check engine light Ram 2500 2020 User Guide

[x] Cancel search | Manufacturer: RAM, Model Year: 2020, Model line: 2500, Model: Ram 2500 2020Pages: 553, PDF Size: 21.99 MB

Page 184 of 553

182SAFETY

The ORC contains a backup power supply

system that may deploy the air bag system even

if the battery loses power or it becomes discon -

nected prior to deployment.

The ORC turns on the Air Bag Warning Light in

the instrument panel for approximately four to

eight seconds for a self-check when the ignition

switch is first in the ON/RUN position. After the

self-check, the Air Bag Warning Light will turn

off. If the ORC detects a malfunction in any part

of the system, it turns on the Air Bag Warning

Light, either momentarily or continuously. A

single chime will sound to alert you if the light

comes on again after initial startup.

The ORC also includes diagnostics that will illu-

minate the instrument panel Air Bag Warning

Light if a malfunction is detected that could

affect the air bag system. The diagnostics also

record the nature of the malfunction. While the

air bag system is designed to be maintenance

free, if any of the following occurs, have an

authorized dealer service the air bag system

immediately.

The Air Bag Warning Light does not come on

during the four to eight seconds when the

ignition switch is first in the ON/RUN position.

The Air Bag Warning Light remains on after

the four to eight-second interval.

The Air Bag Warning Light comes on intermit -

tently or remains on while driving.

NOTE:

If the speedometer, tachometer, or any engine

related gauges are not working, the Occupant

Restraint Controller (ORC) may also be

disabled. In this condition the air bags may not

be ready to inflate for your protection. Have an

authorized dealer service the air bag system

immediately.

Redundant Air Bag Warning Light

If a fault with the Air Bag Warning

Light is detected, which could affect

the Supplemental Restraint System

(SRS), the Redundant Air Bag Warning

Light will illuminate on the instrument panel.

The Redundant Air Bag Warning Light will stay

on until the fault is cleared. In addition, a single

chime will sound to alert you that the Redun -

dant Air Bag Warning Light has come on and a

fault has been detected. If the Redundant Air

Bag Warning Light comes on intermittently or

remains on while driving have an authorized

dealer service the vehicle immediately.

For additional information regarding the Redun -

dant Air Bag Warning Light refer to “Getting To

Know Your Instrument Panel” section of this

manual.

Front Air Bags

This vehicle has front air bags and lap/shoulder

belts for both the driver and front passenger.

The front air bags are a supplement to the seat

belt restraint systems. The driver front air bag is

mounted in the center of the steering wheel.

The passenger front air bag is mounted in the

WARNING!

Ignoring the Air Bag Warning Light in your

instrument panel could mean you won’t have

the air bag system to protect you in a

collision. If the light does not come on as a

bulb check when the ignition is first turned

on, stays on after you start the vehicle, or if it

comes on as you drive, have an authorized

dealer service the air bag system

immediately.

20_DJD2_OM_EN_USC_t.book Page 182

Page 191 of 553

SAFETY189

(Continued)

Enhanced Accident Response System

In the event of an impact, if the communication

network remains intact, and the power remains

intact, depending on the nature of the event,

the Occupant Restraint Controller (ORC) will

determine whether to have the Enhanced Acci -

dent Response System perform the following

functions:

Cut off fuel to the engine (if equipped)

Cut off battery power to the electric motor (if

equipped)

Flash hazard lights as long as the battery has

power

Turn on the interior lights, which remain on

as long as the battery has power or for

15 minutes from the intervention of the

Enhanced Accident Response System

Unlock the power door locks

Your vehicle may also be designed to perform

any of these other functions in response to the

Enhanced Accident Response System:

Turn off the Fuel Filter Heater, Turn off the

HVAC Blower Motor, Close the HVAC Circula -

tion Door

Cut off battery power to the:

Engine

Electric Motor (if equipped)

Electric power steering

Brake booster

Electric park brake

Automatic transmission gear selector

Horn

Front wiper

Headlamp washer pump

NOTE:

After an accident, remember to cycle the ignition

to the STOP (OFF/LOCK) position and remove the

key from the ignition switch to avoid draining the

battery. Carefully check the vehicle for fuel leaks

in the engine compartment and on the ground

near the engine compartment and fuel tank

before resetting the system and starting the

engine. If there are no fuel leaks or damage to the

vehicle electrical devices (e.g. headlights) after an

accident, reset the system by following the proce -

dure described below. If you have any doubt,

contact an authorized dealer.

Enhanced Accident Response System Reset

Procedure

In order to reset the Enhanced Accident

Response System functions after an event, the

ignition switch must be changed from ignition

START or ON/RUN to ignition OFF. Carefully

check the vehicle for fuel leaks in the engine

compartment and on the ground near the

engine compartment and fuel tank before reset -

ting the system and starting the engine.

Maintaining Your Air Bag System

WARNING!

Modifications to any part of the air bag

system could cause it to fail when you need

it. You could be injured if the air bag system

is not there to protect you. Do not modify

the components or wiring, including adding

any kind of badges or stickers to the

steering wheel hub trim cover or the upper

passenger side of the instrument panel. Do

not modify the front bumper, vehicle body

structure, or add aftermarket side steps or

running boards.

4

20_DJD2_OM_EN_USC_t.book Page 189

Page 212 of 553

210SAFETY

(Continued)

Periodic Safety Checks You Should Make

Outside The Vehicle

Tires

Examine tires for excessive tread wear and

uneven wear patterns. Check for stones, nails,

glass, or other objects lodged in the tread or

sidewall. Inspect the tread for cuts and cracks.

Inspect sidewalls for cuts, cracks, and bulges.

Check the wheel bolts for tightness. Check the

tires (including spare) for proper cold inflation

pressure.

Lights

Have someone observe the operation of brake

lights and exterior lights while you work the

controls. Check turn signal and high beam indi -

cator lights on the instrument panel.

Door Latches

Check for proper closing, latching, and locking.

Fluid Leaks

Check area under the vehicle after overnight

parking for fuel, coolant, oil, or other fluid leaks.

Also, if gasoline fumes are detected or if fuel, or

brake fluid leaks are suspected, the cause

should be located and corrected immediately.

ONLY install floor mats designed to fit your

vehicle. NEVER install a floor mat that

cannot be properly attached and secured to

your vehicle. If a floor mat needs to be

replaced, only use a FCA approved floor

mat for the specific make, model, and year

of your vehicle.

ONLY use the driver’s side floor mat on the

driver’s side floor area. To check for inter -

ference, with the vehicle properly parked

with the engine off, fully depress the accel-

erator, the brake, and the clutch pedal (if

present) to check for interference. If your

floor mat interferes with the operation of

any pedal, or is not secure to the floor,

remove the floor mat from the vehicle and

place the floor mat in your trunk.

ONLY use the passenger’s side floor mat on

the passenger’s side floor area.

WARNING! (Continued)

ALWAYS make sure objects cannot fall or

slide into the driver’s side floor area when

the vehicle is moving. Objects can become

trapped under accelerator, brake, or clutch

pedals and could cause a loss of vehicle

control.

NEVER place any objects under the floor

mat (e.g., towels, keys, etc.). These objects

could change the position of the floor mat

and may cause interference with the accel -

erator, brake, or clutch pedals.

If the vehicle carpet has been removed and

re-installed, always properly attach carpet

to the floor and check the floor mat

fasteners are secure to the vehicle carpet.

Fully depress each pedal to check for inter -

ference with the accelerator, brake, or

clutch pedals then re-install the floor mats.

It is recommended to only use mild soap

and water to clean your floor mats. After

cleaning, always check your floor mat has

been properly installed and is secured to

your vehicle using the floor mat fasteners

by lightly pulling mat.

WARNING! (Continued)

20_DJD2_OM_EN_USC_t.book Page 210

Page 220 of 553

218STARTING AND OPERATING

5. After engine start-up, check to see that

there is oil pressure.

6. Release the parking brake and drive.

NOTE:

Engine idle speed will automatically increase

to 1,000 RPM and engage the Variable

Geometry Turbocharger at low coolant

temperatures to improve engine warm-up.

The engine will not automatically crank after

the engine “Wait To Start” telltale goes off if

a door or the hood is ajar.

If the engine stalls, or if the ignition switch is

left ON for more than two minutes after the

“Wait To Start” telltale goes out, reset the

intake air heater by turning the ignition

switch to the OFF position for at least

5 seconds and then back ON. Repeat steps

1 through 7 of “Keyless Enter-N-Go Starting Procedure – Engine Manifold Air Tempera

-

ture Below 66° F (19° C).”

Extreme Cold Weather

The Cummins® Turbo Diesel engine is

equipped with several features designed to

assist cold weather starting and operation:

The engine block heater is a resistance

heater installed in the water jacket of the

engine just above and behind the oil filter. It

requires a 110–115 Volt AC electrical outlet

with a grounded, three-wire extension cord.

NOTE:

The engine block heater cord is a factory

installed option. If your vehicle is not equipped,

heater cords are available from an authorized

Mopar dealer.

A 12 Volt heater built into the fuel filter hous -

ings aid in preventing fuel gelling. It is

controlled by a built-in thermostat.

A intake air heater system both improves

engine starting and reduces the amount of

white smoke generated by a warming engine.

Normal Starting Procedure — Engine

Manifold Air Temperature Above 66° F

(19° C)

Observe the instrument panel cluster lights

when starting the engine.

1. Always apply the parking brake.

2. Shift into PARK for an automatic transmis -

sion.

3. Place the ignition switch in the ON position and watch the instrument panel cluster

lights.

4. Place the ignition switch in the START posi -

tion and crank the engine. Do not press the

accelerator during starting.

CAUTION!

Do not crank engine for more than 25 seconds

at a time or starter motor damage may result.

Turn the ignition switch to the OFF position and

wait at least two minutes for the starter to cool

before repeating start procedure.

CAUTION!

If the “Water in Fuel Indicator Light” remains

on, DO NOT START the engine before you

drain the water from the fuel filters to avoid

engine damage. Refer to “Draining Fuel/

Water Separator Filter” in “Servicing And

Maintenance” for further information.

20_DJD2_OM_EN_USC_t.book Page 218

Page 221 of 553

STARTING AND OPERATING219

5. Check that the oil pressure warning light

has turned off.

6. Release the parking brake.

Starting Procedure — Engine Manifold Air

Temperature 0°F To 66°F (–18°C to 19°C)

NOTE:

The temperature displayed in the instrument

cluster does not necessarily reflect the engine

manifold air temperature. Refer to “Instrument

Cluster Display” in “Getting To Know Your

Instrument Panel” for further information.

When engine temperatures fall below 66°F

(19°C) the “Wait To Start Light” will remain on

indicating the intake air heater system is active.

Follow the steps in the “Normal Starting” proce -

dure except:

1. The “Wait To Start” telltale will remain on

for a period of time that varies depending

on the engine temperature.

2. While the “Wait To Start” telltale is on, the instrument cluster will additionally display a

gauge or bar whose initial length represents

the full “Wait To Start” time period. Its

length will decrease until it disappears

when the “Wait To Start” time has elapsed.

3. After the “Wait To Start” telltale goes off, place the ignition switch in the START posi -

tion. Do not press the accelerator during

starting. 4. After engine start-up, check that the oil

pressure warning light has turned off.

5. Release the parking brake and drive.

NOTE:

Engine idle speed will automatically increase

to 1,000 RPM and engage the Variable

Geometry Turbocharger at low coolant

temperatures to improve engine warm-up.

Automatic equipped vehicles with optional

Keyless Enter-N-Go – If the start button is

pushed once while in park with the ignition

off and driver’s foot on the brake pedal, the

vehicle will automatically crank and start

after the Wait to Start time has elapsed. If it

is desired to abort the start process before it

CAUTION!

Do not crank engine for more than 25 seconds

at a time or starter motor damage may result.

Turn the ignition switch to the OFF position and

wait at least two minutes for the starter to cool

before repeating start procedure.

CAUTION!

If the “Water in Fuel Indicator Light” remains

on, DO NOT START the engine before you

drain the water from the fuel filters to avoid

engine damage. Refer to “Draining Fuel/

Water Separator Filter” in “Servicing And

Maintenance” for further information.

CAUTION!

Do not crank engine for more than 25 seconds

at a time or starter motor damage may result.

Turn the ignition switch to the OFF position and

wait at least two minutes for the starter to cool

before repeating start procedure.

5

20_DJD2_OM_EN_USC_t.book Page 219

Page 227 of 553

STARTING AND OPERATING225

1. With the transmission in PARK, the parking

brake applied, and the engine running,

push the speed control switch to the ON

position, then push the SET switch.

2. The engine RPM will go up to 1,100 RPM. To increase the RPM, push and hold the

ACCEL/RESUME switch and the idle speed

will increase to approximately 1,500 RPM.

To decrease the RPM, push and hold the

DECEL switch and the idle speed will

decrease to approximately 1,100 RPM.

3. To cancel the Idle–Up feature, either push the CANCEL switch, push the ON/OFF

switch, or press the brake pedal.

Noise

Diesel engines can create noises that may

seem concerning. The nature of a diesel engine

is compression ignition where compressed air and fuel are mixed and ignited. Weather, baro

-

metric pressure, altitude, and temperature will

affect how fuel is ignited in the engine. Engines

will sound different from day to day or previous

model years. Clicking, ticking, or light knocking

is normal and will change from day to day, as

the engine breaks in, and can vary with changes

in ambient temperature. Clicking sound from

under the hood shortly after vehicle shutdown is

normal as actuators such as the EGR valve are

cycled. Fuel pump noise may increase during

low speed/light load conditions when ambient

temperature is above 100°F (38°C), and when

fuel tank level is below 10% which is a normal

condition of the fuel system and controls

strategy. Diesel equipped vehicles also have an

exhaust after-treatment system to reduce emis -

sions utilizing a DPF (refer to “Odor” in this

section for further information) and a Selective

Reduction Catalyst (SCR). The SCR reduces

Nitrogen Oxides (NOx) using the Diesel Exhaust Fluid (DEF) system. DEF is injected directly into

the SCR through a dosing module. This process

will create a clicking sound and at times, will

make noise even with the vehicle shut off. This

is normal as the DEF dosing module is purging

DEF. If at any time the check engine light is on,

please visit an authorized dealer.

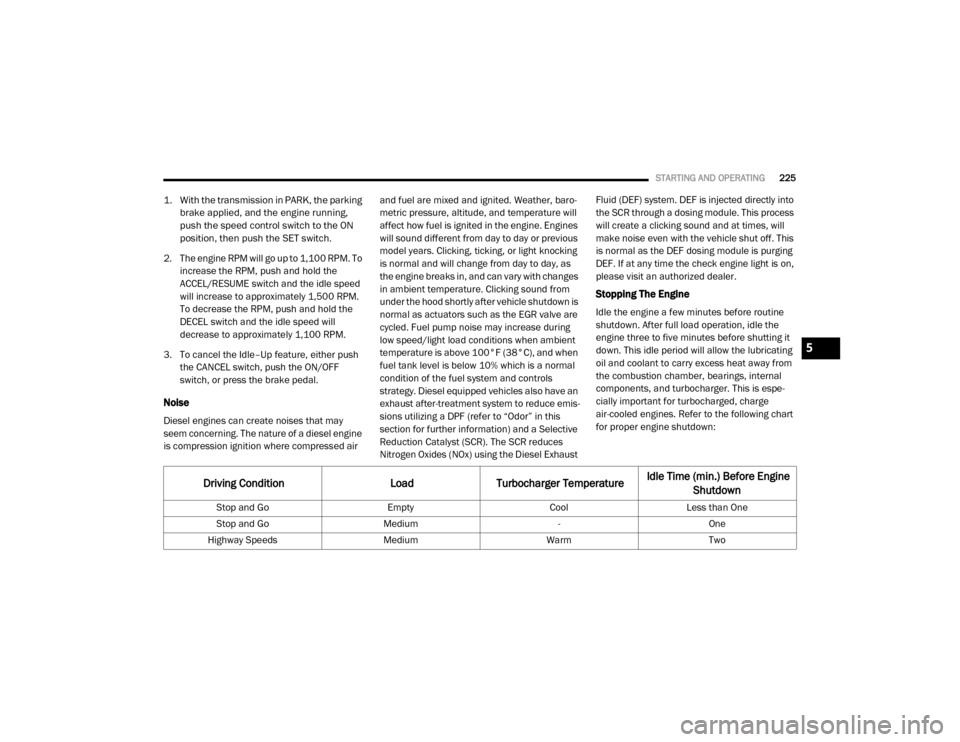

Stopping The Engine

Idle the engine a few minutes before routine

shutdown. After full load operation, idle the

engine three to five minutes before shutting it

down. This idle period will allow the lubricating

oil and coolant to carry excess heat away from

the combustion chamber, bearings, internal

components, and turbocharger. This is espe

-

cially important for turbocharged, charge

air-cooled engines. Refer to the following chart

for proper engine shutdown:

Driving Condition Load Turbocharger Temperature Idle Time (min.) Before Engine

Shutdown

Stop and Go EmptyCoolLess than One

Stop and Go Medium -One

Highway Speeds MediumWarmTwo

5

20_DJD2_OM_EN_USC_t.book Page 225

Page 262 of 553

260STARTING AND OPERATING

Driving Through Water

Extreme care should be taken crossing any type

of water. Water crossings should be avoided if

possible and only be attempted when neces -

sary, in a safe responsible manner. You should

only drive through areas which are designated

and approved. You should tread lightly and

avoid damage to the environment. You should

know your vehicle's abilities and be able to

recover it if something goes wrong. You should

never stop or shut a vehicle off when crossing

deep water unless you ingested water into the

engine air intake. If the engine stalls do not

attempt to restart it. Determine if it has ingested

water first. The key to any crossing is low and

slow. You want to use FIRST gear in 4WD LOW

and proceed very slowly with a constant slow

speed (3-5 mph [5–8 km/h] maximum) and

light throttle. Keep the vehicle moving; do not

try to accelerate through the crossing. After

crossing any water higher than the bottom of

the axle differentials, you should inspect all of

the vehicle fluids for signs of water ingestion.

Before You Cross Any Type Of Water – As you

approach any type of water you need to

determine if you can cross it safely and

responsibly. If necessary, get out and walk

through the water or probe it with a stick. You

need to be sure of its depth, approach angle,

current and bottom condition. Be careful of

murky or muddy waters, check for hidden

obstacles. Make sure you will not be

intruding on any wildlife and you can recover

the vehicle if necessary. The key to a safe

crossing is the water depth, current and

bottom conditions. On soft bottoms the

vehicle will sink in, effectively increasing the

water level on the vehicle. Be sure to

consider this when determining the depth

and the ability to safely cross.

Crossing Puddles, Pools, Flooded Areas Or

Other Standing Water – Puddles, pools,

flooded or other standing water areas

normally contain murky or muddy waters.

These water types normally contain hidden

obstacles and make it difficult to determine

an accurate water depth, approach angle,

and bottom condition. Murky or muddy water

holes are where you want to hook up tow

straps prior to entering. This makes for a

faster, cleaner and easier vehicle recovery. If

you are able to determine you can safely

cross, than proceed using the low and slow

method.

Crossing Ditches, Streams, Shallow Rivers Or

Other Flowing Water – Flowing water can be

extremely dangerous. Never attempt to cross

a fast running stream or river even in shallow

water. Fast moving water can easily push

your vehicle downstream sweeping it out of

control. Even in very shallow water, a high

current can still wash the dirt out from

CAUTION!

Water ingestion into the axles, transmission,

transfer case, engine or vehicle interior can

occur if you drive too fast or through too deep

of water. Water can cause permanent

damage to engine, driveline or other vehicle

components and your brakes will be less

effective once wet and/or muddy.

CAUTION!

Muddy waters can reduce the cooling system

effectiveness by depositing debris onto the

radiator.

20_DJD2_OM_EN_USC_t.book Page 260

Page 266 of 553

264STARTING AND OPERATING

Check threaded fasteners for looseness,

particularly on the chassis, drivetrain compo -

nents, steering, and suspension. Retighten

them, if required, and torque to the values

specified in the Service Manual.

Check for accumulations of plants or brush.

These things could be a fire hazard. They

might hide damage to fuel lines, brake hoses,

axle pinion seals, and propeller shafts.

After extended operation in mud, sand,

water, or similar dirty conditions, have the

radiator, fan, brake rotors, wheels, brake

linings, and axle yokes inspected and

cleaned as soon as possible.

If you experience unusual vibration after

driving in mud, slush or similar conditions,

check the wheels for impacted material.

Impacted material can cause a wheel imbal-

ance and freeing the wheels of it will correct

the situation.

LIMITED-SLIP DIFFERENTIAL

The limited-slip differential provides additional

traction on snow, ice, mud, sand and gravel,

particularly when there is a difference between

the traction characteristics of the surface under

the right and left rear wheels. During normal

driving and cornering, the limited-slip unit

performs similarly to a conventional differential.

On slippery surfaces, however, the differential

delivers more of the driving effort to the rear

wheel having the better traction.

The limited-slip differential is especially helpful

during slippery driving conditions. With both

rear wheels on a slippery surface, a slight appli -

cation of the accelerator will supply maximum

traction. When starting with only one rear wheel

on an excessively slippery surface, slight

momentary application of the parking brake

may be necessary to gain maximum traction. Care should be taken to avoid sudden accelera-

tions when both rear wheels are on a slippery

surface. This could cause both rear wheels to

spin, and allow the vehicle to slide sideways on

the crowned surface of a road or in a turn.

WINCH USAGE — POWER WAGON ONLY (IF

EQUIPPED)

Things To Know Before Using Your Winch

General Winch Information

Your vehicle is equipped with an electric vehicle

recovery winch. This winch uses the electrical

power from the vehicle charging system to

power a motor that winds the winch rope onto

the winch drum via planetary gear reduction. By

nature, a winch is capable of generating very

high forces and should be used with care. Do

WARNING!

Abrasive material in any part of the brakes

may cause excessive wear or unpredictable

braking. You might not have full braking

power when you need it to prevent a collision.

If you have been operating your vehicle in

dirty conditions, get your brakes checked and

cleaned as necessary.

WARNING!

On vehicles equipped with a limited-slip

differential never run the engine with one rear

wheel off the ground since the vehicle may

drive through the rear wheel remaining on the

ground. You could lose control of the vehicle.

20_DJD2_OM_EN_USC_t.book Page 264

Page 331 of 553

STARTING AND OPERATING329

Speed Control — If Equipped

Do not use on hilly terrain or with heavy

loads.

When using the Speed Control, if you experi -

ence speed drops greater than 10 mph

(16 km/h), disengage until you can get back

to cruising speed.

Use Speed Control in flat terrain and with

light loads to maximize fuel efficiency.

Cooling System

To reduce potential for engine and transmission

overheating, take the following actions:

City Driving

In city traffic — while stopped, place the trans -

mission in NEUTRAL, but do not increase

engine idle speed.

Highway Driving

Reduce speed.

Temporarily turn off air conditioning.

Air Suspension System

To aid in attaching/detaching the trailer from

the vehicle, the air suspension system can be

used. Refer to “Air Suspension System” in “Starting And Operating” for further informa

-

tion.

NOTE:

The vehicle must remain in the engine running

position while attaching a trailer for proper

leveling of the air suspension system.

SNOWPLOW

Snowplow Prep Packages are available as a

factory installed option. These packages

include components necessary to equip your

vehicle with a snowplow.

NOTE:

Before installation of a snowplow it is highly

recommended that the owner/installer obtain

and follow the recommendations contained

within the current Body Builders Guide. See

your authorized dealer, installer or snowplow

manufacturer for this information. There are

unique electrical systems that must be

connected to properly ensure operator safety

and prevent overloading vehicle systems.

Before Plowing

Check the hydraulic system for leaks and

proper fluid level.

Check the mounting bolts and nuts for proper

tightness.

Check the runners and cutting edge for

excessive wear. The cutting edge should be

¼ to ½ inches (6 cm to 1.2 cm) above ground

in snow plowing position.

Check that snowplow lighting is connected

and functioning properly.

WARNING!

Attaching a snowplow to this vehicle could

adversely affect performance of the airbag

system in a collision. Do not expect that the

airbag will perform as described earlier in this

manual.

CAUTION!

The “Lamp Out” indicator could illuminate if

exterior lamps are not properly installed.

5

20_DJD2_OM_EN_USC_t.book Page 329

Page 338 of 553

336STARTING AND OPERATING

(Continued)

Off-Road Driving Tips

Care should be taken when attempting to climb

steep hills or driving diagonally across a hill or

slope. If natural obstacles force you to travel

diagonally up or down a hill, choose a mild angle

and keep as little side tilt as possible. Keep the

vehicle moving and make turns slowly and

cautiously. If you must back down a hill, back straight down

using REVERSE gear. Never back down in

NEUTRAL or diagonally across the hill.

When driving over sand, mud, and other soft

terrain, shift to low gear and drive steadily.

Apply the accelerator slowly to avoid spinning

the wheels.

Do not reduce the tire pressures for this type of

driving.

After Driving Off-Road

Off-road operation puts more stress on your

vehicle than does most on-road driving. After

going off-road, it is always a good idea to check

for damage. That way you can get any problems

taken care of right away and have your vehicle

ready when you need it.

Completely inspect the underbody of your

vehicle. Check tires, body structure, steering,

suspension, and exhaust system for damage.

Inspect the radiator for mud and debris and

clean as required.

Driving through standing water limits your

vehicle’s braking capabilities, which

increases stopping distances. Therefore,

after driving through standing water, drive

slowly and lightly press on the brake pedal

several times to dry the brakes.

Failure to follow these warnings may result

in injuries that are serious or fatal to you,

your passengers, and others around you.

CAUTION!

Always check the depth of the standing

water before driving through it. Never drive

through standing water that is deeper than

the bottom of the tire rims mounted on the

vehicle.

Determine the condition of the road or the

path that is under water and if there are any

obstacles in the way before driving through

the standing water.

Do not exceed 5 mph (8 km/h) when

driving through standing water. This will

minimize wave effects.

WARNING!

(Continued)

Driving through standing water may cause

damage to your vehicle’s drivetrain compo -

nents. Always inspect your vehicle’s fluids

(i.e., engine oil, transmission, axle, etc.) for

signs of contamination (i.e., fluid that is

milky or foamy in appearance) after driving

through standing water. Do not continue to

operate the vehicle if any fluid appears

contaminated, as this may result in further

damage. Such damage is not covered by

the New Vehicle Limited Warranty.

Getting water inside your vehicle’s engine

can cause it to lock up and stall out, and

cause serious internal damage to the

engine. Such damage is not covered by the

New Vehicle Limited Warranty.

CAUTION! (Continued)

20_DJD2_OM_EN_USC_t.book Page 336