholstery may result.

21_DT_OM_EN_USC_t.book Page 466

Page 469 of 496

467

TECHNICAL SPECIFICATIONS

VEHICLE IDENTIFICATION NUMBER

The Vehicle Identification Number (VIN) is found

on the left front corner of the instrument panel,

visible through the windshield.

Vehicle Identification Number

NOTE:

It is illegal to remove or alter the VIN.

BRAKE SYSTEM

If power assist is lost for any reason (for

example, repeated brake applications with the

engine off), the brakes will still function.

However, you will experience a substantial

increase in braking effort to stop the vehicle.

If either the front or rear hydraulic system loses

normal braking capability, the remaining

system will still function with some loss of

overall braking effectiveness. This will be

evident by increased pedal travel during

application, greater pedal force required to slow

or stop, and the “Brake Warning Light” and the

“ABS Warning Light” will activate during brake

use.

WHEEL AND TIRE TORQUE SPECIFICATIONS

Proper lug nut/bolt torque is very important to

ensure that the wheel is properly mounted to

the vehicle. Any time a wheel has been removed

and reinstalled on the vehicle, the lug nuts/

bolts should be torqued using a properly

calibrated torque wrench using a six sided (hex)

deep wall socket.

TORQUE SPECIFICATIONS

**Use only authorized dealer recommended lug nuts/

bolts and clean or remove any dirt or oil before tightening.

Lug Nut/ Bolt

Torque Lug Nut/

Bolt Type **Lug

Nut/Bolt Size Lug Nut/

Bolt

Socket Size

130

Ft-Lbs

(176 N·m) Cone

M14 x

1.50 22 mm

9

21_DT_OM_EN_USC_t.book Page 467

Page 470 of 496

468TECHNICAL SPECIFICATIONS

NOTE:

Do not oil wheel studs. For chrome wheels, do

not substitute with chrome plated wheel nuts.

Inspect the wheel mounting surface prior to

mounting the tire and remove any corrosion or

loose particles.

Wheel Mounting Surface

Tighten the lug nuts/bolts in a star pattern until

each nut/bolt has been tightened twice. Ensure

that the socket is fully engaged on the lug nut/

bolt (do not insert it halfway).

After 25 miles (40 km), check the lug nut/bolt torque to be sure that all the lug nuts/bolts are

properly seated against the wheel.

Four, Five, And Six Lug Nuts/Bolts Torque Pattern

FUEL REQUIREMENTS — GASOLINE ENGINE

While operating on gasoline with the required

octane number, hearing a light knocking sound

from the engine is not a cause for concern.

However, if the engine is heard making a heavy

knocking sound, see a dealer immediately. Use

of gasoline with a lower than recommended octane number can cause engine failure and

may void or not be covered by the New Vehicle

Limited Warranty.

Poor quality gasoline can cause problems such

as hard starting, stalling, and hesitations. If you

experience these symptoms, try another brand

of gasoline before considering service for the

vehicle.

3.6L ENGINE

Do not use E-85 flex fuel or ethanol blends

greater than 15% in this engine.

This engine is designed to meet all

emissions regulations and provide

optimum fuel economy and

performance when using high quality

unleaded “Regular” gasoline having a posted

octane number of 87 as specified by the (R+M)/

2 method. The use of higher octane “Premium”

gasoline is not required, as it will not provide

any benefit over “Regular” gasoline in these

engines.WARNING!

To avoid the risk of forcing the vehicle off the

jack, do not tighten the lug nuts/bolts fully

until the vehicle has been lowered. Failure to

follow this warning may result in personal

injury.

21_DT_OM_EN_USC_t.book Page 468