fuel type Ram 4500 Chassis Cab 2018 User Guide

[x] Cancel search | Manufacturer: RAM, Model Year: 2018, Model line: 4500 Chassis Cab, Model: Ram 4500 Chassis Cab 2018Pages: 298, PDF Size: 5.88 MB

Page 62 of 298

Instrument Cluster Display Programmable Features

The instrument cluster display can be used to view or change the following settings. Push theupordown arrow button until System Setup

displays, then push the rightarrow button. Scroll through the settings using the upordown arrow button. Push the rightarrow button to change

the setting. Push the leftarrow button to scroll back to a previous menu or sub menu.

• Language Select • Remote Start Comfort System

• Units • Easy Exit Seat

• ParkSense • Key Off Power Delay

• Tilt Mirror In Reverse • Commercial Settings

• Rain Sensing Wipers • Air Suspension Display Alerts

• Hill Start Assist • Aero Ride Height Mode

• Headlights Off Delay • Tire/Jack Mode

• Illuminated Approach • Transport Mode

• Headlights On With Wipers • Wheel Alignment Mode

• Automatic Highbeams • Horn With Remote Lower

• Flash Lights With Lock • Lights With Remote Lower

• Auto Lock Doors • Trailer Select

• Auto Unlock Doors • Brake Type

• Sound Horn With Remote Start • Trailer Name

• Sound Horn With Remote Lock • Compass Variance

• Remote Unlock Sequence • Calibrate Compass

• Key Fob Linked To Memory • Fuel Saver Display

• Passive Entry • Park Assist Front Chime Volume

• Park Assist Rear Chime Volume

GETTING TO KNOW YOUR INSTRUMENT PANEL

60

Page 68 of 298

CAUTION!

The TPMS has been optimized for the

original equipment tires and wheels.

TPMS pressures and warning have been

established for the tire size equipped on

your vehicle. Undesirable system opera-

tion or sensor damage may result when

using replacement equipment that is not

of the same size, type, and/or style. After-

market wheels can cause sensor damage.

Using aftermarket tire sealants may cause

the Tire Pressure Monitoring System

(TPMS) sensor to become inoperable. Af-

ter using an aftermarket tire sealant it is

recommended that you take your vehicle

to your authorized dealer to have your

sensor function checked.

— Low Fuel Indicator Light

When the fuel level reaches approximately

3.0 gal (11.0 L) this light will turn on, and

remain on until fuel is added.

— Anti-Lock Brake (ABS) Warning

Light

This light monitors the Anti-Lock Brake Sys-

tem (ABS). The light will turn on when the

ignition is placed in the ON/RUN or ACC/ON/

RUN position and may stay on for as long as

four seconds.

If the ABS light remains on or turns on while

driving, then the Anti-Lock portion of the

brake system is not functioning and service is

required as soon as possible. However, the

conventional brake system will continue to

operate normally, assuming the Brake Warn-

ing Light is not also on.

If the ABS light does not turn on when the

ignition is placed in the ON/RUN or ACC/ON/

RUN position, have the brake system in-

spected by an authorized dealer.

— Low Coolant Level Warning Light

This telltale will turn on to indicate the ve-

hicle coolant level is low.

— Loose Fuel Filler Cap Warning Light

— If Equipped

This light will illuminate when the fuel filler

cap is loose. Properly close the filler cap to

disengage the light. If the light does not turn

off, please see your authorized dealer.

SERV4WD— Service 4WD Warning Light —

If Equipped

If the light stays on or comes on during

driving, it means that the 4WD system is not

functioning properly and that service is re-

quired. We recommend you drive to the near-

est service center and have the vehicle ser-

viced immediately.

— Transmission Temperature Warning

Light

This light indicates that the transmission

fluid temperature is running hot. This may

occur with severe usage, such as trailer tow-

ing. If this light turns on, safely pull over and

stop the vehicle. Then, shift the transmission

into PARK and run the engine at idle or

slightly higher until the light turns off.

GETTING TO KNOW YOUR INSTRUMENT PANEL

66

Page 75 of 298

CAUTION!

• The TPMS has been optimized for theoriginal equipment tires and wheels.

TPMS pressures and warning have been

established for the tire size equipped on

your vehicle. Undesirable system opera-

tion or sensor damage may result when

using replacement equipment that is not

of the same size, type, and/or style.

Aftermarket wheels can cause sensor

damage.

• Using aftermarket tire sealants may

cause the Tire Pressure Monitoring Sys-

tem (TPMS) sensor to become inoper-

able. After using an aftermarket tire

sealant it is recommended that you take

your vehicle to an authorized dealership

to have your sensor function checked.

• After inspecting or adjusting the tire

pressure always reinstall the valve stem

cap. This will prevent moisture and dirt

from entering the valve stem, which

could damage the TPMS sensor. NOTE:

• The TPMS is not intended to replace nor-

mal tire care and maintenance or to provide

warning of a tire failure or condition.

• The TPMS should not be used as a tire pressure gauge while adjusting your tire

pressure.

• Driving on a significantly under-inflated tire causes the tire to overheat and can lead to

tire failure. Under-inflation also reduces

fuel efficiency and tire tread life, and may

affect the vehicle’s handling and stopping

ability.

• The TPMS is not a substitute for proper tire maintenance, and it is the driver’s respon-

sibility to maintain correct tire pressure

using an accurate tire pressure gauge, even

if under-inflation has not reached the level

to trigger illumination of the TPM Telltale

Light.

• Seasonal temperature changes will affect tire pressure, and the TPMS will monitor

the actual tire pressure in the tire.

Premium System

The Tire Pressure Monitor System (TPMS)

uses wireless technology with wheel rim

mounted electronic sensors to monitor tire

pressure levels. Sensors, mounted to each

wheel as part of the valve stem, transmit tire

pressure readings to the receiver module.

NOTE:

It is particularly important for you to check

the tire pressure in all of the tires on your

vehicle monthly and to maintain the proper

pressure.

The TPMS consists of the following compo-

nents:

• Receiver module

• Four tire pressure monitoring sensors

• Various tire pressure monitoring systemmessages, which display in the instrument

cluster

• Tire pressure monitoring telltale light

Tire Pressure Monitoring Low Pressure Warnings

73

Page 143 of 298

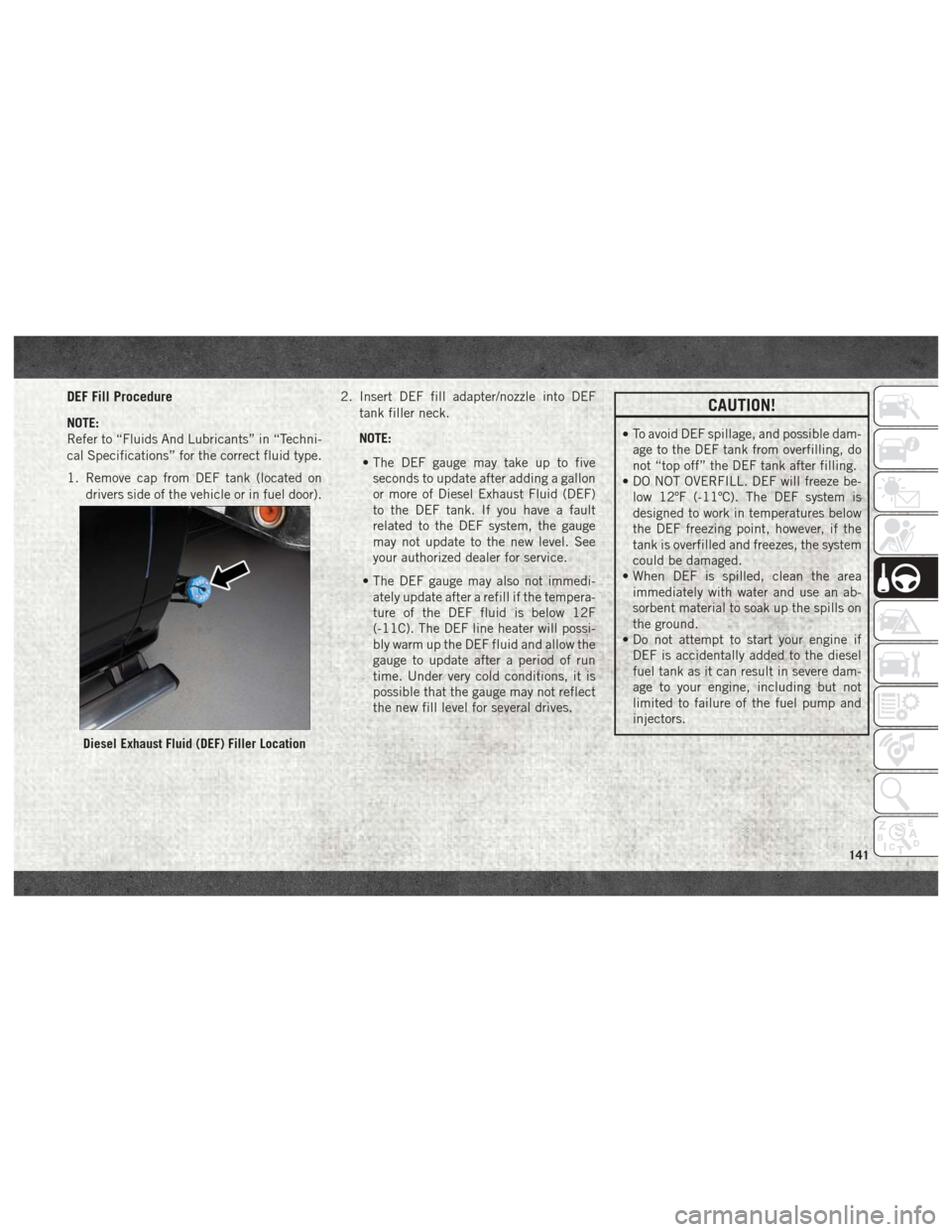

DEF Fill Procedure

NOTE:

Refer to “Fluids And Lubricants” in “Techni-

cal Specifications” for the correct fluid type.

1. Remove cap from DEF tank (located ondrivers side of the vehicle or in fuel door). 2. Insert DEF fill adapter/nozzle into DEF

tank filler neck.

NOTE: • The DEF gauge may take up to five seconds to update after adding a gallon

or more of Diesel Exhaust Fluid (DEF)

to the DEF tank. If you have a fault

related to the DEF system, the gauge

may not update to the new level. See

your authorized dealer for service.

• The DEF gauge may also not immedi- ately update after a refill if the tempera-

ture of the DEF fluid is below 12F

(-11C). The DEF line heater will possi-

bly warm up the DEF fluid and allow the

gauge to update after a period of run

time. Under very cold conditions, it is

possible that the gauge may not reflect

the new fill level for several drives.

CAUTION!

•To avoid DEF spillage, and possible dam-

age to the DEF tank from overfilling, do

not “top off” the DEF tank after filling.

• DO NOT OVERFILL. DEF will freeze be- low 12ºF (-11ºC). The DEF system is

designed to work in temperatures below

the DEF freezing point, however, if the

tank is overfilled and freezes, the system

could be damaged.

• When DEF is spilled, clean the area immediately with water and use an ab-

sorbent material to soak up the spills on

the ground.

• Do not attempt to start your engine if DEF is accidentally added to the diesel

fuel tank as it can result in severe dam-

age to your engine, including but not

limited to failure of the fuel pump and

injectors.

Diesel Exhaust Fluid (DEF) Filler Location

141

Page 175 of 298

SERVICING AND MAINTENANCE

SCHEDULED SERVICING — GASOLINE

ENGINE................... .174

Maintenance Plan – Gasoline Engine . .175

Heavy Duty Use Of The Vehicle ......178

SCHEDULED MAINTENANCE —

6.7L CUMMINS DIESEL ENGINE.....178

Oil Change Indicator System — Cummins

Diesel.....................178

Perform Service Indicator — Cummins

Diesel .....................179

Maintenance Plan — Cummins Diesel

Engine .....................180

ENGINE COMPARTMENT .........184

6.4L Engine.................184

6.7L Diesel Engine — Six-Speed

AS69RC HD (3500/Chassis Cab

Models) ....................185

DEALER SERVICE —

6.7L DIESEL ENGINE ............186

Engine Air Cleaner Filter .........186

Draining Fuel/Water Separator Filter . .187

Engine Mounted Fuel Filter

Replacement .................188

Underbody Mounted Fuel Filter

Replacement .................189

Priming If The Engine Has Run Out

Of Fuel ....................190

HOISTING ................. .191

TIRES .................... .191

Tire Safety Information..........191

Tires — General Information .......199

Tire Types ...................203

Spare Tires — If Equipped .........204

Wheel And Wheel Trim Care .......206

DEPARTMENT OF TRANSPORTATION

UNIFORM TIRE QUALITY GRADES . . . .207

Treadwear...................207

Traction Grades ...............207

Temperature Grades .............208

SERVICING AND MAINTENANCE

173

Page 176 of 298

SCHEDULED SERVICING — GASOLINE

ENGINE

Your vehicle is equipped with an automatic

oil change indicator system. The oil change

indicator system will remind you that it is

time to take your vehicle in for scheduled

maintenance.

Based on engine operation conditions, the oil

change indicator message will illuminate.

This means that service is required for your

vehicle. Operating conditions such as fre-

quent short-trips, trailer tow, extremely hot or

cold ambient temperatures, and E85 fuel

usage will influence when the “Oil Change

Required” message is displayed. Severe Op-

erating Conditions can cause the change oil

message to illuminate as early as

3,500 miles (5,600 km) since last reset.

Have your vehicle serviced as soon as pos-

sible, within the next 500 miles (805 km).

Your authorized dealer will reset the oil

change indicator message after completing

the scheduled oil change. If a scheduled oil

change is performed by someone other than

your authorized dealer, the message can bereset by referring to the steps described under

“Warning And Indicator Lights” or “Instru-

ment Cluster Display” in “Getting To Know

Your Instrument Panel” in your Owner’s

Manual at

www.mopar.com/en-us/care/

owner-manual.html (U.S. Residents) or

www.owners.mopar.ca (Canadian Residents)

for further information.

Gasoline Engines:

Under no circumstances should oil change

intervals exceed 8,000 miles (13,000 km),

twelve months or 350 hours of engine run

time, whichever comes first. The 350 hours

of engine run or idle time is generally only a

concern for fleet customers.

Severe Duty:

Change Engine Oil at 4,000 miles

(6,500 km) or 350 hours of engine run time

if the vehicle is operated in a dusty and off

road environment or is operated predomi-

nately at idle or very low engine RPM’s. This

type of vehicle use is considered Severe Duty. Once A Month Or Before A Long Trip:

• Check engine oil level

• Check windshield washer fluid level

• Check the tire inflation pressures and look

for unusual wear or damage

• Check the fluid levels of the coolant reser- voir, brake master cylinder, power steering

and automatic transmission, and fill as

needed

• Check function of all interior and exterior lights

SERVICING AND MAINTENANCE

174

Page 180 of 298

Heavy Duty Use Of The Vehicle

Change engine oil at 4,000 miles (6,500 km)

or 350 hours of engine run time if the vehicle

is operated in a dusty and off road environ-

ment or is operated predominately at idle or

only very low engine RPM’s. This type of

vehicle use is considered Severe Duty.

SCHEDULED MAINTENANCE — 6.7L

CUMMINS DIESEL ENGINE

CAUTION!

Failure to perform the required mainte-

nance items may result in damage to the

vehicle.

At Each Stop For Fuel

Check the engine oil level at least 30 minutes

after a fully warmed engine is shut off.

Checking the oil level while the vehicle is on

level ground will improve the accuracy of the

oil level reading. Add oil only when the level

is at or below the ADD or MIN mark. Once A Month

• Inspect the batteries, and clean and

tighten the terminals as required.

• Check the fluid levels of the coolant reser- voir, brake master cylinder, and automatic

transmission (if equipped), and add as

needed.

At Each Oil Change

• Change the engine oil filter.

• Inspect the exhaust system.

• Inspect engine air filter.

• Check the coolant level, hoses, and clamps.

• Inspect front end, and lubricate — If equipped with serviceable fittings.

• Lube the front drive shaft fitting (4X4 mod- els only).

Inspection and service should also be per-

formed anytime a malfunction is observed or

suspected. Retain all receipts.

Oil Change Indicator System —

Cummins Diesel

Your vehicle is equipped with an engine oil

change indicator system. This system will

alert you when it is time to change your

engine oil by displaying the words “Oil

Change Due” in your instrument cluster dis-

play. The oil change reminder will remind the

owner to change the engine oil every

15,000 miles or 500 hours, whichever

comes first, except for the Chassis Cab mod-

els and Pickup models configured with op-

tional B20 capability that are using B20 bio-

diesel, which are 12,500 miles or 400 hours,

whichever comes first. Failure to change the

engine oil per the maintenance schedule can

result in internal engine damage.

Replace the engine oil and oil filter every

15,000 miles (24,000 km) or six months, or

sooner if prompted by the oil change indicator

system. Under no circumstances should oil

change intervals exceed 15,000 miles

(24,000 km) or six months, whichever comes

first.

SERVICING AND MAINTENANCE

178

Page 216 of 298

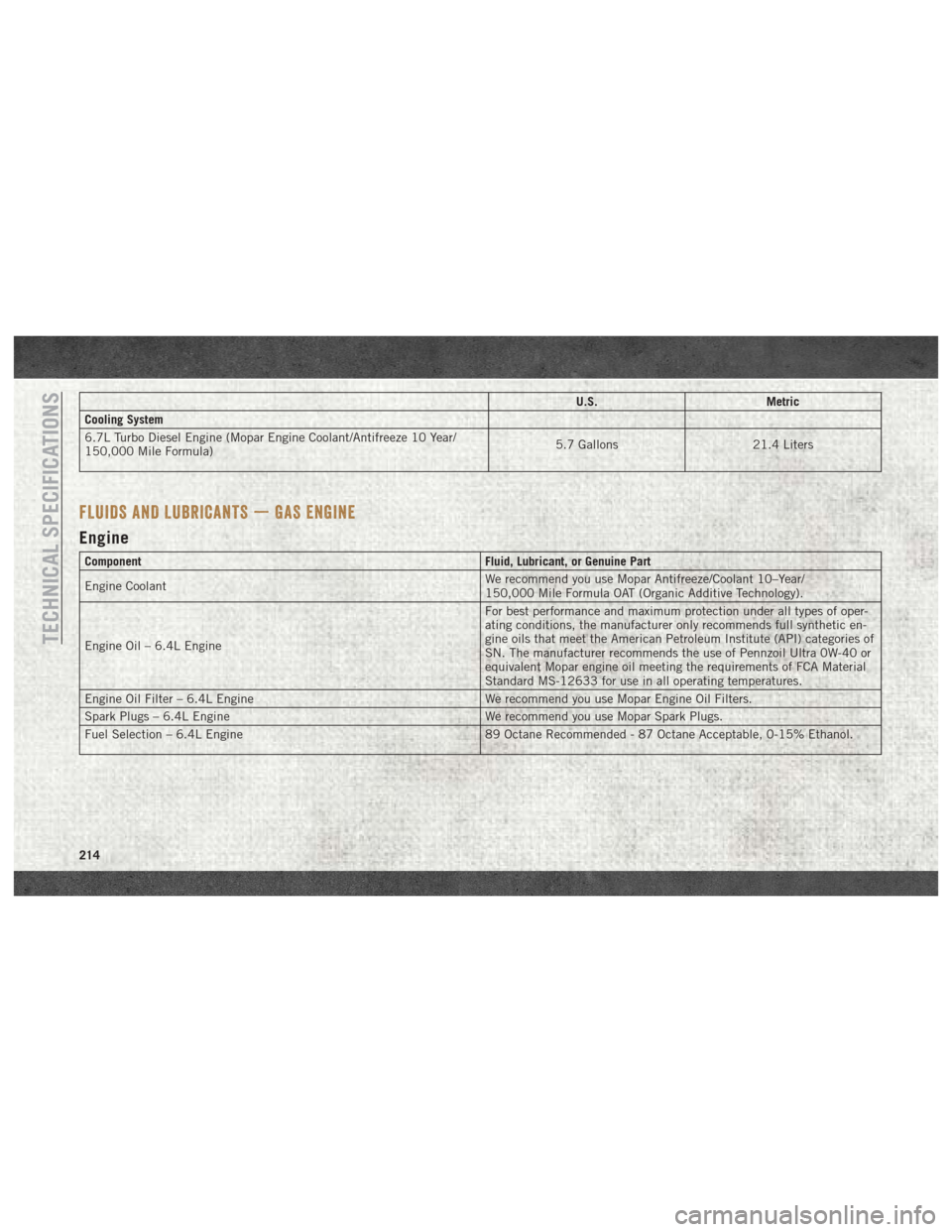

U.S.Metric

Cooling System

6.7L Turbo Diesel Engine (Mopar Engine Coolant/Antifreeze 10 Year/

150,000 Mile Formula) 5.7 Gallons

21.4 Liters

FLUIDS AND LUBRICANTS — GAS ENGINE

Engine

Component Fluid, Lubricant, or Genuine Part

Engine Coolant We recommend you use Mopar Antifreeze/Coolant 10–Year/

150,000 Mile Formula OAT (Organic Additive Technology).

Engine Oil – 6.4L Engine For best performance and maximum protection under all types of oper-

ating conditions, the manufacturer only recommends full synthetic en-

gine oils that meet the American Petroleum Institute (API) categories of

SN. The manufacturer recommends the use of Pennzoil Ultra 0W-40 or

equivalent Mopar engine oil meeting the requirements of FCA Material

Standard MS-12633 for use in all operating temperatures.

Engine Oil Filter – 6.4L Engine We recommend you use Mopar Engine Oil Filters.

Spark Plugs – 6.4L Engine We recommend you use Mopar Spark Plugs.

Fuel Selection – 6.4L Engine 89 Octane Recommended - 87 Octane Acceptable, 0-15% Ethanol.

TECHNICAL SPECIFICATIONS

214

Page 291 of 298

Accessories..................219

Mopar ...................219

Adding Fuel ..............138, 139

Additives, Fuel ................139

Adjustable Pedals ...............29

Air Bag Air Bag Operation .............90

Air Bag Warning Light ..........87

Enhanced Accident Response . .94, 171

Event Data Recorder (EDR) ......171

If A Deployment Occurs .........94

Knee Impact Bolsters ..........90

Maintaining Your Air Bag System . . .95

Transporting Pets ............115

Air Bag Light ............61, 87, 116

Air Bag Maintenance .............95

Air Cleaner, Engine (Engine Air Cleaner Filter) .......186

Air Conditioning Filter ............44

Air Conditioning, Operating Tips ......44

Air Conditioning System ...........43

Air Filter ...................186

Air Pressure, Tires ..............200

Alarm, Panic ..................15

Alarm (Security Alarm) .........17, 63 Alarm System (Security Alarm)

.......17

Antifreeze (Engine Coolant) Capacities ................213

Anti-Lock Warning Light ...........66

Audio Jack ..................257

Automatic Headlights ............33

Automatic High Beams ...........32

Automatic Temperature Control (ATC) . . .43

Automatic Transmission Fluid Type ............216, 218

Shifting .................129

Axle Fluid ...............216, 218

Back-Up ...................136

Back-Up Camera ..............136

Battery .....................62

Charging System Light .........62

Belts, Seat ..................116

Body Builders Guide ..............2

B-Pillar Location ..............196

Brake Fluid ................. .216

Brake

System

Warning Light ...............61

Brake/Transmission Interlock .......129

Bulb Replacement .............154 Bulbs, Light

..............118, 154

Camera ....................136

Camera, Rear ................136

Capacities, Antifreeze (Engine Coolant) .............213

Capacities, Fluid ..............213

Caps, Filler Oil (Engine) ...............184

Carbon Monoxide Warning .........115

Cargo Light ...................34

Changing A Flat Tire ............160

Chart, Tire Sizing ..............192

Checking Your Vehicle For Safety . . . .115

Checks, Safety ................115

Child Restraint ................96

Child Restraints Booster Seats ...............99

Child Restraints ..............96

Child Seat Installation .....107, 109

How To Stow An Unused

ALR Seat Belt ..............106

Infants And Child Restraints ......97

Locating The LATCH Anchorages . .104

INDEX

289