technical specifications Ram 4500 Chassis Cab 2018 User Guide

[x] Cancel search | Manufacturer: RAM, Model Year: 2018, Model line: 4500 Chassis Cab, Model: Ram 4500 Chassis Cab 2018Pages: 298, PDF Size: 5.88 MB

Page 4 of 298

HOW TO USE THIS MANUAL

Essential Information

Each time direction instructions (left/right or

forwards/backwards) about the vehicle are

given, these must be intended as regarding

an occupant in the driver's seat. Special

cases not complying with this rule will be

properly specified in the text.

The figures in this User Guide are provided by

way of example only: this might imply that

some details of the image do not correspond

to the actual arrangement of your vehicle.

In addition, the User Guide has been con-

ceived considering vehicles with steering

wheel on the left side; it is therefore possible

that on vehicles with steering wheel on the

right side, the position or construction of

some controls is not exactly mirror-like with

respect to the figure.

To identify the chapter with the information

needed you can consult the index at the end

of this User Guide.Chapters can be rapidly identified with dedi-

cated graphic tabs, at the side of each odd

page. A few pages further there is a key for

getting to know the chapter order and the

relevant symbols in the tabs. There is anyway

a textual indication of the current chapter at

the side of each even page.

Symbols

Some vehicle components have colored la-

bels whose symbols indicate precautions to

be observed when using this component.

WARNINGS AND CAUTIONS

While reading this User Guide you will find a

series of WARNINGS to be followed to pre-

vent incorrect use of components which

could cause accidents or injuries.

There are also CAUTIONS that must be fol-

lowed to prevent against procedures that

could result in damage to your vehicle.

VAN CONVERSIONS/CAMPERS

The New Vehicle Limited Warranty does not

apply to body modifications or special equip- ment installed by van conversion/camper

manufacturers/body builders. U.S. residents

refer to the Warranty Information book, Sec-

tion 2.1.C. Canadian residents refer to the

“What Is Not Covered” section of the War-

ranty Information book. Such equipment in-

cludes video monitors, VCRs, heaters, stoves,

refrigerators, etc. For warranty coverage and

service on these items, contact the appli-

cable manufacturer.

Operating instructions for the special equip-

ment installed by the conversion/camper

manufacturer should also be supplied with

your vehicle. If these instructions are miss-

ing, please contact your authorized dealer for

assistance in obtaining replacement docu-

ments from the applicable manufacturer.

For information on the Body Builder’s Guide

refer to www.rambodybuilder.com. This web-

site contains dimensional and technical

specifications for your vehicle. It is intended

for Second Stage Manufacturer's technical

support. For service issues, contact your au-

thorized dealer.

INTRODUCTION

2

Page 5 of 298

GRAPHICAL TABLE OF CONTENTS

GETTING TO KNOW YOUR VEHICLE

GETTING TO KNOW YOUR INSTRUMENT PANEL SAFETY

STARTING AND OPERATING IN CASE OF EMERGENCY

SERVICING AND MAINTENANCE TECHNICAL SPECIFICATIONS MULTIMEDIA

CUSTOMER ASSISTANCE INDEX

Page 129 of 298

Driving ConditionLoadTurbocharger Temperature Idle Time (min.)

Before Engine Shutdown

Stop and Go EmptyCoolLess than One

Stop and Go Medium -One

Highway Speeds MediumWarmTwo

City Traffic Maximum GCWR -Three

Highway Speeds Maximum GCWR -Four

Uphill Grade Maximum GCWR HotFive

ENGINE BREAK-IN

RECOMMENDATIONS — GASOLINE

ENGINE

A long break-in period is not required for the

engine and drivetrain (transmission and axle)

in your vehicle.

Drive moderately during the first 300 miles

(500 km). After the initial 60 miles

(100 km), speeds up to 50 or 55 mph (80 or

90 km/h) are desirable.

While cruising, brief full-throttle acceleration

within the limits of local traffic laws contrib-

utes to a good break-in. Wide-open throttle

acceleration in low gear can be detrimental

and should be avoided. The engine oil installed in the engine at the

factory is a high-quality energy conserving

type lubricant. Oil changes should be consis-

tent with anticipated climate conditions un-

der which vehicle operations will occur. For

the recommended viscosity and quality

grades, refer to “Fluids And Lubricants” in

“Technical Specifications”.

CAUTION!

Never use Non-Detergent Oil or Straight

Mineral Oil in the engine or damage may

result.

NOTE:

A new engine may consume some oil during

its first few thousand miles (kilometers) of

operation. This should be considered a nor-

mal part of the break-in and not interpreted

as a problem. Please check your oil level with

the engine oil indicator often during the

break in period. Add oil as required.

ENGINE BREAK-IN

RECOMMENDATIONS — 6.7L DIESEL

The Cummins turbocharged diesel engine

does not require a break-in period due to its

construction. Normal operation is allowed,

providing the following recommendations are

followed:

127

Page 165 of 298

4. By rotating the lug wrench clockwise,raise the vehicle until the wheel just

clears the surface.

WARNING!

Raising the vehicle higher than necessary

can make the vehicle less stable. It could

slip off the jack and hurt someone near it.

Raise the vehicle only enough to remove

the tire.

5. Remove the lug nuts and pull the wheel off. Install the spare wheel and lug nuts

with the cone shaped end of the nuts

toward the wheel on single rear wheel

(SRW) models. On dual rear wheel models

(DRW) the lug nuts are a two-piece assem-

bly with a flat face. Lightly tighten the

nuts. To avoid risk of forcing the vehicle

off the jack, do not fully tighten the nuts

until the vehicle has been lowered.

6. Using the lug wrench, finish tightening the nuts using a crisscross pattern. For

the proper lug nut torque specifications

refer to “Wheel And Tire Torque Specifi-

cations” in “Technical Specifications.” If

in doubt about the correct tightness, have them checked with a torque wrench by an

authorized dealer or at a service station.

WARNING!

A loose tire or jack thrown forward in a

collision or hard stop, could endanger the

occupants of the vehicle. Always stow the

jack parts and the spare tire in the places

provided.

7. Install wheel center cap (if equipped) and remove wheel blocks. Do not install

chrome or aluminum wheel center caps

on the spare wheel. This may result in cap

damage.

8. Lower the jack to its fully closed position. If the jack will not lower by turning the

dial (thumbwheel) by hand, it may be

necessary to use the jack driver in order to

lower the jack. Stow the replaced tire,

jack, and tools as previously described.

9. Adjust the tire pressure when possible.

To Stow The Flat Or Spare —

If Equipped

Refer to Upfitters Body Builders Guide for

information on stowing your spare tire (if

equipped).

Hub Caps/Wheel Covers —

If Equipped

The hub caps must be removed before raising

the vehicle off the ground.

CAUTION!

Use extreme caution when removing the

front and rear center caps. Damage can

occur to the center cap and/or the wheel if

screwdriver type tools are used. A pulling

motion, not a pry off motion, is recom-

mended to remove the caps.

For single rear wheel (SRW) models, use the

flat blade on the end of the lug wrench to pull

the hub cap off. Insert the blade end into the

pull off notch and carefully pull the hub cap

off with a back and forth motion.

163

Page 211 of 298

TECHNICAL SPECIFICATIONS

WHEEL AND TIRE TORQUE

SPECIFICATIONS..............210

Torque Specifications ...........210

Dual Rear Wheels ..............211

FLUID CAPACITIES — GAS ENGINE . . .213 FLUID CAPACITIES — 6.7L CUMMINS

DIESEL ENGINE

...............213

FLUIDS AND LUBRICANTS —

GAS ENGINE ................ .214Engine.....................214

Chassis ....................216

FLUIDS AND LUBRICANTS —

6.7L DIESEL ENGINES ...........216

Engine.....................216

Chassis ....................218

MOPAR ACCESSORIES ...........219

Authentic Accessories By Mopar .....219

TECHNICAL SPECIFICATIONS

209

Page 212 of 298

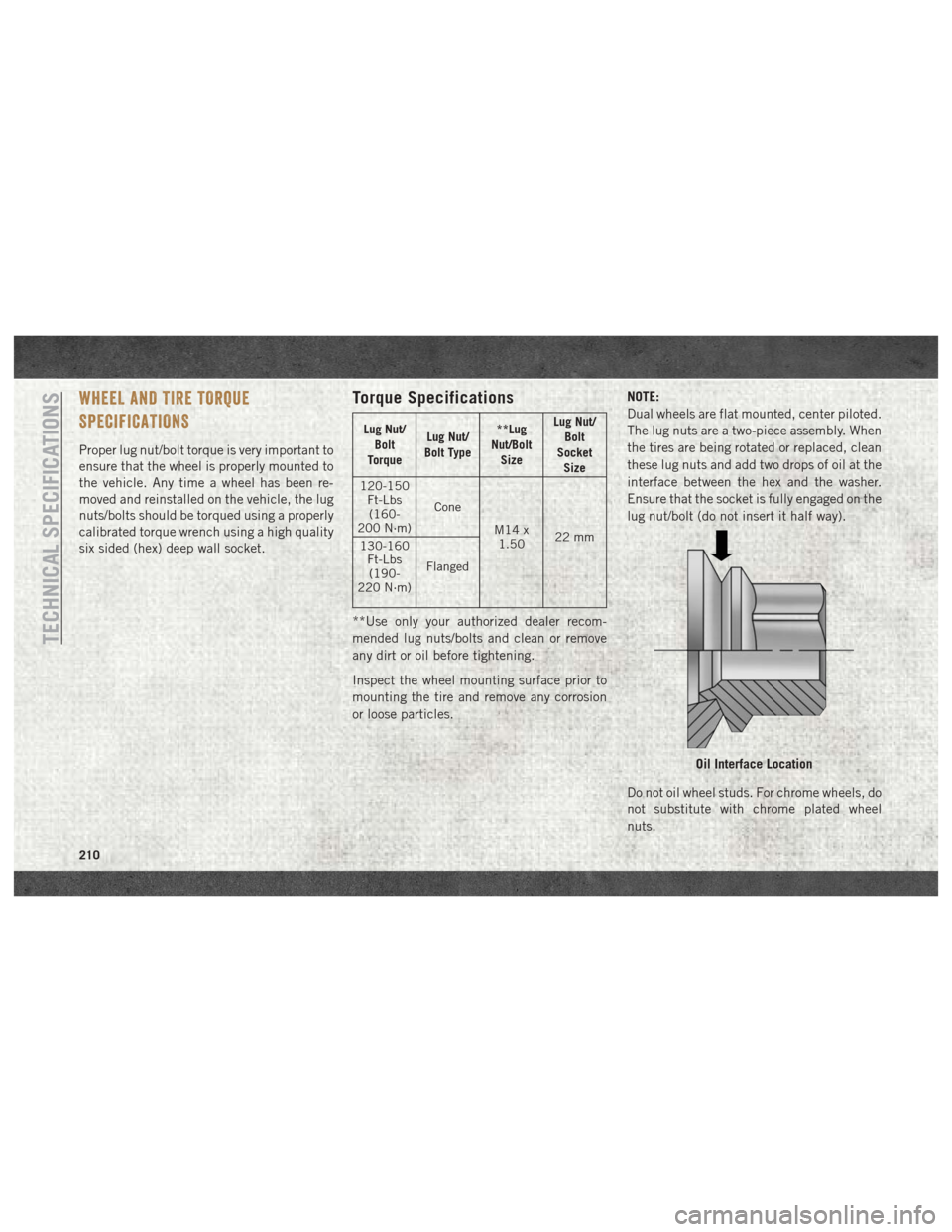

WHEEL AND TIRE TORQUE

SPECIFICATIONS

Proper lug nut/bolt torque is very important to

ensure that the wheel is properly mounted to

the vehicle. Any time a wheel has been re-

moved and reinstalled on the vehicle, the lug

nuts/bolts should be torqued using a properly

calibrated torque wrench using a high quality

six sided (hex) deep wall socket.

Torque Specifications

Lug Nut/Bolt

Torque Lug Nut/

Bolt Type **Lug

Nut/Bolt Size Lug Nut/

Bolt

Socket Size

120-150 Ft-Lbs(160-

200 N·m) Cone

M14 x1.50 22 mm

130-160

Ft-Lbs(190-

220 N·m) Flanged

**Use only your authorized dealer recom-

mended lug nuts/bolts and clean or remove

any dirt or oil before tightening.

Inspect the wheel mounting surface prior to

mounting the tire and remove any corrosion

or loose particles. NOTE:

Dual wheels are flat mounted, center piloted.

The lug nuts are a two-piece assembly. When

the tires are being rotated or replaced, clean

these lug nuts and add two drops of oil at the

interface between the hex and the washer.

Ensure that the socket is fully engaged on the

lug nut/bolt (do not insert it half way).

Do not oil wheel studs. For chrome wheels, do

not substitute with chrome plated wheel

nuts.

Oil Interface Location

TECHNICAL SPECIFICATIONS

210

Page 214 of 298

NOTE:

When installing a spare tire (if equipped) as

part of a dual rear wheel end combination,

the tire diameter of the two individual tires

must be compared. If there is a significant

difference, the larger tire should be installed

in a front location. The correct direction of

rotation for dual tire installations must also

be observed.

These dual rear wheels should be tightened as

follows:It is recommended that wheel stud nuts be

kept torqued to specifications at all times.

Torque wheel stud nuts to specifications at

each lubrication interval.

Wheel Nuts Numbered Sequence (8)

Wheel Nuts Numbered Sequence (10)TECHNICAL SPECIFICATIONS

212

Page 216 of 298

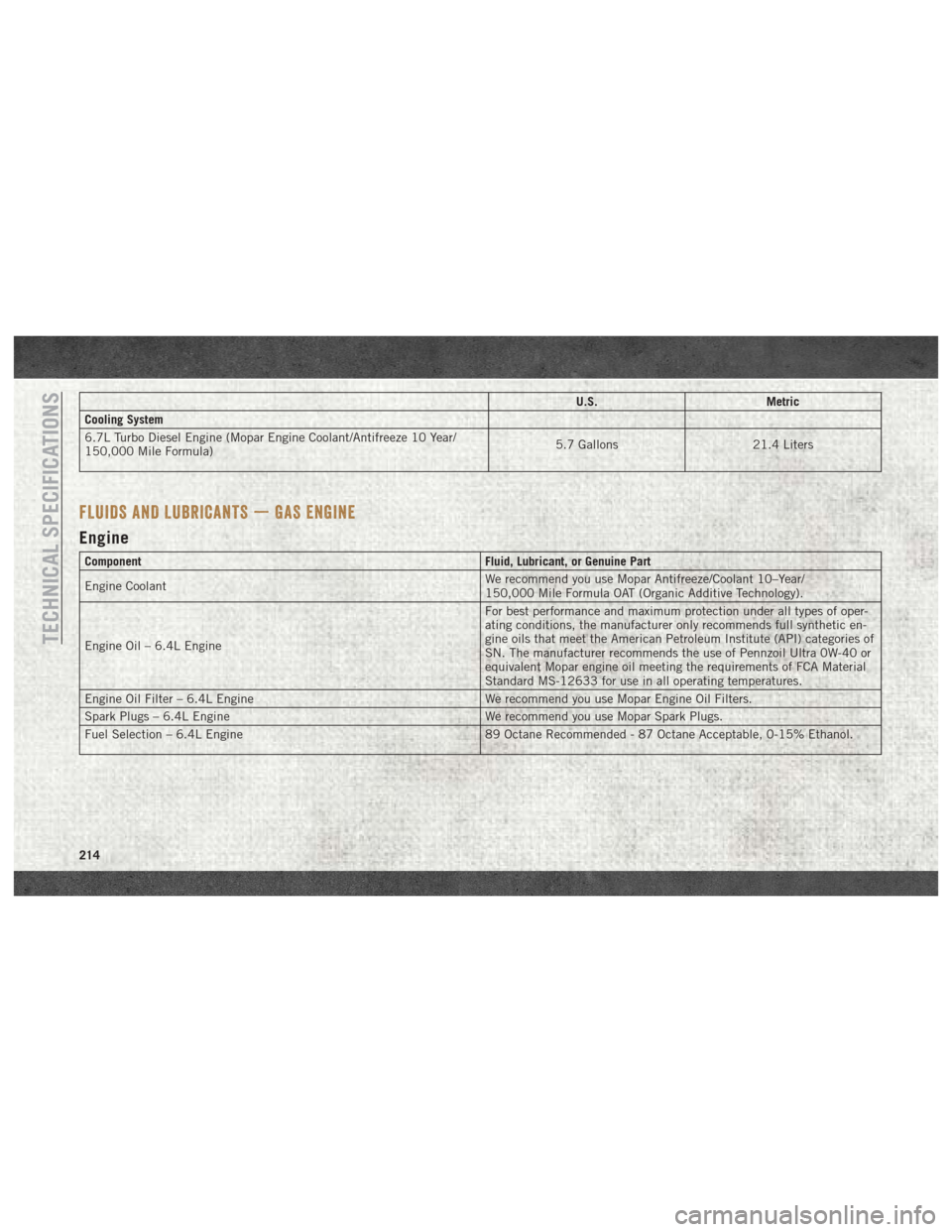

U.S.Metric

Cooling System

6.7L Turbo Diesel Engine (Mopar Engine Coolant/Antifreeze 10 Year/

150,000 Mile Formula) 5.7 Gallons

21.4 Liters

FLUIDS AND LUBRICANTS — GAS ENGINE

Engine

Component Fluid, Lubricant, or Genuine Part

Engine Coolant We recommend you use Mopar Antifreeze/Coolant 10–Year/

150,000 Mile Formula OAT (Organic Additive Technology).

Engine Oil – 6.4L Engine For best performance and maximum protection under all types of oper-

ating conditions, the manufacturer only recommends full synthetic en-

gine oils that meet the American Petroleum Institute (API) categories of

SN. The manufacturer recommends the use of Pennzoil Ultra 0W-40 or

equivalent Mopar engine oil meeting the requirements of FCA Material

Standard MS-12633 for use in all operating temperatures.

Engine Oil Filter – 6.4L Engine We recommend you use Mopar Engine Oil Filters.

Spark Plugs – 6.4L Engine We recommend you use Mopar Spark Plugs.

Fuel Selection – 6.4L Engine 89 Octane Recommended - 87 Octane Acceptable, 0-15% Ethanol.

TECHNICAL SPECIFICATIONS

214

Page 218 of 298

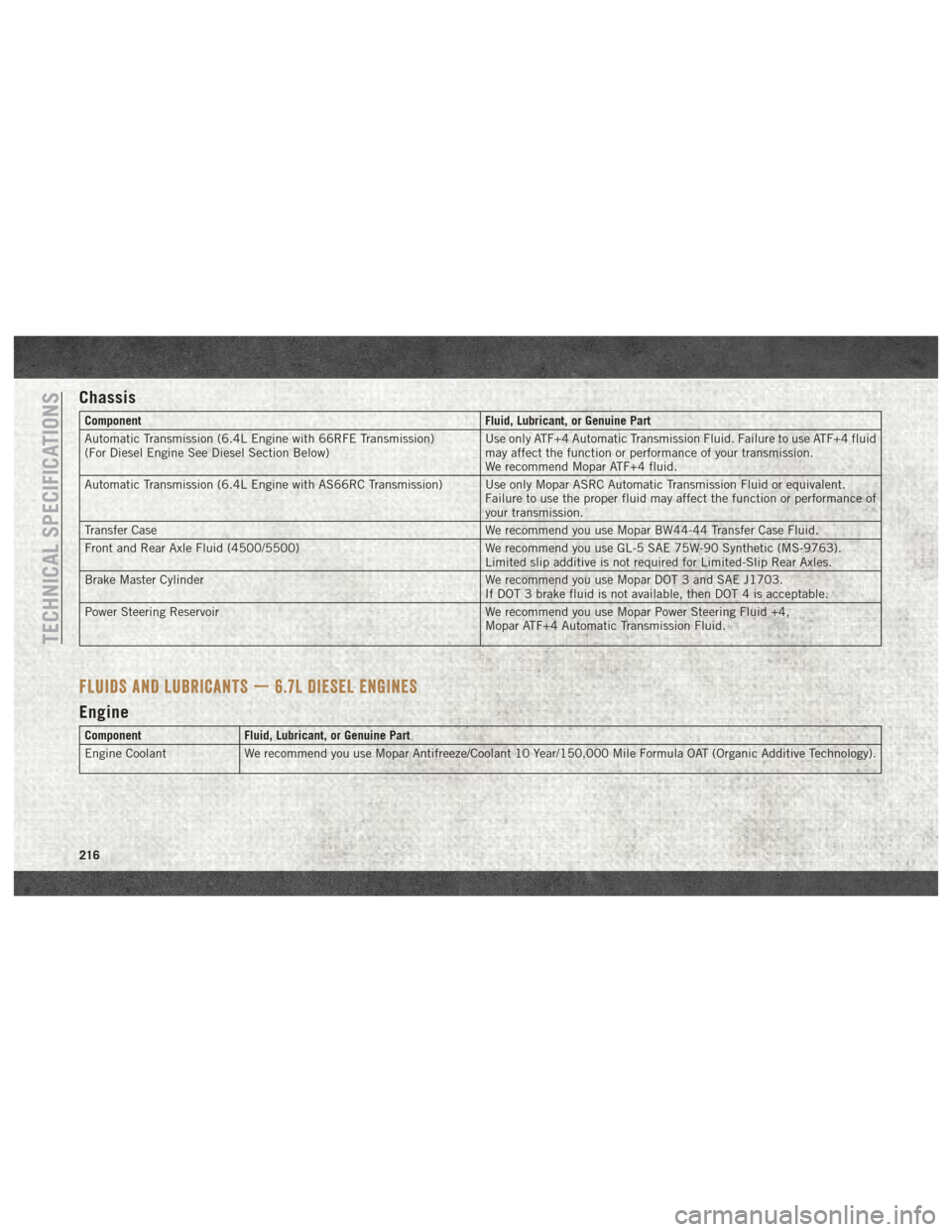

Chassis

ComponentFluid, Lubricant, or Genuine Part

Automatic Transmission (6.4L Engine with 66RFE Transmission)

(For Diesel Engine See Diesel Section Below) Use only ATF+4 Automatic Transmission Fluid. Failure to use ATF+4 fluid

may affect the function or performance of your transmission.

We recommend Mopar ATF+4 fluid.

Automatic Transmission (6.4L Engine with AS66RC Transmission) Use only Mopar ASRC Automatic Transmission Fluid or equivalent. Failure to use the proper fluid may affect the function or performance of

your transmission.

Transfer Case We recommend you use Mopar BW44-44 Transfer Case Fluid.

Front and Rear Axle Fluid (4500/5500) We recommend you use GL-5 SAE 75W-90 Synthetic (MS-9763).

Limited slip additive is not required for Limited-Slip Rear Axles.

Brake Master Cylinder We recommend you use Mopar DOT 3 and SAE J1703.

If DOT 3 brake fluid is not available, then DOT 4 is acceptable.

Power Steering Reservoir We recommend you use Mopar Power Steering Fluid +4,

Mopar ATF+4 Automatic Transmission Fluid.

FLUIDS AND LUBRICANTS — 6.7L DIESEL ENGINES

Engine

Component Fluid, Lubricant, or Genuine Part

Engine Coolant We recommend you use Mopar Antifreeze/Coolant 10 Year/150,000 Mile Formula OAT (Organic Additive Technology).

TECHNICAL SPECIFICATIONS

216

Page 220 of 298

Chassis

ComponentFluid, Lubricant, or Genuine Part

Automatic Transmission – If Equipped 6.7L Diesel with (Six-Speed

68RFE) – 2500/3500 Pickup models without PTO Only use ATF+4 Automatic Transmission Fluid. Failure to use ATF+4 fluid

may affect the function or performance of your transmission. We recom-

mend Mopar ATF+4 fluid.

Automatic Transmission – If Equipped 6.7L Diesel with (Six-Speed

AS69RC) – Pickup models with PTO and All Chassis Cab models Only use Mopar ASRC Automatic Transmission Fluid or equivalent. Failure

to use the proper fluid may affect the function or performance of your

transmission.

Transfer Case We recommend you use Mopar BW44–44 Transfer Case Fluid.

Front and Rear Axle Fluid (2500/3500) We recommend you use SAE 75W-85 HD Ram GL-5 Synthetic Axle

Lubricant. Limited slip additive is not required for Limited-Slip Rear

Axles.

Front and Rear Axle Fluid (4500/5500) We recommend you use GL-5 SAE 75W-90 Synthetic (MS-9763). Limited

slip additive is not required for Limited-Slip Rear Axles.

Clutch Linkage We recommend you use Mopar Multi-Purpose Grease, NLGI Grade 2 E.P.

or equivalent.

Manual Transmission (G-56) – If Equipped We recommend you use Mopar ATF+4 Automatic Transmission Fluid or

equivalent licensed ATF+4 product.

TECHNICAL SPECIFICATIONS

218