run flat Ram 2500 2020 User Guide

[x] Cancel search | Manufacturer: RAM, Model Year: 2020, Model line: 2500, Model: Ram 2500 2020Pages: 553, PDF Size: 21.99 MB

Page 212 of 553

210SAFETY

(Continued)

Periodic Safety Checks You Should Make

Outside The Vehicle

Tires

Examine tires for excessive tread wear and

uneven wear patterns. Check for stones, nails,

glass, or other objects lodged in the tread or

sidewall. Inspect the tread for cuts and cracks.

Inspect sidewalls for cuts, cracks, and bulges.

Check the wheel bolts for tightness. Check the

tires (including spare) for proper cold inflation

pressure.

Lights

Have someone observe the operation of brake

lights and exterior lights while you work the

controls. Check turn signal and high beam indi -

cator lights on the instrument panel.

Door Latches

Check for proper closing, latching, and locking.

Fluid Leaks

Check area under the vehicle after overnight

parking for fuel, coolant, oil, or other fluid leaks.

Also, if gasoline fumes are detected or if fuel, or

brake fluid leaks are suspected, the cause

should be located and corrected immediately.

ONLY install floor mats designed to fit your

vehicle. NEVER install a floor mat that

cannot be properly attached and secured to

your vehicle. If a floor mat needs to be

replaced, only use a FCA approved floor

mat for the specific make, model, and year

of your vehicle.

ONLY use the driver’s side floor mat on the

driver’s side floor area. To check for inter -

ference, with the vehicle properly parked

with the engine off, fully depress the accel-

erator, the brake, and the clutch pedal (if

present) to check for interference. If your

floor mat interferes with the operation of

any pedal, or is not secure to the floor,

remove the floor mat from the vehicle and

place the floor mat in your trunk.

ONLY use the passenger’s side floor mat on

the passenger’s side floor area.

WARNING! (Continued)

ALWAYS make sure objects cannot fall or

slide into the driver’s side floor area when

the vehicle is moving. Objects can become

trapped under accelerator, brake, or clutch

pedals and could cause a loss of vehicle

control.

NEVER place any objects under the floor

mat (e.g., towels, keys, etc.). These objects

could change the position of the floor mat

and may cause interference with the accel -

erator, brake, or clutch pedals.

If the vehicle carpet has been removed and

re-installed, always properly attach carpet

to the floor and check the floor mat

fasteners are secure to the vehicle carpet.

Fully depress each pedal to check for inter -

ference with the accelerator, brake, or

clutch pedals then re-install the floor mats.

It is recommended to only use mild soap

and water to clean your floor mats. After

cleaning, always check your floor mat has

been properly installed and is secured to

your vehicle using the floor mat fasteners

by lightly pulling mat.

WARNING! (Continued)

20_DJD2_OM_EN_USC_t.book Page 210

Page 249 of 553

STARTING AND OPERATING247

2WD Or 4WD HIGH To 4WD LOW

NOTE:

When shifting into or out of 4WD LOW some

gear noise may be heard. This noise is normal

and is not detrimental to the vehicle or occu -

pants.

Shifting can be performed with the vehicle

rolling 2 to 3 mph (3 to 5 km/h) or completely

stopped. You can use either of the following

procedures:

Preferred Procedure

1. With the engine running, slow the vehicle to 2 to 3 mph (3 to 5 km/h).

2. Shift the transmission into NEUTRAL.

3. While still rolling, push the desired position on the transfer case control switch.

4. After the desired position indicator light is on (not flashing), shift the transmission

back into gear. Alternate Procedure

1. Bring the vehicle to a complete stop.

2. With the ignition switch in the ON position

and the engine running, shift the transmis -

sion into NEUTRAL.

3. Push the desired position on the transfer case control switch.

4. After the desired position indicator light is on (not flashing), shift the transmission

back into gear.

NOTE:

If Steps 1 or 2 of either the Preferred or Alter -

nate Procedure are not satisfied prior to

attempting the shift, then the desired posi -

tion indicator light will flash continuously

while the original position indicator light is

on, until all requirements have been met.

The ignition switch must be in the ON position

for a shift to take place and for the position

indicator lights to be operable. If the ignition

switch is not in the ON position, the shift will

not take place and no position indicator lights

will be on or flashing.

Manually Shifted Transfer Case — If

Equipped

The transfer case provides four mode positions:

Two-Wheel Drive High Range (2H)

Four-Wheel Drive Lock High Range (4H)

N (Neutral)

Four-Wheel Drive Low Range (4L)

For additional information on the appropriate

use of each transfer case mode position, see

the information below:

2H

Two-Wheel Drive High Range — This range is for

normal street and highway driving on dry, hard

surfaced roads.

4H

Four-Wheel Drive Lock High Range — This range

locks the front and rear driveshafts together

forcing the front and rear wheels to rotate at the

same speed. Additional traction for loose, slip -

pery road surfaces only.

N (Neutral)

N (Neutral) — This range disengages both the

front and rear driveshafts from the powertrain.

To be used for flat towing behind another

5

20_DJD2_OM_EN_USC_t.book Page 247

Page 331 of 553

STARTING AND OPERATING329

Speed Control — If Equipped

Do not use on hilly terrain or with heavy

loads.

When using the Speed Control, if you experi -

ence speed drops greater than 10 mph

(16 km/h), disengage until you can get back

to cruising speed.

Use Speed Control in flat terrain and with

light loads to maximize fuel efficiency.

Cooling System

To reduce potential for engine and transmission

overheating, take the following actions:

City Driving

In city traffic — while stopped, place the trans -

mission in NEUTRAL, but do not increase

engine idle speed.

Highway Driving

Reduce speed.

Temporarily turn off air conditioning.

Air Suspension System

To aid in attaching/detaching the trailer from

the vehicle, the air suspension system can be

used. Refer to “Air Suspension System” in “Starting And Operating” for further informa

-

tion.

NOTE:

The vehicle must remain in the engine running

position while attaching a trailer for proper

leveling of the air suspension system.

SNOWPLOW

Snowplow Prep Packages are available as a

factory installed option. These packages

include components necessary to equip your

vehicle with a snowplow.

NOTE:

Before installation of a snowplow it is highly

recommended that the owner/installer obtain

and follow the recommendations contained

within the current Body Builders Guide. See

your authorized dealer, installer or snowplow

manufacturer for this information. There are

unique electrical systems that must be

connected to properly ensure operator safety

and prevent overloading vehicle systems.

Before Plowing

Check the hydraulic system for leaks and

proper fluid level.

Check the mounting bolts and nuts for proper

tightness.

Check the runners and cutting edge for

excessive wear. The cutting edge should be

¼ to ½ inches (6 cm to 1.2 cm) above ground

in snow plowing position.

Check that snowplow lighting is connected

and functioning properly.

WARNING!

Attaching a snowplow to this vehicle could

adversely affect performance of the airbag

system in a collision. Do not expect that the

airbag will perform as described earlier in this

manual.

CAUTION!

The “Lamp Out” indicator could illuminate if

exterior lamps are not properly installed.

5

20_DJD2_OM_EN_USC_t.book Page 329

Page 333 of 553

STARTING AND OPERATING331

RECREATIONAL TOWING (BEHIND MOTORHOME, ETC.)

Towing This Vehicle Behind Another Vehicle

NOTE:

When towing your vehicle, always follow

applicable state and provincial laws. Contact

state and provincial Highway Safety offices

for additional details.

Vehicles equipped with air suspension must

be placed in Transport mode before tying

them down (from the body) on a trailer or

flatbed truck. Refer to “Air Suspension – If

Equipped” for more information. If the

vehicle cannot be placed in Transport mode (for example, engine will not run), tie-downs

must be fastened to the axles (not to the

body). Failure to follow these instructions

may cause fault codes to be set and/or

cause loss of proper tie-down tension.Recreational Towing — Two-Wheel Drive

Models

DO NOT flat tow this vehicle. Damage to the

drivetrain will result.

Recreational towing (for two-wheel drive

models) is allowed

ONLY if the rear wheels are OFF

the ground. This may be accomplished

using a tow dolly or vehicle trailer. If using a tow

dolly, follow this procedure:

NOTE:

If vehicle is equipped with air suspension,

ensure the vehicle is set to Normal Ride Height.

1. Properly secure the dolly to the tow vehicle, following the dolly manufacturer's instruc -

tions.

2. Drive the rear wheels onto the tow dolly.

Towing Condition Wheels OFF The

Ground Two-Wheel Drive

Models Four-Wheel Drive Models

Flat Tow

NONENOT ALLOWED See Instructions

Automatic transmission in PARK

Transfer case in NEUTRAL (N)

Tow in forward direction

Dolly Tow Front

NOT ALLOWED NOT ALLOWED

Rear OK NOT ALLOWED

On Trailer ALLOK OK

5

20_DJD2_OM_EN_USC_t.book Page 331

Page 349 of 553

IN CASE OF EMERGENCY347

(Continued)

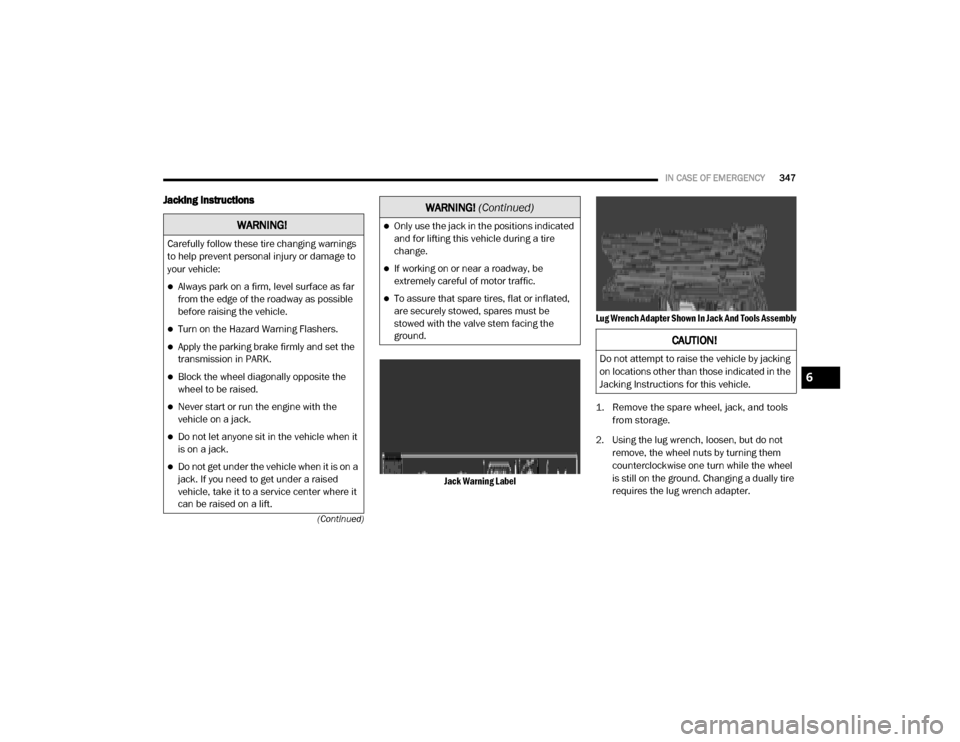

Jacking Instructions

Jack Warning Label Lug Wrench Adapter Shown In Jack And Tools Assembly

1. Remove the spare wheel, jack, and tools

from storage.

2. Using the lug wrench, loosen, but do not remove, the wheel nuts by turning them

counterclockwise one turn while the wheel

is still on the ground. Changing a dually tire

requires the lug wrench adapter.

WARNING!

Carefully follow these tire changing warnings

to help prevent personal injury or damage to

your vehicle:

Always park on a firm, level surface as far

from the edge of the roadway as possible

before raising the vehicle.

Turn on the Hazard Warning Flashers.

Apply the parking brake firmly and set the

transmission in PARK.

Block the wheel diagonally opposite the

wheel to be raised.

Never start or run the engine with the

vehicle on a jack.

Do not let anyone sit in the vehicle when it

is on a jack.

Do not get under the vehicle when it is on a

jack. If you need to get under a raised

vehicle, take it to a service center where it

can be raised on a lift.

Only use the jack in the positions indicated

and for lifting this vehicle during a tire

change.

If working on or near a roadway, be

extremely careful of motor traffic.

To assure that spare tires, flat or inflated,

are securely stowed, spares must be

stowed with the valve stem facing the

ground.

WARNING! (Continued)

CAUTION!

Do not attempt to raise the vehicle by jacking

on locations other than those indicated in the

Jacking Instructions for this vehicle.

6

20_DJD2_OM_EN_USC_t.book Page 347

Page 371 of 553

IN CASE OF EMERGENCY369

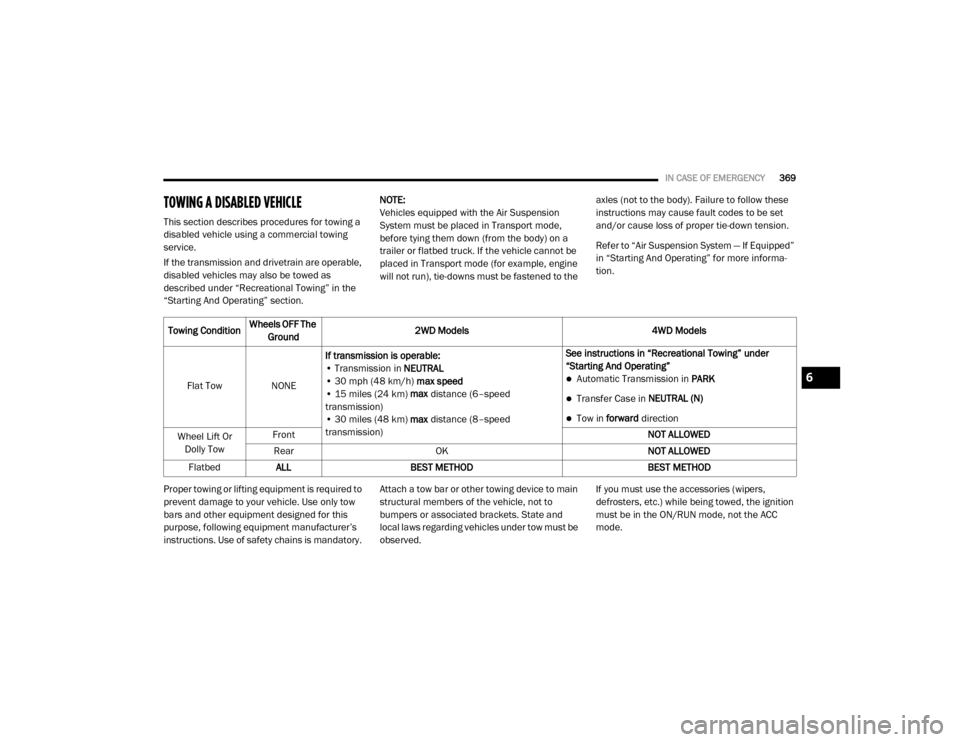

TOWING A DISABLED VEHICLE

This section describes procedures for towing a

disabled vehicle using a commercial towing

service.

If the transmission and drivetrain are operable,

disabled vehicles may also be towed as

described under “Recreational Towing” in the

“Starting And Operating” section. NOTE:

Vehicles equipped with the Air Suspension

System must be placed in Transport mode,

before tying them down (from the body) on a

trailer or flatbed truck. If the vehicle cannot be

placed in Transport mode (for example, engine

will not run), tie-downs must be fastened to the

axles (not to the body). Failure to follow these

instructions may cause fault codes to be set

and/or cause loss of proper tie-down tension.

Refer to “Air Suspension System — If Equipped”

in “Starting And Operating” for more informa

-

tion.

Proper towing or lifting equipment is required to

prevent damage to your vehicle. Use only tow

bars and other equipment designed for this

purpose, following equipment manufacturer’s

instructions. Use of safety chains is mandatory. Attach a tow bar or other towing device to main

structural members of the vehicle, not to

bumpers or associated brackets. State and

local laws regarding vehicles under tow must be

observed.If you must use the accessories (wipers,

defrosters, etc.) while being towed, the ignition

must be in the ON/RUN mode, not the ACC

mode.

Towing Condition

Wheels OFF The

Ground 2WD Models

4WD Models

Flat Tow NONE If transmission is operable:

• Transmission in NEUTRAL

• 30 mph (48 km/h) max speed

• 15 miles (24 km) max distance (6–speed

transmission)

• 30 miles (48 km) max distance (8–speed

transmission) See instructions in “Recreational Towing” under

“Starting And Operating”

Automatic Transmission in

PARK

Transfer Case in NEUTRAL (N)

Tow in forward direction

Wheel Lift Or Dolly Tow Front

NOT ALLOWED

Rear OK NOT ALLOWED

Flatbed ALL BEST METHOD BEST METHOD

6

20_DJD2_OM_EN_USC_t.book Page 369

Page 432 of 553

430SERVICING AND MAINTENANCE

Tire Repair

If your tire becomes damaged, it may be

repaired if it meets the following criteria:

The tire has not been driven on when flat.

The damage is only on the tread section of

your tire (sidewall damage is not repairable).

The puncture is no greater than a ¼ of an

inch (6 mm).

Consult an authorized tire dealer for tire repairs

and additional information.

Damaged Run Flat tires, or Run Flat tires that

have experienced a loss of pressure should be

replaced immediately with another Run Flat tire

of identical size and service description (Load

Index and Speed Symbol). Replace the tire pres -

sure sensor as well as it is not designed to be

reused.

Run Flat Tires — If Equipped

Run Flat tires allow you the capability to drive

50 miles (80 km) at 50 mph (80 km/h) after a rapid loss of inflation pressure. This rapid loss

of inflation is referred to as the Run Flat mode.

A Run Flat mode occurs when the tire inflation

pressure is of/or below 14 psi (96 kPa). Once a

Run Flat tire reaches the run flat mode it has limited driving capabilities and needs to be

replaced immediately. A Run Flat tire is not

repairable. When a run flat tire is changed after

driving with underinflated tire condition, please

replace the TPM sensor as it is not designed to

be reused when driven under run flat mode 14

psi (96 kPa) condition.

NOTE:

TPM Sensor must be replaced after driving the

vehicle on a flat tire condition.

It is not recommended driving a vehicle loaded

at full capacity or to tow a trailer while a tire is in

the run flat mode.

See the tire pressure monitoring section for

more information.

Tire Spinning

When stuck in mud, sand, snow, or ice condi

-

tions, do not spin your vehicle's wheels above

30 mph (48 km/h) or for longer than 30

seconds continuously without stopping.

Refer to “Freeing A Stuck Vehicle” in “In Case Of

Emergency” for further information.

Tread Wear Indicators

Tread wear indicators are in the original equip -

ment tires to help you in determining when your

tires should be replaced.

Tire Tread

WARNING!

Fast spinning tires can be dangerous. Forces

generated by excessive wheel speeds may

cause tire damage or failure. A tire could

explode and injure someone. Do not spin your

vehicle's wheels faster than 30 mph (48 km/h)

for more than 30 seconds continuously when

you are stuck, and do not let anyone near a

spinning wheel, no matter what the speed.

1 — Worn Tire

2 — New Tire

20_DJD2_OM_EN_USC_t.book Page 430

Page 441 of 553

SERVICING AND MAINTENANCE439

Standard No. 109. Grades B and A repre -

sent higher levels of performance on the

laboratory test wheel, than the minimum

required by law.

STORING THE VEHICLE

If you are storing your vehicle for more than

21 days, we recommend that you take the

following steps to minimize the drain on your

vehicle's battery:

Disconnect the negative cable from battery.

Any time you store your vehicle or keep it out

of service (i.e., vacation) for two weeks or

more, run the air conditioning system at idle

for about five minutes in the fresh air and high blower setting. This will ensure

adequate system lubrication to minimize the

possibility of compressor damage when the

system is started again.

BODYWORK

Protection From Atmospheric Agents

Vehicle body care requirements vary according

to geographic locations and usage. Chemicals

that make roads passable in snow and ice and

those that are sprayed on trees and road

surfaces during other seasons are highly corro

-

sive to the metal in your vehicle. Outside

parking, which exposes your vehicle to airborne

contaminants, road surfaces on which the

vehicle is operated, extreme hot or cold weather

and other extreme conditions will have an

adverse effect on paint, metal trim, and under -

body protection.

The following maintenance recommendations

will enable you to obtain maximum benefit from

the corrosion resistance built into your vehicle.

What Causes Corrosion?

Corrosion is the result of deterioration or

removal of paint and protective coatings from

your vehicle. The most common causes are:

Road salt, dirt and moisture accumulation.

Stone and gravel impact.

Insects, tree sap and tar.

Salt in the air near seacoast localities.

Atmospheric fallout/industrial pollutants.

Body And Underbody Maintenance

Cleaning Headlights

Your vehicle is equipped with plastic headlights

and fog lights that are lighter and less suscep

-

tible to stone breakage than glass headlights.

Plastic is not as scratch resistant as glass and

therefore different lens cleaning procedures

must be followed.

To minimize the possibility of scratching the

lenses and reducing light output, avoid wiping

with a dry cloth. To remove road dirt, wash with

a mild soap solution followed by rinsing.

Do not use abrasive cleaning components,

solvents, steel wool or other aggressive mate -

rial to clean the lenses.

WARNING!

The temperature grade for this tire is

established for a tire that is properly inflated

and not overloaded. Excessive speed,

under-inflation, or excessive loading, either

separately or in combination, can cause heat

buildup and possible tire failure.

7

20_DJD2_OM_EN_USC_t.book Page 439

Page 544 of 553

542

Differential, Limited Slip

................................ 264

Disabled Vehicle Towing................................ 369

Disposal Antifreeze (Engine Coolant)

....................... 414

Do Not Disturb............................................... 532

Door Ajar........................................................ 133

Door Ajar Light............................................... 133Door LocksAutomatic

.................................................... 31

Doors............................................................... 27Draining Fuel/Water Separator Filter............ 403

Driver’s Seat Back Tilt..................................... 32

DrivingOff-Pavement

............................................ 255

Off-Road.................................................... 255Through Flowing, Rising, Or Shallow Standing Water

..................................... 335

Dual Rear Wheels................................ 437, 444

E

Electric Brake Control System

....................... 145

Anti-Lock Brake System............................. 144

Electronic Roll Mitigation................. 149, 153

Electrical Power Outlets................................... 88Electronic Range Select (ERS)............. 236, 241

Electronic Stability Control (ESC)...................146

Electronic Throttle Control Warning Light...... 132

Electronically Shifted Transfer Case.............. 244

Emergency Braking........................................ 229

Emergency, In Case OfFreeing Vehicle When Stuck

..................... 367

Hazard Warning Flasher........................... 338

Jump Starting........................................... 362

Emission Control System Maintenance........ 142

Engine......................................... 391, 392, 393

Air Cleaner................................................ 398Block Heater.................................... 218, 227

Break-In Recommendations..................... 228

Compartment.................................. 392, 393Compartment Identification...................... 391

Coolant (Antifreeze)......................... 452, 454

Exhaust Gas Caution....................... 208, 448

Fails To Start............................................ 214

Flooded, Starting...................................... 214Fuel Requirements.......................... 446, 451

Identifcation.................................... 392, 393

Idling........................................................ 224

Jump Starting........................................... 362Oil..................................396, 451, 452, 454

Oil Filler Cap.................................... 391, 397

Oil Filter.................................................... 398

Oil Reset................................................... 119

Oil Selection.................................... 396, 451

Oil Synthetic............................................. 398

Overheating.............................................. 367

Runaway................................................... 312

Starting..................................................... 212

Engine Oil Viscosity....................................... 397

Enhanced Accident Response

Feature

................................................ 189, 371

Entry System, Illuminated................................55

Ethanol.......................................................... 446

Exhaust Brake............................................... 230

Exhaust Gas Cautions.......................... 208, 448

Exhaust System..........................208, 410, 419Exterior Lighting...............................................49

Exterior Lights........................................ 49, 210

F

FiltersAir Cleaner

................................................ 398

Air Conditioning................................. 70, 401

Engine Fuel............................................... 403

Engine Oil...............................398, 452, 454

Engine Oil Disposal................................... 398

FlashersTurn Signals

.............................. 52, 140, 210

Flash-To-Pass...................................................51

Flat Tire Stowage.......................................... 350

Fluid Capacities............................................ 451

Fluid Leaks.................................................... 210

Fluid Level ChecksBrake........................................................ 415

Fluid, Brake................................................... 454

Fluids And Lubricants........................... 452, 454

Fog Lights.............................................. 52, 376

Fold Flat Load Floor.........................................86

Fold-Flat Seats.................................................32

20_DJD2_OM_EN_USC_t.book Page 542