brakes Ram 4500 Chassis Cab 2018 User Guide

[x] Cancel search | Manufacturer: RAM, Model Year: 2018, Model line: 4500 Chassis Cab, Model: Ram 4500 Chassis Cab 2018Pages: 298, PDF Size: 5.88 MB

Page 131 of 298

WARNING!

• Never leave children alone in a vehicle,or with access to an unlocked vehicle.

Allowing children to be in a vehicle un-

attended is dangerous for a number of

reasons. A child or others could be seri-

ously or fatally injured. Children should

be warned not to touch the parking

brake, brake pedal or the transmission

gear selector.

•

Do not leave the key fob in or near the

vehicle (or in a location accessible to chil-

dren), and do not leave the ignition (in a

vehicle equipped with Keyless Enter-N-

Go) in the ACC or ON/RUN mode. A child

could operate power windows, other con-

trols, or move the vehicle.

CAUTION!

Damage to the transmission may occur if the

following precautions are not observed:

• Shift into or out of PARK or REVERSE

only after the vehicle has come to a

complete stop.

CAUTION!

• Do not shift between PARK, REVERSE,NEUTRAL, or DRIVE when the engine is

above idle speed.

• Before shifting into any gear, make sure

your foot is firmly pressing the brake

pedal.

NOTE:

You must press and hold the brake pedal

while shifting out of PARK.

Key Ignition Park Interlock

This vehicle is equipped with a Key Ignition

Park Interlock which requires the transmis-

sion to be in PARK before the ignition can be

turned to the LOCK/OFF (key removal) posi-

tion. The key fob can only be removed from

the ignition when the ignition is in the LOCK/

OFF position, and the transmission is locked

in PARK whenever the ignition is in the

LOCK/OFF position. NOTE:

If a malfunction occurs, the system will trap

the key fob in the ignition to warn you that

this safety feature is inoperable. The engine

can be started and stopped but the key fob

cannot be removed until you obtain service.

Brake/Transmission Shift

Interlock System

This vehicle is equipped with a Brake Trans-

mission Shift Interlock system (BTSI) that

holds the transmission gear selector in PARK

unless the brakes are applied. To shift the

transmission out of PARK, the ignition must

be in the ON/RUN mode (engine running or

not) and the brake pedal must be pressed.

Six–Speed Automatic

Transmission — If Equipped

Chassis Cab models (with automatic trans-

mission) may use either the AS66RC or

AS69RC transmission (which are equipped

with a Power Take-Off (PTO) access cover on

the side of the transmission case), or the

66RFE transmission (which has no PTO ac-

cess cover).

129

Page 133 of 298

If the transmission cannot be reset, autho-

rized dealer service is required.

Electronic Range Select (ERS) Operation

The Electronic Range Select (ERS) shift con-

trol allows the driver to limit the highest

available gear when the transmission is in

DRIVE. For example, if you set the transmis-

sion gear limit to 4 (fourth gear), the trans-

mission will not shift above fourth gear, but

will shift through the lower gears normally.

You can switch between DRIVE and ERS

mode at any vehicle speed. When the gear

selector is in the DRIVE position, the trans-

mission will operate automatically, shifting

between all available gears. Tapping the ERS

(-) switch will activate ERS mode, display the

current gear in the instrument cluster, and

set that gear as the top available gear. Once

in ERS mode, tapping (-) or (+) will change

the top available gear.To exit ERS mode, simply push and hold the

ERS (+) switch until the gear limit display

disappears from the instrument cluster.

WARNING!

Do not downshift for additional engine

braking on a slippery surface. The drive

wheels could lose their grip and the ve-

hicle could skid, causing a collision or

personal injury.

NOTE:

To select the proper gear position for maxi-

mum deceleration (engine braking), simply

push and hold the ERS (-) switch. The trans-

mission will shift to the range from which the

vehicle can best be slowed down.

CAUTION!

When using ERS for engine braking while

descending steep grades, be careful not to

overspeed the engine. Apply the brakes as

needed to prevent engine overspeed.

FOUR-WHEEL DRIVE OPERATION —

IF EQUIPPED

• Four-wheel drive trucks are equipped with either a manually shifted transfer case or an

electronically shifted transfer case. Refer to

the operating instructions for electronic

transfer case, located in this section for

further information.

• For further information on the manually shifted transfer case, refer to “Four Wheel

Drive Operation” in “Starting And Operat-

ing” in your Owner’s Manual located at

www.mopar.com/en-us/care/owners-manual.html

(U.S. Residents) or www.owners.mopar.ca

(Canadian Residents).

Column Gear Selector

131

Page 145 of 298

CAUTION!

• Then, during the first 500 miles(805 km) that a trailer is towed, do not

drive over 50 mph (80 km/h) and do not

make starts at full throttle. This helps

the engine and other parts of the vehicle

wear in at the heavier loads.

Perform the maintenance listed in the

“Scheduled Servicing”. Refer to “Scheduled

Servicing” in “Servicing And Maintenance”

for the proper maintenance intervals. When

towing a trailer, never exceed the GAWR or

GCWR ratings.

WARNING!

Improper towing can lead to a collision.

Follow these guidelines to make your

trailer towing as safe as possible:

• Make certain that the load is secured in the trailer and will not shift during travel.

When trailering cargo that is not fully

secured, dynamic load shifts can occur

that may be difficult for the driver to

WARNING!

control. You could lose control of your

vehicle and have a collision.

• When hauling cargo or towing a trailer,

do not overload your vehicle or trailer.

Overloading can cause a loss of control,

poor performance or damage to brakes,

axle, engine, transmission, steering,

suspension, chassis structure or tires.

• Safety chains must always be used be-

tween your vehicle and trailer. Always

connect the chains to the hook retainers

of the vehicle hitch. Cross the chains

under the trailer tongue and allow

enough slack for turning corners.

• Vehicles with trailers should not be

parked on a grade. When parking, apply

the parking brake on the tow vehicle. Put

the tow vehicle transmission in PARK.

For four-wheel drive vehicles, make sure

the transfer case is not in NEUTRAL.

Always, block or "chock" the trailer

wheels.

• GCWR must not be exceeded.

WARNING!

• Total weight must be distributed between

the tow vehicle and the trailer such that the

following four ratings are not exceeded:

1. GVWR

2. GTW

3. GAWR

4. Tongue weight rating for the trailer hitch utilized.

Towing Requirements — Trailer Brakes

•Do notinterconnect the hydraulic brake

system or vacuum system of your vehicle

with that of the trailer. This could cause

inadequate braking and possible personal

injury.

• An electronically actuated trailer brake controller is required when towing a trailer

with electronically actuated brakes. When

towing a trailer equipped with a hydraulic

surge actuated brake system, an electronic

brake controller is not required.

143

Page 146 of 298

• Trailer brakes are recommended for trailersover 1,000 lbs (453 kg) and required for

trailers in excess of 2,000 lbs (907 kg).

WARNING!

•Do not connect trailer brakes to your vehi-

cle's hydraulic brake lines. It can overload

your brake system and cause it to fail. You

might not have brakes when you need them

and could have a collision.

• Towing any trailer will increase your stopping distance. When towing you

should allow for additional space be-

tween your vehicle and the vehicle in

front of you. Failure to do so could result

in a collision.

CAUTION!

If the trailer weighs more than 1,000 lbs

(453 kg) loaded, it should have its own

brakes and they should be of adequate

capacity. Failure to do this could lead to

accelerated brake lining wear, higher

brake pedal effort, and longer stopping

distances.

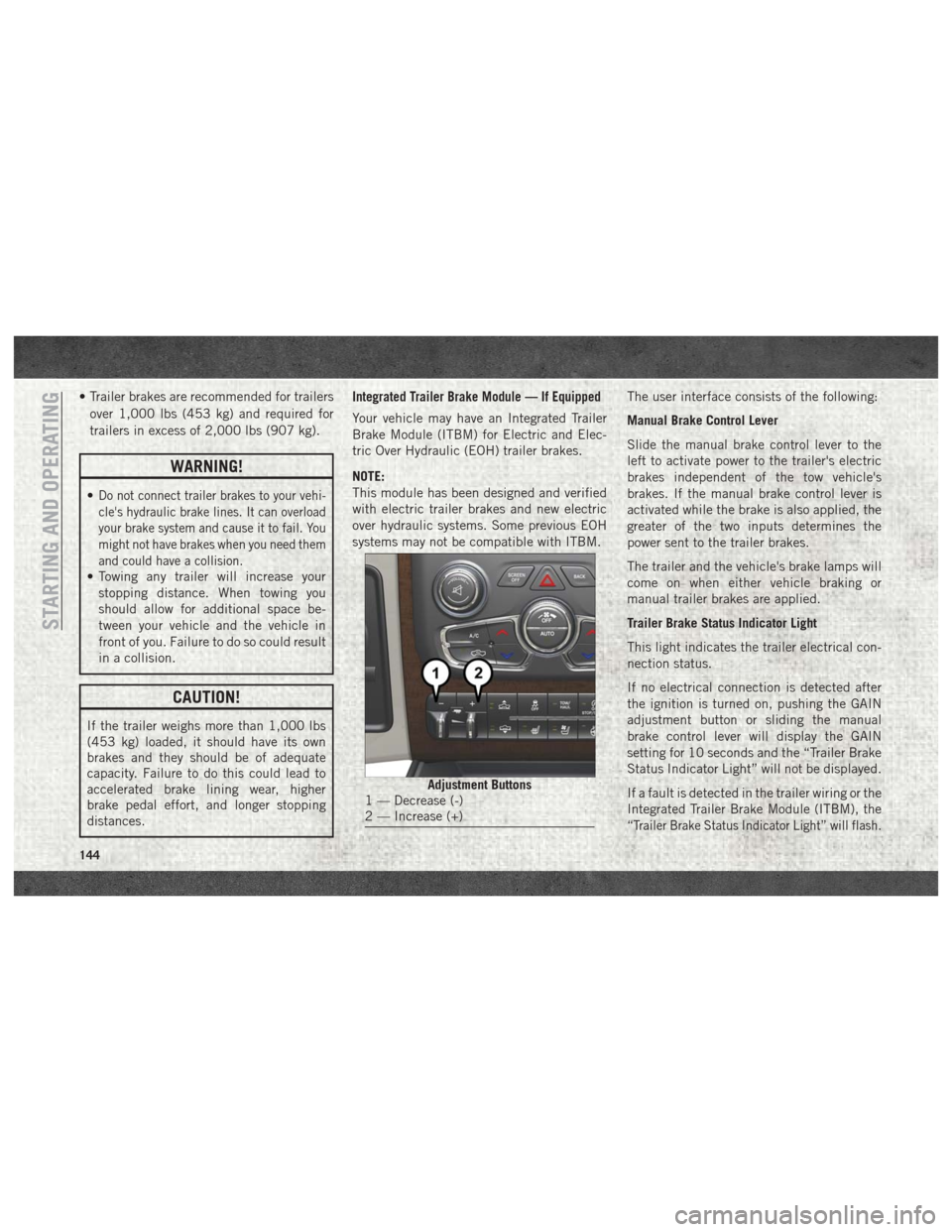

Integrated Trailer Brake Module — If Equipped

Your vehicle may have an Integrated Trailer

Brake Module (ITBM) for Electric and Elec-

tric Over Hydraulic (EOH) trailer brakes.

NOTE:

This module has been designed and verified

with electric trailer brakes and new electric

over hydraulic systems. Some previous EOH

systems may not be compatible with ITBM. The user interface consists of the following:

Manual Brake Control Lever

Slide the manual brake control lever to the

left to activate power to the trailer's electric

brakes independent of the tow vehicle's

brakes. If the manual brake control lever is

activated while the brake is also applied, the

greater of the two inputs determines the

power sent to the trailer brakes.

The trailer and the vehicle's brake lamps will

come on when either vehicle braking or

manual trailer brakes are applied.

Trailer Brake Status Indicator Light

This light indicates the trailer electrical con-

nection status.

If no electrical connection is detected after

the ignition is turned on, pushing the GAIN

adjustment button or sliding the manual

brake control lever will display the GAIN

setting for 10 seconds and the “Trailer Brake

Status Indicator Light” will not be displayed.

If a fault is detected in the trailer wiring or the

Integrated Trailer Brake Module (ITBM), the

“Trailer Brake Status Indicator Light” will flash.

Adjustment Buttons1 — Decrease (-)

2 — Increase (+)

STARTING AND OPERATING

144

Page 147 of 298

GAIN Adjustment Buttons (+/-)

Pushing these buttons will adjust the brake

control power output to the trailer brakes in

0.5 increments. The GAIN setting can be

increased to a maximum of 10 or decreased

to a minimum of 0 (no trailer braking).

GAIN

The GAIN setting is used to set the trailer

brake control for the specific towing condi-

tion and should be changed as towing condi-

tions change. Changes to towing conditions

include trailer load, vehicle load, road condi-

tions and weather.

Adjusting GAIN

NOTE:

This should only be performed in a traffic free

environment at speeds of approximately 20–

25 mph (30–40 km/h).

1. Make sure the trailer brakes are in goodworking condition, functioning normally

and properly adjusted. See your trailer

dealer if necessary. 2. Hook up the trailer and make the electri-

cal connections according to the trailer

manufacturer's instructions.

3. When a trailer with electric/EOH brakes is plugged in, the trailer connected message

should appear in the instrument cluster

display (if the connection is not recog-

nized by the ITBM, braking functions will

not be available), the GAIN setting will

illuminate and the correct type of trailer

must be selected from the instrument

cluster display options.

4. Push the UP or DOWN button on the steering wheel until “TRAILER TOW” ap-

pears on the screen.

5. Push the RIGHT arrow on the steering wheel to enter “TRAILER TOW”.

6. Push the UP or DOWN buttons until the Trailer Brake Type appears on the screen. 7. Push the RIGHT arrow and then push the

UP or DOWN buttons until the proper

Trailer Brake Type appears on the screen.

8. In a traffic-free environment, tow the trailer on a dry, level surface at a speed of

20–25 mph (30–40 km/h) and squeeze

the manual brake control lever

completely.

9. If the trailer wheels lockup (indicated by squealing tires), reduce the GAIN setting;

if the trailer wheels turn freely, increase

the GAIN setting.

Repeat steps 8 and 9 until the GAIN setting

is at a point just below trailer wheel lockup. If

towing a heavier trailer, trailer wheel lockup

may not be attainable even with the maxi-

mum GAIN setting of 10.

145

Page 148 of 298

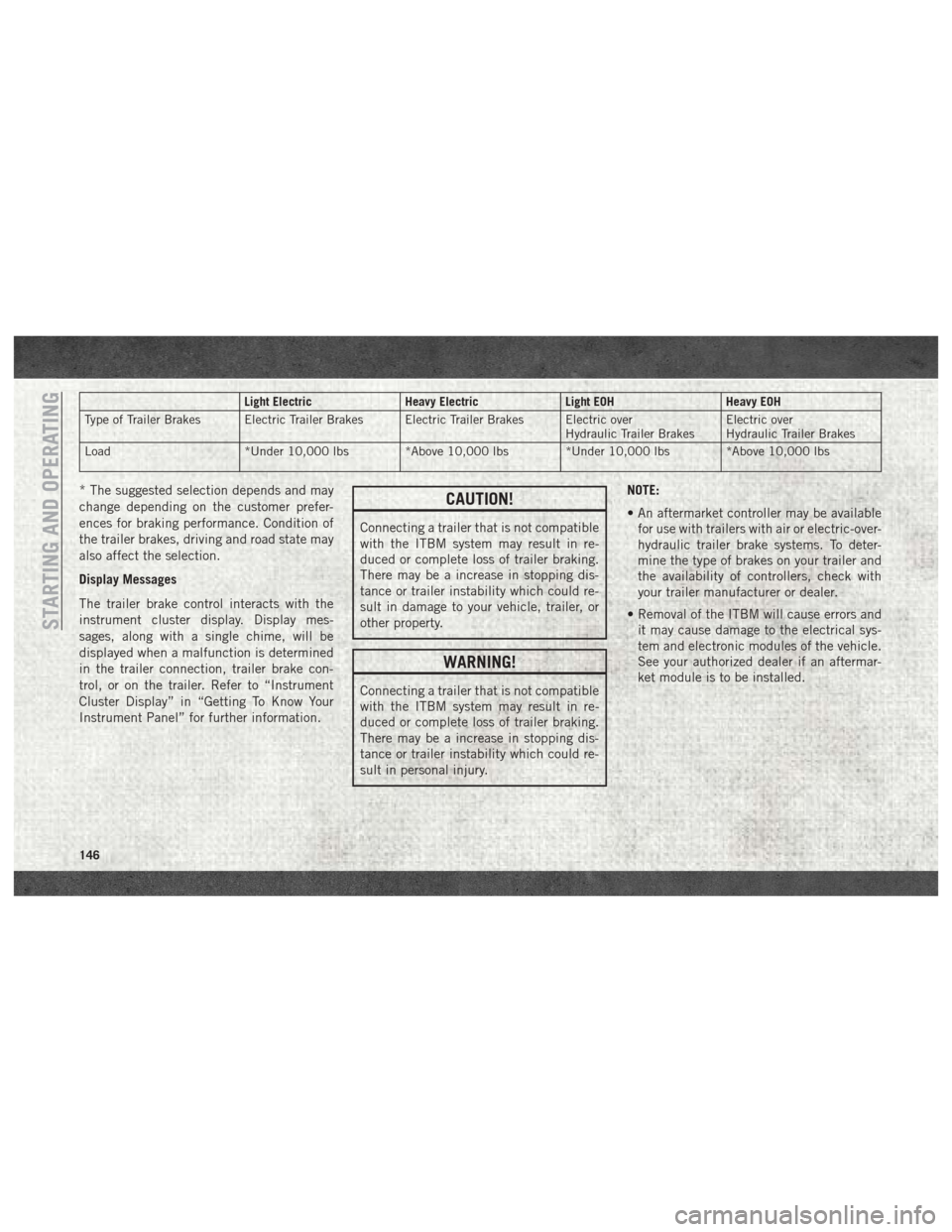

Light ElectricHeavy ElectricLight EOHHeavy EOH

Type of Trailer Brakes Electric Trailer Brakes Electric Trailer Brakes Electric over Hydraulic Trailer BrakesElectric over

Hydraulic Trailer Brakes

Load *Under 10,000 lbs *Above 10,000 lbs *Under 10,000 lbs *Above 10,000 lbs

* The suggested selection depends and may

change depending on the customer prefer-

ences for braking performance. Condition of

the trailer brakes, driving and road state may

also affect the selection.

Display Messages

The trailer brake control interacts with the

instrument cluster display. Display mes-

sages, along with a single chime, will be

displayed when a malfunction is determined

in the trailer connection, trailer brake con-

trol, or on the trailer. Refer to “Instrument

Cluster Display” in “Getting To Know Your

Instrument Panel” for further information.CAUTION!

Connecting a trailer that is not compatible

with the ITBM system may result in re-

duced or complete loss of trailer braking.

There may be a increase in stopping dis-

tance or trailer instability which could re-

sult in damage to your vehicle, trailer, or

other property.

WARNING!

Connecting a trailer that is not compatible

with the ITBM system may result in re-

duced or complete loss of trailer braking.

There may be a increase in stopping dis-

tance or trailer instability which could re-

sult in personal injury. NOTE:

• An aftermarket controller may be available

for use with trailers with air or electric-over-

hydraulic trailer brake systems. To deter-

mine the type of brakes on your trailer and

the availability of controllers, check with

your trailer manufacturer or dealer.

• Removal of the ITBM will cause errors and it may cause damage to the electrical sys-

tem and electronic modules of the vehicle.

See your authorized dealer if an aftermar-

ket module is to be installed.

STARTING AND OPERATING

146

Page 157 of 298

FUSES

WARNING!

• When replacing a blown fuse, always usean appropriate replacement fuse with

the same amp rating as the original fuse.

Never replace a fuse with another fuse of

higher amp rating. Never replace a

blown fuse with metal wires or any other

material. Do not place a fuse inside a

circuit breaker cavity or vice versa. Fail-

ure to use proper fuses may result in

serious personal injury, fire and/or prop-

erty damage.

WARNING!

• Before replacing a fuse, make sure thatthe ignition is off and that all the other

services are switched off and/or disen-

gaged.

• If the replaced fuse blows again, contact

an authorized dealer.

• If a general protection fuse for safety

systems (air bag system, braking sys-

tem), power unit systems (engine sys-

tem, transmission system) or steering

system blows, contact an authorized

dealer.

Power Distribution Center

The Power Distribution Center is located in

the engine compartment near the battery.

This center contains cartridge fuses, micro

fuses, relays, and circuit breakers. A descrip-

tion of each fuse and component may be

stamped on the inside cover, otherwise the

cavity number of each fuse is stamped on the

inside cover that corresponds to the following

chart.

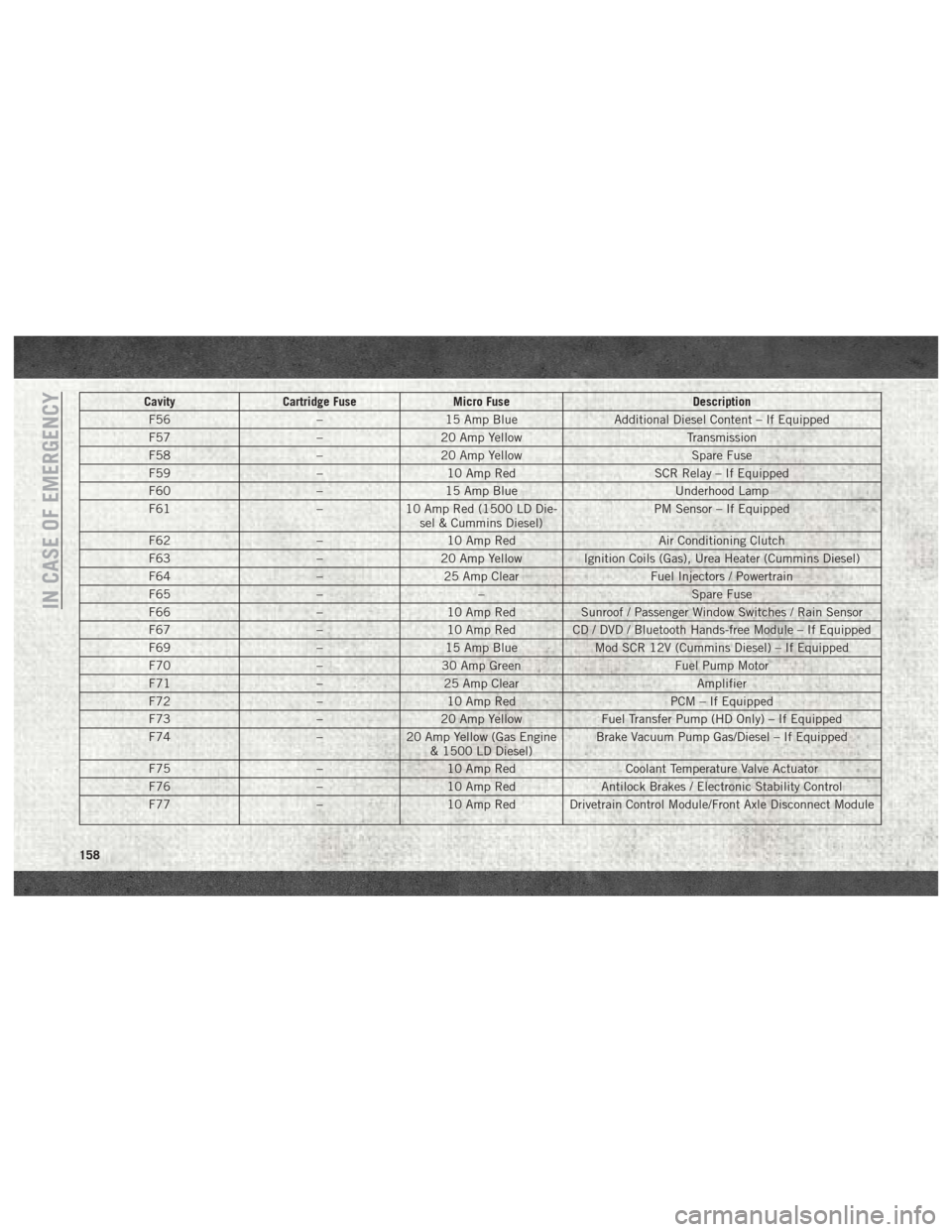

Cavity Cartridge Fuse Micro Fuse Description

F01 80 Amp Black –Rad Fan Control Module – If Equipped

F03 60 Amp Yellow –Rad Fan – If Equipped

F05 40 Amp Green –Compressor for Air Suspension – If Equipped

F06 40 Amp Green –Antilock Brakes/Electronic Stability Control Pump

F07 40 Amp Green – Starter Solenoid

F08 20 Amp Blue (1500 LD/

Cummins Diesel) –

Emissions Diesel – If Equipped

155

Page 158 of 298

CavityCartridge Fuse Micro Fuse Description

F09 40 Amp Green (Special

Services Vehicle & Cum- mins Diesel) –

Diesel Fuel Heater – If Equipped

F10 40 Amp Green –Body Controller / Exterior Lighting #2

F10 50 Amp Red –Body Controller / Exterior Lighting #2 – If Equipped with

Stop/Start

F11 30 Amp Pink –Integrated Trailer Brake Module – If Equipped

F12 40 Amp Green –Body Controller #3 / Power Locks

F13 40 Amp Green – Blower Motor

F14 40 Amp Green –Body Controller #4 / Interior Lighting

F16 30 Amp Pink –Smart Bar – If Equipped

F19 20 Amp Blue (1500 LD

Diesel)

30 Amp Pink (Cummins Diesel) –

SCR – If Equipped

F20 30 Amp Pink –Passenger Door Module

F21 30 Amp Pink –Drive Train Control Module

F22 20 Amp Blue

30 Amp Pink (Cummins Diesel) –

Engine Control Module

F23 30 Amp Pink –Body Controller #1 / Interior Lighting

F24 30 Amp Pink –Driver Door Module

F25 30 Amp Pink – Front Wiper

F26 30 Amp Pink –Antilock Brakes / Stability Control Module / Valves

F28 20 Amp Blue –Trailer Tow Backup Lights – If Equipped

IN CASE OF EMERGENCY

156

Page 160 of 298

CavityCartridge Fuse Micro Fuse Description

F56 –15 Amp Blue Additional Diesel Content – If Equipped

F57 –20 Amp Yellow Transmission

F58 –20 Amp Yellow Spare Fuse

F59 –10 Amp Red SCR Relay – If Equipped

F60 –15 Amp Blue Underhood Lamp

F61 –10 Amp Red (1500 LD Die-

sel & Cummins Diesel) PM Sensor – If Equipped

F62 –10 Amp Red Air Conditioning Clutch

F63 –20 Amp Yellow Ignition Coils (Gas), Urea Heater (Cummins Diesel)

F64 –25 Amp Clear Fuel Injectors / Powertrain

F65 –– Spare Fuse

F66 –10 Amp Red Sunroof / Passenger Window Switches / Rain Sensor

F67 –10 Amp Red CD / DVD / Bluetooth Hands-free Module – If Equipped

F69 –15 Amp Blue Mod SCR 12V (Cummins Diesel) – If Equipped

F70 –30 Amp Green Fuel Pump Motor

F71 –25 Amp Clear Amplifier

F72 –10 Amp Red PCM – If Equipped

F73 –20 Amp Yellow Fuel Transfer Pump (HD Only) – If Equipped

F74 –20 Amp Yellow (Gas Engine

& 1500 LD Diesel) Brake Vacuum Pump Gas/Diesel – If Equipped

F75 –10 Amp Red Coolant Temperature Valve Actuator

F76 –10 Amp Red Antilock Brakes / Electronic Stability Control

F77 –10 Amp Red Drivetrain Control Module/Front Axle Disconnect Module

IN CASE OF EMERGENCY

158

Page 169 of 298

• In city traffic — while stopped, place thetransmission in NEUTRAL, but do not in-

crease the engine idle speed while prevent-

ing vehicle motion with the brakes.

NOTE:

There are steps that you can take to slow

down an impending overheat condition:

• If your air conditioner (A/C) is on, turn it off. The A/C system adds heat to the engine

cooling system and turning the A/C off can

help remove this heat.

• You can also turn the temperature control to maximum heat, the mode control to floor

and the blower control to high. This allows

the heater core to act as a supplement to

the radiator and aids in removing heat from

the engine cooling system.

WARNING!

You or others can be badly burned by hot

engine coolant (antifreeze) or steam from

your radiator. If you see or hear steam

coming from under the hood, do not open

the hood until the radiator has had time to

cool. Never try to open a cooling system

WARNING!

pressure cap when the radiator or coolant

bottle is hot.

CAUTION!

Driving with a hot cooling system could

damage your vehicle. If the temperature

gauge reads HOT (H), pull over and stop

the vehicle. Idle the vehicle with the air

conditioner turned off until the pointer

drops back into the normal range. If the

pointer remains on HOT (H), and you hear

continuous chimes, turn the engine off

immediately and call for service.

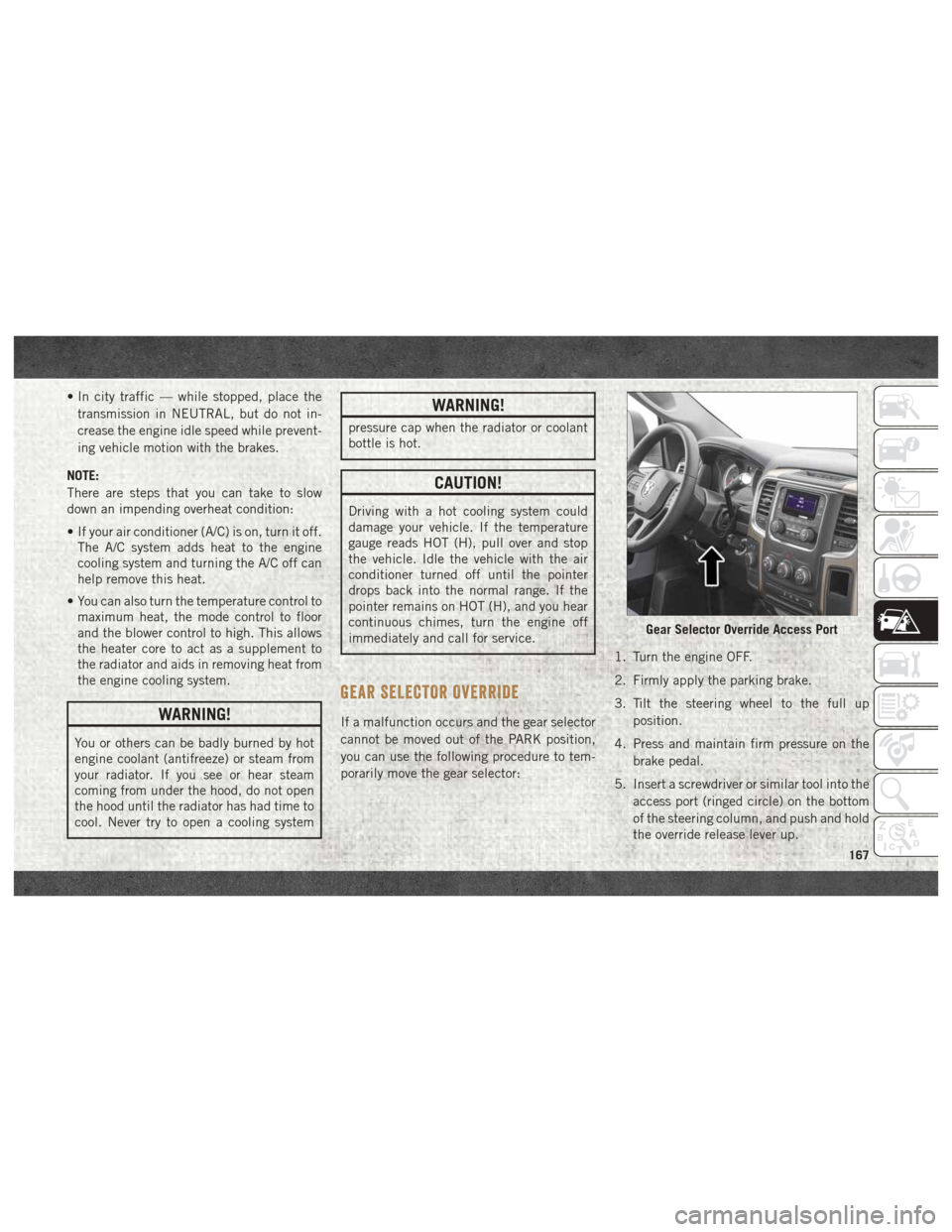

GEAR SELECTOR OVERRIDE

If a malfunction occurs and the gear selector

cannot be moved out of the PARK position,

you can use the following procedure to tem-

porarily move the gear selector: 1. Turn the engine OFF.

2. Firmly apply the parking brake.

3. Tilt the steering wheel to the full up

position.

4. Press and maintain firm pressure on the brake pedal.

5. Insert a screwdriver or similar tool into the access port (ringed circle) on the bottom

of the steering column, and push and hold

the override release lever up.

Gear Selector Override Access Port

167