lock Ram 3500 2020 Owner's Manual

[x] Cancel search | Manufacturer: RAM, Model Year: 2020, Model line: 3500, Model: Ram 3500 2020Pages: 568

Page 357 of 568

IN CASE OF EMERGENCY355

4. Reach through the access hole of the wheel

house splash shield and disengage the side

marker socket by rotating counterclockwise

a quarter turn.

Side Marker Socket

5. Pull the socket and bulb straight out from the housing.

6. Separate the bulb from the socket without twisting.

7. Reverse the procedure for installation of new bulb and covers.

Fog Lamps — If Equipped

Please see an authorized dealer for service on

LED and Halogen front fog lamps. Halogen

1. Reach under and behind the front bumper

to access the back of the front fog lamp

housing.

2. Disconnect the fog lamp wiring harness connector from the fog lamp bulb.

3. Rotate the bulb counterclockwise a quarter turn to unlock the bulb from the housing.

Fog Lamp Bulb

4. Pull the bulb straight out from the housing.

Rear Tail/Stop, Turn Signal And Backup

Lamps

1. Remove the two screws and push pins that pass through the bed sheet metal.

Tail Lamp Locations

CAUTION!

Do not contaminate the bulb glass by

touching it with your fingers or by allowing it

to contact other oily surfaces. Shortened bulb

life will result.

1 — Tail Lamp

2 — Screws

3 — Fasteners

6

20_DJD2_OM_EN_USC_t.book Page 355

Page 358 of 568

356IN CASE OF EMERGENCY

2. Pull the outboard side of the lamp rearward

far enough to unsnap the two receptacles

on the outboard side of the lamp housing

from the two plastic snap post retainers in

the outer box side panel.

Tail Lamp Removed

3. Disconnect the wiring harness connectors from the bulb socket.

4. Rotate the bulb socket counterclockwise a quarter turn to unlock it from the housing.

5. Pull the bulb straight out of the socket. 6. Reverse the procedure to install the bulb

and housing.

Center High Mounted Stop Lamp (CHMSL)

With Cargo Lamp

1. Remove the two screws holding the housing/lens to the body as shown.

CHMSL Mounting Screw Locations

2. Separate the connector holding the housing and wiring harness to the body.

3. Turn the desired bulb socket a quarter turn and remove the socket and bulb from

housing. 4. Pull the desired bulb straight from the

socket.

CHMSL Bulb And Socket

Outside Bulbs: Cargo Lamps

Inside Bulb: Center High Mounted Stop

Lamp

5. Reverse the procedure for installation of bulbs and housing.

CAUTION!

Do not contaminate the bulb glass by

touching it with your fingers or by allowing it

to contact other oily surfaces. Shortened bulb

life will result.

CAUTION!

Do not contaminate the bulb glass by

touching it with your fingers or by allowing it

to contact other oily surfaces. Shortened bulb

life will result.

20_DJD2_OM_EN_USC_t.book Page 356

Page 359 of 568

IN CASE OF EMERGENCY357

Cab Top Clearance Lamps — If Equipped

1. Remove the screws from the top of the

lamp.

Removing Rear Screw From Clearance Lamp

2. Rotate the bulb socket a quarter turn and pull it from the lamp assembly.

Removing Bulb Socket From Clearance Lamp

3. Pull the bulb straight from it's socket and

replace.

Rear Lamp Bar ID Marker (Dual Rear

Wheels) — If Equipped

1. Loosen the two screws and the housing to gain access to the bulb sockets.

Screw Locations

2. Turn the socket a quarter turn counter -

clockwise to access the bulb.

3. Pull the bulb straight out from the socket.

4. Reverse the procedure for installation of the bulbs and housing.

Side Marker Lamps (Dual Rear Wheels) —

If Equipped

Side Marker Lamp Locations

1. Push rearward on the side marker lamp assembly.

2. Pull the entire assembly from the fender.

3. Turn the socket a quarter turn counter -

clockwise and remove from assembly to

access the bulb.

4. Pull the bulb straight out from socket.

5. Reverse the procedure for installation of the bulbs and housing.

6

20_DJD2_OM_EN_USC_t.book Page 357

Page 361 of 568

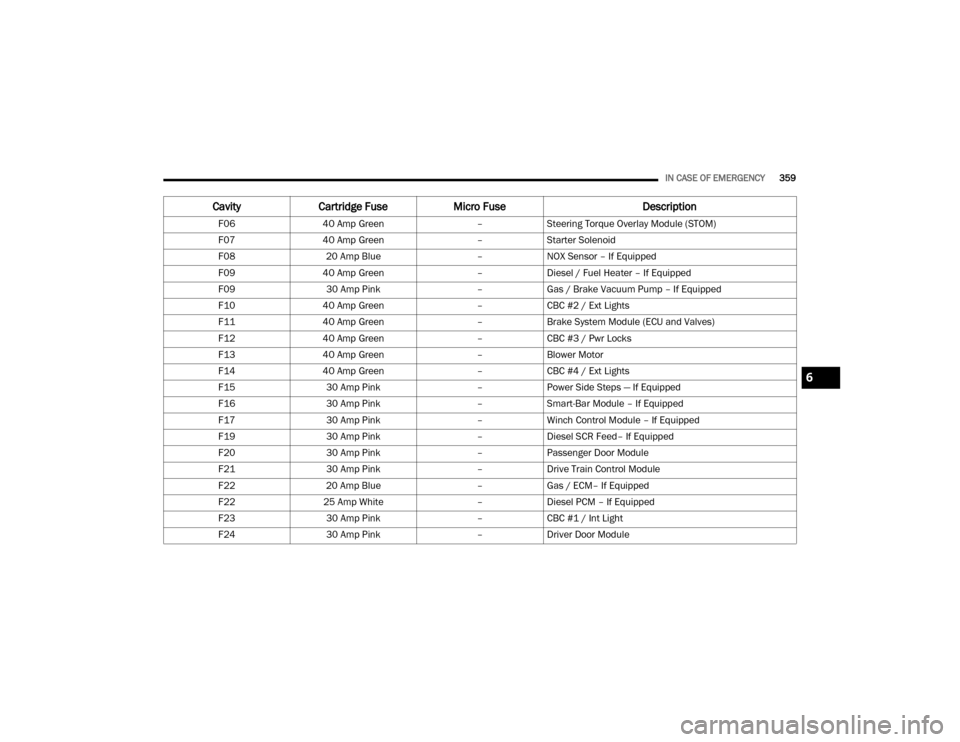

IN CASE OF EMERGENCY359

F0640 Amp Green –Steering Torque Overlay Module (STOM)

F07 40 Amp Green –Starter Solenoid

F08 20 Amp Blue –NOX Sensor – If Equipped

F09 40 Amp Green –Diesel / Fuel Heater – If Equipped

F09 30 Amp Pink –Gas / Brake Vacuum Pump – If Equipped

F10 40 Amp Green –CBC #2 / Ext Lights

F11 40 Amp Green –Brake System Module (ECU and Valves)

F12 40 Amp Green –CBC #3 / Pwr Locks

F13 40 Amp Green –Blower Motor

F14 40 Amp Green –CBC #4 / Ext Lights

F15 30 Amp Pink –Power Side Steps — If Equipped

F16 30 Amp Pink –Smart-Bar Module – If Equipped

F17 30 Amp Pink –Winch Control Module – If Equipped

F19 30 Amp Pink –Diesel SCR Feed– If Equipped

F20 30 Amp Pink –Passenger Door Module

F21 30 Amp Pink –Drive Train Control Module

F22 20 Amp Blue –Gas / ECM– If Equipped

F22 25 Amp White –Diesel PCM – If Equipped

F23 30 Amp Pink –CBC #1 / Int Light

F24 30 Amp Pink –Driver Door Module

Cavity Cartridge Fuse Micro Fuse Description

6

20_DJD2_OM_EN_USC_t.book Page 359

Page 363 of 568

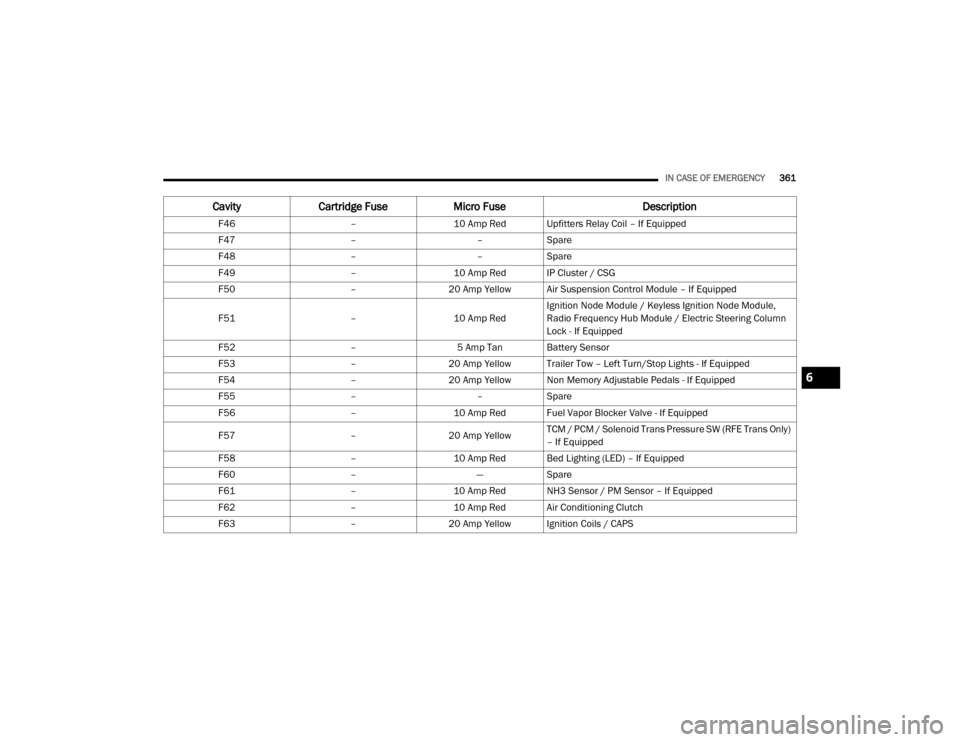

IN CASE OF EMERGENCY361

F46 –10 Amp Red Upfitters Relay Coil – If Equipped

F47 ––Spare

F48 ––Spare

F49 –10 Amp Red IP Cluster / CSG

F50 –20 Amp Yellow Air Suspension Control Module – If Equipped

F51 –10 Amp RedIgnition Node Module / Keyless Ignition Node Module,

Radio Frequency Hub Module / Electric Steering Column

Lock - If Equipped

F52 –5 Amp Tan Battery Sensor

F53 –20 Amp Yellow Trailer Tow – Left Turn/Stop Lights - If Equipped

F54 –20 Amp Yellow Non Memory Adjustable Pedals - If Equipped

F55 ––Spare

F56 –10 Amp Red Fuel Vapor Blocker Valve - If Equipped

F57 –20 Amp Yellow TCM / PCM / Solenoid Trans Pressure SW (RFE Trans Only)

– If Equipped

F58 –10 Amp Red Bed Lighting (LED) – If Equipped

F60 –—Spare

F61 –10 Amp Red NH3 Sensor / PM Sensor – If Equipped

F62 –10 Amp Red Air Conditioning Clutch

F63 –20 Amp Yellow Ignition Coils / CAPS

CavityCartridge Fuse Micro Fuse Description

6

20_DJD2_OM_EN_USC_t.book Page 361

Page 367 of 568

IN CASE OF EMERGENCY365

JACKING AND TIRE CHANGING NOTE:

If your vehicle is equipped with an air suspen -

sion system, there is a feature which allows the

automatic leveling to be disabled to assist with

changing a tire.

This feature can be activated through the Ucon -

nect system.

Refer to “Uconnect Settings” in “Multimedia”

for further information.

JACK LOCATION

The jack and tools are stored under the front

passenger seat.

REMOVAL OF JACK AND TOOLS

To access the jack and jack tools, you must

remove the plastic access cover located on the

side of the front passenger’s seat. To remove

the cover, pull the front part of the cover

(closest to the front of the seat) toward you to

release a locking tab. Once the front of the

cover is loose, slide the cover toward the front

of the seat until it is free from the seat frame.

Jack Access Cover

Remove the jack and tools by turning the wing

bolt counterclockwise, remove the wing bolt

and then slide the assembly out from under the

seat.

Wing Bolt/Jack And Tools

WARNING!

Do not attempt to change a tire on the side

of the vehicle close to moving traffic. Pull

far enough off the road to avoid the danger

of being hit when operating the jack or

changing the wheel.

Being under a jacked-up vehicle is

dangerous. The vehicle could slip off the

jack and fall on you. You could be crushed.

Never put any part of your body under a

vehicle that is on a jack. If you need to get

under a raised vehicle, take it to a service

center where it can be raised on a lift.

Never start or run the engine while the

vehicle is on a jack.

The jack is designed to be used as a tool for

changing tires only. The jack should not be

used to lift the vehicle for service purposes.

The vehicle should be jacked on a firm level

surface only. Avoid ice or slippery areas.

6

20_DJD2_OM_EN_USC_t.book Page 365

Page 368 of 568

366IN CASE OF EMERGENCY

(Continued)

Remove the jack and tools from the bracket

assembly. Turn the jack turn-screw

counterclockwise to release jack from bracket

assembly.

Jack And Tools Bracket AssemblyJacking Tools

There are two ways to assemble the tools:

Assembled For Spare Tire Lowering/Raising

Assembled For Spare Tire Lowering/Raising

Assembled For Jack Operation

Assembled For Jack Operation

1 — Lug Wrench

2 — Extension 2

3 — Extension 3

4 — Extension 4

CAUTION!

The lug wrench can only be attached to

extension two (2).

When attaching the tool to the winch mech -

anism be sure the large flared end opening

on extension four (4) is positioned correctly

over the winch mechanism adjusting nut.

Damage to the lug wrench, extensions and

winch mechanism may occur from

improper tool assembly.

1 — Lug Wrench

2 — Extension 2

3 — Extension 3

4 — Extension 4

5 — Jack Driver

CAUTION! (Continued)

20_DJD2_OM_EN_USC_t.book Page 366

Page 369 of 568

IN CASE OF EMERGENCY367

REMOVING THE SPARE TIRE

1. Remove the spare tire before attempting to

jack up the truck. Attach the lug wrench to

the extension tubes with the curved angle

facing away from the vehicle. Insert the

extension tube through the access hole

between the lower tailgate and the top of the

bumper and into the winch mechanism tube.

Winch Mechanism Tube Inserting The Extension Tubes Into The Access Hole

2. Rotate the lug wrench handle counter -

clockwise until the spare tire is on the

ground with enough cable slack to allow you

to pull it out from under the vehicle.

Rotating The Lug Wrench Handle

3. Pull the spare tire out from under the vehicle to gain access to the spare tire retainer.

4. Lift the spare tire with one hand to give

clearance to tilt the retainer at the end of

the cable.

Gaining Access To The Retainer

5. Pull the retainer through the center of the wheel.

Pulling The Retainer Through The Center Of The Wheel

WARNING!

After using the jack and tools, always reinstall

them in the original carrier and location.

While driving you may experience abrupt

stopping, rapid acceleration or sharp turns. A

loose jack, tools, bracket or other objects in

the vehicle may move around with force,

resulting in serious injury.

6

20_DJD2_OM_EN_USC_t.book Page 367

Page 370 of 568

368IN CASE OF EMERGENCY

(Continued)

NOTE:

The winch mechanism is designed for use with

the extension tubes only. Use of an air wrench

or other power tools is not recommended and

can damage the winch.

PREPARATIONS FOR JACKING

1. Park the vehicle on a firm, level surface. Avoid ice or slippery areas.

2. Turn on the Hazard Warning Flashers.

3. Apply the parking brake.

4. Shift the transmission into Park (P).

5. Turn the ignition OFF.

6. Block both the front and rear of the wheel diagonally opposite the jacking position. For

example, if the driver’s front wheel is being

changed, block the passenger’s rear wheel.

Wheel Blocked

NOTE:

Passengers should not remain in the vehicle

when the vehicle is being raised or lifted.

JACKING INSTRUCTIONS

WARNING!

Do not attempt to change a tire on the side of

the vehicle close to moving traffic. Pull far

enough off the road to avoid being hit when

operating the jack or changing the wheel.

WARNING!

Carefully follow these tire changing warnings

to help prevent personal injury or damage to

your vehicle:

Always park on a firm, level surface as far

from the edge of the roadway as possible

before raising the vehicle.

Turn on the Hazard Warning Flashers.

Apply the parking brake firmly and set the

transmission in PARK.

Block the wheel diagonally opposite the

wheel to be raised.

Never start or run the engine with the

vehicle on a jack.

Do not let anyone sit in the vehicle when it

is on a jack.

Do not get under the vehicle when it is on a

jack. If you need to get under a raised

vehicle, take it to a service center where it

can be raised on a lift.

Only use the jack in the positions indicated

and for lifting this vehicle during a tire

change.

If working on or near a roadway, be

extremely careful of motor traffic.

To assure that spare tires, flat or inflated,

are securely stowed, spares must be

stowed with the valve stem facing the

ground.

WARNING! (Continued)

20_DJD2_OM_EN_USC_t.book Page 368

Page 371 of 568

IN CASE OF EMERGENCY369

Jack Warning Label

Lug Wrench Adapter Shown In Jack And Tools Assembly

1. Remove the spare wheel, jack, and tools

from storage.

2. Using the lug wrench, loosen, but do not remove, the wheel nuts by turning them

counterclockwise one turn while the wheel

is still on the ground. Changing a dually tire

requires the lug wrench adapter.

NOTE:

If your vehicle is equipped with hub caps/wheel

covers they must be removed before raising the

vehicle off the ground. Refer to ”Hub Caps/

Wheel Covers — If Equipped” in this section.

Lug Wrench Adapter

Lug Wrench Adapter And Wrench

3. Placement of the jack is critical:

CAUTION!

Do not attempt to raise the vehicle by jacking

on locations other than those indicated in the

Jacking Instructions for this vehicle.

6

20_DJD2_OM_EN_USC_t.book Page 369