weight RAM 1500 2022 User Guide

[x] Cancel search | Manufacturer: RAM, Model Year: 2022, Model line: 1500, Model: RAM 1500 2022Pages: 496, PDF Size: 18.03 MB

Page 214 of 496

212STARTING AND OPERATING

TIRE SIZE

The tire size on the Vehicle Certification Label

represents the actual tire size on your vehicle.

Replacement tires must be equal to the load

capacity of this tire size.

RIM SIZE

This is the rim size that is appropriate for the tire

size listed.

INFLATION PRESSURE

This is the cold tire inflation pressure for your

vehicle for all loading conditions up to full Gross

Axle Weight Rating (GAWR).

CURB WEIGHT

The curb weight of a vehicle is defined as the total

weight of the vehicle with all fluids, including

vehicle fuel, at full capacity conditions, and with no

occupants or cargo loaded into the vehicle. The

front and rear curb weight values are determined

by weighing your vehicle on a commercial scale

before any occupants or cargo are added.

LOADING

The actual total weight and the weight of the front

and rear of your vehicle at the ground can best be

determined by weighing it when it is loaded and

ready for operation.

The entire vehicle should first be weighed on a

commercial scale to insure that the Gross Vehicle

Weight Rating (GVWR) has not been exceeded. The

weight on the front and rear of the vehicle should

then be determined separately to be sure that the

load is properly distributed over the front and rear

axle. Weighing the vehicle may show that the Gross

Axle Weight Rating (GAWR) of either the front or

rear axles has been exceeded but the total load is

within the specified GVWR. If so, weight must be

shifted from front to rear or rear to front as

appropriate until the specified weight limitations

are met. Store the heavier items down low and be

sure that the weight is distributed equally. Stow all

loose items securely before driving.

Improper weight distributions can have an adverse

effect on the way your vehicle steers and handles

and the way the brakes operate.

TRAILER TOWING

In this section you will find safety tips and

information on limits to the type of towing you can

reasonably do with your vehicle. Before towing a

trailer, carefully review this information to tow your

load as efficiently and safely as possible.

To maintain the New Vehicle Limited Warranty

coverage, follow the requirements and

recommendations in this manual concerning

vehicles used for trailer towing.

CAUTION!

Do not load your vehicle any heavier than the

GVWR or the maximum front and rear GAWR. If

you do, parts on your vehicle can break, or it can

change the way your vehicle handles. This could

cause you to lose control. Also, overloading can

shorten the life of your vehicle.

22_DT_OM_EN_USC_t.book Page 212

Page 215 of 496

STARTING AND OPERATING213

COMMON TOWING DEFINITIONS

The following trailer towing related definitions will

assist you in understanding the following

information:

Gross Vehicle Weight Rating (GVWR)

The GVWR is the total allowable weight of your

vehicle. This includes driver, passengers, cargo

and tongue weight. The total load must be limited

so that you do not exceed the GVWR Ú page 211.

Gross Trailer Weight (GTW)

The GTW is the weight of the trailer plus the weight

of all cargo, consumables and equipment

(permanent or temporary) loaded in or on the

trailer in its “loaded and ready for operation”

condition.

The recommended way to measure GTW is to put

your fully loaded trailer on a vehicle scale. The

entire weight of the trailer must be supported by

the scale.

Gross Combination Weight Rating (GCWR)

The GCWR is the total allowable weight of your

vehicle and trailer when weighed in combination.

Gross Axle Weight Rating (GAWR)

The GAWR is the maximum capacity of the front

and rear axles. Distribute the load over the front

and rear axles evenly. Make sure that you do not

exceed either front or rear GAWR Úpage 211.

Tongue Weight (TW)

The TW is the downward force exerted on the hitch

ball by the trailer. You must consider this as part of

the load on your vehicle.

Trailer Frontal Area

The frontal area is the maximum height multiplied

by the maximum width of the front of a trailer.

Trailer Sway Control (TSC)

The TSC can be a mechanical telescoping link that

can be installed between the hitch receiver and the

trailer tongue that typically provides adjustable

friction associated with the telescoping motion to

dampen any unwanted trailer swaying motions

while traveling.

The electronic TSC (If equipped) recognizes a

swaying trailer and automatically applies individual

wheel brakes and/or reduces engine power to

attempt to eliminate the trailer sway.

Weight-Carrying Hitch

A weight-carrying hitch supports the trailer tongue

weight, just as if it were luggage located at a hitch

ball or some other connecting point of the vehicle.

These kinds of hitches are commonly used to tow

small and medium sized trailers.

WARNING!

If the gross trailer weight is 5,000 lb (2,267 kg)

or more, it is recommended to use a

weight-distributing hitch to ensure stable

handling of your vehicle. If you use a standard

weight-carrying hitch, you could lose control of

your vehicle and cause a collision.

WARNING!

It is important that you do not exceed the

maximum front or rear GAWR. A dangerous

driving condition can result if either rating is

exceeded. You could lose control of the vehicle

and have a collision.

4

22_DT_OM_EN_USC_t.book Page 213

Page 216 of 496

214STARTING AND OPERATING

Weight-Distributing Hitch

A weight-distributing system works by applying

leverage through spring (load) bars. They are

typically used for heavier loads to distribute trailer

tongue weight to the tow vehicle's front axle and

the trailer axle(s). When used in accordance with

the manufacturer's directions, it provides for a

more level ride, offering more consistent steering

and brake control, thereby enhancing towing

safety. The addition of a friction/hydraulic sway

control also dampens sway caused by traffic and

crosswinds and contributes positively to tow

vehicle and trailer stability. Trailer Sway Control

and a weight-distributing (load equalizing) hitch

are recommended for heavier Tongue Weights

(TW) and may be required depending on vehicle

and trailer configuration/loading to comply with

GAWR requirements.

Without Weight-Distributing Hitch (Incorrect)With Weight-Distributing Hitch (Correct)

Improper Adjustment Of Weight-Distributing Hitch (Incorrect)

WARNING!

An improperly adjusted weight-distributing

hitch system may reduce handling, stability

and braking performance and could result in a

collision.

Weight-distributing systems may not be

compatible with surge brake couplers. Consult

with your hitch and trailer manufacturer or a

reputable Recreational Vehicle dealer for

additional information.

22_DT_OM_EN_USC_t.book Page 214

Page 217 of 496

STARTING AND OPERATING215

RECOMMENDED DISTRIBUTION HITCH

ADJUSTMENT

Towing With Air Suspension — If Equipped

1. Verify that the vehicle is at the normal ride

height.

NOTE:The vehicle must remain in the engine run position

with all doors closed while attaching a trailer for

proper leveling of the air suspension system.

2. Position the truck to be ready to connect to the trailer (do not connect the trailer).

3. Enable tire jack mode through the instrument cluster or touchscreen radio settings. Tire jack

mode will be canceled and the procedure must

be restarted if the vehicle is driven at speeds

above 5 mph (8 km/h).

4. Measure the height from the top of the front wheel opening on the fender to ground; this is

height H1.

Measuring Height (H)

5. Attach the trailer to the vehicle without the weight-distributing bars connected.

6. Measure the height from the top of the front wheel opening on the fender to the ground;

this is height H2.

7. Install and adjust the tension in the weight-distributing bars per the

manufacturer’s recommendations so that the

height of the front fender is approximately

(H2-H1)/3+H1 (about 1/3 the difference

between H2 and H1 above normal ride height

[H1]). 8. Use the instrument cluster or touchscreen

radio settings and switch off tire jack mode.

Make sure the truck returns to normal ride

height. Perform a visual inspection of the

trailer and weight-distributing hitch to confirm

the manufacturer’s recommendations have

been met.

9. The truck can now be driven.

NOTE:For all towing conditions, we recommend towing

with Tow/Haul mode engaged.

Measurement Example Example Height (mm)

H1

925

H2 946

H2-H1 21

(H2-H1)/3 7

(H2-H1)/3 + H1 932

4

22_DT_OM_EN_USC_t.book Page 215

Page 218 of 496

216STARTING AND OPERATING

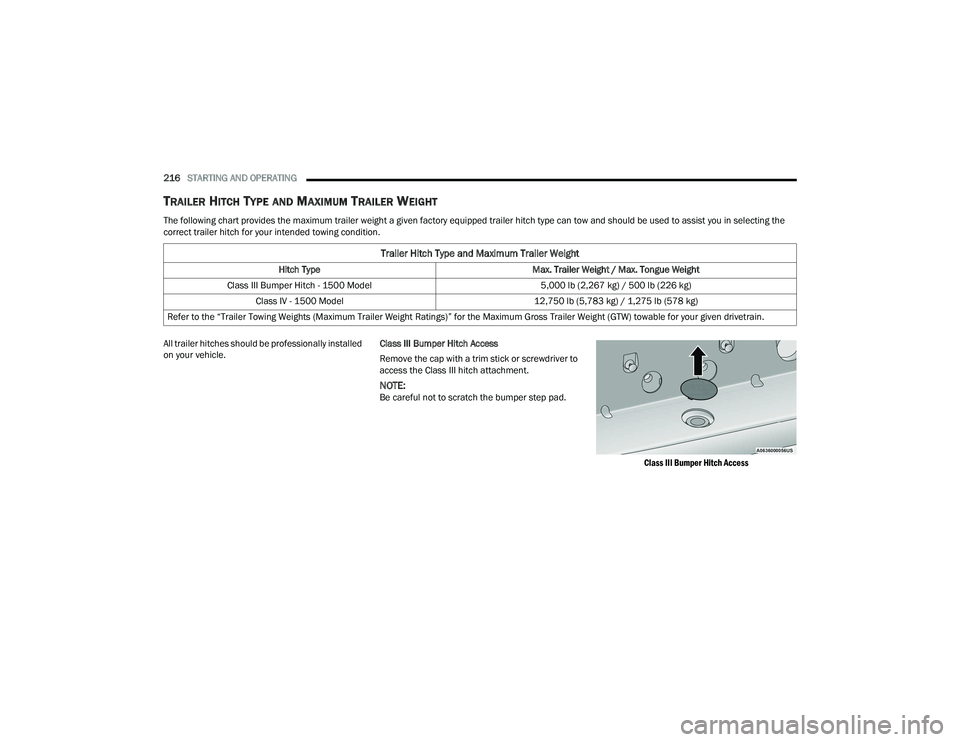

TRAILER HITCH TYPE AND MAXIMUM TRAILER WEIGHT

The following chart provides the maximum trailer weight a given factory equipped trailer hitch type can tow and should be used to assist you in selecting the

correct trailer hitch for your intended towing condition.

All trailer hitches should be professionally installed

on your vehicle. Class III Bumper Hitch Access

Remove the cap with a trim stick or screwdriver to

access the Class III hitch attachment.

NOTE:Be careful not to scratch the bumper step pad.

Class III Bumper Hitch Access

Trailer Hitch Type and Maximum Trailer Weight

Hitch TypeMax. Trailer Weight / Max. Tongue Weight

Class III Bumper Hitch - 1500 Model 5,000 lb (2,267 kg) / 500 lb (226 kg)

Class IV - 1500 Model 12,750 lb (5,783 kg) / 1,275 lb (578 kg)

Refer to the “Trailer Towing Weights (Maximum Trailer Weight Ratings)” for the Maximum Gross Trailer Weight (GTW) towable for your given drivetrain.

22_DT_OM_EN_USC_t.book Page 216

Page 219 of 496

STARTING AND OPERATING217

TRAILER TOWING WEIGHTS (MAXIMUM

T

RAILER WEIGHT RATINGS)

NOTE:For trailer towing information (maximum trailer

weight ratings) refer to the following website

addresses:

ramtrucks.com/en/towing_guide/

ramtruck.ca (Canada)

rambodybuilder.com

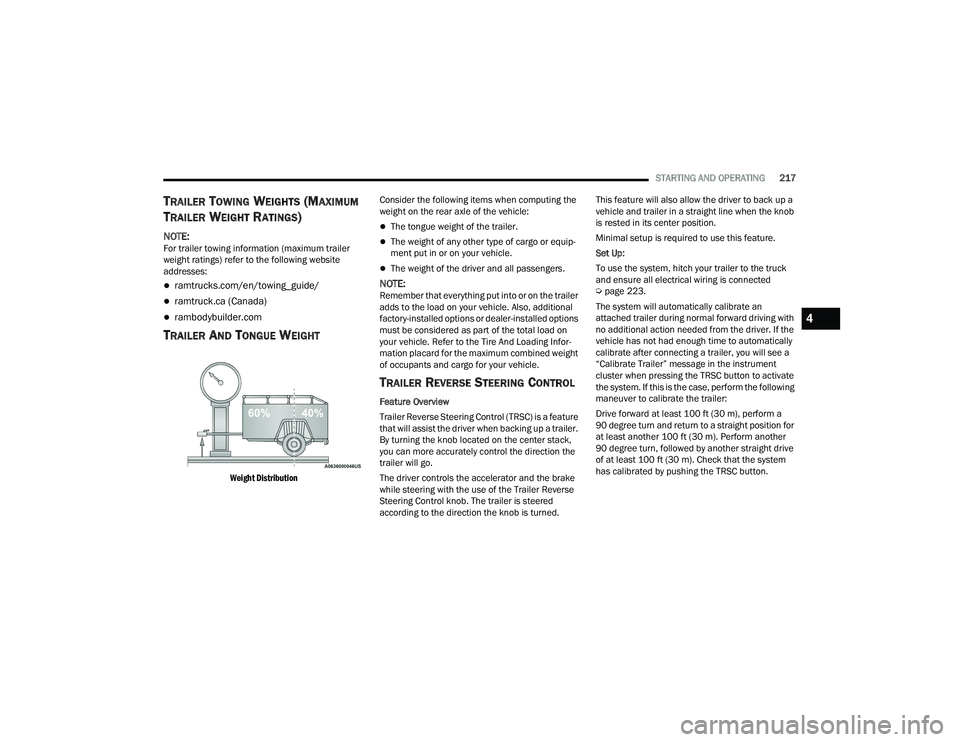

TRAILER AND TONGUE WEIGHT

Weight Distribution

Consider the following items when computing the

weight on the rear axle of the vehicle:

The tongue weight of the trailer.

The weight of any other type of cargo or equip

-

ment put in or on your vehicle.

The weight of the driver and all passengers.

NOTE:Remember that everything put into or on the trailer

adds to the load on your vehicle. Also, additional

factory-installed options or dealer-installed options

must be considered as part of the total load on

your vehicle. Refer to the Tire And Loading Infor -

mation placard for the maximum combined weight

of occupants and cargo for your vehicle.

TRAILER REVERSE STEERING CONTROL

Feature Overview

Trailer Reverse Steering Control (TRSC) is a feature

that will assist the driver when backing up a trailer.

By turning the knob located on the center stack,

you can more accurately control the direction the

trailer will go.

The driver controls the accelerator and the brake

while steering with the use of the Trailer Reverse

Steering Control knob. The trailer is steered

according to the direction the knob is turned. This feature will also allow the driver to back up a

vehicle and trailer in a straight line when the knob

is rested in its center position.

Minimal setup is required to use this feature.

Set Up:

To use the system, hitch your trailer to the truck

and ensure all electrical wiring is connected

Ú

page 223.

The system will automatically calibrate an

attached trailer during normal forward driving with

no additional action needed from the driver. If the

vehicle has not had enough time to automatically

calibrate after connecting a trailer, you will see a

“Calibrate Trailer” message in the instrument

cluster when pressing the TRSC button to activate

the system. If this is the case, perform the following

maneuver to calibrate the trailer:

Drive forward at least 100 ft (30 m), perform a

90 degree turn and return to a straight position for

at least another 100 ft (30 m). Perform another 90 degree turn, followed by another straight drive

of at least 100 ft (30 m). Check that the system has calibrated by pushing the TRSC button.

4

22_DT_OM_EN_USC_t.book Page 217

Page 222 of 496

220STARTING AND OPERATING

(Continued)

Perform the maintenance listed in the Scheduled

Servicing section for the proper maintenance

intervals

Úpage 393. When towing a trailer, never

exceed the GAWR or GCWR ratings.

Towing Requirements — Tires

Do not attempt to tow a trailer while using a

compact spare tire.

Do not drive more than 50 mph (80 km/h) when

towing while using a full size spare tire.

Proper tire inflation pressures are essential to

the safe and satisfactory operation of your

vehicle.

Check the trailer tires for proper tire inflation

pressures before trailer usage.

Check for signs of tire wear or visible tire

damage before towing a trailer.

Replacing tires with a higher load carrying

capacity will not increase the vehicle's GVWR

and GAWR limits.

For further information Ú page 444.

Towing Requirements — Trailer Brakes

Do not interconnect the hydraulic brake system

or vacuum system of your vehicle with that of

the trailer.

An electronically actuated trailer brake

controller is required when towing a trailer with

electronically actuated brakes. When towing a

trailer equipped with a hydraulic surge actuated

brake system, an electronic brake controller is

not required.

Then, during the first 500 miles (805 km) that

a trailer is towed, do not drive over 50 mph

(80 km/h) and do not make starts at full

throttle. This helps the engine and other parts

of the vehicle wear in at the heavier loads.

WARNING!

Make certain that the load is secured in the

trailer and will not shift during travel. When

trailering cargo that is not fully secured,

dynamic load shifts can occur that may be

difficult for the driver to control. You could lose

control of your vehicle and have a collision.

When hauling cargo or towing a trailer, do not

overload your vehicle or trailer. Overloading

can cause a loss of control, poor performance

or damage to brakes, axle, engine, transmis -

sion, steering, suspension, chassis structure

or tires.

CAUTION!

Safety chains must always be used between

your vehicle and trailer. Always connect the

chains to the hook retainers of the vehicle

hitch. Cross the chains under the trailer

tongue and allow enough slack for turning

corners.

Vehicles with trailers should not be parked on

a grade. When parking, apply the parking

brake on the tow vehicle. Put the tow vehicle

transmission in PARK. For four-wheel drive

vehicles, make sure the transfer case is not in

NEUTRAL. Always, block or "chock" the trailer

wheels.

GCWR must not be exceeded.

Total weight must be distributed between the

tow vehicle and the trailer such that the

following four ratings are not exceeded :

GVWR

GTW

GAWR

Tongue weight rating for the trailer hitch

utilized.

WARNING!

22_DT_OM_EN_USC_t.book Page 220

Page 227 of 496

STARTING AND OPERATING225

TOWING TIPS

Before towing, practice turning, stopping, and

backing up the trailer in an area located away from

heavy traffic.

Automatic Transmission

The DRIVE range can be selected when towing. The

transmission controls include a drive strategy to

avoid frequent shifting when towing. However, if

frequent shifting does occur while in DRIVE, select

TOW/HAUL mode or select a lower gear range

(using the Electronic Range Select (ERS) shift

control).

NOTE:Using TOW/HAUL mode or selecting a lower gear

range (using the ERS shift control) while operating

the vehicle under heavy loading conditions will

improve performance and extend transmission life

by reducing excessive shifting and heat build up.

This action will also provide better engine braking.

Tow/Haul Mode

To reduce potential for automatic transmission

overheating, activate TOW/HAUL mode when

driving in hilly areas, or select a lower gear range

(using the (ERS) shift control) on more severe

grades.

Cruise Control — If Equipped

Do not use on hilly terrain or with heavy loads.

When using the Cruise Control, if you experience

speed drops greater than 10 mph (16 km/h),

disengage until you can get back to cruising

speed.

Use Cruise Control in flat terrain and with light

loads to maximize fuel efficiency.

Air Suspension System

To aid in attaching/detaching the trailer from the

vehicle, the air suspension system can be used

Úpage 165. Selecting Tow/Haul or connecting a

trailer with an Integrated Trailer Brake Module

(ITBM) will disable Automatic Aero mode to avoid

height changes while towing and shifting loads or

tongue weights.

NOTE:The vehicle must remain in the engine running

position while attaching a trailer for proper leveling

of the air suspension system.

SNOWPLOW

Snowplow Prep Packages are available as a factory

installed option. These packages include

components necessary to equip your vehicle with a

snowplow.

NOTE:Before installation of a snowplow it is highly recom -

mended that the owner/installer obtain and follow

the recommendations contained within the current

Body Builder’s Guide. See an authorized dealer,

installer or snowplow manufacturer for this infor -

mation. There are unique electrical systems that

must be connected to properly ensure operator

safety and prevent overloading vehicle systems.

WARNING!

Attaching a snowplow to this vehicle could

adversely affect performance of the airbag

system in a collision. Do not expect that the

airbag will perform as described earlier in this

manual.

CAUTION!

The “Lamp Out” indicator could illuminate if

exterior lamps are not properly installed.

4

22_DT_OM_EN_USC_t.book Page 225

Page 228 of 496

226STARTING AND OPERATING

BEFORE PLOWING

Check the hydraulic system for leaks and proper

fluid level.

Check the mounting bolts and nuts for proper

tightness.

Check the runners and cutting edge for exces -

sive wear. The cutting edge should be ¼ to

½ inches (6 cm to 1.2 cm) above ground in

snow plowing position.

Check that snowplow lighting is connected and

functioning properly.

SNOWPLOW PREP PACKAGE MODEL

A

VAILABILITY

For Information about snowplow applications visit

www.ramtrucks.com or refer to the current Body

Builder’s Guide.

1. The maximum number of occupants in the

truck should not exceed two.

2. The total GVWR, Front GAWR or the Rear GAWR should never be exceeded.

3. Cargo capacity will be reduced by the addition of options or passengers, etc.

The loaded vehicle weight, including the snowplow

system, all aftermarket accessories, driver,

passengers, options, and cargo, must not exceed

either the Gross Vehicle Weight (GVWR) or Gross Axle Weight (GAWR) ratings. These weights

are specified on the Safety Compliance

Certification Label on the driver's side door

opening.

NOTE:Detach the snowplow when transporting

passengers.

Vehicle front end wheel alignment was set to

specifications at the factory without consideration

for the weight of the plow. Front end toe-in should

be checked and reset if necessary at the beginning

and end of the snowplow season. This will help

prevent uneven tire wear.

The blade should be lowered whenever the vehicle

is parked.

Maintain and operate your vehicle and snowplow

equipment following the recommendations

provided by the specific snowplow manufacturer.

OVER THE ROAD OPERATION WITH

S

NOWPLOW ATTACHED

The blade restricts air flow to the radiator and

causes the engine to operate at higher than

normal temperatures. Therefore, when

transporting the plow, angle the blade completely

and position it as low as road or surface conditions

permit. Do not exceed 40 mph (64 km/h). The

operator should always maintain a safe stopping

distance and allow adequate passing clearance.

OPERATING TIPS

Under ideal snow plowing conditions, 20 mph

(32 km/h) should be maximum operating speed.

The operator should be familiar with the area and

surface to be cleaned. Reduce speed and use

extreme caution when plowing unfamiliar areas or

under poor visibility.

GENERAL MAINTENANCE

Snowplows should be maintained in accordance

with the plow manufacturer's instructions.

Keep all snowplow electrical connections and

battery terminals clean and free of corrosion.

When plowing snow, to avoid transmission and

drivetrain damage, the following precautions

should be observed:

Operate with transfer case in 4WD LOW when

plowing small or congested areas where speeds

are not likely to exceed 15 mph (24 km/h).

At higher speeds operate in 4WD HIGH.

Vehicles with automatic transmissions should

use 4WD LOW when plowing deep or heavy

snow for extended periods of time to avoid

transmission overheating.

Do not shift the transmission unless the engine

has returned to idle and wheels have stopped.

Make a practice of stepping on the brake pedal

while shifting the transmission.

22_DT_OM_EN_USC_t.book Page 226

Page 321 of 496

SAFETY319

Rain Brake Support (RBS)

RBS may improve braking performance in wet

conditions. It will periodically apply a small amount

of brake pressure to remove any water buildup on

the front brake rotors. It functions when the

windshield wipers are in LO or HI speed. When Rain

Brake Support is active, there is no notification to

the driver and no driver interaction is required.

Ready Alert Braking (RAB)

RAB may reduce the time required to reach full

braking during emergency braking situations. It

anticipates when an emergency braking situation

may occur by monitoring how fast the throttle is

released by the driver. The Electronic Brake

Control system will prepare the brake system for a

panic stop.

Traction Control System (TCS)

The TCS monitors the amount of wheel spin of

each of the driven wheels. If wheel spin is

detected, the TCS may apply brake pressure to the

spinning wheel(s) and/or reduce engine power to

provide enhanced acceleration and stability. A

feature of the TCS, Brake Limited Differential (BLD)

functions similarly to a limited slip differential and

controls the wheel spin across a driven axle. If one

wheel on a driven axle is spinning faster than the

other, the system will apply the brake of the spinning wheel. This will allow more engine torque

to be applied to the wheel that is not spinning. BLD

may remain enabled even if TCS and Electronic

Stability Control (ESC) are in reduced modes.

Trailer Sway Control (TSC)

TSC uses sensors in the vehicle to recognize an

excessively swaying trailer and will take the

appropriate actions to attempt to stop the sway.

NOTE:TSC cannot stop all trailers from swaying. Always

use caution when towing a trailer and follow the

trailer tongue weight recommendations

Ú

page 212.

When TSC is functioning, the ESC Activation/

Malfunction Indicator Light will flash, the engine

power may be reduced and you may feel the

brakes being applied to individual wheels to

attempt to stop the trailer from swaying. TSC is

disabled when the ESC system is in the “Partial

Off” or “Full Off” modes.

AUXILIARY DRIVING SYSTEMS

BLIND SPOT MONITORING (BSM) —

I

F EQUIPPED

BSM uses two radar sensors, located inside the

taillights, to detect highway licensable vehicles

(automobiles, trucks, motorcycles, etc.) that enter

the blind spot zones from the rear/front/side of

the vehicle.

Rear Detection Zones

When the vehicle is started, the BSM Warning Light

will momentarily illuminate in both outside

rearview mirrors to let the driver know that the

system is operational. The BSM system sensors

operate when the vehicle is in any forward gear

and enters standby mode when the vehicle is in

PARK.

WARNING!

If TSC activates while driving, slow the vehicle

down, stop at the nearest safe location, and

adjust the trailer load to eliminate trailer sway.

6

22_DT_OM_EN_USC_t.book Page 319