ECU Ram 3500 2020 Workshop Manual

[x] Cancel search | Manufacturer: RAM, Model Year: 2020, Model line: 3500, Model: Ram 3500 2020Pages: 568

Page 277 of 568

STARTING AND OPERATING275

5. Pull the wire to the anchor point. Pull out

enough wire rope to reach your anchor

point. To prevent losing the end, hold the

hook strap while you work.

Pulling Synthetic Rope

6. Secure to the anchor point. Once you have established your anchor point, secure the

tree-trunk protector or choker-chain around

the object.

Tree Trunk Protector

NOTE:

How to choose an anchor point: A secure

anchor is critical to winching operations. An

anchor must be strong enough to hold while

winching. Natural anchors include trees,

stumps and rocks. Hook the cable as low as

possible. If no natural anchors are available

when recovering another vehicle, your vehicle

becomes the anchor point. In this case, be sure

to put the transmission in NEUTRAL, apply the

hand brake and block its wheels to prevent your

vehicle from moving. Ideally, you'll want an

anchor point that will enable you to pull straight in the direction the vehicle will move. This

allows the synthetic rope to wind tightly and

evenly onto the spooling drum. An anchor point

as far away as possible will provide the winch

with its greatest pulling power.

7. Attach the Clevis/D-Shackle and Tree Trunk

Protector. Attach the shackle to the two

ends of the strap or chain and through the

hook, being careful not to over tighten

(tighten and back-off 1/2 turn).

Clevis/D-Shackles

8. Lock the clutch. Lock the winch drum by rotating the clutch lever on the winch to

engage.

NOTE:

Always ensure the clutch is fully engaged or

disengaged.

WARNING!

Never touch winch rope or hook while

someone else is at the control switch or

during winching operation.

Never touch winch rope or hook while

under tension or under load.

CAUTION!

Always be certain the anchor you select will

withstand the load.5

20_DJD2_OM_EN_USC_t.book Page 275

Page 278 of 568

276STARTING AND OPERATING

9. Connect the remote control to the winch

control box, located on the front bumper. Be

careful not to let the remote control cord

dangle in front of the winch. If you choose to

control the winch from inside your vehicle,

always pass the remote through a window

to avoid pinching the cord in the door.

Always disconnect the remote control when

not in use.

Winch Box Remote Control Connector

10. Put synthetic rope under tension. Using the remote control switch, slowly wind the rope

until no slack remains. Once the rope is

under tension, stand well clear of it and

never step over it.

Pulling Synthetic Rope Under Tension

11. Check your anchor. Make sure all connections are secured and free of debris

before continuing with the winching

procedure.

12. Check synthetic rope. The rope should be neatly wound around the spooling drum.

Improper winding can cause damage to the

synthetic rope.

Synthetic Rope Neatly Wound Around

The Spooling Drum

Heavy Blanket Over Rope

20_DJD2_OM_EN_USC_t.book Page 276

Page 280 of 568

278STARTING AND OPERATING

synthetic rope tends to stack up at one end of

the drum. This stack can become large

enough to cause serious damage to the

winch. So, line up pulls as straight ahead as

possible and stop winching if the synthetic

rope comes close to the tie rods or mounting

plate. To fix an uneven stack, spool out that

section of the rope and reposition it to the

opposite end of the drum, which will free up

space for continued winching.

15. Secure vehicle. Once recovery of the vehicle is complete, be sure to secure the vehicle's

brakes and shift the transmission to PARK.

Release tension in the synthetic rope.

16. Disconnect the synthetic rope, and disconnect from the anchor.

17. Rewind the synthetic rope. The person handling the synthetic rope should walk the

rope in and not let it slide through the hand,

control the winch at all times.

Rewinding The Synthetic Rope

NOTE:

How to spool under no load: Arrange the remote

control lead so it cannot be caught in the winch.

Arrange the synthetic rope so it will not kink or

tangle when spooled. Be sure any synthetic

rope already on the spooling drum is wound

tightly and evenly layered. Tighten and

straighten the layer if necessary. Keep the

synthetic rope under light tension and spool the

rope back and onto the winch drum in even

layers. Stop frequently to tighten and straighten

the layers as necessary. Repeat this process until the winch hook is the same distance as the

full length of the remote control from the winch.

Pinch the hook between your thumb and fore

-

finger and attach the hook strap. Hold the hook

strap between the thumb and forefinger to keep

tension on the synthetic rope. Walk the

synthetic rope towards the fairlead, carefully

spooling in the remaining rope by pulsing the

remote control switch.

18. Store the hook on the most outboard loop of

the hawse fairlead.

Hook In Stored Position

19. Disconnect the remote control. Disconnect the remote control cord from the control box

and store in a clean and dry place. Winching

operations are now complete. Put the cap

on the solenoid plug-in.

WARNING!

To prevent serious injury, NEVER put your

fingers inside the hook area as you are

powering-in.

20_DJD2_OM_EN_USC_t.book Page 278

Page 281 of 568

STARTING AND OPERATING279

NOTE:

Always store the remote control in a protected,

clean, dry area.

RIGGING TECHNIQUES

Various winching situations will require

application of other winching techniques. These

could range from too little distance to achieve

maximum pull using straight line rigging, simply

increasing pulling power, or maintaining a

straight-line pulling situation. You will have to

assess what technique is correct for your

situation. Think "safety" at all times.

How To Change The Pulling Direction

Change Pulling Directions

All winching operations should have a straight

line from the winch to the object being pulled. This minimizes the synthetic rope collecting on

one side of the drum affecting pulling efficiency

and damaging synthetic rope. A snatch block,

secured to a point directly in front of the vehicle

will enable you to change your pulling direction

while still allowing the synthetic rope to be at

90° to wind properly onto the spooling drum.

Increasing Pulling Power

In some cases, you may find yourself needing

more pulling power. The use of snatch blocks

increases mechanical advantage and that

increases your pulling power.

Double Line

Wire Rope Routing

Because pulling power decreases with the

number of layers of synthetic rope on the winch drum, you can use a snatch block to double line

out more rope. This decreases the number of

layers of synthetic rope on the drum, and

increases pulling power. Start by feeding out

enough synthetic rope to free the winch hook.

Attach the hook to your vehicle's frame/tow

hook and run the rope through a snatch block.

Disengage the clutch and, using the snatch

block, pull out enough synthetic rope to reach

your anchor point. Do not attach the hook to the

mounting kit. Secure to the anchor point with a

tree trunk protector or choker chain. Attach the

clevis/shackle. Attach the shackle to the two

ends of the strap/chain, being careful not to

over tighten (tighten and back-off 1/2 turn).

FUEL SAVER TECHNOLOGY — GAS ENGINE

(IF EQUIPPED)

This feature offers improved fuel economy by

shutting off four of the engine's eight cylinders

during light load and cruise conditions. The

system is automatic with no driver inputs or

additional driving skills required.

NOTE:

This system may take some time to return to full

functionality after a battery disconnect.

5

20_DJD2_OM_EN_USC_t.book Page 279

Page 322 of 568

320STARTING AND OPERATING

Tighten the gas cap until you hear a “clicking”

sound. This is an indication that the gas cap

is tightened properly. The MIL in the instru -

ment cluster may turn on if the gas cap is not

secured properly. Make sure that the gas cap

is tightened each time the vehicle is refueled.

LOOSE FUEL FILLER CAP MESSAGE

If the vehicle diagnostic system

determines that the fuel filler cap is

loose, improperly installed, or

damaged, a loose gASCAP indicator

will display in the instrument cluster telltale

display area. Refer to “Instrument Cluster Display” in “Getting To Know Your Instrument

Panel” for further information. Tighten the fuel

filler cap properly and push the RIGHT button to

turn off the message. If the problem continues,

the message will appear the next time the

vehicle is started.

REFUELING THE VEHICLE — DIESEL ENGINE

1. Open the fuel filler door.

Fill Locations

NOTE:

There is no fuel filler cap. A flapper door inside

the filler pipe seals the system. 2. Insert the fuel nozzle fully into the filler pipe

– the nozzle opens and holds the flapper

door while refueling.

3. Fill the vehicle with fuel – when the fuel nozzle “clicks” or shuts off the fuel tank is

full.

4. Remove the fuel nozzle and close the fuel door.

Emergency Fuel Can Refueling

NOTE:

In the event that you run the vehicle out of fuel,

once refueled, place the ignition in the ON posi -

tion for 30 seconds, then turn the ignition OFF

and wait 30 seconds. Repeat this procedure

three times, prior to cranking the engine.

Most fuel cans will not open the flapper door.

A funnel is provided to open the flapper door to

allow emergency refueling with a fuel can.

1. Retrieve fuel funnel from the jack kit located under the front passenger seat.

2. Insert funnel into same filler pipe opening as the fuel nozzle.

WARNING!

Always place container on the ground

before filling.

Keep the pump nozzle in contact with the

container when you are filling it.

Use only approved containers for flam -

mable liquid.

Do not leave container unattended while

filling.

A static electric charge could cause a spark

and fire hazard.

1 — Diesel Exhaust Fluid (DEF) Fill Location

2 — Diesel Fuel Fill Location

20_DJD2_OM_EN_USC_t.book Page 320

Page 327 of 568

STARTING AND OPERATING325

The entire vehicle should first be weighed on a

commercial scale to ensure that the GVWR has

not been exceeded. The weight on the front and

rear of the vehicle should then be determined

separately to be sure that the load is properly

distributed over the front and rear axles.

Weighing the vehicle may show that the GAWR

of either the front or rear axle has been

exceeded but the total load is within the

specified GVWR. If so, weight must be shifted

from front to rear or rear to front as appropriate

until the specified weight limitations are met.

Store the heavier items down low and be sure

that the weight is distributed equally. Stow all

loose items securely before driving.

Improper weight distributions can have an

adverse effect on the way your vehicle steers

and handles and the way the brakes operate.TRAILER TOWING

In this section you will find safety tips and

information on limits to the type of towing you

can reasonably do with your vehicle. Before

towing a trailer, carefully review this information

to tow your load as efficiently and safely as

possible.

To maintain the New Vehicle Limited Warranty

coverage, follow the requirements and

recommendations in this manual concerning

vehicles used for trailer towing.

COMMON TOWING DEFINITIONS

The following trailer towing-related definitions

will assist you in understanding the following

information:

Gross Vehicle Weight Rating (GVWR)

The GVWR is the total allowable weight of your

vehicle. This includes driver, passengers, cargo

and tongue weight. The total load must be

limited so that you do not exceed the GVWR.

Refer to “Vehicle Loading/Vehicle Certification

Label” in “Starting And Operating” for further

information.

Gross Trailer Weight (GTW)

The GTW is the weight of the trailer plus the

weight of all cargo, consumables and

equipment (permanent or temporary) loaded in

or on the trailer in its "loaded and ready for

operation" condition.

The recommended way to measure GTW is to

put your fully loaded trailer on a vehicle scale.

The entire weight of the trailer must be

supported by the scale.

Gross Combination Weight Rating (GCWR)

The GCWR is the total allowable weight of your

vehicle and trailer when weighed in

combination.

CAUTION!

Do not load your vehicle any heavier than the

GVWR or the maximum front and rear GAWR.

If you do, parts on your vehicle can break, or

it can change the way your vehicle handles.

This could cause you to lose control. Also

overloading can shorten the life of your

vehicle.

WARNING!

If the gross trailer weight is 5,000 lbs (2,267 kg)

or more, it is recommended to use a

weight-distributing hitch to ensure stable

handling of your vehicle. If you use a standard

weight-carrying hitch, you could lose control of

your vehicle and cause a collision.

5

20_DJD2_OM_EN_USC_t.book Page 325

Page 332 of 568

330STARTING AND OPERATING

(Continued)

TRAILER TOWING WEIGHTS (MAXIMUM

T

RAILER WEIGHT RATINGS)

NOTE:

For trailer towing information (maximum trailer

weight ratings) refer to the following website

addresses:

ramtrucks.com/en/towing_guide/

ramtruck.ca (Canada)

rambodybuilder.com

TRAILER AND TONGUE WEIGHT

Weight Distribution

Consider the following items when computing

the weight on the rear axle of the vehicle:

The tongue weight of the trailer.

The weight of any other type of cargo or

equipment put in or on your vehicle.

The weight of the driver and all passengers.

NOTE:

Remember that everything put into or on the

trailer adds to the load on your vehicle. Also,

additional factory-installed options or

dealer-installed options must be considered as

part of the total load on your vehicle. Refer to

the “Tire And Loading Information” placard for

the maximum combined weight of occupants

and cargo for your vehicle.

TOWING REQUIREMENTS

To promote proper break-in of your new vehicle

drivetrain components, the following guidelines

are recommended.

Perform the maintenance listed in the

“Scheduled Servicing”. Refer to “Scheduled

Servicing” in “Servicing And Maintenance” for the

proper maintenance intervals. When towing a

trailer, never exceed the GAWR or GCWR ratings.

CAUTION!

Do not tow a trailer at all during the first

500 miles (805 km) the new vehicle is driven.

The engine, axle or other parts could be

damaged.

Then, during the first 500 miles (805 km) that

a trailer is towed, do not drive over 50 mph

(80 km/h) and do not make starts at full

throttle. This helps the engine and other parts

of the vehicle wear in at the heavier loads.

WARNING!

Make certain that the load is secured in the

trailer and will not shift during travel. When

trailering cargo that is not fully secured,

dynamic load shifts can occur that may be diffi

-

cult for the driver to control. You could lose

control of your vehicle and have a collision.

20_DJD2_OM_EN_USC_t.book Page 330

Page 341 of 568

STARTING AND OPERATING339

RECREATIONAL TOWING (BEHIND MOTORHOME, ETC.)

TOWING THIS VEHICLE BEHIND ANOTHER VEHICLE

NOTE:

When towing your vehicle, always follow

applicable state and provincial laws. Contact

state and provincial Highway Safety offices

for additional details.

Vehicles equipped with air suspension must

be placed in Transport mode before tying

them down (from the body) on a trailer or

flatbed truck. Refer to “Air Suspension – If

Equipped” for more information. If the

vehicle cannot be placed in Transport mode (for example, engine will not run), tie-downs

must be fastened to the axles (not to the

body). Failure to follow these instructions

may cause fault codes to be set and/or

cause loss of proper tie-down tension.RECREATIONAL TOWING — TWO-WHEEL

D

RIVE MODELS

DO NOT flat tow this vehicle. Damage to the

drivetrain will result. Recreational towing (for two-wheel drive

models) is allowed

ONLY if the rear wheels are

OFF the ground. This may be accomplished

using a tow dolly or vehicle trailer. If using a tow

dolly, follow this procedure:

NOTE:

If vehicle is equipped with air suspension,

ensure the vehicle is set to Normal Ride Height.

1. Properly secure the dolly to the tow vehicle, following the dolly manufacturer's

instructions.

Towing Condition Wheels OFF The

Ground Two-Wheel Drive

Models Four-Wheel Drive Models

Flat Tow

NONENOT ALLOWED See InstructionsAutomatic transmission in PARK

Transfer case in NEUTRAL (N)

Tow in forward direction

Dolly Tow Front

NOT ALLOWED NOT ALLOWED

Rear OK NOT ALLOWED

On Trailer ALLOK OK5

20_DJD2_OM_EN_USC_t.book Page 339

Page 342 of 568

340STARTING AND OPERATING

(Continued)

2. Drive the rear wheels onto the tow dolly.

3. Firmly apply the parking brake. Place automatic transmission in PARK.

4. Properly secure the rear wheels to the dolly, following the dolly manufacturer's

instructions.

5. Turn the ignition OFF and remove the key fob.

6. Install a suitable clamping device, designed for towing, to secure the front wheels in the

straight position.RECREATIONAL TOWING —

F

OUR-WHEEL DRIVE MODELS

NOTE:

Both the manual shift and electronic shift

transfer cases must be shifted into NEUTRAL

(N) for recreational towing. Automatic transmis -

sions must be shifted into PARK for recreational

towing. Refer to the following for the proper

transfer case NEUTRAL (N) shifting procedure

for your vehicle.

CAUTION!

Towing with the rear wheels on the ground

will cause severe transmission damage.

Damage from improper towing is not

covered under the New Vehicle Limited

Warranty.

Do not disconnect the driveshaft because

fluid may leak from the transmission,

causing damage to internal parts.

CAUTION!

DO NOT dolly tow any 4WD vehicle. Towing

with only one set of wheels on the ground

(front or rear) will cause severe transmis -

sion and/or transfer case damage. Tow

with all four wheels either ON the ground, or

OFF the ground (using a vehicle trailer).

Tow only in the forward direction. Towing

this vehicle backwards can cause severe

damage to the transfer case.

Before recreational towing, the transfer

case must be in NEUTRAL. To be certain the

transfer case is fully in NEUTRAL, perform

the procedure outlined under “Shifting Into

NEUTRAL”. Internal transmission damage

will result, if the transfer case is not in

NEUTRAL during towing.

The transmission must be placed in PARK

for recreational towing.

Towing this vehicle in violation of the above

requirements can cause severe transmis -

sion and/or transfer case damage.

Damage from improper towing is not

covered under the New Vehicle Limited

Warranty.

Do not disconnect the rear driveshaft

because fluid will leak from the transfer

case, causing damage to internal parts.

Do not use a bumper-mounted clamp-on

tow bar on your vehicle. The bumper face

bar will be damaged.

CAUTION! (Continued)

20_DJD2_OM_EN_USC_t.book Page 340

Page 361 of 568

IN CASE OF EMERGENCY359

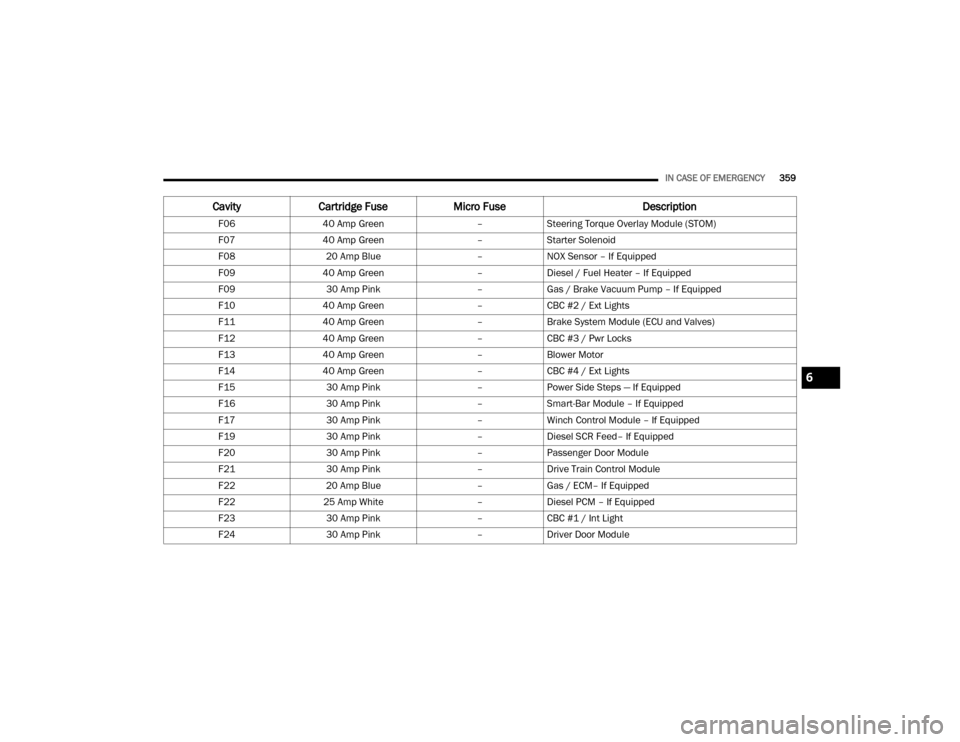

F0640 Amp Green –Steering Torque Overlay Module (STOM)

F07 40 Amp Green –Starter Solenoid

F08 20 Amp Blue –NOX Sensor – If Equipped

F09 40 Amp Green –Diesel / Fuel Heater – If Equipped

F09 30 Amp Pink –Gas / Brake Vacuum Pump – If Equipped

F10 40 Amp Green –CBC #2 / Ext Lights

F11 40 Amp Green –Brake System Module (ECU and Valves)

F12 40 Amp Green –CBC #3 / Pwr Locks

F13 40 Amp Green –Blower Motor

F14 40 Amp Green –CBC #4 / Ext Lights

F15 30 Amp Pink –Power Side Steps — If Equipped

F16 30 Amp Pink –Smart-Bar Module – If Equipped

F17 30 Amp Pink –Winch Control Module – If Equipped

F19 30 Amp Pink –Diesel SCR Feed– If Equipped

F20 30 Amp Pink –Passenger Door Module

F21 30 Amp Pink –Drive Train Control Module

F22 20 Amp Blue –Gas / ECM– If Equipped

F22 25 Amp White –Diesel PCM – If Equipped

F23 30 Amp Pink –CBC #1 / Int Light

F24 30 Amp Pink –Driver Door Module

Cavity Cartridge Fuse Micro Fuse Description

6

20_DJD2_OM_EN_USC_t.book Page 359