fuel Ram 3500 2018 Owner's Manual

[x] Cancel search | Manufacturer: RAM, Model Year: 2018, Model line: 3500, Model: Ram 3500 2018Pages: 372, PDF Size: 7.1 MB

Page 151 of 372

NOTE:

The engine block heater cord is a factory

installed option. If your vehicle is not

equipped, heater cords are available from

your authorized Mopar dealer.

• A 12 Volt heater built into the fuel filterhousings aid in preventing fuel gelling. It is

controlled by a built-in thermostat.

• A heated intake air system both improves engine starting and reduces the amount of

white smoke generated by a warming

engine.NORMAL OPERATION — 3.0L DIESEL

ENGINE

Observe the following when the diesel engine

is operating.

• All message center lights are off.

• Malfunction Indicator Light (MIL) is off.

• Engine Oil Pressure telltale is not illumi-nated.

• Voltmeter operation:

The voltmeter may show a gauge fluctuation

at various engine temperatures. This is

caused by the glow plug heating system. The

number of cycles and the length of the cy-

cling operation is controlled by the engine

control module. Glow plug heater operation

can run for several minutes, once the heater

operation is complete the voltmeter needle

will stabilize.

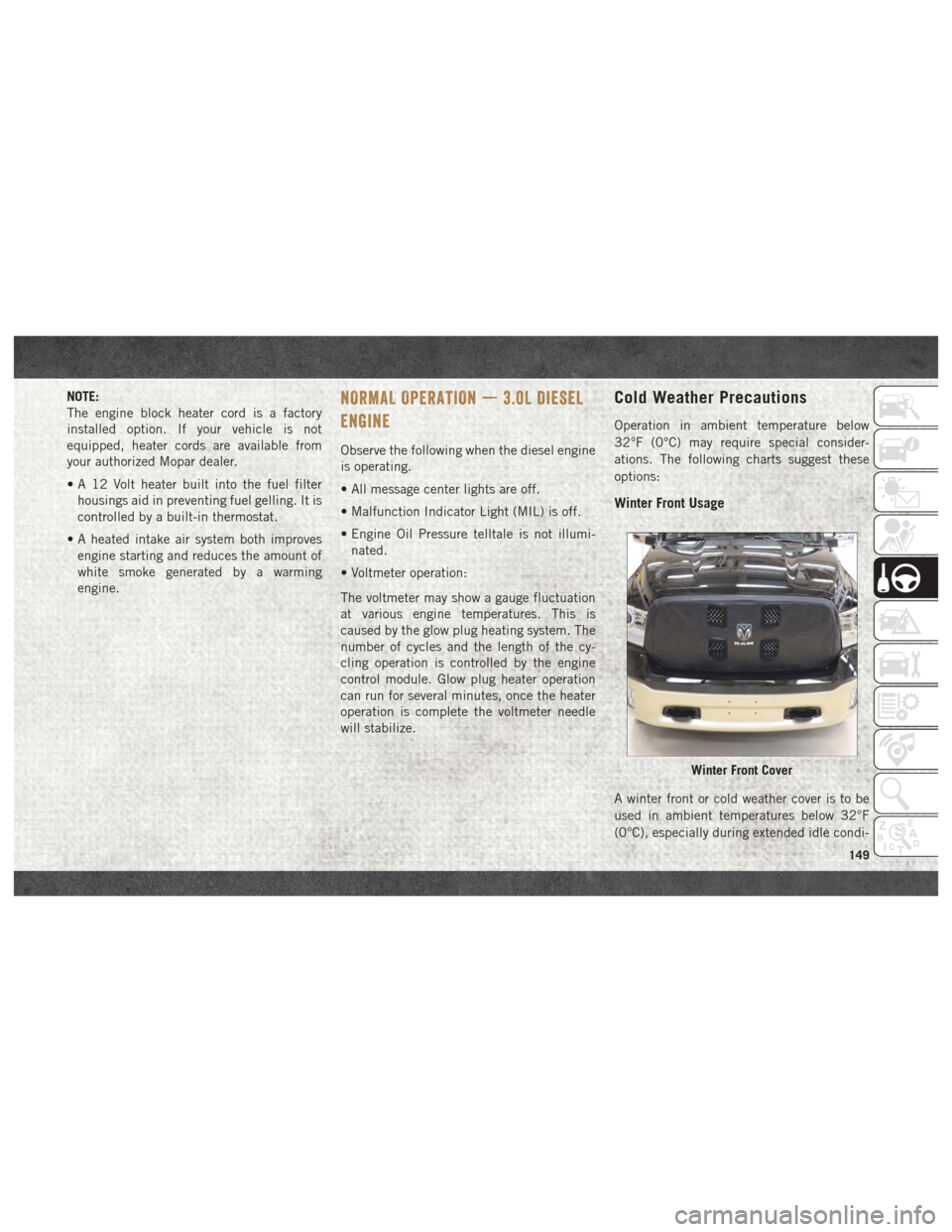

Cold Weather Precautions

Operation in ambient temperature below

32°F (0°C) may require special consider-

ations. The following charts suggest these

options:

Winter Front Usage

A winter front or cold weather cover is to be

used in ambient temperatures below 32°F

(0°C), especially during extended idle condi-

Winter Front Cover

149

Page 153 of 372

NORMAL OPERATION — 6.7L DIESEL

ENGINE

Observe the following when the engine is

operating.

• All message center lights are off.

• Malfunction Indicator Light (MIL) is off.

• Engine oil pressure is above 10 psi(69 kPa) at idle.

• Voltmeter operation:

The voltmeter may show a gauge fluctuation

at various engine temperatures. This cycling

operation is caused by the post-heat cycle of

the intake manifold heater system. The num-

ber of cycles and the length of the cycling

operation is controlled by the engine control

module. Post-heat operation can run for sev-

eral minutes, and then the electrical system

and voltmeter needle will stabilize.

The cycling action will cause temporary dim-

ming of the headlamps, interior lamps, and

also a noticeable reduction in blower motor

speed.

Cold Weather Precautions

Operation in ambient temperature below

32°F (0°C) may require special consider-

ations. The following charts suggest these

options:

Winter Front Cover Usage

A winter front or cold weather cover is to be

used in ambient temperatures below 32°F

(0°C), especially during extended idle condi-

tions. This cover is equipped with four flaps

for managing total grille opening in varying

ambient temperatures. If a winter front or

cold weather cover is to be used the flaps

should be left in the full open position to

allow air flow to the charge air cooler and

automatic transmission oil cooler. When am-

bient temperatures drop below 0°F (-17°C)

the four flaps need to be closed. A suitable

cold weather cover is available from your

Mopar dealer.

Engine Idling

Avoid prolonged idling, long periods of idling

may be harmful to your engine because com-

bustion chamber temperatures can drop so low that the fuel may not burn completely.

Incomplete combustion allows carbon and

varnish to form on piston rings, engine valves,

and injector nozzles. Also, the unburned fuel

can enter the crankcase, diluting the oil and

causing rapid wear to the engine.

If the engine is allowed to idle or the truck is

driven on low engine speed drive cycles for

more than 2 hours, the system will automati-

cally enter an emissions operating mode that

will increase the engine idle speed to

900 RPM (1050 RPM for Chassis Cab).

While in this mode, which is designed to help

maintain the diesel particulate filter, the en-

gine idle speed will return to normal when the

brake pedal is applied. A small change in

engine tone or a slight change in engine

performance while accelerating may also be

noticeable at speeds below 20 mph

(32 kmh). This operating mode may last for

up to an hour of idle time, or around 20 min-

utes of driving time.

Your truck may have been ordered with an

optional voltage monitoring idle up feature. If

a load is placed on the electrical system while

the truck is in park, this feature will attempt

151

Page 156 of 372

ENGINE BREAK-IN

RECOMMENDATIONS — 3.0L DIESEL

The diesel engine does not require a break-in

period due to its construction. Normal opera-

tion is allowed, providing the following rec-

ommendations are followed:

• Warm up the engine before placing it underload.

• Do not operate the engine at idle for pro- longed periods.

• Use the appropriate transmission gear to prevent engine lugging.

• Observe vehicle oil pressure and tempera- ture indicators.

• Check the coolant and oil levels frequently.

• Vary throttle position at highway speeds when carrying or towing significant weight.

NOTE:

Light duty operation such as light trailer

towing or no load operation will extend the

time before the engine is at full efficiency.

Reduced fuel economy and power may be

seen at this time. The engine oil installed in the engine at the

factory is a high-quality energy conserving

type lubricant. Oil changes should be consis-

tent with anticipated climate conditions un-

der which vehicle operations will occur. The

recommended viscosity and quality grades

are shown under “Fluids And Lubricants” in

"Technical Specifications” in this manual.

NON-DETERGENT OR STRAIGHT MINERAL

OILS MUST NEVER BE USED.

ENGINE BREAK-IN

RECOMMENDATIONS — 6.7L DIESEL

The Cummins turbocharged diesel engine

does not require a break-in period due to its

construction. Normal operation is allowed,

providing the following recommendations are

followed:

• Warm up the engine before placing it under

load.

• Do not operate the engine at idle for pro- longed periods.

• Use the appropriate transmission gear to prevent engine lugging. • Observe vehicle oil pressure and tempera-

ture indicators.

• Check the coolant and oil levels frequently.

• Vary throttle position at highway speeds when carrying or towing significant weight.

NOTE:

Light duty operation such as light trailer

towing or no load operation will extend the

time before the engine is at full efficiency.

Reduced fuel economy and power may be

seen at this time.

For additional vehicle break-in requirements,

refer to “Trailer Towing” in “Starting And

Operating” of the Owner’s Manual.

Because of the construction of the Cummins

turbocharged diesel engine, engine run-in is

enhanced by loaded operating conditions

which allow the engine parts to achieve final

finish and fit during the first 6,000 miles

(10 000 km).STARTING AND OPERATING

154

Page 167 of 372

4WD LOCK

Four-Wheel Drive Lock High Range — This

range maximizes torque to the front drive-

shaft, forcing the front and rear wheels to

rotate at the same speed. Additional traction

for loose, slippery road surfaces only.

4WD LOW

Four-Wheel Drive Low Range — This range

provides low speed four-wheel drive. It maxi-

mizes torque to the front driveshaft, forcing

the front and rear wheels to rotate at the same

speed. This range provides additional trac-

tion and maximum pulling power for loose,

slippery road surfaces only. Do not exceed

25 mph (40 km/h).

NEUTRAL (N)

Neutral — This range disengages both the

front and rear driveshafts from the pow-

ertrain. To be used for flat towing behind

another vehicle. Refer to “Recreational Tow-

ing” in this section for further information.This electronically shifted transfer case is

designed to be driven in the two-wheel drive

position (2WD) or four-wheel drive position

(4WD AUTO) for normal street and highway

conditions on dry hard surfaced roads). Driv-

ing the vehicle in 2WD will have greater fuel

economy benefits as the front axle is not

engaged in 2WD.

For variable driving conditions, the 4WD

AUTO mode can be used. In this mode, the

front axle is engaged, but the vehicle's power

is sent to the rear wheels. Four-wheel drive

will be automatically engaged when the ve-

hicle senses a loss of traction. Because the

front axle is engaged, this mode will result in

lower fuel economy than the 2WD mode.

When additional traction is required, the

transfer case 4WD LOCK and 4WD LOW po-

sitions can be used to maximize torque to the

front driveshaft, forcing the front and rear

wheels to rotate at the same speed. This is

accomplished by rotating the 4WD Control

Switch to the desired position.Refer to “Shifting Procedure” in the “Start-

ing And Operating” section of you Owner’s

Manual for specific shifting instructions.

WARNING!

You or others could be injured or killed if

you leave the vehicle unattended with the

transfer case in the NEUTRAL position

without first fully engaging the parking

brake. The transfer case NEUTRAL posi-

tion disengages both the front and rear

drive shafts from the powertrain and will

allow the vehicle to roll, even if the trans-

mission is in PARK. The parking brake

should always be applied when the driver

is not in the vehicle.

165

Page 169 of 372

4WD LOW

Four-Wheel Drive Low Range — This range

provides low speed four-wheel drive. It maxi-

mizes torque to the front driveshaft, forcing

the front and rear wheels to rotate at the same

speed. This range provides additional trac-

tion and maximum pulling power for loose,

slippery road surfaces only. Do not exceed

25 mph (40 km/h).

NEUTRAL (N)

Neutral — This range disengages both the

front and rear driveshafts from the pow-

ertrain. To be used for flat towing behind

another vehicle. Refer to “Recreational Tow-

ing” in this section for further information.

This electronically shifted transfer case is

designed to be driven in the two–wheel drive

position (2WD) for normal street and highway

conditions on dry hard surfaced roads). Driv-

ing the vehicle in 2WD will have greater fuel

economy benefits as the front axle is not

engaged in 2WD.When additional traction is required, the

transfer case 4WD LOCK and 4WD LOW po-

sitions can be used to maximize torque to the

front driveshaft, forcing the front and rear

wheels to rotate at the same speed. This is

accomplished by pushing the desired posi-

tion on the 4WD control switch.

Refer to “Shifting Procedure” in the “Start-

ing And Operating” section of your Owner’s

Manual for specific shifting instructions.

WARNING!

• You or others could be injured or killed if

you leave the vehicle unattended with

the transfer case in the NEUTRAL (N)

position without first fully engaging the

parking brake. The transfer case NEU-

TRAL (N) position disengages both the

front and rear drive shaft from the pow-

ertrain, and will allow the vehicle to roll,

even if the automatic transmission is in

PARK (or manual transmission is in

gear). The parking brake should always

be applied when the driver is not in the

vehicle.

WARNING!

• The transmission may not engage PARKif the vehicle is moving. Always bring the

vehicle to a complete stop before shift-

ing to PARK, and verify that the trans-

mission gear position indicator solidly

indicates PARK (P) without blinking. En-

sure that the vehicle is completely

stopped, and the PARK position is prop-

erly indicated, before exiting the ve-

hicle.

167

Page 171 of 372

4WD LOCK

Four-Wheel Drive Lock High Range — This

range maximizes torque to the front drive-

shaft, forcing the front and rear wheels to

rotate at the same speed. Additional traction

for loose, slippery road surfaces only.

4WD LOW

Four-Wheel Drive Low Range — This range

provides low speed four-wheel drive. It maxi-

mizes torque to the front driveshaft, forcing

the front and rear wheels to rotate at the same

speed. This range provides additional trac-

tion and maximum pulling power for loose,

slippery road surfaces only. Do not exceed

25 mph (40 km/h).

NEUTRAL (N)

Neutral — This range disengages both the

front and rear driveshafts from the pow-

ertrain. To be used for flat towing behind

another vehicle. Refer to “Recreational Tow-

ing” in this section for further information.

This electronically shifted transfer case is

designed to be driven in the two–wheel drive

position (2WD) or four-wheel drive position

(4WD AUTO) for normal street and highwayconditions on dry hard surfaced roads). Driv-

ing the vehicle in 2WD will have greater fuel

economy benefits as the front axle is not

engaged in 2WD.

For variable driving conditions, the 4WD

AUTO mode can be used. In this mode, the

front axle is engaged, but the vehicle's power

is sent to the rear wheels. Four-wheel drive

will be automatically engaged when the ve-

hicle senses a loss of traction. Because the

front axle is engaged, this mode will result in

lower fuel economy than the 2WD mode.

When additional traction is required, the

transfer case 4WD LOCK and 4WD LOW po-

sitions can be used to maximize torque to the

front driveshaft, forcing the front and rear

wheels to rotate at the same speed. This is

accomplished pushing the desired position

on the 4WD Control Switch.

Refer to “Shifting Procedure” in the “Start-

ing And Operating” section of your Owner’s

Manual for further details.WARNING!

• You or others could be injured or killed if

you leave the vehicle unattended with

the transfer case in the NEUTRAL (N)

position without first fully engaging the

parking brake. The transfer case NEU-

TRAL (N) position disengages both the

front and rear drive shaft from the pow-

ertrain, and will allow the vehicle to roll,

even if the automatic transmission is in

PARK (or manual transmission is in

gear). The parking brake should always

be applied when the driver is not in the

vehicle.

• The transmission may not engage PARK

if the vehicle is moving. Always bring the

vehicle to a complete stop before shift-

ing to PARK, and verify that the trans-

mission gear position indicator solidly

indicates PARK (P) without blinking. En-

sure that the vehicle is completely

stopped, and the PARK position is prop-

erly indicated, before exiting the ve-

hicle.

169

Page 183 of 372

REFUELING THE VEHICLE — GAS

ENGINE

The fuel filler cap (gas cap) is located behind

the fuel filler door, on the left side of the

vehicle. Open the fuel door and remove the

fuel cap by turning it counter-clockwise.

NOTE:

When removing the fuel filler cap, lay the cap

tether in the hook, located on the fuel filler

door.

WARNING!

• Never have any smoking materials lit inor near the vehicle when the gas cap is

removed or the tank is being filled.

• Never add fuel to the vehicle when the

engine is running.

• A fire may result if gasoline is pumped

into a portable container that is inside of

a vehicle. You could be burned. Always

place gas containers on the ground while

filling.

CAUTION!

• Damage to the fuel system or emissionscontrol system could result from using

an improper fuel tank filler tube cap.

• A poorly fitting fuel filler cap could let

impurities into the fuel system.

• A poorly fitting fuel filler cap may cause

the “Malfunction Indicator Light (MIL)”

to turn on.

• To avoid fuel spillage and overfilling, do

not “top off” the fuel tank after filling.

When the fuel nozzle “clicks” or shuts

off, the fuel tank is full.

NOTE:

• When the fuel nozzle “clicks” or shuts off, the fuel tank is full.

• Tighten the gas cap until you hear a “click- ing” sound. This is an indication that the

gas cap is tightened properly. The MIL in

the instrument cluster may turn on if the

gas cap is not secured properly. Make sure

that the gas cap is tightened each time the

vehicle is refueled.

WARNING!

Static electricity can cause an ignition of

flammable liquid, vapor or gas in any ve-

hicle or trailer. To reduce risk of serious

injury or death when filling containers:

• Always place container on the ground before filling.

• Keep the pump nozzle in contact with

the container when you are filling it.

• Use only approved containers for flam-

mable liquid.

• Do not leave container unattended while

filling.

• A static electric charge could cause a

spark and fire hazard.

181

Page 184 of 372

Materials Added To Fuel

Designated TOP TIER

Detergent Gasoline

contains a higher level

of detergents to fur-

ther aide in minimiz-

ing engine and fuel

system deposits. When

available, the usage of

Top Tier Detergent gasoline is recommended.

Visit www.toptiergas.com for a list of TOP

TIER Detergent Gasoline Retailers.

Indiscriminate use of fuel system cleaning

agents should be avoided. Many of these

materials intended for gum and varnish re-

moval may contain active solvents or similar

ingredients. These can harm fuel system gas-

ket and diaphragm materials.

REFUELING THE VEHICLE—

1500 DIESEL MODELS

1. Open the fuel filler door.NOTE:

There is no fuel filler cap. A flapper door

inside the filler pipe seals the system. 2. Insert the fuel nozzle fully into the filler

pipe – the nozzle opens and holds the

flapper door while refueling.

3. Fill the vehicle with fuel – when the fuel nozzle “clicks” or shuts off the fuel tank is

full.

4. Remove the fuel nozzle and close the fuel door.

Emergency Fuel Can Refueling

Most fuel cans will not open the flapper door.

A funnel is provided to open the flapper door

to allow emergency refueling with a fuel can.

1. Retrieve fuel funnel from the jack kit located under the front passenger seat.

Fill Locations

1 — Diesel Exhaust Fluid (DEF) Fill

Location

2 — Diesel Fuel Fill Location

STARTING AND OPERATING

182

Page 185 of 372

2. Insert funnel into same filler pipe openingas the fuel nozzle.

NOTE:

Ensure funnel is inserted fully to hold

flapper door open. 3. Pour fuel into funnel opening.

4. Remove funnel from filler pipe, clean off

prior to putting back in the jack kit.

WARNING!

• Never have any smoking materials lit inor near the vehicle when the fuel door is

open or the tank is being filled.

• Never add fuel when the engine is run-

ning. This is in violation of most state

and federal fire regulations and may

cause the “Malfunction Indicator Light”

to turn on.

• A fire may result if fuel is pumped into a

portable container that is inside of a

vehicle. You could be burned. Always

place fuel containers on the ground

while filling.

CAUTION!

To avoid fuel spillage and overfilling, do

not “top off” the fuel tank after filling.

Diesel Exhaust Fluid

Your vehicle is equipped with a Selective

Catalytic Reduction system to meet the very

stringent diesel emissions standards required

by the Environmental Protection Agency.

The purpose of the SCR system is to reduce

levels of NOx (oxides of nitrogen emitted from

engines) that are harmful to our health and

the environment to a near-zero level. Small

quantities of Diesel Exhaust Fluid (DEF) is

injected into the exhaust upstream of a cata-

lyst where, when vaporized, it converts smog-

forming nitrogen oxides (NOx) into harmless

nitrogen (N2) and water vapor (H2O), two

natural components of the air we breathe.

You can operate with the comfort that your

vehicle is contributing to a cleaner, healthier

world environment for this and generations to

come.

System Overview

This vehicle is equipped with a Diesel Ex-

haust Fluid (DEF) injection system and a

Selective Catalytic Reduction (SCR) catalyst

to meet the emission requirements.

Fill Locations And Funnel Useage

1 — Diesel Exhaust Fluid (DEF) Fill

Location

2 — Diesel Fuel Fill Location

3 — Emergency Diesel Fuel Fill Funnel

183

Page 186 of 372

The DEF injection system consists of the

following components:

• DEF tank

• DEF pump

• DEF injector

• Electronically-heated DEF lines

• NOx sensors

• Temperature sensors

• SCR catalyst

The DEF injection system and SCR catalyst

enable the achievement of diesel emissions

requirements; while maintaining outstanding

fuel economy, drivability, torque and power

ratings.

Refer to “Instrument Cluster Display” in

“Getting To Know Your Instrument Panel” for

system messages and warnings.

NOTE:

• Your vehicle is equipped with a DEF injec-tion system. You may occasionally hear an

audible clicking noise from under the ve-

hicle at a stop. This is normal operation. • The DEF pump will run for a period of time

after engine shutdown to purge the DEF

system. This is normal operation and may

be audible from the rear of the vehicle.

Adding Diesel Exhaust Fluid

The DEF gauge (located on the instrument

cluster) will display the level of DEF remain-

ing in the tank. Refer to “Instrument Cluster”

and “Instrument Cluster Descriptions” in

“Getting To Know Your Instrument Panel” for

further information.

NOTE:

• Driving conditions (altitude, vehicle speed,load, etc.) will effect the amount of DEF

that is used in your vehicle.

• Another factor is that outside temperature can affect DEF consumption. In cold con-

ditions, 12° F (-11° C) and below, the DEF

gauge needle can stay on a fixed position

and may not move for extended periods of

time. This is a normal function of the sys-

tem. • There is an electric heater inside the DEF

tank that automatically works when neces-

sary. And if the DEF supply does freeze, the

truck will operate normally until it thaws.

DEF Fill Procedure

NOTE:

Refer to “Fluids And Lubricants” in “Techni-

cal Specifications” for the correct fluid type.

1. Remove cap from DEF tank (located on

drivers side of the vehicle or in fuel door).

STARTING AND OPERATING

184