ECO mode Ram 4500 Chassis Cab 2018 Owner's Guide

[x] Cancel search | Manufacturer: RAM, Model Year: 2018, Model line: 4500 Chassis Cab, Model: Ram 4500 Chassis Cab 2018Pages: 298, PDF Size: 5.88 MB

Page 170 of 298

6. Move the gear selector to the NEUTRALposition.

7. The vehicle may then be started in NEUTRAL.

FREEING A STUCK VEHICLE

If your vehicle becomes stuck in mud, sand,

or snow, it can often be moved using a rock-

ing motion. Turn the steering wheel right and

left to clear the area around the front wheels.

Next, shift back and forth between DRIVE

and REVERSE (with automatic transmission)

or SECOND GEAR and REVERSE (with

manual transmission) while gently pressing

the accelerator. Use the least amount of ac-

celerator pedal pressure that will maintain

the rocking motion, without spinning the

wheels or racing the engine. NOTE:

Push the "ESC Off" switch, to place the Elec-

tronic Stability Control (ESC) system in "Par-

tial Off" mode, before rocking the vehicle.

Refer to “Electronic Brake Control System”

in “Safety” in the Owner’s Manual at

www.mopar.com/en-us/care/owners-manual.html

(U.S. Residents) or www.owners.mopar.ca

(Canadian Residents) for further information.

Once the vehicle has been freed, push the

"ESC Off" switch again to restore "ESC On"

mode.

WARNING!

Fast spinning tires can be dangerous.

Forces generated by excessive wheel

speeds may cause damage, or even failure,

of the axle and tires. A tire could explode

and injure someone. Do not spin your

vehicle's wheels faster than 30 mph

(48 km/h) or for longer than 30 seconds

continuously without stopping when you

are stuck and do not let anyone near a

spinning wheel, no matter what the speed.

CAUTION!

• Racing the engine or spinning the

wheels may lead to transmission over-

heating and failure. Allow the engine to

idle with the transmission in NEUTRAL

for at least one minute after every five

rocking-motion cycles. This will mini-

mize overheating and reduce the risk of

clutch or transmission failure during

prolonged efforts to free a stuck vehicle.

• When “rocking” a stuck vehicle by shift-

ing between DRIVE/SECOND GEAR and

REVERSE, do not spin the wheels faster

than 15 mph (24 km/h), or drivetrain

damage may result.

• Revving the engine or spinning the

wheels too fast may lead to transmission

overheating and failure. It can also dam-

age the tires. Do not spin the wheels

above 30 mph (48 km/h) while in gear

(no transmission shifting occurring).

IN CASE OF EMERGENCY

168

Page 172 of 298

CAUTION!

• Do not use sling type equipment whentowing. Vehicle damage may occur.

• When securing the vehicle to a flat bed

truck, do not attach to front or rear

suspension components. Damage to

your vehicle may result from improper

towing.

Two-Wheel Drive Models

The manufacturer recommends towing your

vehicle with all four wheels OFFthe ground

using a flatbed.

If flatbed equipment is not available, and the

transmission is operable, the vehicle may be

towed (with the rear wheels on the ground)

under the following conditions:

• The transmission must be in NEUTRAL.

• The towing speed must not exceed 30 mph (48 km/h).

• The towing distance must not exceed 15 miles (24 km). If the transmission is not operable, or the

vehicle must be towed faster than 30 mph

(48 km/h) or farther than 15 miles (24 km),

tow with the rear wheels

OFFthe ground.

Acceptable methods are to tow the vehicle on

a flatbed, or with the front wheels raised and

the rear wheels on a towing dolly, or (when

using a suitable steering wheel stabilizer to

hold the front wheels in the straight position)

with rear wheels raised and the front wheels

on the ground.CAUTION!

Towing this vehicle in violation of the

above requirements can cause severe en-

gine and/or transmission damage. Damage

from improper towing is not covered under

the New Vehicle Limited Warranty.

Four-Wheel Drive Models

The manufacturer recommends towing with

all wheels OFFthe ground. Acceptable meth-

ods are to tow the vehicle on a flatbed or with

one end of vehicle raised and the opposite

end on a towing dolly. If flatbed equipment is not available, and the

transfer case is operable, the vehicle may be

towed (in the forward direction, with

ALL

wheels on the ground), IFthe transfer case is

in NEUTRAL and the transmission is in PARK

(for automatic transmissions) or in gear (NOT

in NEUTRAL, for manual transmissions). Re-

fer to “Recreational Towing” in “Starting And

Operating” for further information and de-

tailed instructions.

CAUTION!

• Front or rear wheel lifts must not be used (if the remaining wheels are on the

ground). Internal damage to the trans-

mission or transfer case will occur if a

front or rear wheel lift is used when

towing.

• Towing this vehicle in violation of the

above requirements can cause severe

transmission and/or transfer case dam-

age. Damage from improper towing is

not covered under the New Vehicle Lim-

ited Warranty.IN CASE OF EMERGENCY

170

Page 189 of 298

If the vehicle experiences a sudden loss of

engine power while being driven in heavy

snow or rain, or when plowing snow, and/or

the “SERVICE AIR FILTER” message is dis-

played on the instrument cluster along with a

chime that repeats every 60 seconds, visually

inspect the air filter for snow/ice build up or

extreme water saturation. If the air filter is

not damaged, remove all snow/ice and rein-

stall air filter. If the air filter is damaged,

replace filter element.

NOTE:

The air filter housing contains a Mass Air

Flow sensor. This sensor is critical to proper

engine operation and component longevity.

Any damage or modification to this sensor

could result in major engine and/or exhaust

aftertreatment damage. We recommend you

use Mopar brand parts.

Even though your vehicle is equipped with an

Air Filter Monitor, a visual inspection of the

air cleaner filter element is recommended

every 15,000 miles (24,000km) or

12 months – whichever occurs first.Under nocircumstances should the air cleaner filter ele-

ment exceed 30,000 miles (48,000 km) or

24 months, whichever comes first.

CAUTION!

Many aftermarket performance air filter

elements do not adequately filter the air

entering the engine. Use of such filters can

severely damage your engine.

Draining Fuel/Water Separator

Filter

There are two fuel filter assemblies. One is

located on the driver's side of the engine. The

best access to this water drain valve is from

under the hood. The second one is on the

under body, located in front of the rear axle

above the drive shaft on pick-up models. The

Chassis Cab models second filter location is

on the frame behind the front axle. The best

access to this water drain valve is from under

the vehicle.

CAUTION!

• Do not drain the fuel/water separator

filter when the engine is running.

• Diesel fuel will damage blacktop paving

surfaces. Drain the filter into an appro-

priate container.

If water is detected in the water separator

while the engine is running, or while the

ignition switch is in the ON position, the

“Water In Fuel Indicator Light” will illumi-

nate and an audible chime will be heard five

times. At this point you should stop the

engine and drain the water from both of the

filters.

CAUTION!

If the “Water In Fuel Indicator Light” re-

mains on, DO NOT START the engine be-

fore you drain water from the fuel filters to

avoid engine damage.

If the “Water In Fuel Indicator Light” comes

on and a single chime is heard while you are

driving, or with the ignition switch in the ON

187

Page 192 of 298

Priming If The Engine Has Run

Out Of Fuel

WARNING!

Do not open the high pressure fuel system

with the engine running. Engine operation

causes high fuel pressure. High pressure

fuel spray can cause serious injury or

death.

1. Add a substantial amount of fuel to the tank, approximately 2 to 5 gal (8L to

19L).

2. Turn ignition switch to the start position to engage starter for one second, return ig-

nition switch to run position. This will

activate in tank fuel pump for approxi-

mately 15 seconds. Repeat this process

twice.

3. Start the engine using the “Normal Start- ing” procedure. Refer to “Starting Proce-

dures” in “Starting and Operating” for

further information.

CAUTION!

Do not engage the starter motor for more

than 15 seconds at a time. Allow two

minutes between the cranking intervals.

NOTE:

The engine may run rough until the air is

forced from all the fuel lines.

WARNING!

Do not use alcohol or gasoline as a fuel

blending agent. They can be unstable un-

der certain conditions and be hazardous or

explosive when mixed with diesel fuel.

CAUTION!

Due to lack of lubricants in alcohol or

gasoline, the use of these fuels can cause

damage to the fuel system. NOTE:

• A maximum blend of 5% biodiesel, meet-

ing ASTM specification D-975 may be used

with your Cummins diesel engine. (Chassis

Cab models not configured with B20 capa-

bility.)

• A maximum blend of 20% biodiesel, meet- ing ASTM specification D-7467 may be

used with your Cummins diesel engine.

(Pickup models and Chassis Cab models

configured with B20 capability.)

• Use of biodiesel mixture in excess of 20% can negatively impact the fuel filter's abil-

ity to separate water from the fuel, resulting

in high pressure fuel system corrosion or

damage.

• Ethanol blends are not recommended or approved for use with your Cummins diesel

engine.

• In addition, commercially available fuel ad- ditives are not necessary for the proper

operation of your Cummins diesel engine.

SERVICING AND MAINTENANCE

190

Page 203 of 298

Radial Ply Tires

WARNING!

Combining radial ply tires with other types

of tires on your vehicle will cause your

vehicle to handle poorly. The instability

could cause a collision. Always use radial

ply tires in sets of four. Never combine

them with other types of tires.

Tire Repair

If your tire becomes damaged, it may be

repaired if it meets the following criteria:

• The tire has not been driven on when flat.

• The damage is only on the tread section of your tire (sidewall damage is not repair-

able).

• The puncture is no greater thana¼ofan inch (6 mm).

Consult an authorized tire dealer for tire re-

pairs and additional information. Damaged Run Flat tires, or Run Flat tires that

have experienced a loss of pressure should be

replaced immediately with another Run Flat

tire of identical size and service description

(Load Index and Speed Symbol).

Run Flat Tires — If Equipped

Run Flat tires allow you the capability to drive

50 miles (80 km) at 50 mph (80 km/h) after

a rapid loss of inflation pressure. This rapid

loss of inflation is referred to as the Run Flat

mode. A Run Flat mode occurs when the tire

inflation pressure is of/or below 14 psi

(96 kPa). Once a Run Flat tire reaches the

run flat mode it has limited driving capabili-

ties and needs to be replaced immediately. A

Run Flat tire is not repairable.

It is not recommended driving a vehicle

loaded at full capacity or to tow a trailer while

a tire is in the run flat mode.

See the tire pressure monitoring section for

more information.

Tire Spinning

When stuck in mud, sand, snow, or ice con-

ditions, do not spin your vehicle's wheels

above 30 mph (48 km/h) or for longer than

30 seconds continuously without stopping.

Refer to “Freeing A Stuck Vehicle” in “In

Case Of Emergency” for further information.

WARNING!

Fast spinning tires can be dangerous.

Forces generated by excessive wheel

speeds may cause tire damage or failure. A

tire could explode and injure someone. Do

not spin your vehicle's wheels faster than

30 mph (48 km/h) for more than 30 sec-

onds continuously when you are stuck, and

do not let anyone near a spinning wheel,

no matter what the speed.

201

Page 213 of 298

Retighten the wheel nuts in the same se-

quence to the torques listed in the table. Go

through the sequence a second time to verify

that specific torque has been achieved. Re-

tighten to specifications after 25 miles

(40 km) and check the lug nut/bolt torque to

be sure that all the lug nuts/bolts are properly

seated against the wheel.

It is recommended that wheel stud nuts be

kept torqued to specifications at all times.

Torque wheel stud nuts to specifications at

each lubrication interval.

All wheel nuts should be tightened occasion-

ally to eliminate the possibility of wheel studs

being sheared or the bolt holes in the wheels

becoming elongated. This is especially im-

portant during the first few hundred miles/

kilometers of operation to allow the wheel

nuts to become properly set. All wheel nuts

should first be firmly seated against the

wheel. The wheel nuts should then be tight-

ened to recommended torque. Tighten the

wheel nuts to final torque in increments.Progress around the bolt circle, tightening

the wheel nut opposite to the wheel nut just

previously tightened until final torque is

achieved.

WARNING!

To avoid the risk of forcing the vehicle off

the jack, do not tighten the lug nuts fully

until the vehicle has been lowered. Failure

to follow this warning may result in per-

sonal injury.

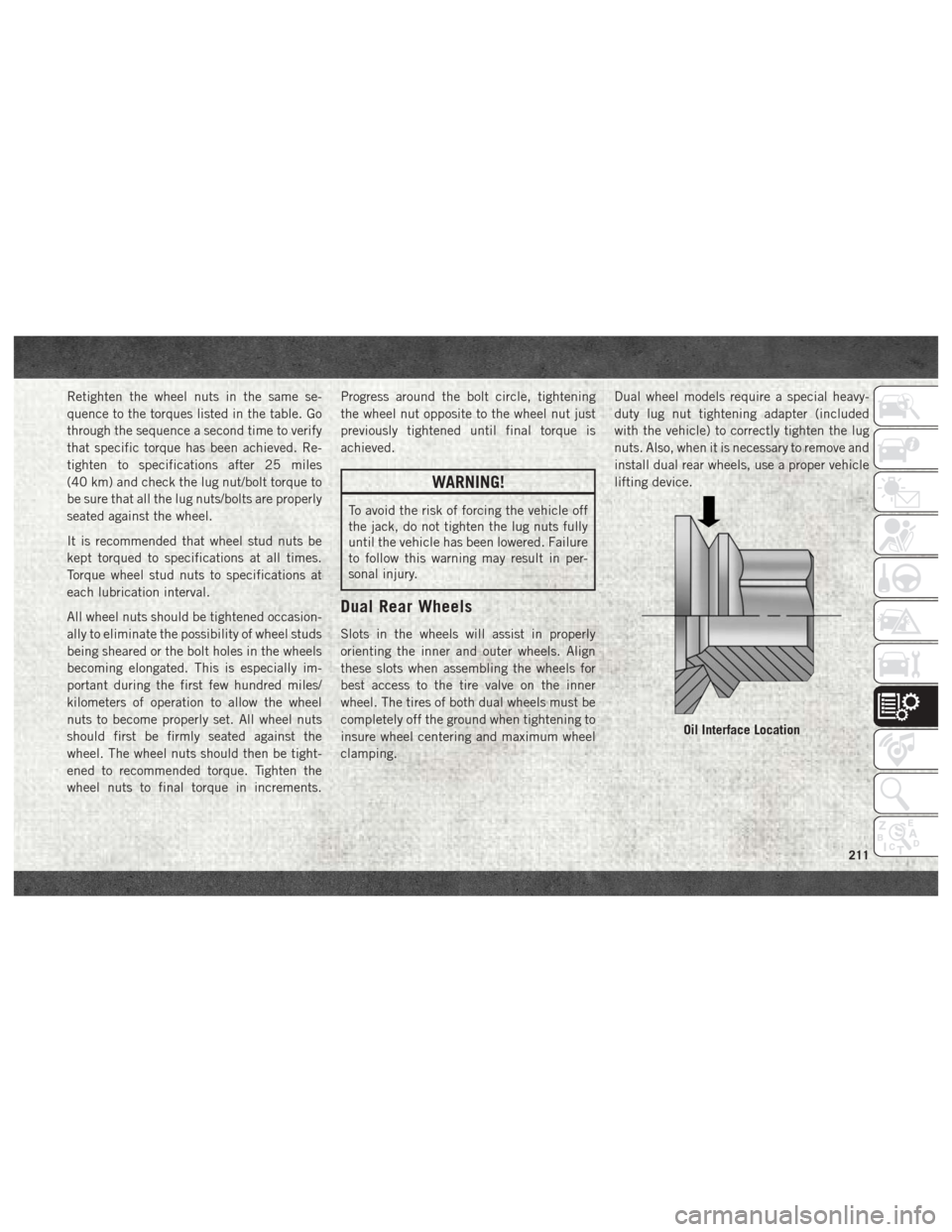

Dual Rear Wheels

Slots in the wheels will assist in properly

orienting the inner and outer wheels. Align

these slots when assembling the wheels for

best access to the tire valve on the inner

wheel. The tires of both dual wheels must be

completely off the ground when tightening to

insure wheel centering and maximum wheel

clamping.

Dual wheel models require a special heavy-

duty lug nut tightening adapter (included

with the vehicle) to correctly tighten the lug

nuts. Also, when it is necessary to remove and

install dual rear wheels, use a proper vehicle

lifting device.

Oil Interface Location

211

Page 215 of 298

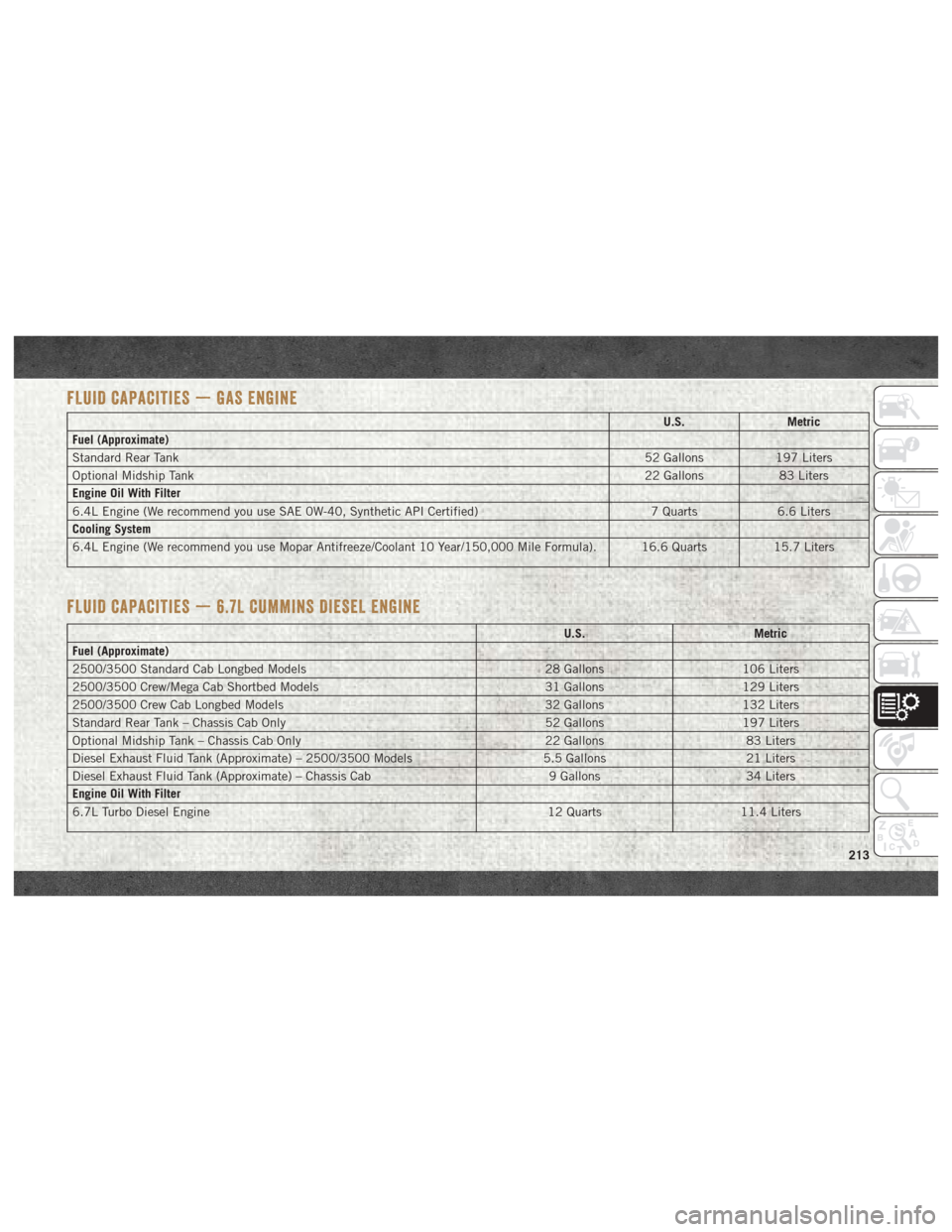

FLUID CAPACITIES — GAS ENGINE

U.S.Metric

Fuel (Approximate)

Standard Rear Tank 52 Gallons197 Liters

Optional Midship Tank 22 Gallons83 Liters

Engine Oil With Filter

6.4L Engine (We recommend you use SAE 0W-40, Synthetic API Certified) 7 Quarts6.6 Liters

Cooling System

6.4L Engine (We recommend you use Mopar Antifreeze/Coolant 10 Year/150,000 Mile Formula). 16.6 Quarts 15.7 Liters

FLUID CAPACITIES — 6.7L CUMMINS DIESEL ENGINE

U.S.Metric

Fuel (Approximate)

2500/3500 Standard Cab Longbed Models 28 Gallons106 Liters

2500/3500 Crew/Mega Cab Shortbed Models 31 Gallons129 Liters

2500/3500 Crew Cab Longbed Models 32 Gallons132 Liters

Standard Rear Tank – Chassis Cab Only 52 Gallons197 Liters

Optional Midship Tank – Chassis Cab Only 22 Gallons83 Liters

Diesel Exhaust Fluid Tank (Approximate) – 2500/3500 Models 5.5 Gallons21 Liters

Diesel Exhaust Fluid Tank (Approximate) – Chassis Cab 9 Gallons34 Liters

Engine Oil With Filter

6.7L Turbo Diesel Engine 12 Quarts11.4 Liters

213

Page 219 of 298

ComponentFluid, Lubricant, or Genuine Part

Engine Oil In ambient temperatures above 0°F (-18°C), we recommend you use 15W-40 engine oil such as Mopar, Shell Rotella

and Shell Rimula that meets FCA Material Standard MS-10902 and the API CJ-4 engine oil category is required.

Products meeting Cummins CES 20081 may also be used. The identification of these engine oils is typically located on

the back of the oil container.

In ambient temperatures below 0°F (-18°C), we recommend you use 5W-40

syntheticengine oil such as Mopar, Shell

Rotella and Shell Rimula that meets FCA Material Standard MS-10902 and the API CJ-4 engine oil category is required.

Engine Oil Filter We recommend you use Mopar Engine Oil Filters.

Fuel Filters We recommend you use Mopar Fuel Filter. Must meet 3 micron rating.

Using a fuel filter that does not meet the

manufacturers filtration and water separating requirements can severely impact fuel system life and reliability.

Crankcase Ventilation Filter We recommend you use Mopar CCV Filter.

Fuel Selection Use good quality diesel fuel from a reputable supplier in your vehicle. Federal law requires that you must fuel this

vehicle with Ultra Low Sulfur Highway Diesel fuel (15 ppm Sulfur maximum) and prohibits the use of Low Sulfur

Highway Diesel fuel (500 ppm Sulfur maximum) to avoid damage to the emissions control system.

For most year-round service, No. 2 diesel fuel meeting ASTM specification D-975 Grade S15 will provide good

performance.

If climatized or diesel Number 1 ULSD fuel is not available, and you are operating below (20°F/-6°C), in sustained arctic

conditions, Mopar Premium Diesel Fuel Treatment (or equivalent) is recommended to avoid gelling.

This vehicle is fully compatible with biodiesel blends up to 5% biodiesel meeting ASTM specification D-975.

Pickup models,

and Chassis Cab models configured with optional B20 capability, are additionally compatible with 20% biodiesel

meeting ASTM specification D-7467.

Diesel Exhaust Fluid Mopar Diesel Exhaust Fluid (API Certified) (DEF) or equivalent that has been API Certified to the ISO 22241 standard.

Use of fluids not API Certified to ISO 22241 may result in system damage. You can receive assistance in locating DEF

in the United States by calling 866-RAM-INFO (866-726-4636). In Canada call 1–800–465–2001 (English) or

1–800–387–9983 (French).

217

Page 220 of 298

Chassis

ComponentFluid, Lubricant, or Genuine Part

Automatic Transmission – If Equipped 6.7L Diesel with (Six-Speed

68RFE) – 2500/3500 Pickup models without PTO Only use ATF+4 Automatic Transmission Fluid. Failure to use ATF+4 fluid

may affect the function or performance of your transmission. We recom-

mend Mopar ATF+4 fluid.

Automatic Transmission – If Equipped 6.7L Diesel with (Six-Speed

AS69RC) – Pickup models with PTO and All Chassis Cab models Only use Mopar ASRC Automatic Transmission Fluid or equivalent. Failure

to use the proper fluid may affect the function or performance of your

transmission.

Transfer Case We recommend you use Mopar BW44–44 Transfer Case Fluid.

Front and Rear Axle Fluid (2500/3500) We recommend you use SAE 75W-85 HD Ram GL-5 Synthetic Axle

Lubricant. Limited slip additive is not required for Limited-Slip Rear

Axles.

Front and Rear Axle Fluid (4500/5500) We recommend you use GL-5 SAE 75W-90 Synthetic (MS-9763). Limited

slip additive is not required for Limited-Slip Rear Axles.

Clutch Linkage We recommend you use Mopar Multi-Purpose Grease, NLGI Grade 2 E.P.

or equivalent.

Manual Transmission (G-56) – If Equipped We recommend you use Mopar ATF+4 Automatic Transmission Fluid or

equivalent licensed ATF+4 product.

TECHNICAL SPECIFICATIONS

218

Page 227 of 298

Clock Setting

1. Push the Menu button at the bottom ofthe radio, and push the Enter/Browse but-

ton for System Settings. Next, select the

Time and Format setting and then select

Set Time by pushing the Enter/Browse

button.

2. Adjust the hours or minutes by turning the Tune/Scroll knob, then pushing the Enter/

Browse button to move to the next entry.

You can also select 12hr or 24hr format by

turning the Tune/Scroll knob, then push-

ing the Enter/Browse button on the de-

sired selection.

3. Once the time is set, press the “Ok” button to exit the time screen.

Audio Setting

• Push the AUDIO button on the radio face-plate.

• The Audio Menu shows the following op- tions for you to customize your audio

settings. Treble, Mid, Bass, Fade, Balance, Speed Ad-

justed Volume, Loudness and AUX Offset

• Select the desired setting to adjust, then

push the ENTER/BROWSE button. Turn the

TUNE/SCROLL knob to adjust the setting +

or - . Push the “Back” button when done.

Radio Operation

Seek Up/Down Buttons

• Push the up or down button to seek throughradio stations in AM, FM or SXM bands.

• Hold either button to bypass stations with- out stopping.

Store Radio Presets Manually

The presets are available for all Radio Modes,

and are activated by pushing any of the six

preset buttons. The Radio stores up to

18 presets in each of the Radio modes. Push

the A-B-C button on the faceplate to select

the A, B, or C preset list. To store a radio preset manually, follow the

steps below:

1. Tune to the desired station.

2. Push and hold the desired numbered but-

ton for more than two seconds, or until you

hear a confirmation beep.Disc Operation — If Equipped

Your vehicle may have a remote CD player

located in the lower center console storage

bin, or in the lower center bench seat bin.

• CD/Disc Mode is entered by either insertinga CD/Disc or by pushing the MEDIA button

located on the side of the display. Once in

Media Mode, select “Disc.”

Gently insert one CD into the CD player with

the CD label facing as indicated on the illus-

tration located on the Disc player.

Seek Up/Down Buttons

• Push to seek through CD tracks.

• Hold either button to bypass tracks without stopping.

225