light RAM CHASSIS CAB 2007 Owners Manual

[x] Cancel search | Manufacturer: RAM, Model Year: 2007, Model line: CHASSIS CAB, Model: RAM CHASSIS CAB 2007Pages: 532, PDF Size: 2.69 MB

Page 346 of 532

Weight Ratings)” for the website address that contains

the necessary information for your specific drivetrain.

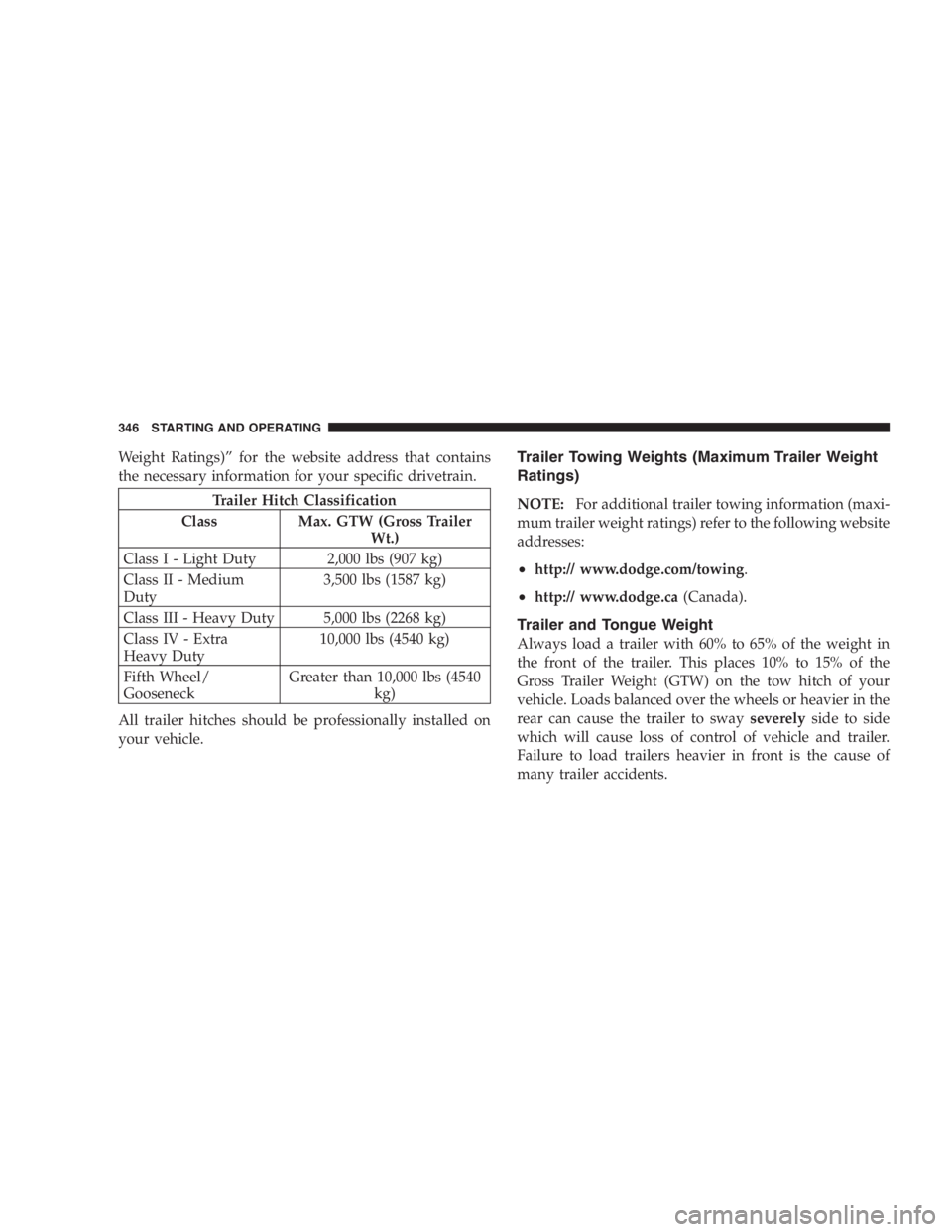

Trailer Hitch Classification

Class Max. GTW (Gross Trailer

Wt.)

ClassI-Light Duty 2,000 lbs (907 kg)

Class II - Medium

Duty 3,500 lbs (1587 kg)

Class III - Heavy Duty 5,000 lbs (2268 kg)

Class IV - Extra

Heavy Duty 10,000 lbs (4540 kg)

Fifth Wheel/

Gooseneck Greater than 10,000 lbs (4540

kg)

All trailer hitches should be professionally installed on

your vehicle. Trailer Towing Weights (Maximum Trailer Weight

Ratings)

NOTE: For additional trailer towing information (maxi-

mum trailer weight ratings) refer to the following website

addresses:

• http:// www.dodge.com/towing .

• http:// www.dodge.ca (Canada).

Trailer and Tongue Weight

Always load a trailer with 60% to 65% of the weight in

the front of the trailer. This places 10% to 15% of the

Gross Trailer Weight (GTW) on the tow hitch of your

vehicle. Loads balanced over the wheels or heavier in the

rear can cause the trailer to sway severely side to side

which will cause loss of control of vehicle and trailer.

Failure to load trailers heavier in front is the cause of

many trailer accidents.346 STARTING AND OPERATING

Page 351 of 532

WARNING!Do not connect trailer brakes to your vehicle’s hy-

draulic brake lines. It can overload your brake sys-

tem and cause it to fail. You might not have brakes

when you need them and could have an accident.

Towing any trailer will increase your stopping dis-

tance. When towing you should allow for additional

space between your vehicle and the vehicle in front

of you. Failure to do so could result in an accident. Towing Requirements — Trailer Lights & Wiring

Whenever you pull a trailer, regardless of the trailer size,

stop lights and turn signals on the trailer are required for

motoring safety.

The Trailer Tow Package may includ ea4and7pin

wiring harness. Use a factory approved trailer harness

and connector.

NOTE: Do not cut or splice wiring into the vehicles

wiring harness. STARTING AND OPERATING 351

5

Page 353 of 532

If using a manual transmission vehicle for trailer towing,

all starts must be in FIRST gear to avoid excessive clutch

slippage.

Towing Tips — Automatic Transmission

The “D” range can be selected when towing. However, if

frequent shifting occurs while in this range, the “TOW

HAUL” or “OD/OFF” range should be selected.

NOTE: Using the “TOW HAUL” or “OD/OFF” range

while operating the vehicle under heavy operating con-

ditions will improve performance and extend transmis-

sion life by reducing excessive shifting and heat build up.

This action will also provide better engine braking.

The automatic transmission fluid and filter should be

changed if you REGULARLY tow a trailer for more than

45 minutes of continuous operation. See Schedule “B” in

section 8 of this manual for transmission fluid change

intervals. NOTE: Check the automatic transmission fluid level

before towing.

Towing Tips — Tow/Haul (If Equipped)

To reduce potential for automatic transmission overheat-

ing, turn the “TOW HAUL OD/OFF” feature ON when

driving in hilly areas or shift the transmission to Drive

position 2 on more severe grades.

Towing Tips — Electronic Speed Control (If

Equipped)

� Don’t use in hilly terrain or with heavy loads.

� When using the speed control, if you experience speed

drops greater than 10 mph (16 km/h), disengage until

you can get back to cruising speed.

� Use speed control in flat terrain and with light loads to

maximize fuel efficiency. STARTING AND OPERATING 353

5

Page 356 of 532

NOTE: Before installation of a snowplow it is highly

recommended that the owner / installer obtain and

follow the recommendations contained within the cur-

rent Dodge BODY BUILDER’S GUIDE. See your dealer,

installer or snowplow manufacture for this information.

There are unique electrical systems that must be con-

nected to properly assure operator safety and prevent

overloading vehicle systems.

WARNING!Attaching a snowplow to this vehicle could ad-

versely affect performance of the airbag system in an

accident. Do not expect that the airbag will perform

as described earlier in this manual CAUTION!The “Lamp Out” indicator could illuminate if exte-

rior lamps are not properly installed.

Before plowing

• Check the hydraulic system for leaks and proper fluid

level.

• Check the mounting bolts and nuts for proper tight-

ness.

• Check the runners and cutting edge for excessive wear.

The cutting edge should be 1/4 to 1/2 inch above

ground in snow plowing position.

• Check that snowplow lighting is connected and func-

tioning properly.356 STARTING AND OPERATING

Page 364 of 532

6. Using the point of a ballpoint pen or similar object,

depress the recessed transfer case Neutral (N) button for

4 seconds.

7. After shift is completed and the Neutral (N) light

comes on release Neutral (N) button.

8. Start engine.

9. Shift automatic transmission into Reverse (R).

10. Release brake pedal for five seconds and ensure that

there is no vehicle movement.

11. Repeat steps 9 and 10 with the transmission in Drive

(D).

12. Shut engine OFF and place ignition key to the

unlocked OFF position.

13. Shift automatic transmission into Park (P).

14. Apply parking brake. 15. Attach vehicle to tow vehicle with tow bar.

16. Release parking brake.

NOTE: Items 1 through 5 are requirements that must be

met prior to depressing the Neutral (N) selection button,

and must continue to be met until the 4 seconds elapses

and the shift has been completed. If any of these require-

ments (with the exception of 3 - Key ON) are not met

prior to depressing the Neutral (N) button or are no

longer met during the 4 second timer, then the Neutral

(N) indicator light will flash continuously until all re-

quirements are met or until the Neutral (N) button is

released.

NOTE: The ignition key must be ON for a shift to take

place and for the position indicator lights to be operable.

If the key in not ON, the shift will not take place and no

position indicator lights will be on or flashing.364 STARTING AND OPERATING

Page 365 of 532

NOTE: Flashing neutral (N) position indicator light

indicates that shift requirements have not been met.

CAUTION!Damage to the transmission may occur if the trans-

mission is shifted into Park (P) with the transfer case

in Neutral (N) and the engine RUNNING. With the

transfer case in Neutral (N) ensure that the engine is

OFF prior to shifting the transmission into Park (P).

Returning to Normal Operation — Electronic Shift

Transfer Case

Use the following procedure to prepare your vehicle for

normal usage.

1. Bring vehicle to a complete stop.

2. Shut OFF the engine. 3. Turn the ignition key to the ON position, but do not

start the engine.

4. Depress the brake pedal.

5. Shift automatic transmission to Neutral (N) or depress

clutch on manual transmission.

6. Using the point of a ballpoint pen or similar object,

depress the recessed transfer case Neutral (N) button for

1 second.

7. After the Neutral (N) indicator light turns off release

the Neutral (N) button.

8. After the Neutral (N) button has been released the

transfer case will shift to the position identified by the

selector switch.

9. Shift automatic transmission into P (Park).

NOTE: The transfer case can not be shifted into Neutral

(N) from the 4Auto (if equipped) position. STARTING AND OPERATING 365

5

Page 366 of 532

NOTE: Items 1 through 5 are requirements that must be

met prior to depressing the Neutral (N) selection button,

and must continue to be met until 1 second elapses and

the shift has been completed. If any of these requirements

(with the exception of 3 - key ON) are not met prior to

depressing the Neutral (N) button or are no longer met

during the 1 second time, then all of the mode position

indicator lights will flash continuously until all require-

ments are met or until the Neutral (N) button is released.

NOTE: The ignition key must be ON for a shift to take

place and for the position indicator lights to be operable.

If the key is not ON, the shift will not take place and no

position indicator lights will be on or flashing.

NOTE: Flashing neutral (N) position indicator light

indicates that shift requirements have not been met. WARNING!You or others could be injured if you leave the

vehicle unattended with the transfer case in the

Neutral (N) position without first fully engaging the

parking brake. The transfer case Neutral (N) position

disengages both the front and rear driveshafts from

the powertrain and will allow the vehicle to move

despite the transmission position. The parking

brake should always be applied when the driver is

not in the vehicle.366 STARTING AND OPERATING

Page 370 of 532

HAZARD WARNING FLASHER

The Hazard Warning switch is mounted on the top of the

steering column as shown in the illustration.

To engage the Hazard Warning lights, depress the button

on the top of the steering column. When the Hazard

Warning switch is activated, all directional turn signals will flash off and on to warn oncoming traffic of an

emergency. Push the button a second time to turn off the

flashers.

This is an emergency warning system and should not be

used when the vehicle is in motion. Use it when your

vehicle is disabled and is creating a safety hazard for

other motorists.

When you must leave the vehicle to seek assistance, the

Hazard Warning lights will continue to operate even

though the ignition switch is OFF.

NOTE: With extended use, the Hazard Warning lights

may discharge your battery.Hazard Light Warning Switch370 WHAT TO DO IN EMERGENCIES

Page 376 of 532

4. By rotating the wheel wrench clockwise, raise the

vehicle until the wheel just clears the surface.

WARNING!Raising the vehicle higher than necessary can make

the vehicle unstable and cause an accident. It could

slip off the jack and hurt someone near it. Raise the

vehicle only enough to remove the tire.

5. Remove the wheel nuts and pull the wheel off. Install

the spare wheel and wheel nuts with the cone shaped end

of the nuts toward the wheel on single rear wheel (SRW)

models. On dual rear wheel models (DRW) the lug nuts

are a two piece assembly with a flat face. Lightly tighten

the nuts. To avoid risk of forcing the vehicle off the jack,

do not fully tighten the nuts until the vehicle has been

lowered. 6. Using the wheel wrench, finish tightening the nuts

using a crisscross pattern. Correct nut tightness is 135 ft.

lbs. (183 N·m) torque for single rear wheel (SRW) models

and 145 ft. lbs. (197 N·m) for dual rear wheel models. If in

doubt about the correct tightness, have them checked

with a torque wrench by your dealer or at a service

station.

WARNING!A loose tire or jack thrown forward in a collision or

hard stop could injure someone in the vehicle.

Always stow the jack parts and the extra tire and

wheel in the places provided.376 WHAT TO DO IN EMERGENCIES

Page 382 of 532

JUMP-STARTING

WARNING!To prevent personal injury or damage to clothing, do

not allow battery fluid to contact eyes, skin or

fabrics. Do not lean over a battery when connecting

jumper cables or allow cable clamps to touch each

other. Keep open flames or sparks away from battery

vent holes. Always wear eye protection when work-

ing with batteries.

Do not use a booster battery or any other booster

source that has a greater than 12 volt system, i.e. do

not use a 24 volt power source. NOTE: Replacement batteries should both be of equal

size to prevent damage to the vehicles charging system.

Your vehicle is equipped with two 12–volt batteries. If it

becomes necessary to use a booster battery, with jumper

cables, to start a vehicle’s engine because its batteries are

discharged, the following procedure should be followed:

Set the parking brake and place an automatic transmis-

sion in PARK (or NEUTRAL for a manual transmission).

Turn off lights, heater and other electrical loads. Observe

charge indicator (if equipped) in both batteries. If indica-

tor (if equipped) is light or yellow on either battery,

replace that battery.382 WHAT TO DO IN EMERGENCIES