ABS RAM CHASSIS CAB 2021 User Guide

[x] Cancel search | Manufacturer: RAM, Model Year: 2021, Model line: CHASSIS CAB, Model: RAM CHASSIS CAB 2021Pages: 463, PDF Size: 21.5 MB

Page 276 of 463

274SAFETY

Anti-Lock Brake System (ABS) Warning

Light

The yellow ABS Warning Light will turn on when

the ignition is placed in the ON/RUN mode and

may stay on for as long as four seconds.

If the ABS Warning Light remains on or comes

on while driving, it indicates that the anti-lock

portion of the brake system is not functioning

and that service is required. However, the

conventional brake system will continue to

operate normally if the ABS Warning Light is on.

If the ABS Warning Light is on, the brake system

should be serviced as soon as possible to

restore the benefits of Anti-Lock brakes. If the

ABS Warning Light does not come on when the

ignition is placed in the ON/RUN mode, have

the light repaired as soon as possible.

ELECTRONIC BRAKE CONTROL (EBC)

S

YSTEM

Your vehicle is equipped with an advanced

Electronic Brake Control (EBC) system. This

system includes Anti-Lock Brake System (ABS),

Brake Assist System (BAS), Electronic Brake

Force Distribution (EBD), Hill Start Assist (HSA), Electronic Roll Mitigation (ERM), Electronic

Stability Control (ESC), and Traction Control

System (TCS). These systems work together to

enhance both vehicle stability and control in

various driving conditions.

Your vehicle may also be equipped with Trailer

Sway Control (TSC) and Hill Descent Control

(HDC).

Brake Assist System (BAS)

The BAS is designed to optimize the vehicle’s

braking capability during emergency braking

maneuvers. The system detects an emergency

braking situation by sensing the rate and amount

of brake application and then applies optimum

pressure to the brakes. This can help reduce

braking distances. The BAS complements the

Anti-Lock Brake System (ABS). Applying the

brakes very quickly results in the best BAS

assistance. To receive the benefit of the system,

you must apply continuous braking pressure

during the stopping sequence (do not “pump” the

brakes). Do not reduce brake pedal pressure

unless braking is no longer desired. Once the

brake pedal is released, the BAS is deactivated.

Brake System Warning Light

The red Brake System Warning Light will turn on

when the ignition is placed in the ON/RUN mode

and may stay on for as long as four seconds.

If the Brake System Warning Light remains on or

comes on while driving, it indicates that the

brake system is not functioning properly and

that immediate service is required. If the Brake

System Warning Light does not come on when

the ignition is placed in the ON/RUN mode,

have the light repaired as soon as possible.

WARNING!

The Brake Assist System (BAS) cannot prevent

the natural laws of physics from acting on

the vehicle, nor can it increase the traction

afforded by prevailing road conditions.

BAS cannot prevent collisions, including those

resulting from excessive speed in turns, driving

on very slippery surfaces, or hydroplaning.

The capabilities of a BAS-equipped vehicle

must never be exploited in a reckless or

dangerous manner, which could jeopardize

the user's safety or the safety of others.

21_DPF_OM_EN_USC_t.book Page 274

Page 277 of 463

SAFETY275

Electronic Brake Force Distribution (EBD)

EBD manages the distribution of the braking

torque between the front and rear axles by

limiting braking pressure to the rear axle. This is

done to prevent overslip of the rear wheels to

avoid vehicle instability, and to prevent the rear

axle from entering ABS before the front axle.

Electronic Roll Mitigation (ERM)

ERM anticipates the potential for wheel lift by

monitoring the driver’s steering wheel input and

the speed of the vehicle. When ERM determines

that the rate of change of the steering wheel

angle and vehicle’s speed are sufficient to

potentially cause wheel lift, it then applies the

appropriate brake and may also reduce engine

power to lessen the chance that wheel lift will

occur. ERM can only reduce the chance of

wheel lift occurring during severe or evasive

driving maneuvers; it cannot prevent wheel lift

due to other factors, such as road conditions,

leaving the roadway, or striking objects or other

vehicles.

NOTE:

ERM is disabled any time the ESC is in “Full Off”

mode (if equipped). For a complete explanation

of the available ESC modes, see Ú page 275.

Electronic Stability Control (ESC)

ESC enhances directional control and stability

of the vehicle under various driving conditions.

ESC corrects for oversteering or understeering

of the vehicle by applying the brake of the

appropriate wheel(s) to counteract the above

conditions. Engine power may also be reduced

to help the vehicle maintain the desired path.

Oversteer — when the vehicle is turning more

than appropriate for the steering wheel position.

Understeer — when the vehicle is turning less

than appropriate for the steering wheel position.

ESC uses sensors in the vehicle to determine

the vehicle path intended by the driver and

compares it to the actual path of the vehicle.

When the actual path does not match the

intended path, ESC applies the brake of the

appropriate wheel to assist in counteracting the

oversteer or understeer condition.

The ESC Activation/Malfunction Indicator Light

located in the instrument cluster will start to flash

as soon as the ESC system becomes active.

The ESC Activation/Malfunction Indicator Light

also flashes when the TCS is active. If the ESC

Activation/Malfunction Indicator Light begins to

flash during acceleration, ease up on the

accelerator and apply as little throttle as possible.

Be sure to adapt your speed and driving to the

prevailing road conditions.

WARNING!

Many factors, such as vehicle loading, road

conditions and driving conditions, influence

the chance that wheel lift or rollover may occur.

ERM cannot prevent all wheel lift or roll overs,

especially those that involve leaving the

roadway or striking objects or other vehicles.

The capabilities of an ERM-equipped vehicle

must never be exploited in a reckless or

dangerous manner which could jeopardize

the user's safety or the safety of others.

6

21_DPF_OM_EN_USC_t.book Page 275

Page 308 of 463

306SAFETY

Supplemental Side Air Bags

Supplemental Seat-Mounted Side Air Bags

(SABs) — If Equipped

Your vehicle may be equipped with

Supplemental Seat-Mounted Side Air Bags

(SABs). If your vehicle is equipped with

Supplemental Seat-Mounted Side Air Bags

(SABs), please refer to the information below.

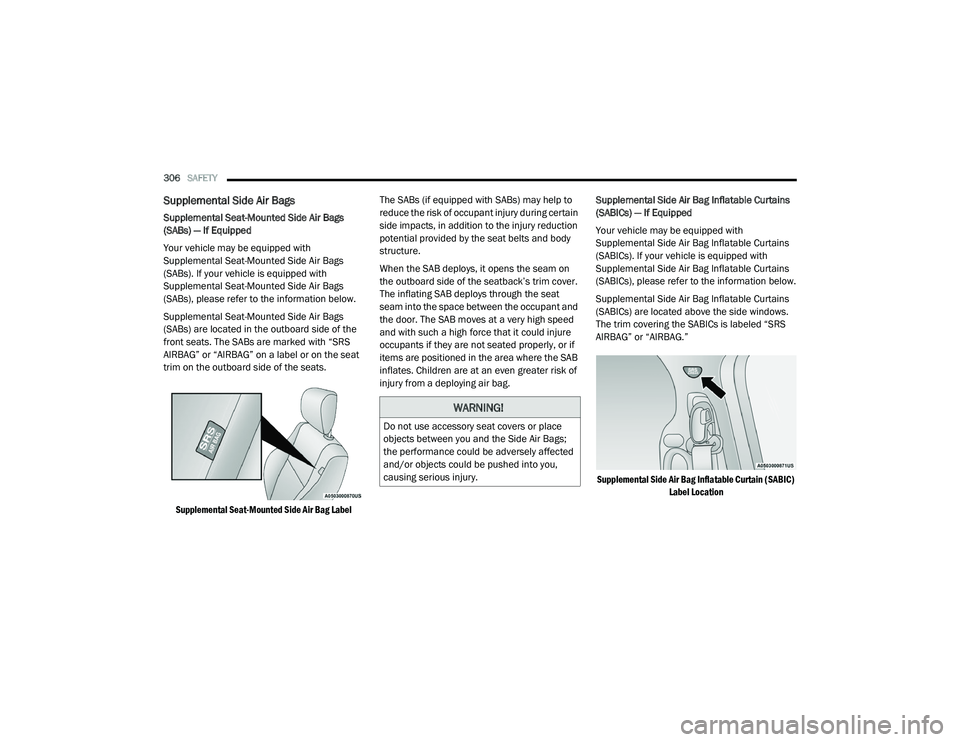

Supplemental Seat-Mounted Side Air Bags

(SABs) are located in the outboard side of the

front seats. The SABs are marked with “SRS

AIRBAG” or “AIRBAG” on a label or on the seat

trim on the outboard side of the seats.

Supplemental Seat-Mounted Side Air Bag Label

The SABs (if equipped with SABs) may help to

reduce the risk of occupant injury during certain

side impacts, in addition to the injury reduction

potential provided by the seat belts and body

structure.

When the SAB deploys, it opens the seam on

the outboard side of the seatback’s trim cover.

The inflating SAB deploys through the seat

seam into the space between the occupant and

the door. The SAB moves at a very high speed

and with such a high force that it could injure

occupants if they are not seated properly, or if

items are positioned in the area where the SAB

inflates. Children are at an even greater risk of

injury from a deploying air bag.

Supplemental Side Air Bag Inflatable Curtains

(SABICs) — If Equipped

Your vehicle may be equipped with

Supplemental Side Air Bag Inflatable Curtains

(SABICs). If your vehicle is equipped with

Supplemental Side Air Bag Inflatable Curtains

(SABICs), please refer to the information below.

Supplemental Side Air Bag Inflatable Curtains

(SABICs) are located above the side windows.

The trim covering the SABICs is labeled “SRS

AIRBAG” or “AIRBAG.”

Supplemental Side Air Bag Inflatable Curtain (SABIC) Label Location

WARNING!

Do not use accessory seat covers or place

objects between you and the Side Air Bags;

the performance could be adversely affected

and/or objects could be pushed into you,

causing serious injury.

21_DPF_OM_EN_USC_t.book Page 306

Page 373 of 463

SERVICING AND MAINTENANCE371

2. Lift the engine air cleaner filter cover to

access the engine air cleaner filter.

3. Remove the engine air cleaner filter from the housing assembly.

Engine Air Cleaner Filter

Engine Air Cleaner Filter Installation

NOTE:

Inspect and clean the housing if dirt or debris is

present before replacing the engine air cleaner

filter.

1. Install the engine air cleaner filter into the

housing assembly with the engine air

cleaner filter inspection surface facing

downward.

2. Install the engine air cleaner filter cover onto the housing assembly locating tabs.

3. Install screws to secure the engine air cleaner filter cover to the housing assembly.

AIR CONDITIONER MAINTENANCE

For best possible performance, your air

conditioner should be checked and serviced by

an authorized dealer at the start of each warm

season. This service should include cleaning of

the condenser fins and a performance test.

Drive belt tension should also be checked at

this time.

1 — Engine Air Cleaner Filter

2 — Engine Air Cleaner Filter Inspection Surface

WARNING!

Use only refrigerants and compressor lubri -

cants approved by the manufacturer for

your air conditioning system. Some unap -

proved refrigerants are flammable and can

explode, injuring you. Other unapproved

refrigerants or lubricants can cause the

system to fail, requiring costly repairs.

Refer to Warranty Information Book, for

further warranty information.

The air conditioning system contains refrig -

erant under high pressure. To avoid risk of

personal injury or damage to the system,

adding refrigerant or any repair requiring

lines to be disconnected should be done by

an experienced technician.

CAUTION!

Do not use chemical flushes in your air

conditioning system as the chemicals can

damage your air conditioning components.

Such damage is not covered by the New

Vehicle Limited Warranty.

8

21_DPF_OM_EN_USC_t.book Page 371

Page 375 of 463

SERVICING AND MAINTENANCE373

3. There are travel stops on both sides of the

glove compartment. Push inward on right

side of the glove compartment travel stop to

disengage the stop. Then pull the right of

the glove compartment outward (away from

the hinge) to disengaging the right side of

the compartment from the hinge. Continue

by removing the left side from the hinge by

slightly lowering the compartment while

pulling outward until it is completely

disengaged from the hinge.

Glove Compartment

4. Remove the filter cover by pushing in on the

finger tabs on each end of the filter cover.

Filter Cover

Filter Cover Removal

5. Remove the cabin air filter by pulling it

straight out of the housing.

Cabin Air Filter

6. Install the cabin air filter with the arrow on the filter pointing toward the floor. When

installing the filter cover, press on each end

until you hear an audible click.

7. Reinstall the glove compartment on the hinges.

1 — Glove Compartment Travel Stop

2 — Glove Compartment Tension Tether

3 — Glove Compartment Door

1 — Finger Tabs

CAUTION!

The cabin air filter is identified with an arrow

to indicate airflow direction through the filter.

Failure to properly install the filter will result

in the need to replace it more often.

8

21_DPF_OM_EN_USC_t.book Page 373

Page 389 of 463

SERVICING AND MAINTENANCE387

(Continued)

BRAKE SYSTEM

In order to ensure brake system performance,

all brake system components should be

inspected periodically Ú page 354.

Fluid Level Check — Brake Master Cylinder

The fluid level of the master cylinder should be

checked when performing under the hood

service or immediately if the brake system

warning lamp indicates system failure.

If necessary, add fluid to bring level within the

designated marks on the side of the reservoir of the

brake master cylinder. Be sure to clean the top of

the master cylinder area before removing cap.

With disc brakes the fluid level can be expected

to fall as the brake linings wear. However, an

unexpected drop in fluid level may be caused by

a leak and a system check should be conducted.

For further information Ú

page 444.

AUTOMATIC TRANSMISSION

Special Additives

The manufacturer strongly recommends against

using any special additives in the transmission.

Automatic Transmission Fluid (ATF) is an

engineered product and its performance may be

impaired by supplemental additives. Therefore,

do not add any fluid additives to the transmission.

The only exception to this policy is the use of special

dyes for diagnosing fluid leaks in six-speed

transmissions. Avoid using transmission sealers as

they may adversely affect seals.

WARNING!

Riding the brakes can lead to brake failure

and possibly a collision. Driving with your foot

resting or riding on the brake pedal can result

in abnormally high brake temperatures,

excessive lining wear, and possible brake

damage. You would not have your full braking

capacity in an emergency.WARNING!

Use only manufacturer's recommended

brake fluid Úpage 444. Using the wrong

type of brake fluid can severely damage

your brake system and/or impair its perfor -

mance. The proper type of brake fluid for

your vehicle is also identified on the original

factory installed hydraulic master cylinder

reservoir.

To avoid contamination from foreign matter

or moisture, use only new brake fluid or fluid

that has been in a tightly closed container.

Keep the master cylinder reservoir cap

secured at all times. Brake fluid in a open

container absorbs moisture from the air

resulting in a lower boiling point. This may

cause it to boil unexpectedly during hard or

prolonged braking, resulting in sudden brake

failure. This could result in a collision.

Overfilling the brake fluid reservoir can

result in spilling brake fluid on hot engine

parts, causing the brake fluid to catch fire.

Brake fluid can also damage painted and

vinyl surfaces, care should be taken to

avoid its contact with these surfaces.

Do not allow petroleum based fluid to

contaminate the brake fluid. Brake seal

components could be damaged, causing

partial or complete brake failure. This could

result in a collision.

WARNING! (Continued)

8

21_DPF_OM_EN_USC_t.book Page 387

Page 397 of 463

SERVICING AND MAINTENANCE395

Power Distribution Center

The Power Distribution Center is located in the

engine compartment near the battery. This

center contains cartridge fuses, micro fuses,

relays, and circuit breakers. A description of

each fuse and component may be stamped on

the inside cover, otherwise the cavity number of

each fuse is stamped on the inside cover that

corresponds to the following chart.

Power Distribution Center Location

Cavity Cartridge FuseMicro Fuse Description

F01– –Spare

F02 60 Amp Yellow –ABS Pump Motor (HD Only)

F03 60 Amp Yellow –Rad Fan – If Equipped

F04 50 Amp Red 400W Inverter – If Equipped

F05 40 Amp Green –Compressor For Air Suspension – If Equipped

F06 40 Amp Green –Steering Torque Overlay Module (STOM)

F07 40 Amp Green –Starter Solenoid

F08 20 Amp Blue –NOX Sensor – If Equipped

F09 40 Amp Green –Diesel / Fuel Heater – If Equipped

F09 30 Amp Pink –Gas / Brake Vacuum Pump – If Equipped

F10 40 Amp Green –CBC #2 / Ext Lights

F11 40 Amp Green –Brake System Module (ECU and Valves)

8

21_DPF_OM_EN_USC_t.book Page 395

Page 408 of 463

406SERVICING AND MAINTENANCE

2. Rotate the bulb socket a quarter turn and

pull it from the lamp assembly.

Removing Bulb Socket From Clearance Lamp

3. Pull the bulb straight from it's socket and replace.

TIRES

TIRE SAFETY INFORMATION

Tire safety information will cover aspects of the

following information: Tire Markings, Tire

Identification Numbers, Tire Terminology and

Definitions, Tire Pressures, and Tire Loading.

Tire Markings

Tire Markings

NOTE:

P (Passenger) — Metric tire sizing is based on US

design standards. P-Metric tires have the letter “P” molded into the sidewall preceding the size

designation. Example: P215/65R15 95H.

European — Metric tire sizing is based on

European design standards. Tires designed

to this standard have the tire size molded

into the sidewall beginning with the section

width. The letter "P" is absent from this tire

size designation. Example: 215/65R15 96H.

LT (Light Truck) — Metric tire sizing is based

on US design standards. The size designation

for LT-Metric tires is the same as for P-Metric

tires except for the letters “LT” that are

molded into the sidewall preceding the size

designation. Example: LT235/85R16.

Temporary spare tires are designed for

temporary emergency use only. Temporary

high pressure compact spare tires have the

letter “T” or “S” molded into the sidewall

preceding the size designation. Example:

T145/80D18 103M.

High flotation tire sizing is based on US

design standards and it begins with the tire

diameter molded into the sidewall. Example:

31x10.5 R15 LT.

1 — US DOT Safety Standards Code (TIN)

2 — Size Designation

3 — Service Description

4 — Maximum Load

5 — Maximum Pressure

6 — Treadwear, Traction and Tempera

-

ture Grades

21_DPF_OM_EN_USC_t.book Page 406

Page 410 of 463

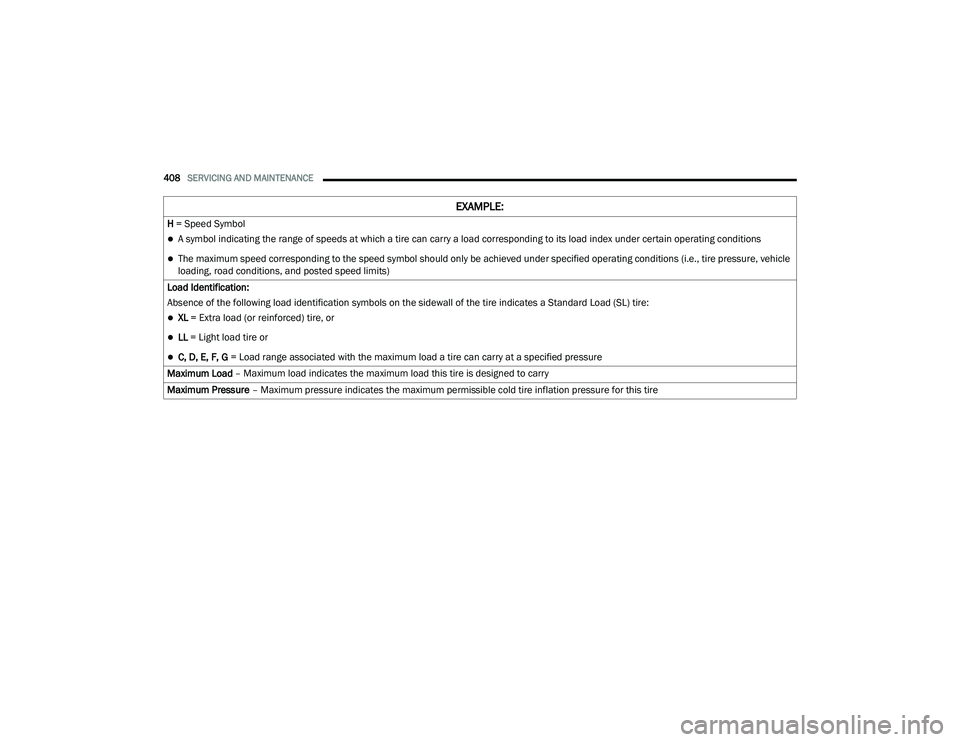

408SERVICING AND MAINTENANCE

H = Speed Symbol

A symbol indicating the range of speeds at which a tire can carry a load corresponding to its load index under certain operating conditions

The maximum speed corresponding to the speed symbol should only be achieved under specified operating conditions (i.e., tire pressure, vehicle

loading, road conditions, and posted speed limits)

Load Identification:

Absence of the following load identification symbols on the sidewall of the tire indicates a Standard Load (SL) tire:

XL = Extra load (or reinforced) tire, or

LL = Light load tire or

C, D, E, F, G = Load range associated with the maximum load a tire can carry at a specified pressure

Maximum Load – Maximum load indicates the maximum load this tire is designed to carry

Maximum Pressure – Maximum pressure indicates the maximum permissible cold tire inflation pressure for this tire

EXAMPLE:

21_DPF_OM_EN_USC_t.book Page 408

Page 433 of 463

431

TECHNICAL SPECIFICATIONS

VEHICLE IDENTIFICATION NUMBER (VIN)

The VIN is found on the left front corner of

the instrument panel, visible through the

windshield.

Vehicle Identification Number

NOTE:

It is illegal to remove or alter the VIN.

BRAKE SYSTEM

If power assist is lost for any reason (for

example, repeated brake applications with

the engine off), the brakes will still function.

However, you will experience a substantial

increase in braking effort to stop the vehicle.

If either the front or rear hydraulic system loses

normal braking capability, the remaining system

will still function with some loss of overall braking

effectiveness. This will be evident by increased

pedal travel during application, greater pedal

force required to slow or stop, and activation of

the “Brake Warning Light” and/or the “ABS

Warning Light” during brake use.

HYDRAULIC BRAKE ASSIST — IF

E

QUIPPED

The brake system power assist is provided by a

hydro-boost unit which shares fluid with the

power steering system. You may experience

some clicking or hissing noises from the

hydro-boost system during hard braking

conditions.

NOTE:

Under cold temperatures, pedal effort will be

higher than normal until the power steering fluid

reaches operating temperature.

9

21_DPF_OM_EN_USC_t.book Page 431