flat tire RAM 1500 2022 Owner's Manual

[x] Cancel search | Manufacturer: RAM, Model Year: 2022, Model line: 1500, Model: RAM 1500 2022Pages: 496, PDF Size: 18.03 MB

Page 381 of 496

IN CASE OF EMERGENCY379

(Continued)

4. Rotate the lug wrench handle counter-

clockwise until the spare tire is on the ground

with enough cable slack to allow you to pull it

out from under the vehicle.

Rotating The Lug Wrench Handle

5. Pull the spare tire out from under the vehicle to gain access to the spare tire retainer.

Pulling The Spare Tire Out

6. Lift the spare tire with one hand to give

clearance to tilt the retainer at the end of the

cable.

7. Pull the retainer through the center of the wheel.

Disengaging The Retainer

JACKING INSTRUCTIONS

WARNING!

Carefully follow these tire changing warnings to

help prevent personal injury or damage to your

vehicle:

Always park on a firm, level surface as far from

the edge of the roadway as possible before

raising the vehicle.

Turn on the Hazard Warning Flashers.

Apply the parking brake firmly and set the

transmission in PARK.

Block the wheel diagonally opposite the wheel

to be raised.

Never start or run the engine with the vehicle

on a jack.

Do not let anyone sit in the vehicle when it is

on a jack.

Do not get under the vehicle when it is on a

jack. If you need to get under a raised vehicle,

take it to a service center where it can be

raised on a lift.

Only use the jack in the positions indicated

and for lifting this vehicle during a tire change.

If working on or near a roadway, be extremely

careful of motor traffic.

To assure that spare tires, flat or inflated, are

securely stowed, spares must be stowed with

the valve stem facing the ground.

WARNING!

7

22_DT_OM_EN_USC_t.book Page 379

Page 384 of 496

382IN CASE OF EMERGENCY

7. Lower the vehicle to the ground and finish tightening the lug nuts. Push down on the

wrench handle for increased leverage. Tighten

the lug nuts in a star pattern until each lug nut

has been tightened twice Ú page 466. If in

doubt about the correct tightness, have them

checked with a torque wrench by an

authorized dealer or at a service station.

8. If your vehicle is equipped with a wheel center cap, install the cap and remove the wheel

blocks. Do not install chrome or aluminum

wheel center caps on the spare wheel. This

may result in cap damage.

9. Lower the jack to its fully closed position. Stow the replaced tire, and secure the jack and tools

in the proper location.

10. Adjust the tire pressure when possible.

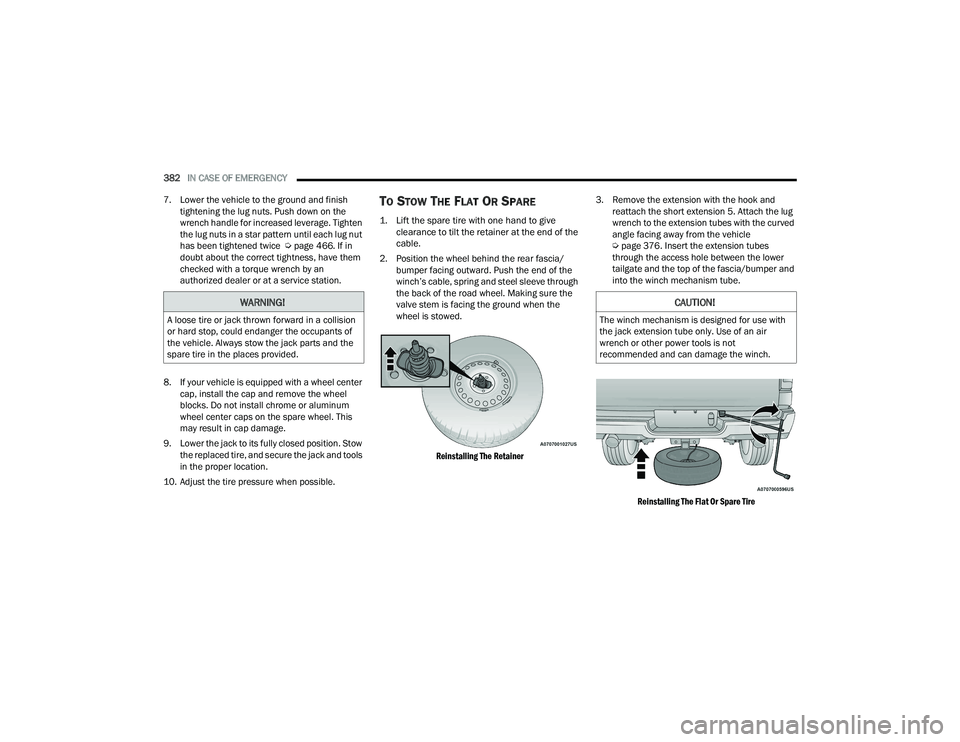

TO STOW THE FLAT OR SPARE

1. Lift the spare tire with one hand to give clearance to tilt the retainer at the end of the

cable.

2. Position the wheel behind the rear fascia/ bumper facing outward. Push the end of the

winch’s cable, spring and steel sleeve through

the back of the road wheel. Making sure the

valve stem is facing the ground when the

wheel is stowed.

Reinstalling The Retainer

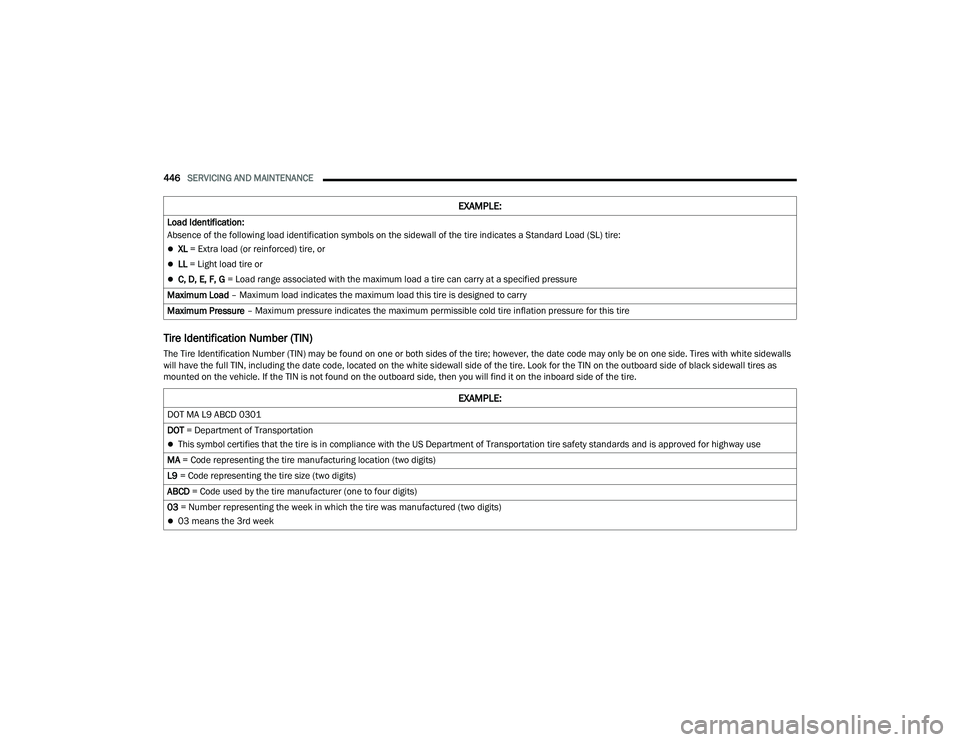

3. Remove the extension with the hook and

reattach the short extension 5. Attach the lug

wrench to the extension tubes with the curved

angle facing away from the vehicle

Úpage 376. Insert the extension tubes

through the access hole between the lower

tailgate and the top of the fascia/bumper and

into the winch mechanism tube.

Reinstalling The Flat Or Spare Tire

WARNING!

A loose tire or jack thrown forward in a collision

or hard stop, could endanger the occupants of

the vehicle. Always stow the jack parts and the

spare tire in the places provided.

CAUTION!

The winch mechanism is designed for use with

the jack extension tube only. Use of an air

wrench or other power tools is not

recommended and can damage the winch.

22_DT_OM_EN_USC_t.book Page 382

Page 385 of 496

IN CASE OF EMERGENCY383

4. Rotate the lug wrench handle clockwise until the wheel is drawn into place against the

underside of the vehicle. Continue to rotate

until you feel the winch mechanism slip, or

click three or four times. It cannot be

overtightened. Push against the tire several

times to ensure it is firmly in place.

Rotating The Lug Wrench Handle

NOTE:Have the flat tire repaired or replaced immediately.

REINSTALLING THE JACK AND TOOLS

1. Tighten the jack all the way down by turning the jack turn-screw counterclockwise until the

jack is snug.

2. Position the jack and tool bag. Make sure the lug wrench is under the jack near the jack

turn-screw.

Jack And Tool Bag

3. Secure the tool bag straps to the jack.

Jack And Tools Tied

WARNING!

A loose tire or jack thrown forward in a collision

or hard stop could endanger the occupants of

the vehicle. Always stow the jack parts and the

spare tire in the places provided. Have the

deflated (flat) tire repaired or replaced

immediately.

7

22_DT_OM_EN_USC_t.book Page 383

Page 392 of 496

390IN CASE OF EMERGENCY

NOTE:Shifts between DRIVE and REVERSE can only be

achieved at wheel speeds of 5 mph (8 km/h) or

less. Whenever the transmission remains in

NEUTRAL (N) for more than two seconds, you must

press the brake pedal to engage DRIVE or

REVERSE.

Push the ESC OFF button to place the Electronic

Stability Control (ESC) system in “Partial OFF”

mode, before rocking the vehicle Ú page 314.

Once the vehicle has been freed, push the ESC OFF

button to restore “ESC On” mode.TOWING A DISABLED VEHICLE

This section describes procedures for towing a

disabled vehicle using a commercial towing

service.

If the transmission and drivetrain are operable,

disabled vehicles may also be towed as described

on Ú page 227.

NOTE:

Vehicles equipped with the Active-Level Four

Corner Air Suspension System must be placed in

Transport mode, before tying them down (from the

body) on a trailer or flatbed truck Ú page 165. If

the vehicle cannot be placed in Transport mode

(for example, engine will not run), tie-downs must

be fastened to the axles (not to the body). Failure

to follow these instructions may cause fault codes

to be set and/or cause loss of proper tie-down

tension.

CAUTION!

Racing the engine or spinning the wheels may

lead to transmission overheating and failure.

Allow the engine to idle with the transmission

in NEUTRAL for at least one minute after every

five rocking-motion cycles. This will minimize

overheating and reduce the risk of transmis -

sion failure during prolonged efforts to free a

stuck vehicle.

When “rocking” a stuck vehicle by shifting

between DRIVE and REVERSE, do not spin the

wheels faster than 15 mph (24 km/h), or

drivetrain damage may result.

Revving the engine or spinning the wheels too

fast may lead to transmission overheating and

failure. It can also damage the tires. Do not

spin the wheels above 30 mph (48 km/h)

while in gear (no transmission shifting occur -

ring).

WARNING!

Fast spinning tires can be dangerous. Forces

generated by excessive wheel speeds may

cause damage, or even failure, of the axle and

tires. A tire could explode and injure someone.

Do not spin your vehicle's wheels faster than

30 mph (48 km/h) or for longer than 30

seconds continuously without stopping when

you are stuck and do not let anyone near a

spinning wheel, no matter what the speed.

22_DT_OM_EN_USC_t.book Page 390

Page 400 of 496

398SERVICING AND MAINTENANCE

SCHEDULED SERVICING — DIESEL ENGINE

Your vehicle is equipped with an automatic oil

change indicator system. The oil change indicator

system will remind you that it is time to take your

vehicle in for scheduled maintenance.

Based on engine operation conditions, the oil

change indicator message will illuminate. This

means that service is required for your vehicle.

Operating conditions such as frequent short-trips,

trailer tow, extremely hot or cold ambient

temperatures will influence when the “Oil Change

Required” message is displayed. Have your vehicle

serviced as soon as possible, within the next

500 miles (805 km). An authorized dealer will reset the oil change

indicator message after completing the scheduled

oil change. If a scheduled oil change is performed

by someone other than an authorized dealer, the

message can be reset by referring to the steps

described under Instrument Cluster Display

Ú

page 114.

NOTE:Under no circumstances should oil change

intervals exceed 10,000 miles (16,000 km) or

12 months, whichever comes first. Once A Month Or Before A Long Trip:

Check engine oil level.

Check windshield washer fluid level.

Check the tire inflation pressures and look for

unusual wear or damage.

Check the fluid levels of the coolant reservoir,

brake master cylinder, and power steering, and

fill as needed.

Check function of all interior and exterior lights.

22_DT_OM_EN_USC_t.book Page 398

Page 448 of 496

446SERVICING AND MAINTENANCE

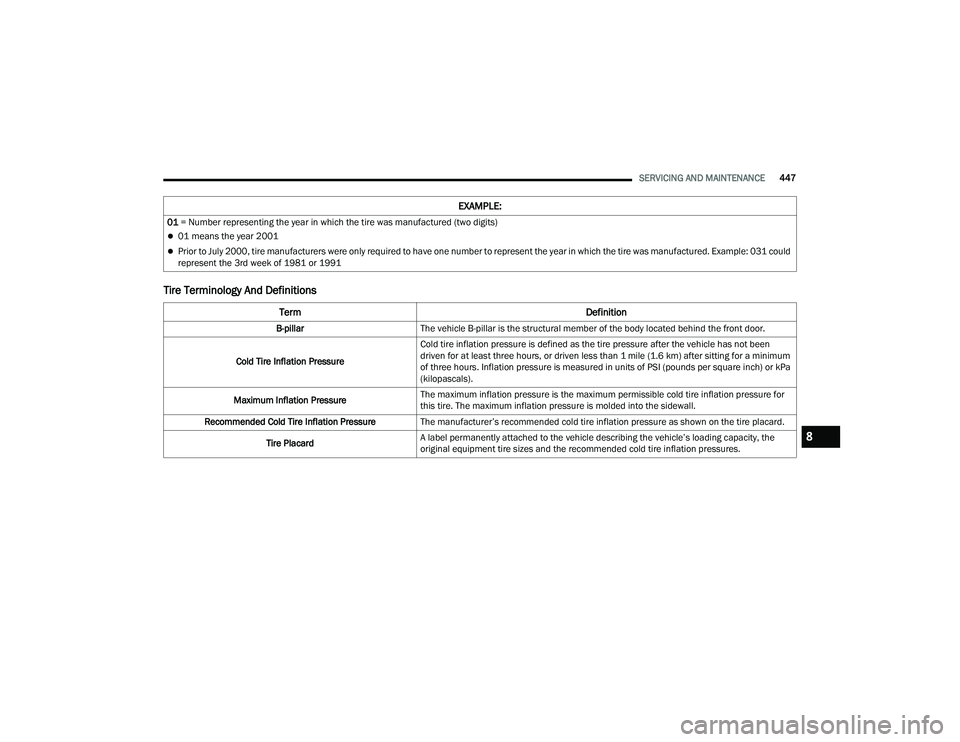

Tire Identification Number (TIN)

The Tire Identification Number (TIN) may be found on one or both sides of the tire; however, the date code may only be on one side. Tires with white sidewalls

will have the full TIN, including the date code, located on the white sidewall side of the tire. Look for the TIN on the outboard side of black sidewall tires as

mounted on the vehicle. If the TIN is not found on the outboard side, then you will find it on the inboard side of the tire.Load Identification:

Absence of the following load identification symbols on the sidewall of the tire indicates a Standard Load (SL) tire:

XL = Extra load (or reinforced) tire, or

LL

= Light load tire or

C, D, E, F, G = Load range associated with the maximum load a tire can carry at a specified pressure

Maximum Load – Maximum load indicates the maximum load this tire is designed to carry

Maximum Pressure – Maximum pressure indicates the maximum permissible cold tire inflation pressure for this tire

EXAMPLE:

EXAMPLE:

DOT MA L9 ABCD 0301

DOT = Department of Transportation

This symbol certifies that the tire is in compliance with the US Department of Transportation tire safety standards and is approved for highway use

MA = Code representing the tire manufacturing location (two digits)

L9 = Code representing the tire size (two digits)

ABCD = Code used by the tire manufacturer (one to four digits)

03 = Number representing the week in which the tire was manufactured (two digits)

03 means the 3rd week

22_DT_OM_EN_USC_t.book Page 446

Page 449 of 496

SERVICING AND MAINTENANCE447

Tire Terminology And Definitions

01 = Number representing the year in which the tire was manufactured (two digits)

01 means the year 2001

Prior to July 2000, tire manufacturers were only required to have one number to represent the year in which the tire was manufactured. Example: 031 could

represent the 3rd week of 1981 or 1991

Term Definition

B-pillarThe vehicle B-pillar is the structural member of the body located behind the front door.

Cold Tire Inflation Pressure Cold tire inflation pressure is defined as the tire pressure after the vehicle has not been

driven for at least three hours, or driven less than 1 mile (1.6 km) after sitting for a minimum

of three hours. Inflation pressure is measured in units of PSI (pounds per square inch) or kPa

(kilopascals).

Maximum Inflation Pressure The maximum inflation pressure is the maximum permissible cold tire inflation pressure for

this tire. The maximum inflation pressure is molded into the sidewall.

Recommended Cold Tire Inflation Pressure The manufacturer’s recommended cold tire inflation pressure as shown on the tire placard.

Tire Placard A label permanently attached to the vehicle describing the vehicle’s loading capacity, the

original equipment tire sizes and the recommended cold tire inflation pressures.

EXAMPLE:

8

22_DT_OM_EN_USC_t.book Page 447

Page 450 of 496

448SERVICING AND MAINTENANCE

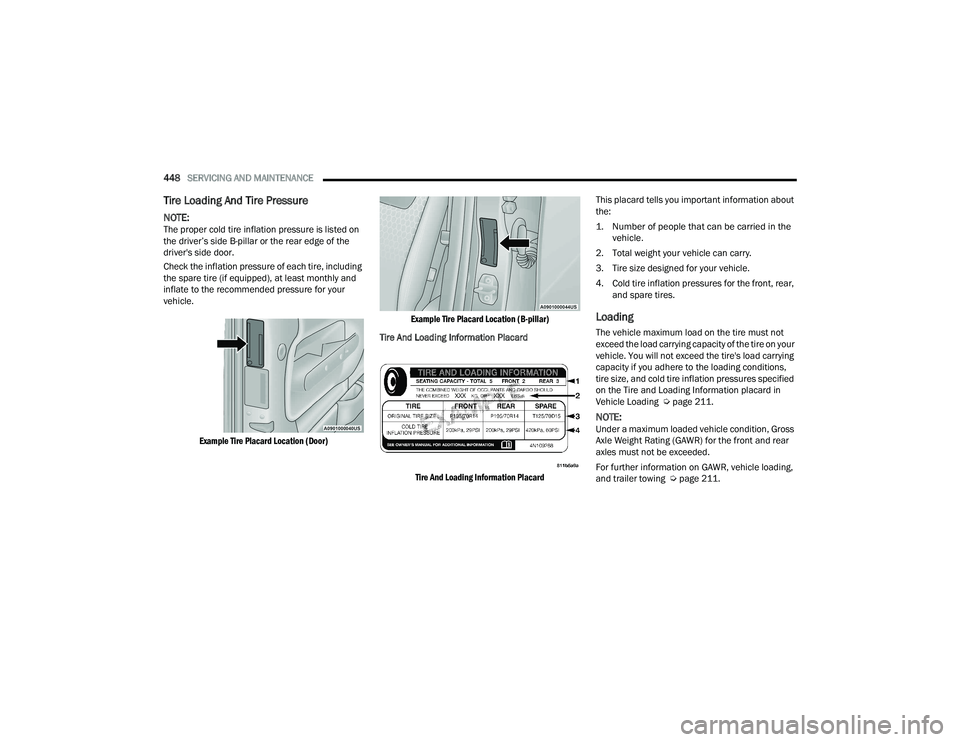

Tire Loading And Tire Pressure

NOTE:The proper cold tire inflation pressure is listed on

the driver’s side B-pillar or the rear edge of the

driver's side door.

Check the inflation pressure of each tire, including

the spare tire (if equipped), at least monthly and

inflate to the recommended pressure for your

vehicle.

Example Tire Placard Location (Door) Example Tire Placard Location (B-pillar)

Tire And Loading Information Placard

Tire And Loading Information Placard

This placard tells you important information about

the:

1. Number of people that can be carried in the

vehicle.

2. Total weight your vehicle can carry.

3. Tire size designed for your vehicle.

4. Cold tire inflation pressures for the front, rear, and spare tires.

Loading

The vehicle maximum load on the tire must not

exceed the load carrying capacity of the tire on your

vehicle. You will not exceed the tire's load carrying

capacity if you adhere to the loading conditions,

tire size, and cold tire inflation pressures specified

on the Tire and Loading Information placard in

Vehicle Loading Ú page 211.

NOTE:Under a maximum loaded vehicle condition, Gross

Axle Weight Rating (GAWR) for the front and rear

axles must not be exceeded.

For further information on GAWR, vehicle loading,

and trailer towing Ú page 211.

22_DT_OM_EN_USC_t.book Page 448

Page 453 of 496

SERVICING AND MAINTENANCE451

TIRES — GENERAL INFORMATION

Tire Pressure

Proper tire inflation pressure is essential to the

safe and satisfactory operation of your vehicle.

Four primary areas are affected by improper tire

pressure:

Safety

Fuel Economy

Tread Wear

Ride Comfort and Vehicle Stability Safety

Both underinflation and overinflation affect the

stability of the vehicle and can produce a feeling of

sluggish response or over responsiveness in the

steering.

NOTE:

Unequal tire pressures from side to side may

cause erratic and unpredictable steering

response.

Unequal tire pressure from side to side may

cause the vehicle to drift left or right.

Fuel Economy

Underinflated tires will increase tire rolling

resistance resulting in higher fuel consumption.

Tread Wear

Improper cold tire inflation pressures can cause

abnormal wear patterns and reduced tread life,

resulting in the need for earlier tire replacement.

Ride Comfort And Vehicle Stability

Proper tire inflation contributes to a comfortable

ride. Overinflation produces a jarring and

uncomfortable ride.

WARNING!

Overloading of your tires is dangerous.

Overloading can cause tire failure, affect vehicle

handling, and increase your stopping distance.

Use tires of the recommended load capacity for

your vehicle. Never overload them.WARNING!

Improperly inflated tires are dangerous and

can cause collisions.

Underinflation increases tire flexing and can

result in overheating and tire failure.

Overinflation reduces a tire's ability to cushion

shock. Objects on the road and chuckholes

can cause damage that result in tire failure.

Overinflated or underinflated tires can affect

vehicle handling and can fail suddenly,

resulting in loss of vehicle control.

Unequal tire pressures can cause steering

problems. You could lose control of your

vehicle.

Unequal tire pressures from one side of the

vehicle to the other can cause the vehicle to

drift to the right or left.

Always drive with each tire inflated to the

recommended cold tire inflation pressure.

8

22_DT_OM_EN_USC_t.book Page 451

Page 454 of 496

452SERVICING AND MAINTENANCE

Tire Inflation Pressures

The proper cold tire inflation pressure is listed on

the driver's side B-pillar or rear edge of the driver's

side door.

At least once a month:

Check and adjust tire pressure with a good

quality pocket-type pressure gauge. Do not

make a visual judgment when determining

proper inflation. Tires may look properly inflated

even when they are underinflated.

Inspect tires for signs of tire wear or visible

damage.

Inflation pressures specified on the placard are

always “cold tire inflation pressure”. Cold tire

inflation pressure is defined as the tire pressure

after the vehicle has not been driven for at least

three hours, or driven less than 1 mile (1.6 km)

after sitting for a minimum of three hours. The cold

tire inflation pressure must not exceed the

maximum inflation pressure molded into the tire

sidewall. Check tire pressures more often if subject to a

wide range of outdoor temperatures, as tire

pressures vary with temperature changes.

Tire pressures change by approximately 1 psi

(7 kPa) per 12°F (7°C) of air temperature change.

Keep this in mind when checking tire pressure

inside a garage, especially in the Winter.

Example: If garage temperature = 68°F (20°C)

and the outside temperature = 32°F (0°C) then

the cold tire inflation pressure should be increased

by 3 psi (21 kPa), which equals 1 psi (7 kPa) for

every 12°F (7°C) for this outside temperature

condition.

Tire pressure may increase from 2 to 6 psi

(13 to 40 kPa) during operation. DO NOT reduce

this normal pressure build up or your tire pressure

will be too low.

Tire Pressures For High Speed Operation

The manufacturer advocates driving at safe

speeds and within posted speed limits. Where

speed limits or conditions are such that the vehicle

can be driven at high speeds, maintaining correct

tire inflation pressure is very important. Increased

tire pressure and reduced vehicle loading may be

required for high-speed vehicle operation. Refer to

an authorized tire dealer or original equipment

vehicle dealer for recommended safe operating

speeds, loading and cold tire inflation pressures.

Radial Ply Tires

Tire Repair

If your tire becomes damaged, it may be repaired if

it meets the following criteria:

The tire has not been driven on when flat

The damage is only on the tread section of your

tire (sidewall damage is not repairable)

The puncture is no greater than a ¼ of an inch

(6 mm)

CAUTION!

After inspecting or adjusting the tire pressure,

always reinstall the valve stem cap. This will

prevent moisture and dirt from entering the

valve stem, which could damage the valve stem.

WARNING!

High speed driving with your vehicle under

maximum load is dangerous. The added strain

on your tires could cause them to fail. You could

have a serious collision. Do not drive a vehicle

loaded to the maximum capacity at continuous

speeds above 75 mph (120 km/h).

WARNING!

Combining radial ply tires with other types of

tires on your vehicle will cause your vehicle to

handle poorly. The instability could cause a

collision. Always use radial ply tires in sets of

four. Never combine them with other types of

tires.

22_DT_OM_EN_USC_t.book Page 452