torque Ram 2500 2020 User Guide

[x] Cancel search | Manufacturer: RAM, Model Year: 2020, Model line: 2500, Model: Ram 2500 2020Pages: 553, PDF Size: 21.99 MB

Page 247 of 553

STARTING AND OPERATING245

This electronically shifted transfer case is

designed to be driven in the two–wheel drive

position (2WD) for normal street and highway

conditions on dry hard surfaced roads. Driving

the vehicle in 2WD will have greater fuel

economy benefits as the front axle is not

engaged in 2WD.

When additional traction is required, the

transfer case 4WD HIGH and 4WD LOW posi -

tions can be used to maximize torque to the

front driveshaft, forcing the front and rear

wheels to rotate at the same speed. This is

accomplished by pushing the desired position

on the 4WD control switch.

Refer to “Shifting Procedure” in this section for

specific shifting instructions. The 4WD HIGH and 4WD LOW positions are

designed for loose, slippery road surfaces only.

Driving in the 4WD HIGH and 4WD LOW posi

-

tions on dry hard surfaced roads may cause

increased tire wear and damage to the driveline

components.

NOTE:

The transfer case NEUTRAL button is located in

the center of the 4WD Control Switch and is

pushed by using a ballpoint pen or similar

object. The transfer case NEUTRAL position is to

be used for recreational towing only. Refer to

“Recreational Towing” in “Starting And Oper -

ating” for further information.

Transfer Case Position Indicator Lights

The Transfer Case Position Indicator Lights

(4WD HIGH and 4WD LOW) are located in the

instrument cluster and indicate the current and

desired transfer case selection. When you

select a different transfer case position, the

indicator lights will do the following:

If All Of The Following Shift Conditions Are Met:

1. The current position indicator light will turn off.

2. The selected position indicator light will

flash until the transfer case completes the

shift.

3. When the shift is complete, the indicator light for the selected position will stop

flashing and remain on.

If One Or More Of The Following Shift Conditions

Are Not Met:

1. The indicator light for the current position will remain on.

2. The newly selected position indicator light will continue to flash.

3. The transfer case will not shift.

NOTE:

Before retrying a selection, make certain that all

the necessary requirements for selecting a new

transfer case position have been met. To retry

the selection, push the current position, wait

five seconds, and retry selection. To find the

shift requirements, refer to the “Shifting Proce-

dure” for your transfer case, located in this

section.

The transmission may not engage PARK if

the vehicle is moving. Always bring the

vehicle to a complete stop before shifting to

PARK, and verify that the transmission gear

position indicator solidly indicates PARK (P)

without blinking. Ensure that the vehicle is

completely stopped, and the PARK position

is properly indicated, before exiting the

vehicle.

WARNING! (Continued)

5

20_DJD2_OM_EN_USC_t.book Page 245

Page 255 of 553

STARTING AND OPERATING253

The locking axles are controlled by the axle

locker switch.

Under normal driving conditions, the switch

should be left in the AXLE UNLOCK position.

NOTE:

Even when the axles are in the AXLE UNLOCK

position, the limited slip differential in the rear

axle still provides torque biasing capability for

moderate low traction environments.

During the command to lock the axle, the indi -

cator light will flash until the axle is locked. After

the lock command has been successfully

executed, the light will remain on solid.

To lock the rear axle, place the vehicle in 4WD

LOW, 4WD HIGH or 2WD. Refer to “Four Wheel

Drive Operation” in “Starting And Operating” for

further information. Push the REAR LOCK

button while traveling less than 10 mph (16 km/h). The RR indicator light will remain on

when the rear axle is locked.

NOTE:

Left to right wheel speed difference may be

necessary to allow the axle to fully lock. If the

indicator light is flashing after placing the switch

in the REAR LOCK or FRONT/REAR LOCK posi

-

tion, drive the vehicle in a turn or on loose gravel

to expedite the locking action.

To lock the front axle, push the FRONT/REAR

LOCK button while traveling less than 10 mph

(16 km/h) in 4WD LOW. The indicator light will

be solid when the front axle is locked.

NOTE:

The rear axle must be locked before the front

axle will lock. When both the axles are locked, to unlock the

front axle, push the REAR LOCK button while in

4WD LOW. The FRONT/REAR LOCK indicator

light will go out when the axle is unlocked.

NOTE:

The axle lockers could be torque locked due to

side to side loads on the axle. Driving slowly

while turning the steering wheel from a left

hand turn to a right hand turn or driving in

REVERSE for a short distance may be required

to release the torque lock and unlock the axles.

To unlock the rear axle, push the AXLE UNLOCK

button. The REAR LOCK indicator light will go

out when the rear axle is unlocked.

STABILIZER/SWAY BAR SYSTEM — POWER

WAGON ONLY

Your vehicle is equipped with an electronic

disconnecting stabilizer/sway bar. This system

allows greater front suspension travel in

off-road situations.

Due to the use of taller springs, this vehicle has

an increased ride height of approximately

1.9 inches (48.3 mm) in the front and

1.5 inches (38.1 mm) in the rear. A major

Do not try to lock the rear axle if the vehicle

is stuck and the tires are spinning. You can

damage drivetrain components. Lock the

rear axle before attempting situations or

navigating terrain, which could possibly

cause the vehicle to become stuck.

CAUTION! (Continued)

WARNING!

Do not use the locked axle position for normal

driving. A locked front axle is intended for

off-road driving only. Locking the front axle

during on-road driving will reduce the steering

ability. This could cause a collision and you

may be seriously injured.5

20_DJD2_OM_EN_USC_t.book Page 253

Page 256 of 553

254STARTING AND OPERATING

advantage to increasing ride height is the posi -

tive effect it has on approach/departure and

break over angles.

This system is controlled by the electronic

control sway bar switch located below the

instrument panel.

Sway Bar Disconnect Button

Push the SWAY BAR switch to activate the

system. Push the switch again to deactivate the

system. The “Sway Bar Indicator Light” (located

in the instrument cluster) will illuminate when

the bar is disconnected. The “Sway Bar Indi -

cator Light” will flash during activation transi -

tion, or when activation conditions are not met.

The stabilizer/sway bar should remain in

on-road mode during normal driving conditions. To disconnect the stabilizer/sway bar, shift to

either 4WD HIGH or 4WD LOW and push the

SWAY BAR button to obtain the Off-Road posi

-

tion. Refer to “Four Wheel Drive Operation” in

“Starting And Operating” for further informa -

tion. The “Sway Bar Indicator Light” will flash

until the stabilizer/sway bar has been fully

disconnected. NOTE:

The stabilizer/sway bar may be torque locked

due to left and right suspension height differ

-

ences. This condition is due to driving surface

differences or vehicle loading. In order for the

stabilizer/sway bar to disconnect/reconnect,

the right and left halves of the bar must be

aligned. This alignment may require that the

vehicle be driven onto level ground or rocked

from side to side.

To return to the On-Road mode, push the SWAY

BAR button again.WARNING!

Do not disconnect the stabilizer bar and drive

on hard surfaced roads or at speeds above

18 mph (29 km/h), you may lose control of

the vehicle, which could result in serious

injury or death. The front stabilizer bar

enhances vehicle stability and assists in

maintaining control of the vehicle. The system

monitors vehicle speed and will attempt to

reconnect the stabilizer bar at speeds over

18 mph (29 km/h). This is indicated by a

flashing off road light and solid on road light.

Once vehicle speed is reduced below 14 mph

(22 km/h), the system will attempt to return

to the Off-Road mode.

WARNING!

If the stabilizer/sway bar will not return to

On-Road mode, vehicle stability is reduced.

Do not attempt to drive the vehicle over

18 mph (29 km/h). Driving faster than

18 mph (29 km/h) may cause loss of control

of the vehicle, which could result in serious

injury or death. Contact your local service

center for assistance.

20_DJD2_OM_EN_USC_t.book Page 254

Page 266 of 553

264STARTING AND OPERATING

Check threaded fasteners for looseness,

particularly on the chassis, drivetrain compo -

nents, steering, and suspension. Retighten

them, if required, and torque to the values

specified in the Service Manual.

Check for accumulations of plants or brush.

These things could be a fire hazard. They

might hide damage to fuel lines, brake hoses,

axle pinion seals, and propeller shafts.

After extended operation in mud, sand,

water, or similar dirty conditions, have the

radiator, fan, brake rotors, wheels, brake

linings, and axle yokes inspected and

cleaned as soon as possible.

If you experience unusual vibration after

driving in mud, slush or similar conditions,

check the wheels for impacted material.

Impacted material can cause a wheel imbal-

ance and freeing the wheels of it will correct

the situation.

LIMITED-SLIP DIFFERENTIAL

The limited-slip differential provides additional

traction on snow, ice, mud, sand and gravel,

particularly when there is a difference between

the traction characteristics of the surface under

the right and left rear wheels. During normal

driving and cornering, the limited-slip unit

performs similarly to a conventional differential.

On slippery surfaces, however, the differential

delivers more of the driving effort to the rear

wheel having the better traction.

The limited-slip differential is especially helpful

during slippery driving conditions. With both

rear wheels on a slippery surface, a slight appli -

cation of the accelerator will supply maximum

traction. When starting with only one rear wheel

on an excessively slippery surface, slight

momentary application of the parking brake

may be necessary to gain maximum traction. Care should be taken to avoid sudden accelera-

tions when both rear wheels are on a slippery

surface. This could cause both rear wheels to

spin, and allow the vehicle to slide sideways on

the crowned surface of a road or in a turn.

WINCH USAGE — POWER WAGON ONLY (IF

EQUIPPED)

Things To Know Before Using Your Winch

General Winch Information

Your vehicle is equipped with an electric vehicle

recovery winch. This winch uses the electrical

power from the vehicle charging system to

power a motor that winds the winch rope onto

the winch drum via planetary gear reduction. By

nature, a winch is capable of generating very

high forces and should be used with care. Do

WARNING!

Abrasive material in any part of the brakes

may cause excessive wear or unpredictable

braking. You might not have full braking

power when you need it to prevent a collision.

If you have been operating your vehicle in

dirty conditions, get your brakes checked and

cleaned as necessary.

WARNING!

On vehicles equipped with a limited-slip

differential never run the engine with one rear

wheel off the ground since the vehicle may

drive through the rear wheel remaining on the

ground. You could lose control of the vehicle.

20_DJD2_OM_EN_USC_t.book Page 264

Page 301 of 553

STARTING AND OPERATING299

LANESENSE — IF EQUIPPED

LaneSense Operation

The LaneSense system is operational at speeds

above 37 mph (60 km/h) and below 112 mph

(180 km/h). It uses a forward looking camera to

detect lane markings and measure vehicle posi -

tion within the lane boundaries.

When both lane markings are detected and the

driver unintentionally drifts out of the lane while

no turn signal has been applied OR the driver

departs the lane on the opposite side of the

applied turn signal (if the left turn signal is applied and the vehicle departs to the right), the

LaneSense system provides a haptic warning in

the form of torque applied to the steering wheel

to prompt the driver to remain within the lane

boundaries. The LaneSense system will also

provide a visual warning through the instrument

cluster display to prompt the driver to remain

within the lane boundaries.

The driver may manually override the haptic

warning by applying torque into the steering

wheel at any time.

When only a single lane marking is detected

and the driver unintentionally drifts across that

lane marking (no turn signal applied), the Lane

-

Sense system provides a visual warning

through the instrument cluster display to

prompt the driver to remain within the lane.

When only a single lane marking is detected, a

haptic (torque) warning will not be provided.

NOTE:

When operating conditions have been met, the

LaneSense system will monitor if the driver’s

hands are on the steering wheel and provides

an audible and visual warning to the driver

when the driver’s hands are not detected on the

steering wheel. The system will cancel if the

driver does not return their hands to the wheel.

WARNING!

Drivers must be careful when backing up

even when using ParkSense. Always check

carefully behind your vehicle, look behind

you, and be sure to check for pedestrians,

animals, other vehicles, obstructions, and

blind spots before backing up. You are

responsible for safety and must continue to

pay attention to your surroundings. Failure

to do so can result in serious injury or

death.

Before using ParkSense, it is strongly

recommended that the ball mount and

hitch ball assembly is disconnected from

the vehicle when the vehicle is not used for

towing. Failure to do so can result in injury

or damage to vehicles or obstacles

because the hitch ball will be much closer

to the obstacle than the rear fascia when

the loudspeaker sounds the continuous

tone. Also, the sensors could detect the ball

mount and hitch ball assembly, depending

on its size and shape, giving a false indica -

tion that an obstacle is behind the vehicle.

CAUTION!

ParkSense is only a parking aid and it is

unable to recognize every obstacle,

including small obstacles. Parking curbs

might be temporarily detected or not

detected at all. Obstacles located above or

below the sensors will not be detected

when they are in close proximity.

The vehicle must be driven slowly when

using ParkSense in order to be able to stop

in time when an obstacle is detected. It is

recommended that the driver looks over

his/her shoulder when using ParkSense.

5

20_DJD2_OM_EN_USC_t.book Page 299

Page 303 of 553

STARTING AND OPERATING301

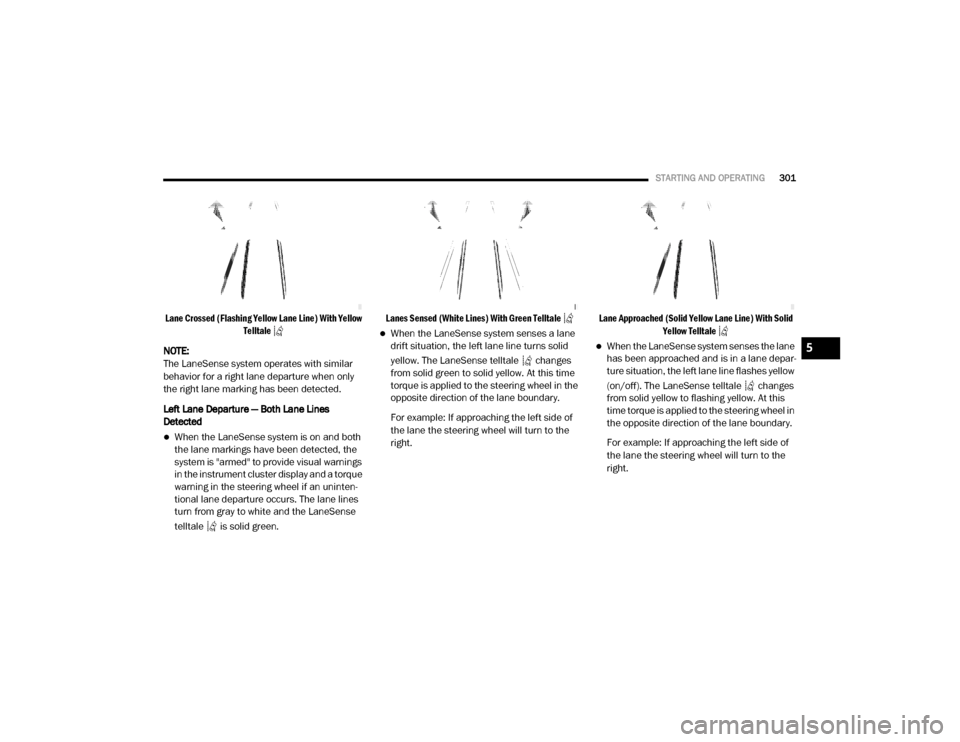

Lane Crossed (Flashing Yellow Lane Line) With Yellow

Telltale

NOTE:

The LaneSense system operates with similar

behavior for a right lane departure when only

the right lane marking has been detected.

Left Lane Departure — Both Lane Lines

Detected

When the LaneSense system is on and both

the lane markings have been detected, the

system is "armed" to provide visual warnings

in the instrument cluster display and a torque

warning in the steering wheel if an uninten -

tional lane departure occurs. The lane lines

turn from gray to white and the LaneSense

telltale is solid green.

Lanes Sensed (White Lines) With Green Telltale

When the LaneSense system senses a lane

drift situation, the left lane line turns solid

yellow. The LaneSense telltale changes

from solid green to solid yellow. At this time

torque is applied to the steering wheel in the

opposite direction of the lane boundary.

For example: If approaching the left side of

the lane the steering wheel will turn to the

right.

Lane Approached (Solid Yellow Lane Line) With Solid

Yellow Telltale

When the LaneSense system senses the lane

has been approached and is in a lane depar -

ture situation, the left lane line flashes yellow

(on/off). The LaneSense telltale changes

from solid yellow to flashing yellow. At this

time torque is applied to the steering wheel in

the opposite direction of the lane boundary.

For example: If approaching the left side of

the lane the steering wheel will turn to the

right.5

20_DJD2_OM_EN_USC_t.book Page 301

Page 304 of 553

302STARTING AND OPERATING

Lane Crossed (Flashing Yellow Lane Line) With Flash -

ing Yellow Telltale

NOTE:

The LaneSense system operates with similar

behavior for a right lane departure.

Changing LaneSense Status

The LaneSense system has settings to adjust

the intensity of the torque warning and the

warning zone sensitivity (Early/Medium/Late)

that you can configure through the Uconnect

system screen. Refer to “Uconnect Settings” in

“Multimedia” for further information. NOTE:

When enabled the system operates above

37 mph (60 km/h) and below 112 mph

(180 km/h).

Use of the turn signal suppresses the warn

-

ings.

The system will not apply torque to the

steering wheel whenever a safety system

engages (Anti-Lock Brakes, Traction Control

System, Electronic Stability Control, Forward

Collision Warning, etc.).

PARKVIEW REAR BACK UP CAMERA

Your vehicle may be equipped with the

ParkView Rear Back Up Camera that allows you

to see an image of the rear surroundings of your

vehicle whenever the gear selector is put into

REVERSE or whenever it is initiated through the

"Backup Camera" button in the "Controls"

menu. Whenever the gear selector is put into

REVERSE, the image will be displayed in the

rearview mirror display (if equipped) or Ucon -

nect screen (if equipped). If the image is

displayed in the Uconnect screen, a caution

note to “check entire surroundings” will display across the top of the screen. After five seconds

this note will disappear.

Manual Activation Of The Rear View Camera:

1. Press the "Controls" button located on the

bottom of the Uconnect display.

2. Press the "Backup Camera" button to turn the Rear View Camera system on.

When the vehicle is shifted out of REVERSE

(with Camera delay turned off), the rear Camera

mode is exited and the previous screen appears

again.

When the vehicle is shifted out of REVERSE

(with Camera delay turned on), the rear Camera

image will be displayed for up to 10 seconds

after shifting to another gear, unless the vehicle

speed exceeds 8 mph (13 km/h), the transmis- sion is shifted into PARK, the ignition is placed

in the OFF position, or the touchscreen button

“X” to disable display of the Rear View Camera

image is pressed.

Whenever the Rear View Camera image is acti -

vated through the "Backup Camera" button in

the "Controls" menu, and the vehicle speed is

greater than, or equal to, 8 mph (13 km/h), a display timer for the image is initiated. The

20_DJD2_OM_EN_USC_t.book Page 302

Page 339 of 553

STARTING AND OPERATING337

Check threaded fasteners for looseness,

particularly on the chassis, drivetrain compo -

nents, steering, and suspension. Retighten

them, if required, and torque to the values

specified in the Service Manual.

Check for accumulations of plants or brush.

These things could be a fire hazard. They

might hide damage to fuel lines, brake hoses,

axle pinion seals, and propeller shafts.

After extended operation in mud, sand,

water, or similar dirty conditions, have the

radiator, fan, brake rotors, wheels, brake

linings, and axle yokes inspected and

cleaned as soon as possible.If you experience unusual vibration after

driving in mud, slush or similar conditions,

check the wheels for impacted material.

Impacted material can cause a wheel imbal-

ance and freeing the wheels of it will correct

the situation.

WARNING!

Abrasive material in any part of the brakes

may cause excessive wear or unpredictable

braking. You might not have full braking

power when you need it to prevent a collision.

If you have been operating your vehicle in

dirty conditions, get your brakes checked and

cleaned as necessary.

5

20_DJD2_OM_EN_USC_t.book Page 337

Page 352 of 553

350IN CASE OF EMERGENCY

Dual Rear Wheel Jack Placement

6. Finish tightening the lug nuts. Push down on the lug wrench while at the end of the handle

for increased leverage. Tighten the lug nuts in

a star pattern until each nut has been tight -

ened twice. For the correct lug nut torque refer

to “Wheel And Tire Torque Specifications” in

“Technical Specifications”. If in doubt about

the correct tightness, have them checked with

a torque wrench by an authorized dealer or

service station. 7. Install the wheel center cap and remove the

wheel blocks. Do not install chrome or

aluminum wheel center caps on the spare

wheel. This may result in cap damage.

8. Lower the jack to its fully closed position. Stow the replaced tire, jack, and tools as

previously described.

NOTE:

The bottle jack will not lower by turning the dial

(thumbwheel) by hand, it may be necessary to

use the jack driver in order to lower the jack.

9. Adjust the tire pressure when possible.

NOTE:

Do not oil wheel studs. For chrome wheels, do

not substitute with chrome plated lug nuts.

To Stow The Flat Or Spare

NOTE:

Have the flat tire repaired or replaced immedi -

ately.

1. Turn the wheel so that the valve stem is facing the ground and toward the rear of

the vehicle for convenience in checking the

spare tire inflation. Slide the wheel retainer

through the center of the wheel.

Reinstalling The Retainer

WARNING!

A loose tire or jack thrown forward in a

collision or hard stop, could endanger the

occupants of the vehicle. Always stow the jack

parts and the spare tire in the places

provided.

WARNING!

A loose tire or jack thrown forward in a

collision or hard stop could endanger the

occupants of the vehicle. Always stow the jack

parts and the spare tire in the places

provided. Have the deflated (flat) tire repaired

or replaced immediately.

20_DJD2_OM_EN_USC_t.book Page 350

Page 356 of 553

354IN CASE OF EMERGENCY

Power Distribution Center

The Power Distribution Center is located in the

engine compartment near the battery. This

center contains cartridge fuses, micro fuses,

relays, and circuit breakers. A description of

each fuse and component may be stamped on

the inside cover, otherwise the cavity number of

each fuse is stamped on the inside cover that

corresponds to the following chart.

Power Distribution Center Location

CavityCartridge Fuse Micro Fuse Description

F0180 Amp Black –Rad Fan Control Module – If Equipped (DS 1500 Only)

F02 60 Amp Yellow –ABS Pump Motor (HD Only)

F03 60 Amp Yellow –Rad Fan – If Equipped

F04 50 Amp Red 400W Inverter – If Equipped (HD Only)

F05 40 Amp Green

50 Amp Red (Special

Services Vehicle (SSV)) –

Compressor For Air Suspension – If Equipped

F06 40 Amp Green –ABS Pump Motor (DS 1500 Only)

Steering Torque Overlay Module (STOM) (HD Only)

F07 40 Amp Green –Starter Solenoid

F08 20 Amp Blue (DS 1500 LD/

Cummins Diesel)40 Amp Green –

–

NOX Sensor – If Equipped

Aux Relay Output- SSV Only

20_DJD2_OM_EN_USC_t.book Page 354