maintenance Ram 4500 Chassis Cab 2018 Owner's Manual

[x] Cancel search | Manufacturer: RAM, Model Year: 2018, Model line: 4500 Chassis Cab, Model: Ram 4500 Chassis Cab 2018Pages: 298, PDF Size: 5.88 MB

Page 184 of 298

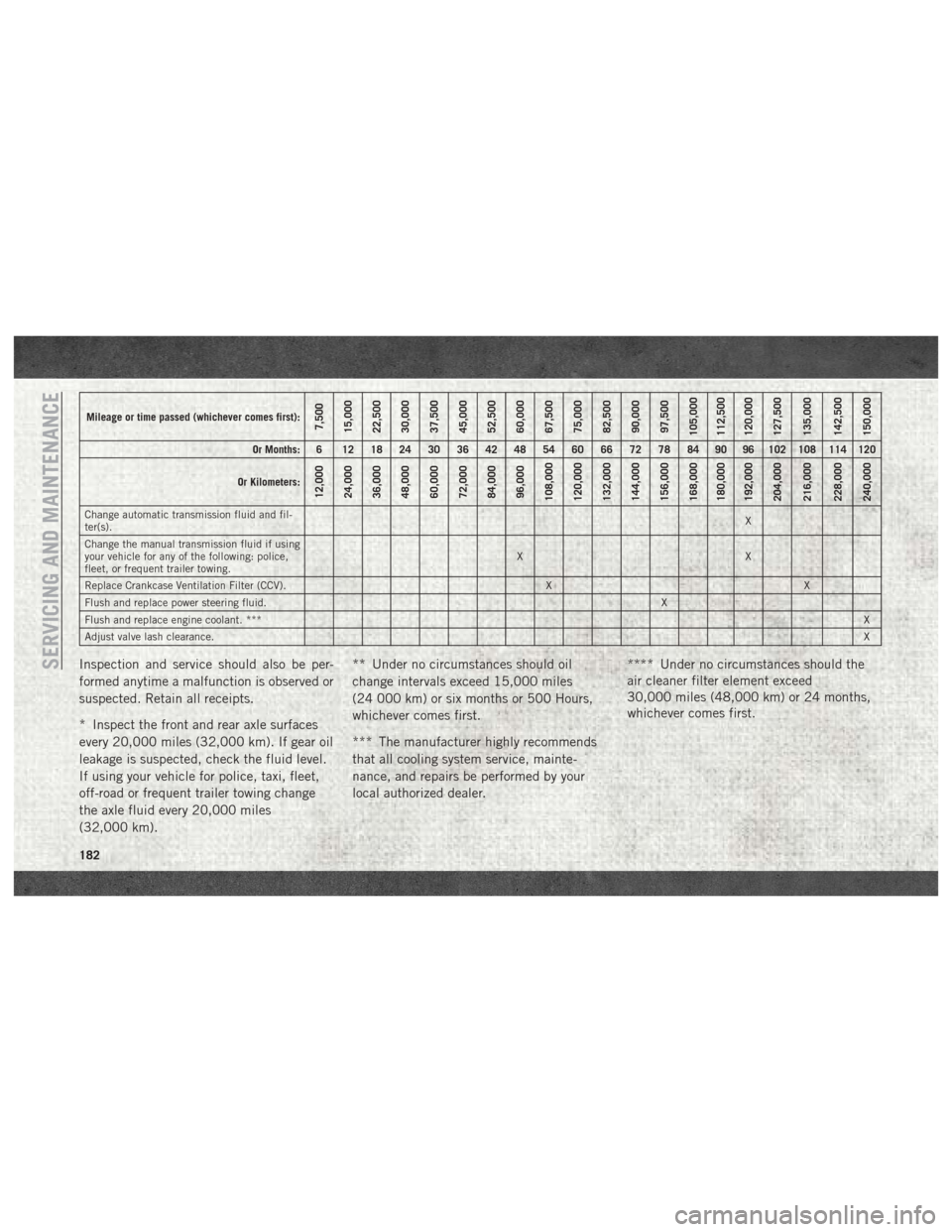

Mileage or time passed (whichever comes first):7,500

15,000

22,500

30,000

37,500

45,000

52,500

60,000

67,500

75,000

82,500

90,000

97,500

105,000

112,500

120,000

127,500

135,000

142,500

150,000

Or Months: 6 12 18 24 30 36 42 48 54 60 66 72 78 84 90 96 102 108 114 120

Or Kilometers:

12,000

24,000

36,000

48,000

60,000

72,000

84,000

96,000

108,000

120,000

132,000

144,000

156,000

168,000

180,000

192,000

204,000

216,000

228,000

240,000

Change automatic transmission fluid and fil-

ter(s). X

Change the manual transmission fluid if using

your vehicle for any of the following: police,

fleet, or frequent trailer towing. XX

Replace Crankcase Ventilation Filter (CCV). X X

Flush and replace power steering fluid. X

Flush and replace engine coolant. *** X

Adjust valve lash clearance. X

Inspection and service should also be per-

formed anytime a malfunction is observed or

suspected. Retain all receipts.

* Inspect the front and rear axle surfaces

every 20,000 miles (32,000 km). If gear oil

leakage is suspected, check the fluid level.

If using your vehicle for police, taxi, fleet,

off-road or frequent trailer towing change

the axle fluid every 20,000 miles

(32,000 km).** Under no circumstances should oil

change intervals exceed 15,000 miles

(24 000 km) or six months or 500 Hours,

whichever comes first.

*** The manufacturer highly recommends

that all cooling system service, mainte-

nance, and repairs be performed by your

local authorized dealer.

**** Under no circumstances should the

air cleaner filter element exceed

30,000 miles (48,000 km) or 24 months,

whichever comes first.SERVICING AND MAINTENANCE

182

Page 186 of 298

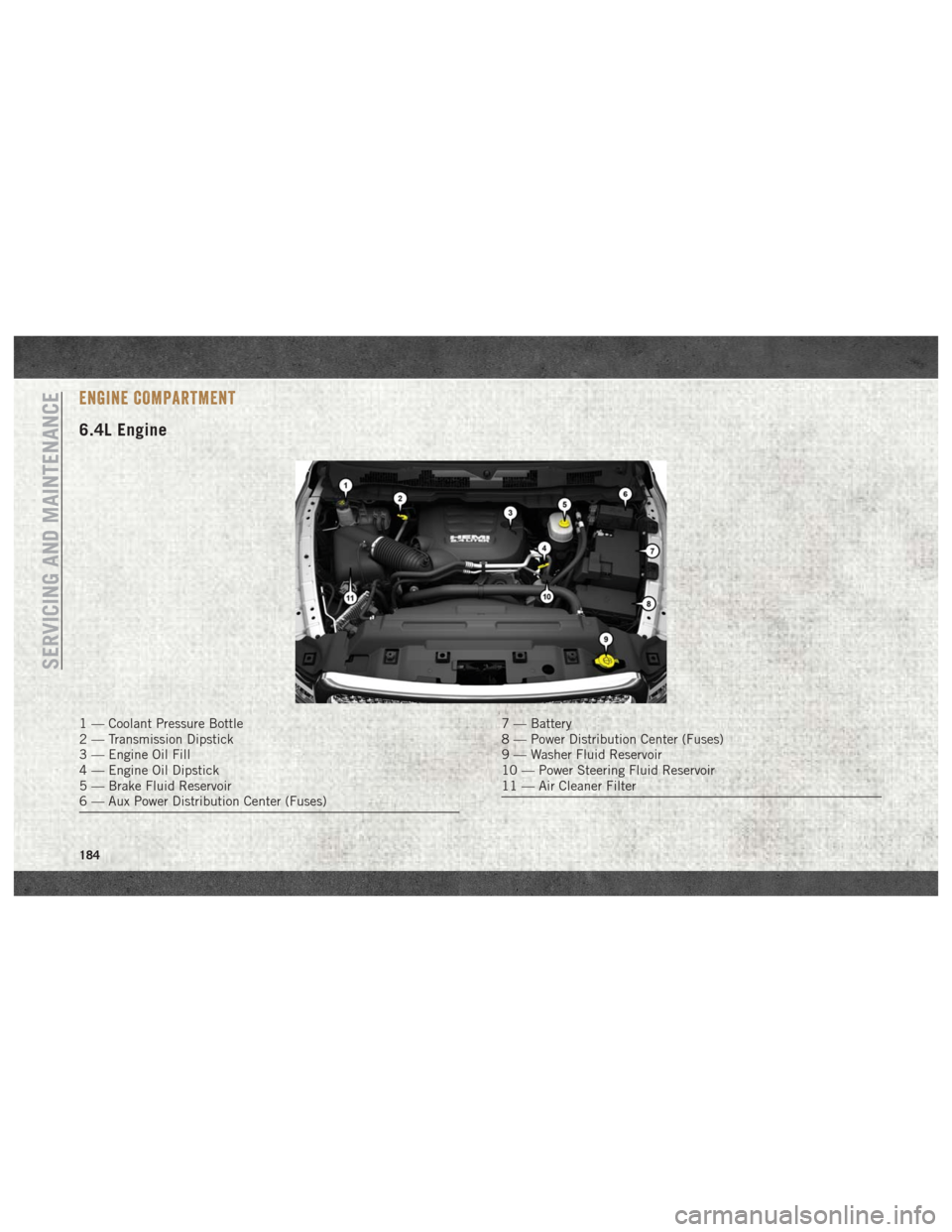

ENGINE COMPARTMENT

6.4L Engine

1 — Coolant Pressure Bottle

2 — Transmission Dipstick

3 — Engine Oil Fill

4 — Engine Oil Dipstick

5 — Brake Fluid Reservoir

6 — Aux Power Distribution Center (Fuses)7 — Battery

8 — Power Distribution Center (Fuses)

9 — Washer Fluid Reservoir

10 — Power Steering Fluid Reservoir

11 — Air Cleaner Filter

SERVICING AND MAINTENANCE

184

Page 188 of 298

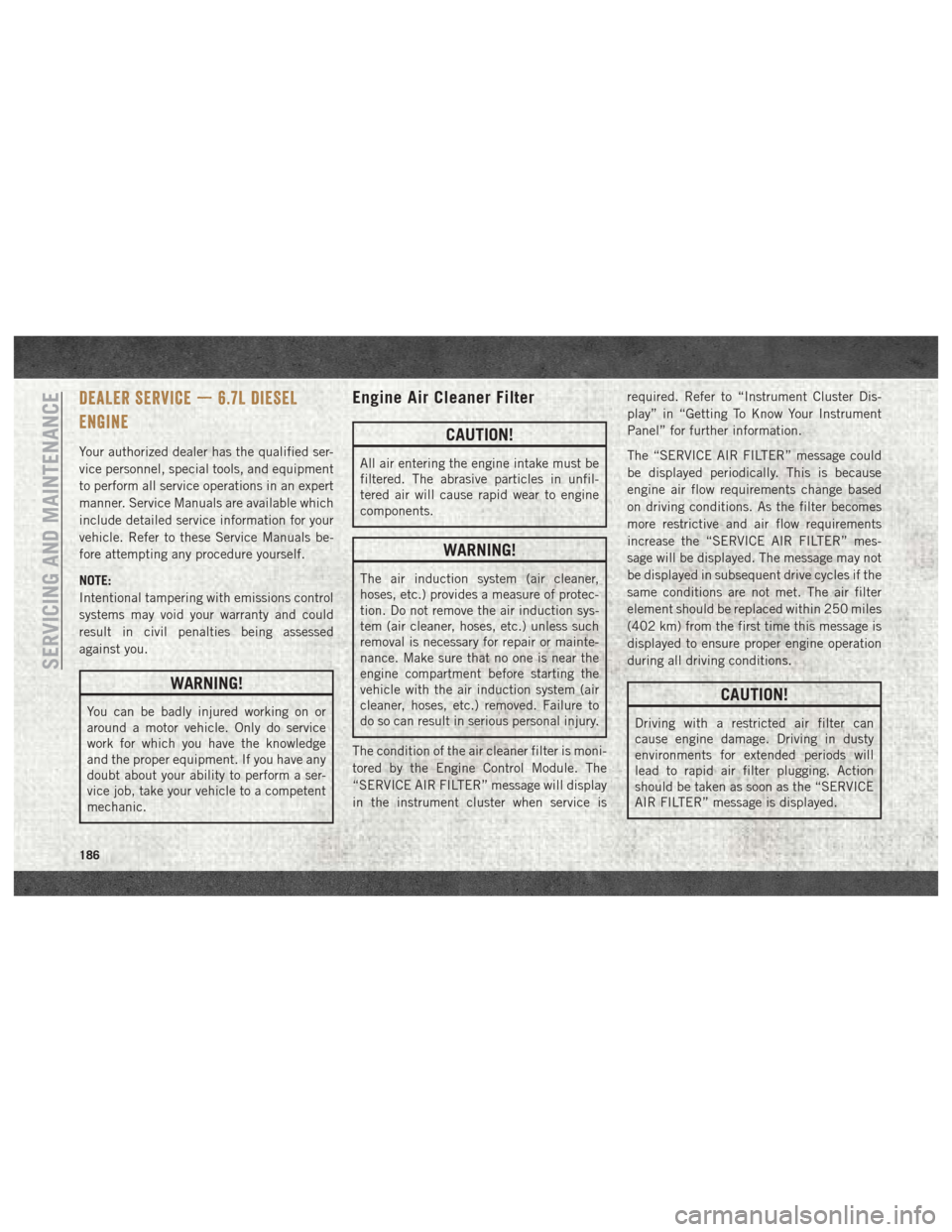

DEALER SERVICE — 6.7L DIESEL

ENGINE

Your authorized dealer has the qualified ser-

vice personnel, special tools, and equipment

to perform all service operations in an expert

manner. Service Manuals are available which

include detailed service information for your

vehicle. Refer to these Service Manuals be-

fore attempting any procedure yourself.

NOTE:

Intentional tampering with emissions control

systems may void your warranty and could

result in civil penalties being assessed

against you.

WARNING!

You can be badly injured working on or

around a motor vehicle. Only do service

work for which you have the knowledge

and the proper equipment. If you have any

doubt about your ability to perform a ser-

vice job, take your vehicle to a competent

mechanic.

Engine Air Cleaner Filter

CAUTION!

All air entering the engine intake must be

filtered. The abrasive particles in unfil-

tered air will cause rapid wear to engine

components.

WARNING!

The air induction system (air cleaner,

hoses, etc.) provides a measure of protec-

tion. Do not remove the air induction sys-

tem (air cleaner, hoses, etc.) unless such

removal is necessary for repair or mainte-

nance. Make sure that no one is near the

engine compartment before starting the

vehicle with the air induction system (air

cleaner, hoses, etc.) removed. Failure to

do so can result in serious personal injury.

The condition of the air cleaner filter is moni-

tored by the Engine Control Module. The

“SERVICE AIR FILTER” message will display

in the instrument cluster when service is required. Refer to “Instrument Cluster Dis-

play” in “Getting To Know Your Instrument

Panel” for further information.

The “SERVICE AIR FILTER” message could

be displayed periodically. This is because

engine air flow requirements change based

on driving conditions. As the filter becomes

more restrictive and air flow requirements

increase the “SERVICE AIR FILTER” mes-

sage will be displayed. The message may not

be displayed in subsequent drive cycles if the

same conditions are not met. The air filter

element should be replaced within 250 miles

(402 km) from the first time this message is

displayed to ensure proper engine operation

during all driving conditions.

CAUTION!

Driving with a restricted air filter can

cause engine damage. Driving in dusty

environments for extended periods will

lead to rapid air filter plugging. Action

should be taken as soon as the “SERVICE

AIR FILTER” message is displayed.

SERVICING AND MAINTENANCE

186

Page 190 of 298

position, there may be a problem with your

water separator wiring or sensor. See your

authorized dealer for service.

Upon proper draining of the water from both

fuel filters, the “Water In Fuel Indicator

Light” will remain illuminated for approxi-

mately 10 seconds. If the water was drained

while the engine was running, the “Water In

Fuel Indicator Light” may remain on for ap-

proximately three minutes.

NOTE:

Care should be taken in disposing of used

fluids from your vehicle. Used fluids, indis-

criminately discarded, can present a problem

to the environment. Contact an authorized

dealer, service station, or government agency

for advice on recycling programs and for

where used fluids and filters can be properly

disposed of in your area.

Drain the fuel/water separator filters when

the “Water In Fuel Indicator Light” is ON.

Within 10 minutes of vehicle shutdown, turn

the engine mounted filter drain valve (located

on the side of the filter assembly) counter-

clockwise 1/4 turn, and turn the under body

mounted filter drain valve (located on thebottom of the filter assembly) counterclock

wise 1 full turn. Then turn the ignition switch

to the ON position, and allow any accumu-

lated water to drain. Leave the drain valve

open until all water and contaminants have

been removed. When clean fuel is visible,

close the drain valves by turning them fully

clockwise, and turn the ignition switch to

OFF.

If more than a couple ounces/milliliters of

fuel have been drained, follow the directions

for “Priming If The Engine Has Run Out Of

Fuel.”

Engine Mounted Fuel Filter

Replacement

NOTE:

• Using a fuel filter that does not meet the

manufacturer's filtration and water separat-

ing requirements can severely impact fuel

system life and reliability.

• The engine mounted filter housing is equipped with a No-Filter-No-Run (NFNR)

feature. Engine will not run if:

1. No filter is installed. 2. Inferior/Non-approved filter is used.

Use of OEM filter is required to ensure

vehicle will run.

CAUTION!

• Diesel fuel will damage blacktop pavingsurfaces. Drain the filter into an appro-

priate container.

• Do not prefill the fuel filter when install-

ing a new fuel filter. There is a possibility

debris could be introduced into the fuel

filter during this action. It is best to

install the filter dry and allow the in-tank

lift pump to prime the fuel system.

1. Ensure engine is turned off.

2. Place drain pan under the fuel filter drain hose.

3. Open the water drain valve 1/4 turn coun- terclockwise and completely drain fuel

and water into the approved container.

4. Close the water drain valve.

5. Remove lid using a socket or strap wrench. Rotate counterclockwise for re-

moval. Remove used o-ring and discard it.

SERVICING AND MAINTENANCE

188

Page 192 of 298

Priming If The Engine Has Run

Out Of Fuel

WARNING!

Do not open the high pressure fuel system

with the engine running. Engine operation

causes high fuel pressure. High pressure

fuel spray can cause serious injury or

death.

1. Add a substantial amount of fuel to the tank, approximately 2 to 5 gal (8L to

19L).

2. Turn ignition switch to the start position to engage starter for one second, return ig-

nition switch to run position. This will

activate in tank fuel pump for approxi-

mately 15 seconds. Repeat this process

twice.

3. Start the engine using the “Normal Start- ing” procedure. Refer to “Starting Proce-

dures” in “Starting and Operating” for

further information.

CAUTION!

Do not engage the starter motor for more

than 15 seconds at a time. Allow two

minutes between the cranking intervals.

NOTE:

The engine may run rough until the air is

forced from all the fuel lines.

WARNING!

Do not use alcohol or gasoline as a fuel

blending agent. They can be unstable un-

der certain conditions and be hazardous or

explosive when mixed with diesel fuel.

CAUTION!

Due to lack of lubricants in alcohol or

gasoline, the use of these fuels can cause

damage to the fuel system. NOTE:

• A maximum blend of 5% biodiesel, meet-

ing ASTM specification D-975 may be used

with your Cummins diesel engine. (Chassis

Cab models not configured with B20 capa-

bility.)

• A maximum blend of 20% biodiesel, meet- ing ASTM specification D-7467 may be

used with your Cummins diesel engine.

(Pickup models and Chassis Cab models

configured with B20 capability.)

• Use of biodiesel mixture in excess of 20% can negatively impact the fuel filter's abil-

ity to separate water from the fuel, resulting

in high pressure fuel system corrosion or

damage.

• Ethanol blends are not recommended or approved for use with your Cummins diesel

engine.

• In addition, commercially available fuel ad- ditives are not necessary for the proper

operation of your Cummins diesel engine.

SERVICING AND MAINTENANCE

190

Page 194 of 298

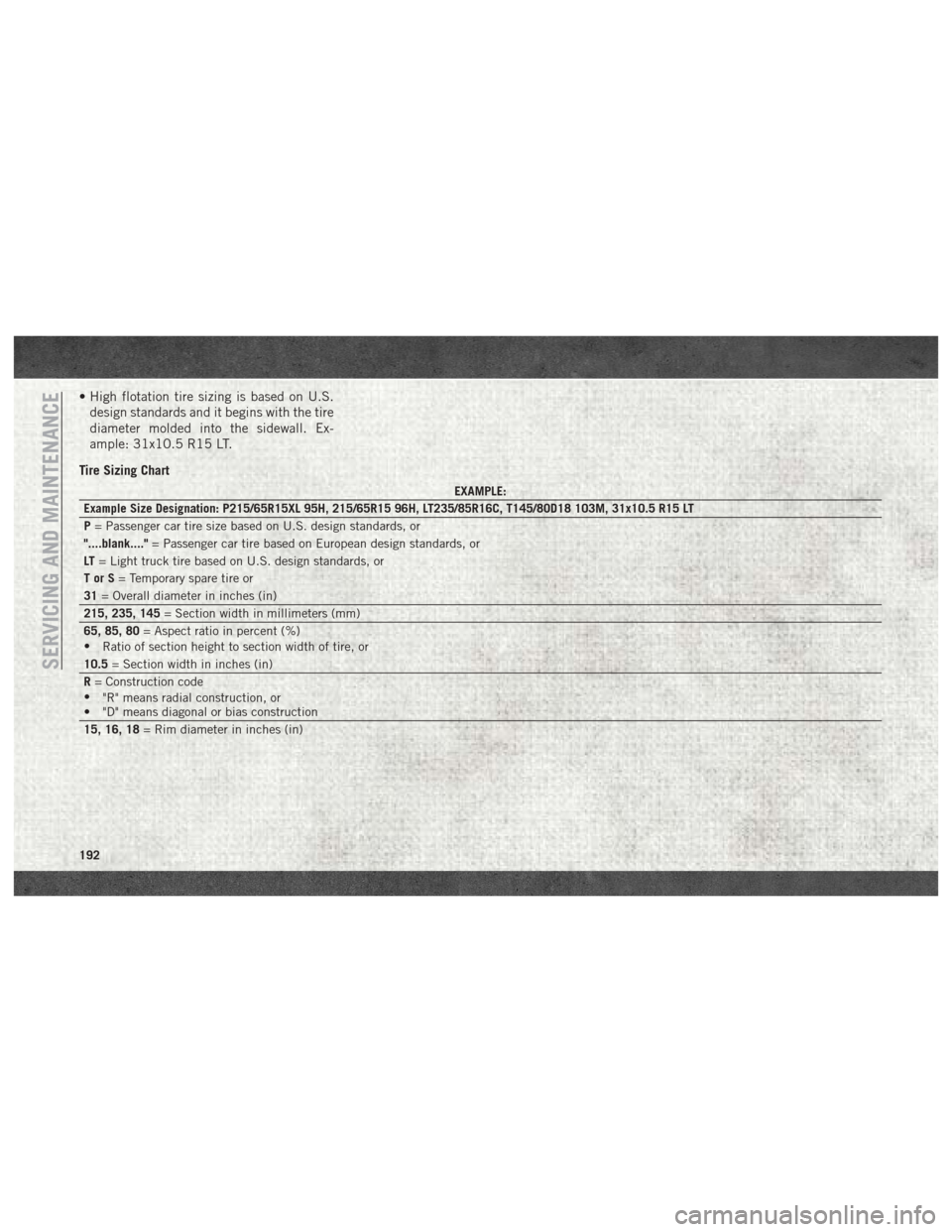

• High flotation tire sizing is based on U.S.design standards and it begins with the tire

diameter molded into the sidewall. Ex-

ample: 31x10.5 R15 LT.

Tire Sizing Chart

EXAMPLE:

Example Size Designation: P215/65R15XL 95H, 215/65R15 96H, LT235/85R16C, T145/80D18 103M, 31x10.5 R15 LT

P = Passenger car tire size based on U.S. design standards, or

"....blank...." = Passenger car tire based on European design standards, or

LT = Light truck tire based on U.S. design standards, or

TorS= Temporary spare tire or

31 = Overall diameter in inches (in)

215, 235, 145 = Section width in millimeters (mm)

65, 85, 80 = Aspect ratio in percent (%)

• Ratio of section height to section width of tire, or

10.5 = Section width in inches (in)

R = Construction code

• "R" means radial construction, or

• "D" means diagonal or bias construction

15, 16, 18 = Rim diameter in inches (in)

SERVICING AND MAINTENANCE

192

Page 196 of 298

Tire Identification Number (TIN)

The TIN may be found on one or both sides of

the tire; however, the date code may only be

on one side. Tires with white sidewalls will

have the full TIN, including the date code,located on the white sidewall side of the tire.

Look for the TIN on the outboard side of black

sidewall tires as mounted on the vehicle. If

the TIN is not found on the outboard side,

then you will find it on the inboard side of the

tire.

EXAMPLE:

DOT MA L9 ABCD 0301

DOT = Department of Transportation

• This symbol certifies that the tire is in compliance with the U.S. Department of Transportation tire safety standards and is approved for highway

use

MA = Code representing the tire manufacturing location (two digits)

L9 = Code representing the tire size (two digits)

ABCD = Code used by the tire manufacturer (one to four digits)

03 = Number representing the week in which the tire was manufactured (two digits)

• 03 means the 3rd week

01 = Number representing the year in which the tire was manufactured (two digits)

• 01 means the year 2001

• Prior to July 2000, tire manufacturers were only required to have one number to represent the year in which the tire was manufactured. Example:

031 could represent the 3rd week of 1981 or 1991

SERVICING AND MAINTENANCE

194

Page 198 of 298

Tire Loading And Tire Pressure

NOTE:

The proper cold tire inflation pressure is

listed on the driver’s side B-Pillar or the rear

edge of the driver's side door.

Check the inflation pressure of each tire,

including the spare tire (if equipped), at least

monthly and inflate to the recommended

pressure for your vehicle.Tire And Loading Information Placard This placard tells you important information

about the:

1. Number of people that can be carried in

the vehicle.

2. Total weight your vehicle can carry.

3. Tire size designed for your vehicle.

4. Cold tire inflation pressures for the front, rear, and spare tires.

Loading

The vehicle maximum load on the tire must

not exceed the load carrying capacity of the

tire on your vehicle. You will not exceed the

tire's load carrying capacity if you adhere to

the loading conditions, tire size, and cold tire

inflation pressures specified on the Tire and

Loading Information placard in “Vehicle

Loading” in the “Starting And Operating”

section of this manual.

NOTE:

Under a maximum loaded vehicle condition,

gross axle weight ratings (GAWRs) for the

front and rear axles must not be exceeded.

Example Tire Placard Location (Door)

Example Tire Placard Location (B-Pillar)

Tire And Loading Information Placard

SERVICING AND MAINTENANCE

196

Page 200 of 298

SERVICING AND MAINTENANCE

198

Page 202 of 298

Tire Inflation Pressures

The proper cold tire inflation pressure is

listed on the driver's side B-Pillar or rear edge

of the driver's side door.

At least once a month:

• Check and adjust tire pressure with a goodquality pocket-type pressure gauge. Do not

make a visual judgement when determining

proper inflation. Tires may look properly

inflated even when they are under-inflated.

• Inspect tires for signs of tire wear or visible damage.

CAUTION!

After inspecting or adjusting the tire pres-

sure, always reinstall the valve stem cap.

This will prevent moisture and dirt from

entering the valve stem, which could dam-

age the valve stem.

Inflation pressures specified on the placard

are always “cold tire inflation pressure”. Cold

tire inflation pressure is defined as the tire

pressure after the vehicle has not been driven

for at least three hours, or driven less than 1 mile (1.6 km) after sitting for a minimum of

three hours. The cold tire inflation pressure

must not exceed the maximum inflation pres-

sure molded into the tire sidewall.

Check tire pressures more often if subject to

a wide range of outdoor temperatures, as tire

pressures vary with temperature changes.

Tire pressures change by approximately 1 psi

(7 kPa) per 12°F (7°C) of air temperature

change. Keep this in mind when checking

tire pressure inside a garage, especially in the

Winter.

Example: If garage temperature = 68°F

(20°C) and the outside temperature = 32°F

(0°C) then the cold tire inflation pressure

should be increased by 3 psi (21 kPa), which

equals 1 psi (7 kPa) for every 12°F (7°C) for

this outside temperature condition.

Tire pressure may increase from 2 to 6 psi

(13 to 40 kPa) during operation. DO NOT

reduce this normal pressure build up or your

tire pressure will be too low.

Tire Pressures For High Speed Operation

The manufacturer advocates driving at safe

speeds and within posted speed limits.

Where speed limits or conditions are such

that the vehicle can be driven at high speeds,

maintaining correct tire inflation pressure is

very important. Increased tire pressure and

reduced vehicle loading may be required for

high-speed vehicle operation. Refer to your

authorized tire dealer or original equipment

vehicle dealer for recommended safe operat-

ing speeds, loading and cold tire inflation

pressures.

WARNING!

High speed driving with your vehicle under

maximum load is dangerous. The added

strain on your tires could cause them to

fail. You could have a serious collision. Do

not drive a vehicle loaded to the maximum

capacity at continuous speeds above

75 mph (120 km/h).SERVICING AND MAINTENANCE

200