oil Ram 4500 Chassis Cab 2018 Owner's Manual

[x] Cancel search | Manufacturer: RAM, Model Year: 2018, Model line: 4500 Chassis Cab, Model: Ram 4500 Chassis Cab 2018Pages: 298, PDF Size: 5.88 MB

Page 183 of 298

Mileage or time passed (whichever comes first):7,500

15,000

22,500

30,000

37,500

45,000

52,500

60,000

67,500

75,000

82,500

90,000

97,500

105,000

112,500

120,000

127,500

135,000

142,500

150,000

Or Months: 6 12 18 24 30 36 42 48 54 60 66 72 78 84 90 96 102 108 114 120

Or Kilometers:

12,000

24,000

36,000

48,000

60,000

72,000

84,000

96,000

108,000

120,000

132,000

144,000

156,000

168,000

180,000

192,000

204,000

216,000

228,000

240,000

Inspect wheel bearings. XX XX X

Additional Maintenance

Replace cabin air filter. XXX XX X

Replace engine fuel filter element. X X X X X X X X X X

Replace chassis mounted fuel filter element. X X X X X X X X X X

Inspect the front and rear axle surfaces. If

gear oil leakage is suspected, check the fluid

level. If using your vehicle for police, taxi,

fleet, off-road or frequent trailer towing

change the axle fluid. *

Inspect the transfer case fluid (4x4), change

for any of the following: police, taxi, fleet, or

frequent trailer towing. XX XX X

Change the transfer case fluid (4x4). XX

Change automatic transmission fluid

(AS69RC transmission only). XX XX X

Change the automatic transmission fluid and

sump filter (AS69RC transmission only). XX

Change automatic transmission fluid and fil-

ter(s) if using your vehicle for any of the fol-

lowing: police, fleet, or frequent trailer towing

(68RFE transmission only). XX

181

Page 184 of 298

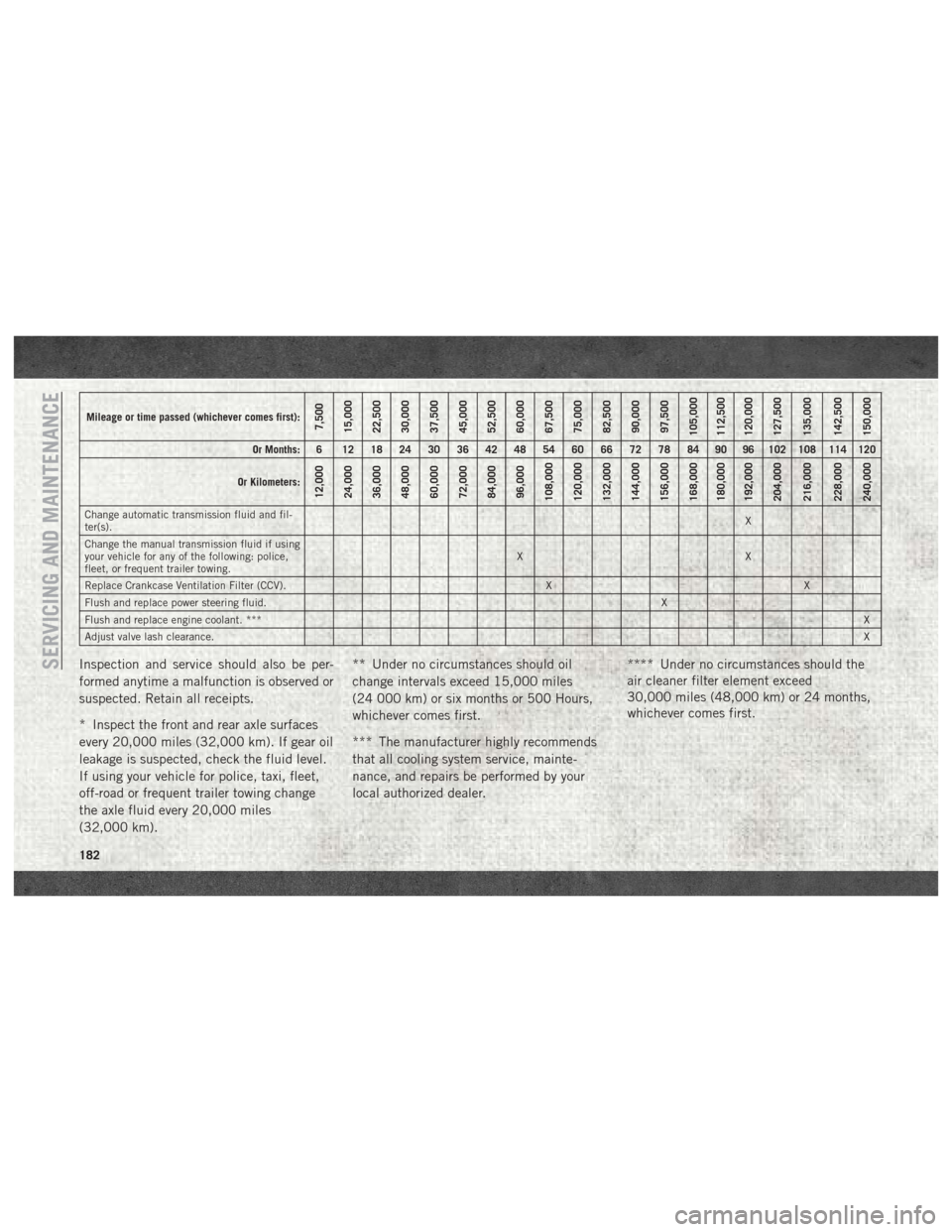

Mileage or time passed (whichever comes first):7,500

15,000

22,500

30,000

37,500

45,000

52,500

60,000

67,500

75,000

82,500

90,000

97,500

105,000

112,500

120,000

127,500

135,000

142,500

150,000

Or Months: 6 12 18 24 30 36 42 48 54 60 66 72 78 84 90 96 102 108 114 120

Or Kilometers:

12,000

24,000

36,000

48,000

60,000

72,000

84,000

96,000

108,000

120,000

132,000

144,000

156,000

168,000

180,000

192,000

204,000

216,000

228,000

240,000

Change automatic transmission fluid and fil-

ter(s). X

Change the manual transmission fluid if using

your vehicle for any of the following: police,

fleet, or frequent trailer towing. XX

Replace Crankcase Ventilation Filter (CCV). X X

Flush and replace power steering fluid. X

Flush and replace engine coolant. *** X

Adjust valve lash clearance. X

Inspection and service should also be per-

formed anytime a malfunction is observed or

suspected. Retain all receipts.

* Inspect the front and rear axle surfaces

every 20,000 miles (32,000 km). If gear oil

leakage is suspected, check the fluid level.

If using your vehicle for police, taxi, fleet,

off-road or frequent trailer towing change

the axle fluid every 20,000 miles

(32,000 km).** Under no circumstances should oil

change intervals exceed 15,000 miles

(24 000 km) or six months or 500 Hours,

whichever comes first.

*** The manufacturer highly recommends

that all cooling system service, mainte-

nance, and repairs be performed by your

local authorized dealer.

**** Under no circumstances should the

air cleaner filter element exceed

30,000 miles (48,000 km) or 24 months,

whichever comes first.SERVICING AND MAINTENANCE

182

Page 186 of 298

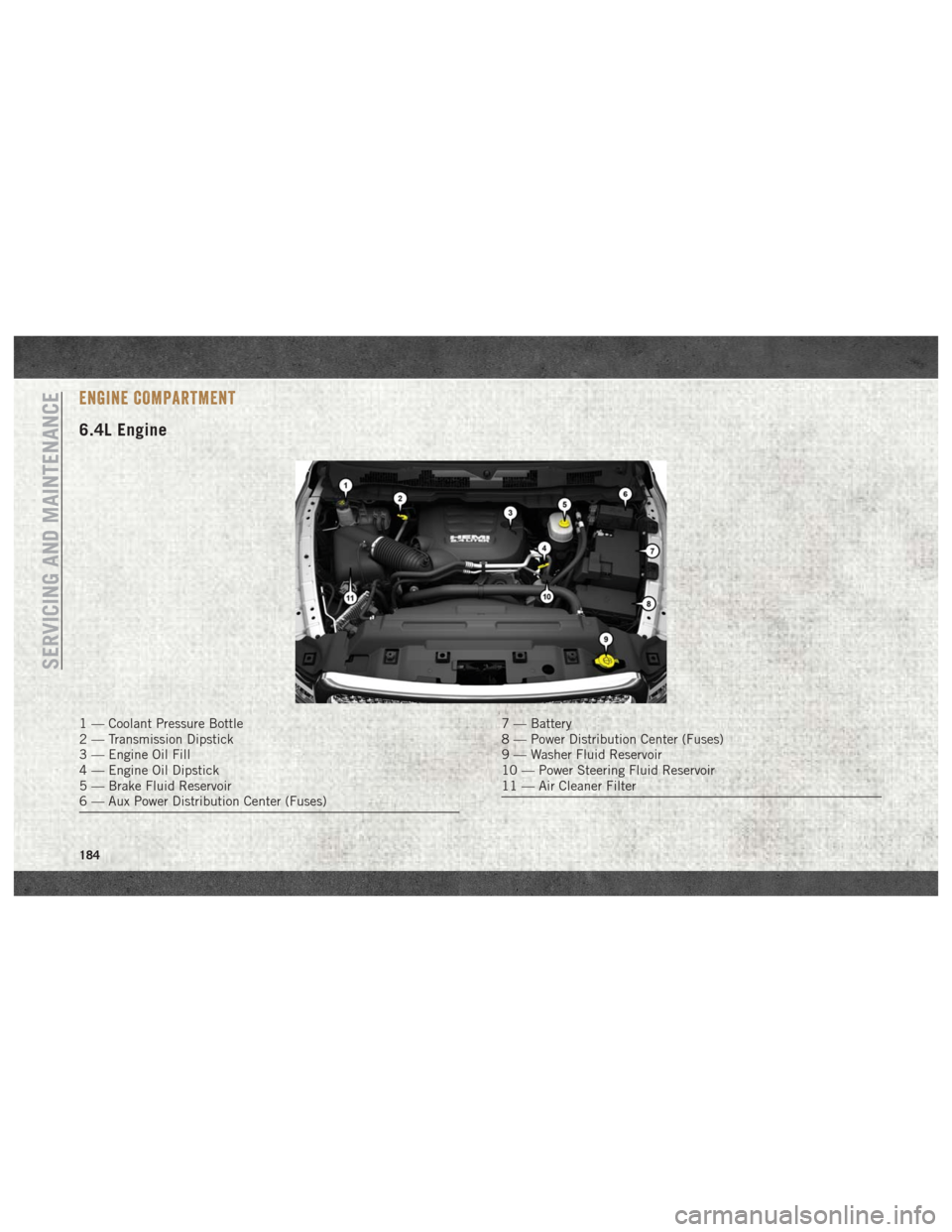

ENGINE COMPARTMENT

6.4L Engine

1 — Coolant Pressure Bottle

2 — Transmission Dipstick

3 — Engine Oil Fill

4 — Engine Oil Dipstick

5 — Brake Fluid Reservoir

6 — Aux Power Distribution Center (Fuses)7 — Battery

8 — Power Distribution Center (Fuses)

9 — Washer Fluid Reservoir

10 — Power Steering Fluid Reservoir

11 — Air Cleaner Filter

SERVICING AND MAINTENANCE

184

Page 187 of 298

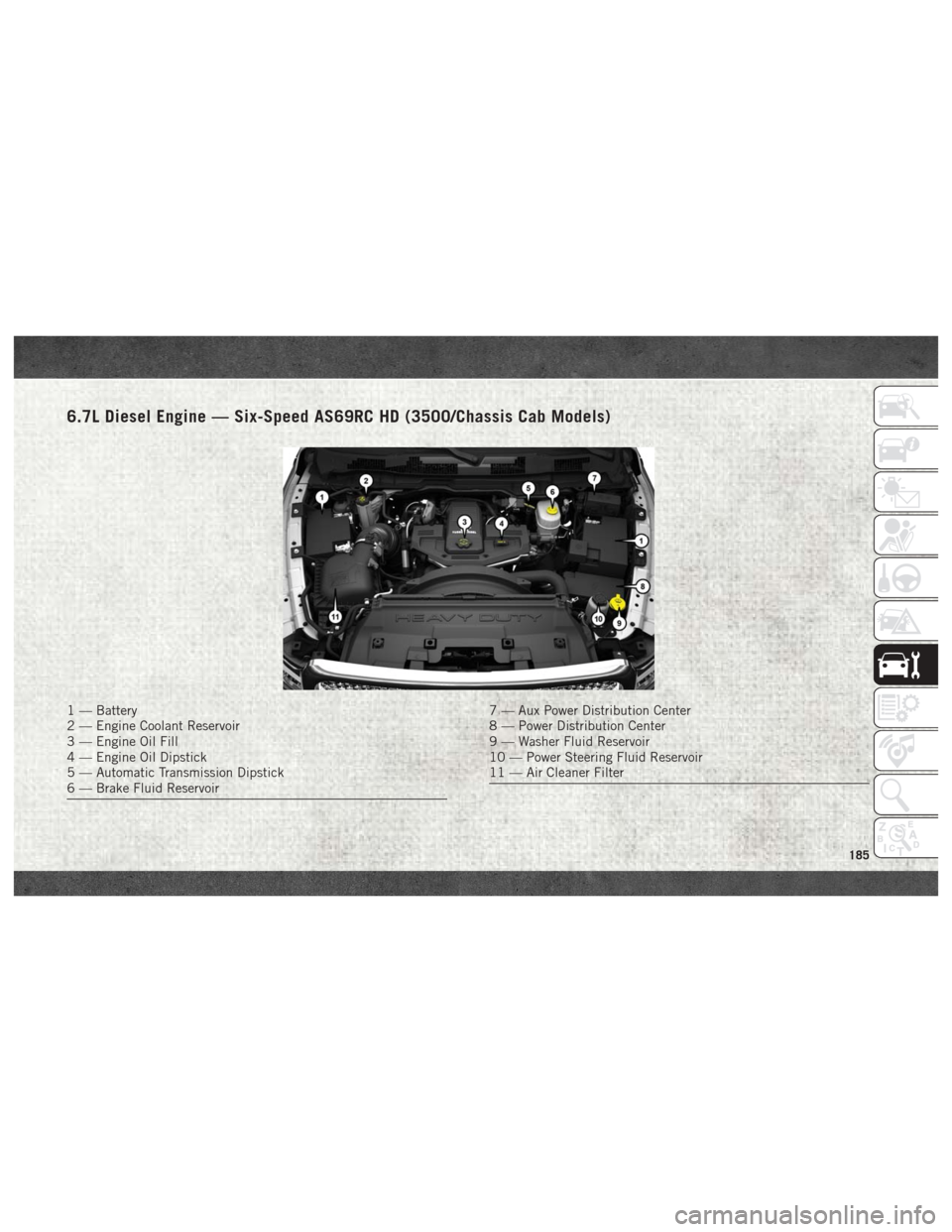

6.7L Diesel Engine — Six-Speed AS69RC HD (3500/Chassis Cab Models)

1 — Battery

2 — Engine Coolant Reservoir

3 — Engine Oil Fill

4 — Engine Oil Dipstick

5 — Automatic Transmission Dipstick

6 — Brake Fluid Reservoir7 — Aux Power Distribution Center

8 — Power Distribution Center

9 — Washer Fluid Reservoir

10 — Power Steering Fluid Reservoir

11 — Air Cleaner Filter

185

Page 191 of 298

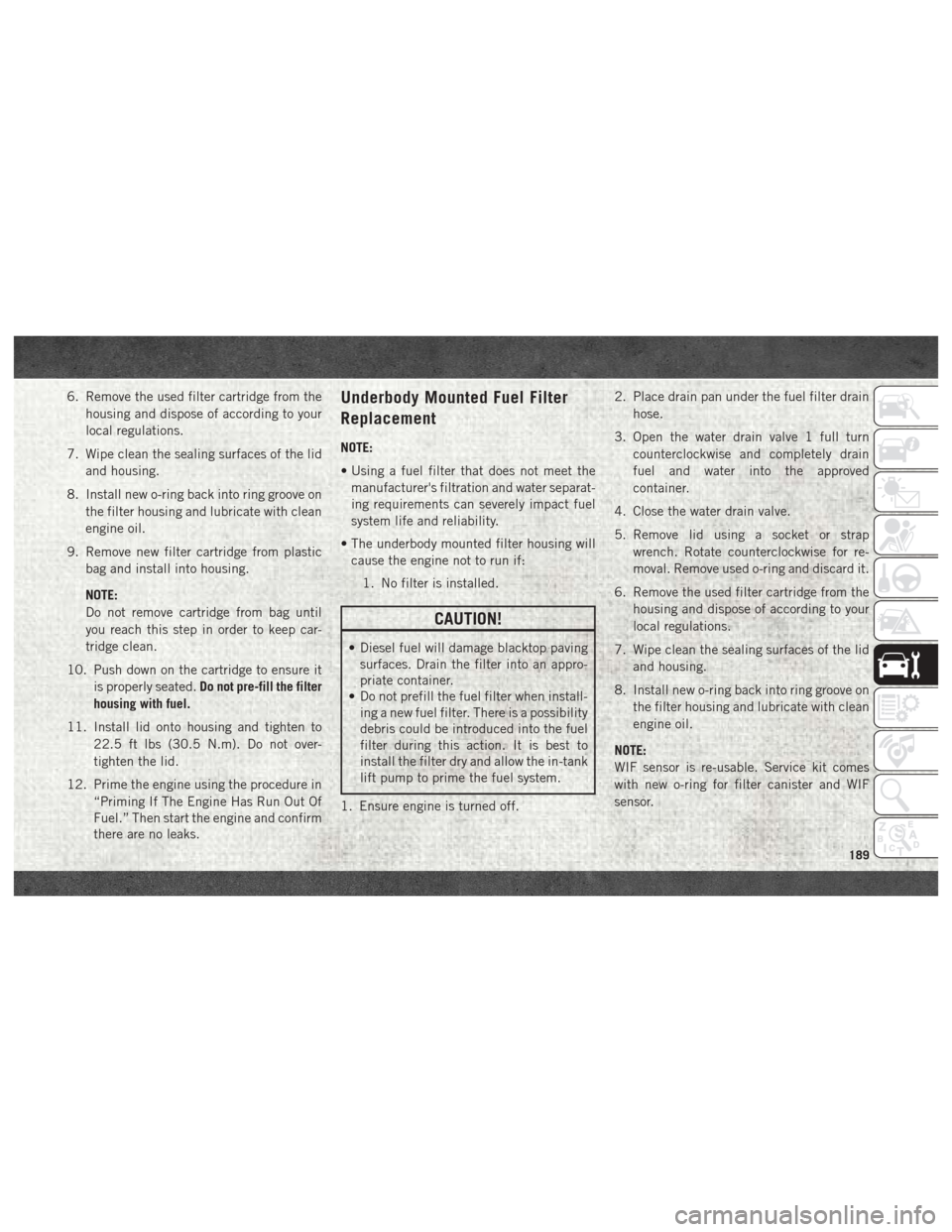

6. Remove the used filter cartridge from thehousing and dispose of according to your

local regulations.

7. Wipe clean the sealing surfaces of the lid and housing.

8. Install new o-ring back into ring groove on the filter housing and lubricate with clean

engine oil.

9. Remove new filter cartridge from plastic bag and install into housing.

NOTE:

Do not remove cartridge from bag until

you reach this step in order to keep car-

tridge clean.

10. Push down on the cartridge to ensure it is properly seated. Do not pre-fill the filter

housing with fuel.

11. Install lid onto housing and tighten to 22.5 ft lbs (30.5 N.m). Do not over-

tighten the lid.

12. Prime the engine using the procedure in “Priming If The Engine Has Run Out Of

Fuel.” Then start the engine and confirm

there are no leaks.Underbody Mounted Fuel Filter

Replacement

NOTE:

• Using a fuel filter that does not meet themanufacturer's filtration and water separat-

ing requirements can severely impact fuel

system life and reliability.

• The underbody mounted filter housing will cause the engine not to run if:

1. No filter is installed.

CAUTION!

• Diesel fuel will damage blacktop paving surfaces. Drain the filter into an appro-

priate container.

• Do not prefill the fuel filter when install-

ing a new fuel filter. There is a possibility

debris could be introduced into the fuel

filter during this action. It is best to

install the filter dry and allow the in-tank

lift pump to prime the fuel system.

1. Ensure engine is turned off. 2. Place drain pan under the fuel filter drain

hose.

3. Open the water drain valve 1 full turn counterclockwise and completely drain

fuel and water into the approved

container.

4. Close the water drain valve.

5. Remove lid using a socket or strap wrench. Rotate counterclockwise for re-

moval. Remove used o-ring and discard it.

6. Remove the used filter cartridge from the housing and dispose of according to your

local regulations.

7. Wipe clean the sealing surfaces of the lid and housing.

8. Install new o-ring back into ring groove on the filter housing and lubricate with clean

engine oil.

NOTE:

WIF sensor is re-usable. Service kit comes

with new o-ring for filter canister and WIF

sensor.

189

Page 204 of 298

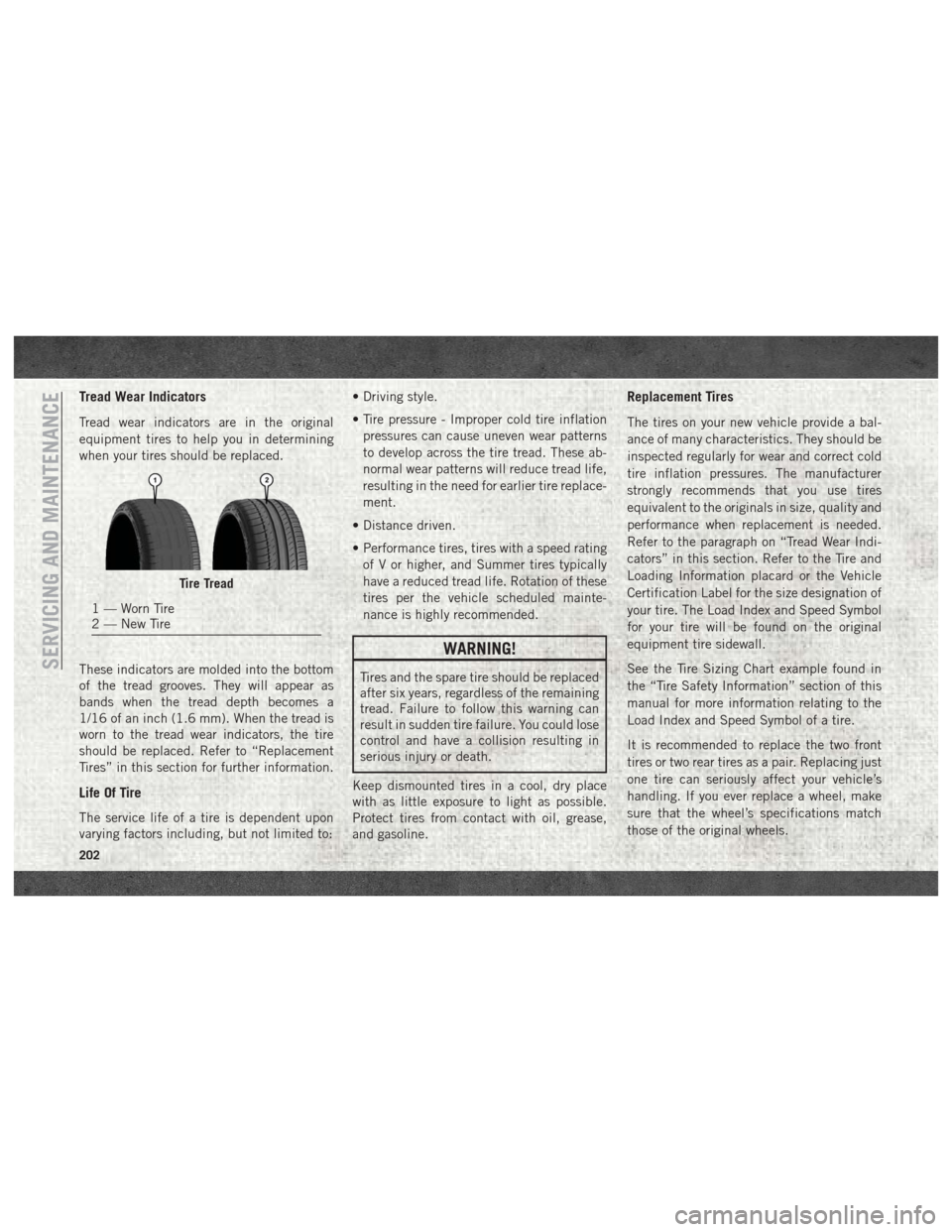

Tread Wear Indicators

Tread wear indicators are in the original

equipment tires to help you in determining

when your tires should be replaced.

These indicators are molded into the bottom

of the tread grooves. They will appear as

bands when the tread depth becomes a

1/16 of an inch (1.6 mm). When the tread is

worn to the tread wear indicators, the tire

should be replaced. Refer to “Replacement

Tires” in this section for further information.

Life Of Tire

The service life of a tire is dependent upon

varying factors including, but not limited to:• Driving style.

• Tire pressure - Improper cold tire inflation

pressures can cause uneven wear patterns

to develop across the tire tread. These ab-

normal wear patterns will reduce tread life,

resulting in the need for earlier tire replace-

ment.

• Distance driven.

• Performance tires, tires with a speed rating of V or higher, and Summer tires typically

have a reduced tread life. Rotation of these

tires per the vehicle scheduled mainte-

nance is highly recommended.

WARNING!

Tires and the spare tire should be replaced

after six years, regardless of the remaining

tread. Failure to follow this warning can

result in sudden tire failure. You could lose

control and have a collision resulting in

serious injury or death.

Keep dismounted tires in a cool, dry place

with as little exposure to light as possible.

Protect tires from contact with oil, grease,

and gasoline.

Replacement Tires

The tires on your new vehicle provide a bal-

ance of many characteristics. They should be

inspected regularly for wear and correct cold

tire inflation pressures. The manufacturer

strongly recommends that you use tires

equivalent to the originals in size, quality and

performance when replacement is needed.

Refer to the paragraph on “Tread Wear Indi-

cators” in this section. Refer to the Tire and

Loading Information placard or the Vehicle

Certification Label for the size designation of

your tire. The Load Index and Speed Symbol

for your tire will be found on the original

equipment tire sidewall.

See the Tire Sizing Chart example found in

the “Tire Safety Information” section of this

manual for more information relating to the

Load Index and Speed Symbol of a tire.

It is recommended to replace the two front

tires or two rear tires as a pair. Replacing just

one tire can seriously affect your vehicle’s

handling. If you ever replace a wheel, make

sure that the wheel’s specifications match

those of the original wheels.

Tire Tread

1 — Worn Tire

2 — New Tire

SERVICING AND MAINTENANCE

202

Page 212 of 298

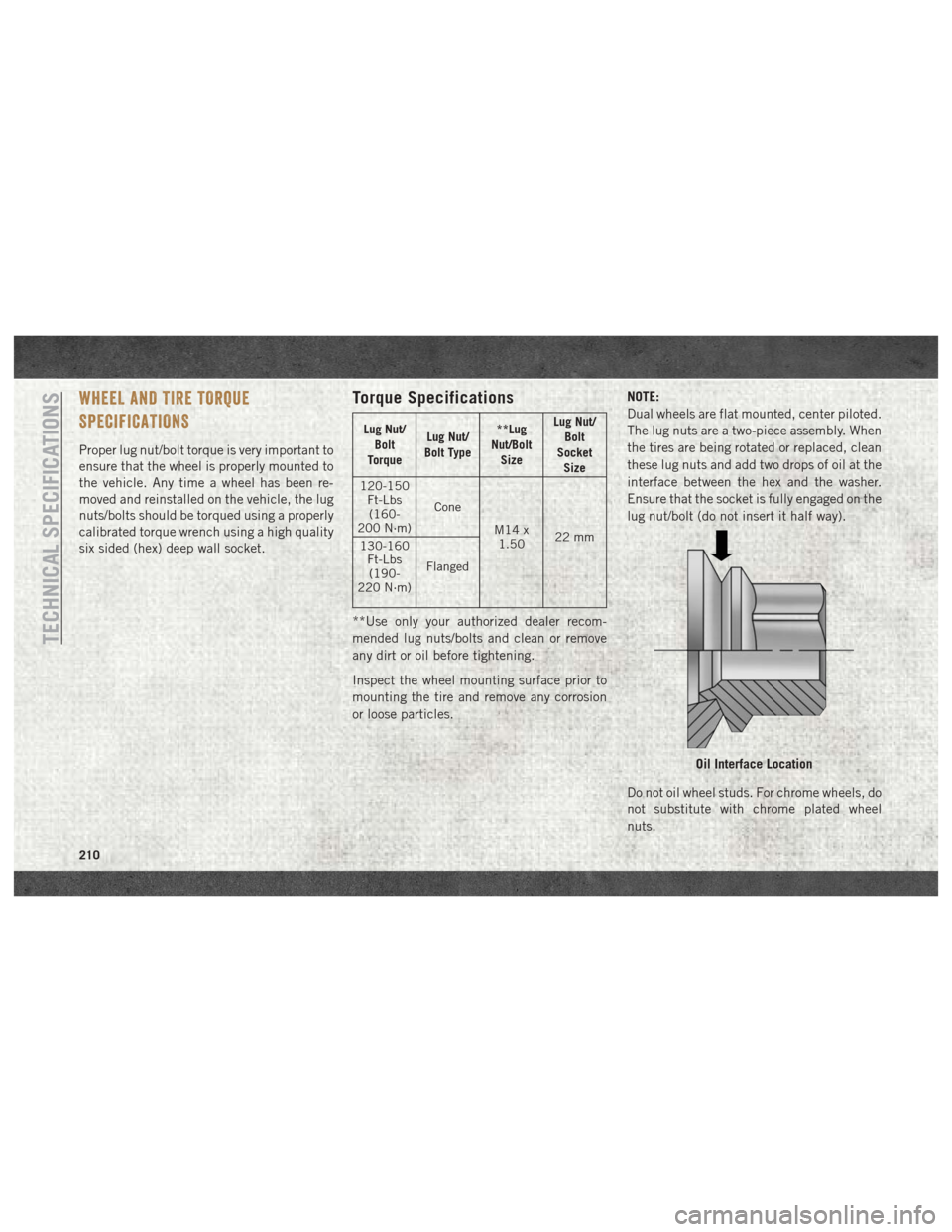

WHEEL AND TIRE TORQUE

SPECIFICATIONS

Proper lug nut/bolt torque is very important to

ensure that the wheel is properly mounted to

the vehicle. Any time a wheel has been re-

moved and reinstalled on the vehicle, the lug

nuts/bolts should be torqued using a properly

calibrated torque wrench using a high quality

six sided (hex) deep wall socket.

Torque Specifications

Lug Nut/Bolt

Torque Lug Nut/

Bolt Type **Lug

Nut/Bolt Size Lug Nut/

Bolt

Socket Size

120-150 Ft-Lbs(160-

200 N·m) Cone

M14 x1.50 22 mm

130-160

Ft-Lbs(190-

220 N·m) Flanged

**Use only your authorized dealer recom-

mended lug nuts/bolts and clean or remove

any dirt or oil before tightening.

Inspect the wheel mounting surface prior to

mounting the tire and remove any corrosion

or loose particles. NOTE:

Dual wheels are flat mounted, center piloted.

The lug nuts are a two-piece assembly. When

the tires are being rotated or replaced, clean

these lug nuts and add two drops of oil at the

interface between the hex and the washer.

Ensure that the socket is fully engaged on the

lug nut/bolt (do not insert it half way).

Do not oil wheel studs. For chrome wheels, do

not substitute with chrome plated wheel

nuts.

Oil Interface Location

TECHNICAL SPECIFICATIONS

210

Page 213 of 298

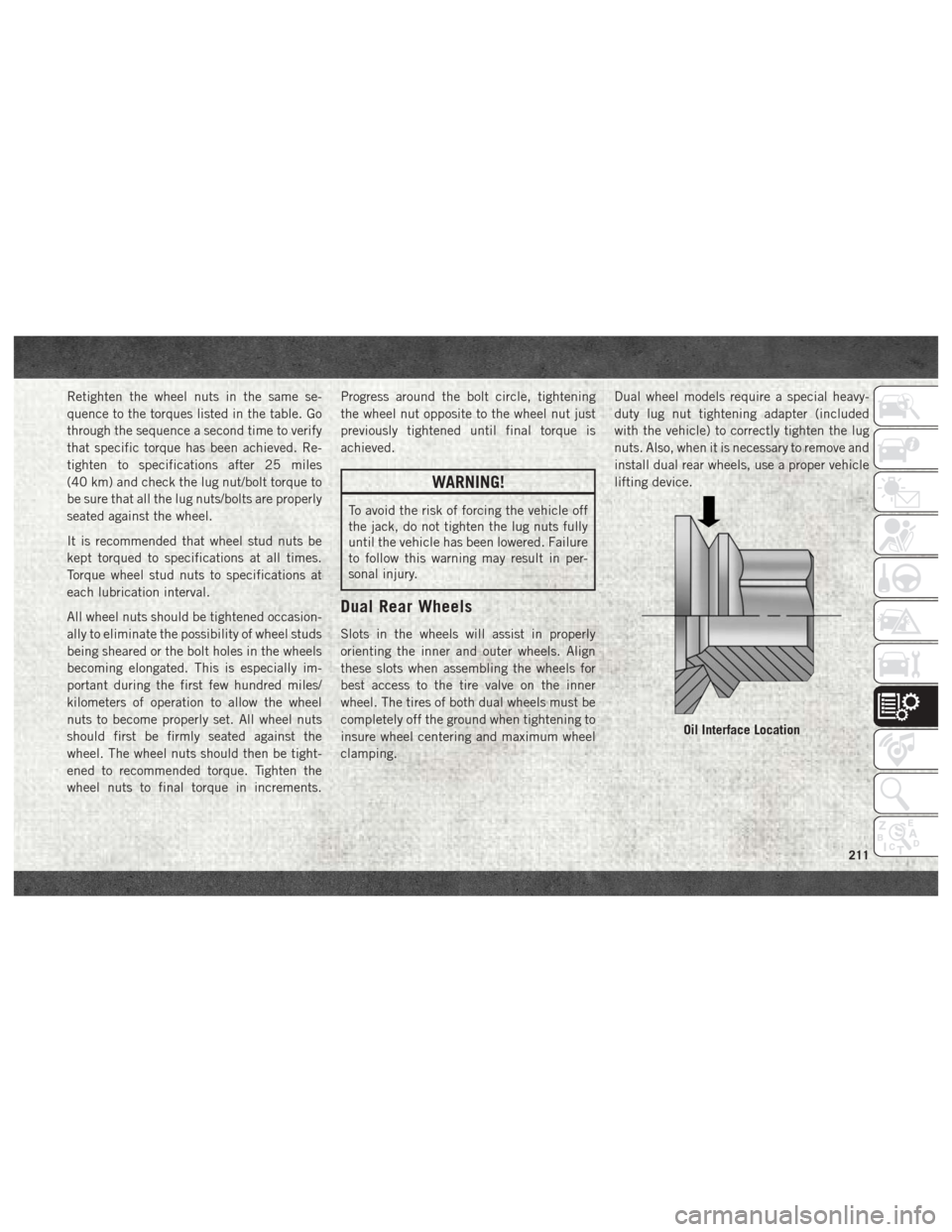

Retighten the wheel nuts in the same se-

quence to the torques listed in the table. Go

through the sequence a second time to verify

that specific torque has been achieved. Re-

tighten to specifications after 25 miles

(40 km) and check the lug nut/bolt torque to

be sure that all the lug nuts/bolts are properly

seated against the wheel.

It is recommended that wheel stud nuts be

kept torqued to specifications at all times.

Torque wheel stud nuts to specifications at

each lubrication interval.

All wheel nuts should be tightened occasion-

ally to eliminate the possibility of wheel studs

being sheared or the bolt holes in the wheels

becoming elongated. This is especially im-

portant during the first few hundred miles/

kilometers of operation to allow the wheel

nuts to become properly set. All wheel nuts

should first be firmly seated against the

wheel. The wheel nuts should then be tight-

ened to recommended torque. Tighten the

wheel nuts to final torque in increments.Progress around the bolt circle, tightening

the wheel nut opposite to the wheel nut just

previously tightened until final torque is

achieved.

WARNING!

To avoid the risk of forcing the vehicle off

the jack, do not tighten the lug nuts fully

until the vehicle has been lowered. Failure

to follow this warning may result in per-

sonal injury.

Dual Rear Wheels

Slots in the wheels will assist in properly

orienting the inner and outer wheels. Align

these slots when assembling the wheels for

best access to the tire valve on the inner

wheel. The tires of both dual wheels must be

completely off the ground when tightening to

insure wheel centering and maximum wheel

clamping.

Dual wheel models require a special heavy-

duty lug nut tightening adapter (included

with the vehicle) to correctly tighten the lug

nuts. Also, when it is necessary to remove and

install dual rear wheels, use a proper vehicle

lifting device.

Oil Interface Location

211

Page 215 of 298

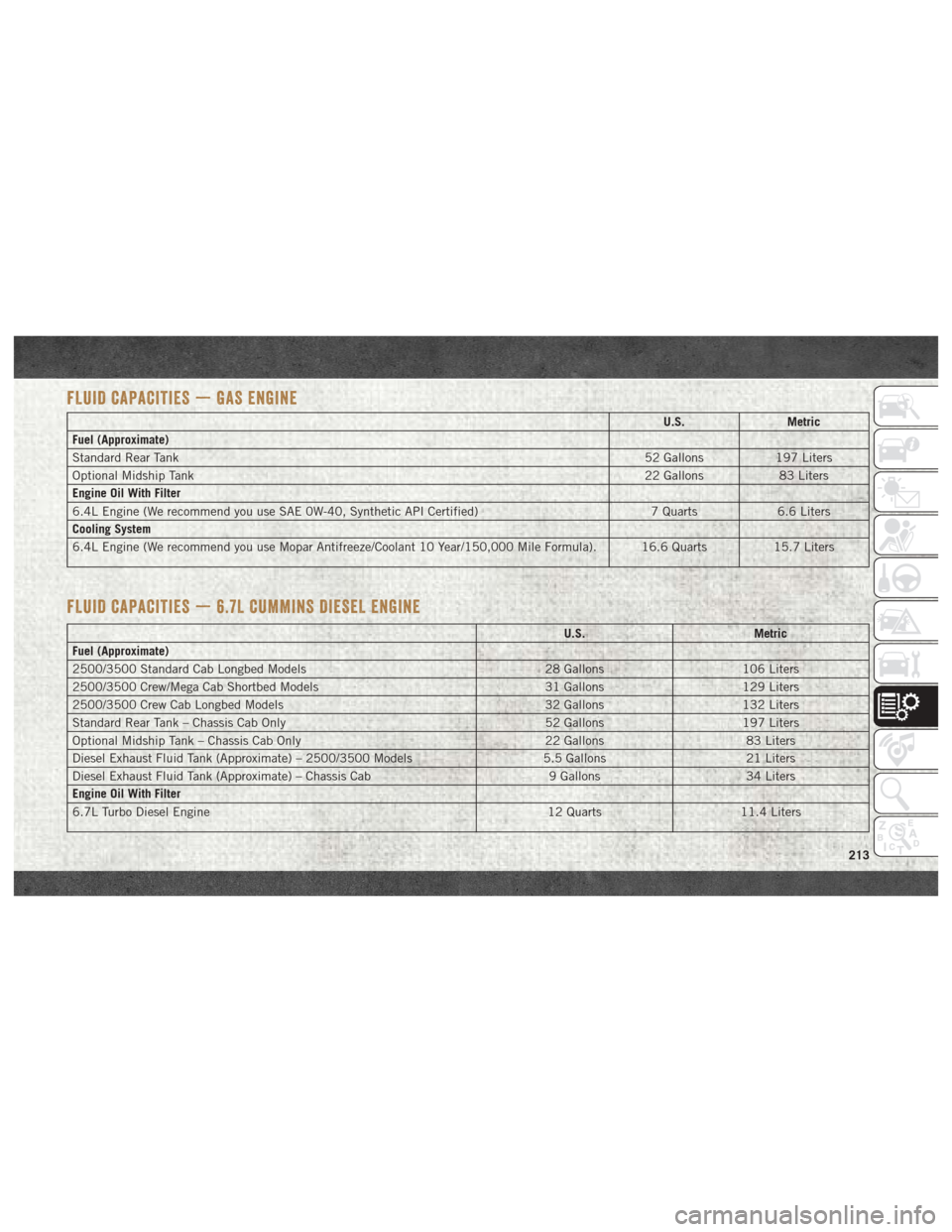

FLUID CAPACITIES — GAS ENGINE

U.S.Metric

Fuel (Approximate)

Standard Rear Tank 52 Gallons197 Liters

Optional Midship Tank 22 Gallons83 Liters

Engine Oil With Filter

6.4L Engine (We recommend you use SAE 0W-40, Synthetic API Certified) 7 Quarts6.6 Liters

Cooling System

6.4L Engine (We recommend you use Mopar Antifreeze/Coolant 10 Year/150,000 Mile Formula). 16.6 Quarts 15.7 Liters

FLUID CAPACITIES — 6.7L CUMMINS DIESEL ENGINE

U.S.Metric

Fuel (Approximate)

2500/3500 Standard Cab Longbed Models 28 Gallons106 Liters

2500/3500 Crew/Mega Cab Shortbed Models 31 Gallons129 Liters

2500/3500 Crew Cab Longbed Models 32 Gallons132 Liters

Standard Rear Tank – Chassis Cab Only 52 Gallons197 Liters

Optional Midship Tank – Chassis Cab Only 22 Gallons83 Liters

Diesel Exhaust Fluid Tank (Approximate) – 2500/3500 Models 5.5 Gallons21 Liters

Diesel Exhaust Fluid Tank (Approximate) – Chassis Cab 9 Gallons34 Liters

Engine Oil With Filter

6.7L Turbo Diesel Engine 12 Quarts11.4 Liters

213

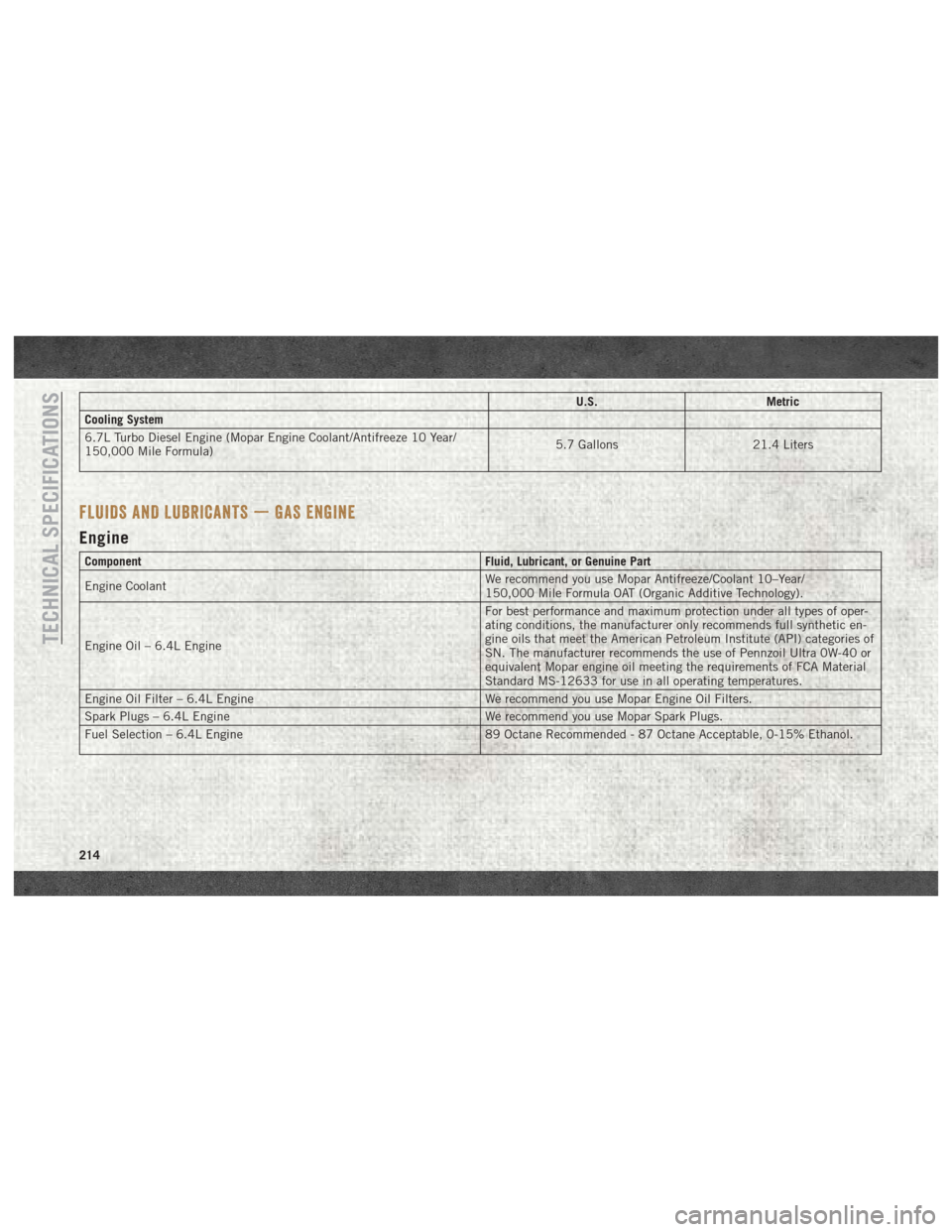

Page 216 of 298

U.S.Metric

Cooling System

6.7L Turbo Diesel Engine (Mopar Engine Coolant/Antifreeze 10 Year/

150,000 Mile Formula) 5.7 Gallons

21.4 Liters

FLUIDS AND LUBRICANTS — GAS ENGINE

Engine

Component Fluid, Lubricant, or Genuine Part

Engine Coolant We recommend you use Mopar Antifreeze/Coolant 10–Year/

150,000 Mile Formula OAT (Organic Additive Technology).

Engine Oil – 6.4L Engine For best performance and maximum protection under all types of oper-

ating conditions, the manufacturer only recommends full synthetic en-

gine oils that meet the American Petroleum Institute (API) categories of

SN. The manufacturer recommends the use of Pennzoil Ultra 0W-40 or

equivalent Mopar engine oil meeting the requirements of FCA Material

Standard MS-12633 for use in all operating temperatures.

Engine Oil Filter – 6.4L Engine We recommend you use Mopar Engine Oil Filters.

Spark Plugs – 6.4L Engine We recommend you use Mopar Spark Plugs.

Fuel Selection – 6.4L Engine 89 Octane Recommended - 87 Octane Acceptable, 0-15% Ethanol.

TECHNICAL SPECIFICATIONS

214