engine RAM CHASSIS CAB 2022 Owners Manual

[x] Cancel search | Manufacturer: RAM, Model Year: 2022, Model line: CHASSIS CAB, Model: RAM CHASSIS CAB 2022Pages: 428, PDF Size: 20.18 MB

Page 359 of 428

SERVICING AND MAINTENANCE357

Checking Coolant Level — 6.4L Engine

The level of the coolant in the pressurized coolant

bottle should be between the “MIN” and “MAX”

range on the bottle when the engine is cold.

The radiator normally remains completely full, so

there is no need to remove the cap unless

checking for coolant freeze point or replacing

engine coolant (antifreeze). Advise your service

attendant of this. As long as the engine operating

temperature is satisfactory, the coolant bottle

need only be checked once a month. When

additional engine coolant is needed to maintain

the proper level, it should be added to the coolant

bottle. Do not overfill.

Cooling System Notes

NOTE:When the vehicle is stopped after a few miles/kilo -

meters of operation, you may observe vapor

coming from the front of the engine compartment.

This is normally a result of moisture from rain,

snow, or high humidity accumulating on the

radiator and being vaporized when the thermostat

opens, allowing hot engine coolant (antifreeze) to

enter the radiator.

If an examination of your engine compartment

shows no evidence of radiator or hose leaks, the

vehicle may be safely driven. The vapor will soon

dissipate.

Do not overfill the coolant expansion bottle.

Check the coolant freeze point in the radiator

and in the coolant expansion bottle. If engine

coolant (antifreeze) needs to be added, the

contents of the coolant expansion bottle must

also be protected against freezing.

If frequent engine coolant additions are

required, the cooling system should be pressure

tested for leaks.

Maintain engine coolant concentration at a

minimum of 50% OAT coolant (conforming to

MS.90032) and distilled water for proper corro -

sion protection of your engine which contains

aluminum components.

Make sure that the coolant expansion bottle

overflow hoses are not kinked or obstructed.

Keep the front of the radiator clean. If your

vehicle is equipped with air conditioning, keep

the front of the condenser clean.

Do not change the thermostat for Summer or

Winter operation. If replacement is ever neces -

sary, install ONLY the correct type thermostat.

Other designs may result in unsatisfactory

engine cooling performance, poor gas mileage,

and increased emissions.

CHARGE AIR COOLER — INTER-COOLER

The charge air cooler is positioned below the

radiator and the air conditioner condenser. Air

enters the engine through the air cleaner and

passes through the turbocharger, where it is

pressurized. This pressurized air rapidly reaches

high temperature. The air is then directed through

a hose to the charge air cooler and through

another hose to the intake manifold of the engine.

The air entering the engine has been cooled by

about 50° to 100°F (10° to 38°C). This cooling

process enables more efficient burning of fuel

resulting in fewer emissions.

To guarantee optimum performance of the system,

keep the surfaces of the charge air cooler,

condenser and radiator clean and free of debris.

Periodically check the hoses leading to and from

the charge air cooler for cracks or loose clamps

resulting in loss of pressure and reduced engine

performance.

8

22_DPF_OM_EN_USC_t.book Page 357

Page 360 of 428

358SERVICING AND MAINTENANCE

(Continued)

BRAKE SYSTEM

In order to ensure brake system performance, all

brake system components should be inspected

periodically Úpage 329.

Fluid Level Check — Brake Master Cylinder

The fluid level of the master cylinder should be

checked when performing under the hood service

or immediately if the Brake System Warning Light

indicates system failure.

If necessary, add fluid to bring level within the

designated marks on the side of the reservoir of

the brake master cylinder. Be sure to clean the top

of the master cylinder area before removing cap.

With disc brakes the fluid level can be expected to

fall as the brake linings wear. However, an

unexpected drop in fluid level may be caused by a

leak and a system check should be conducted.

For further information Ú page 407.

AUTOMATIC TRANSMISSION

Special Additives

The manufacturer strongly recommends against

using any special additives in the transmission.

Automatic Transmission Fluid (ATF) is an

engineered product and its performance may be

impaired by supplemental additives. Therefore, do

not add any fluid additives to the transmission. The

only exception to this policy is the use of special

dyes for diagnosing fluid leaks in 6-speed

transmissions. Avoid using transmission sealers as

they may adversely affect seals.

WARNING!

Riding the brakes can lead to brake failure and

possibly a collision. Driving with your foot resting

or riding on the brake pedal can result in

abnormally high brake temperatures, excessive

lining wear, and possible brake damage. You

would not have your full braking capacity in an

emergency.

WARNING!

Use only manufacturer's recommended brake

fluid Úpage 407. Using the wrong type of

brake fluid can severely damage your brake

system and/or impair its performance. The

proper type of brake fluid for your vehicle is

also identified on the original factory installed

hydraulic master cylinder reservoir.

To avoid contamination from foreign matter or

moisture, use only new brake fluid or fluid that

has been in a tightly closed container. Keep

the master cylinder reservoir cap secured at

all times. Brake fluid in an open container

absorbs moisture from the air resulting in a

lower boiling point. This may cause it to boil

unexpectedly during hard or prolonged

braking, resulting in sudden brake failure. This

could result in a collision.

Overfilling the brake fluid reservoir can result

in spilling brake fluid on hot engine parts,

causing the brake fluid to catch fire. Brake

fluid can also damage painted and vinyl

surfaces, care should be taken to avoid its

contact with these surfaces.

Do not allow petroleum based fluid to contam -

inate the brake fluid. Brake seal components

could be damaged, causing partial or

complete brake failure. This could result in a

collision.

CAUTION!

Do not use chemical flushes in your

transmission as the chemicals can damage your

transmission components. Such damage is not

covered by the New Vehicle Limited Warranty.

WARNING!

22_DPF_OM_EN_USC_t.book Page 358

Page 361 of 428

SERVICING AND MAINTENANCE359

Fluid Level Check — 8-Speed Transmission

The fluid level is preset at the factory and does not

require adjustment under normal operating

conditions. Routine fluid level checks are not

required, therefore the transmission has no

dipstick. An authorized dealer can check your

transmission fluid level using special service tools.

If you notice fluid leakage or transmission

malfunction, visit an authorized dealer

immediately to have the transmission fluid level

checked. Operating the vehicle with an improper

fluid level can cause severe transmission damage.

Fluid Level Check — 6-Speed Transmission

It is best to check the fluid level when the

transmission is at normal operating temperature

(158-176°F / 70-80°C). This normally occurs

after at least 15 miles (25 km) of driving. At normal

operating temperature the fluid cannot be held

comfortably between the fingertips. You can read

the transmission sump temperature in the

instrument cluster screen Ú page 81.Use the following procedure to check the

transmission fluid level properly:

1. Monitor the transmission temperature using

the instrument cluster display, and operate

the vehicle as required to reach the normal

operating temperature. If the transmission is

not functioning properly, or the vehicle cannot

be driven, see the NOTE and CAUTION below

about checking the fluid level at colder

temperatures.

2. Park the vehicle on level ground.

3. Run the engine at normal idle speed for at least 60 seconds, and leave the engine

running for the rest of this procedure.

4. Fully apply the parking brake, and press the brake pedal.

5. Place the gear selector momentarily into each gear position (allowing time for the

transmission to fully engage in each position),

ending with the transmission in PARK.

6. Remove the dipstick, wipe it clean and reinsert it until seated.

7. Remove the dipstick again and note the fluid level on both sides. The fluid level reading is

only valid if there is a solid coating of oil on

both sides of the dipstick. Note that the holes

in the dipstick will be full of fluid if the actual

level is at or above the hole. The fluid level

should be between the “HOT” (upper) reference holes on the dipstick at normal

operating temperature. If the fluid level is low,

add fluid through the dipstick tube to bring it to

the proper level.

Do not overfill. Use ONLY the

specified fluid Ú page 407. After adding any

quantity of oil through the dipstick tube, wait a

minimum of two minutes for the oil to fully

drain into the transmission before rechecking

the fluid level.

NOTE:If it is necessary to check the transmission below

the operating temperature, the fluid level should

be between the two “COLD” (lower) holes on the

dipstick with the fluid at 60-70°F / 16-21°C. Only

use the COLD region of the dipstick as a rough

reference when setting the fluid level after a trans -

mission service or fluid change. Re-check the fluid

level, and adjust as required, once the trans -

mission reaches normal operating temperature.

8. Reinsert the dipstick. Check for leaks. Release the parking brake.

CAUTION!

If a transmission fluid leak occurs, visit an

authorized dealer immediately. Severe

transmission damage may occur. An authorized

dealer has the proper tools to adjust the fluid

level accurately.

CAUTION!

If the fluid temperature is below 50°F (10°C) it

may not register on the dipstick. Do not add fluid

until the temperature is elevated enough to

produce an accurate reading. Run the engine at

idle, in PARK, to warm the fluid.

8

22_DPF_OM_EN_USC_t.book Page 359

Page 362 of 428

360SERVICING AND MAINTENANCE

NOTE:If it is necessary to check the transmission below

the operating temperature, the fluid level should

be between the two COLD (lower) holes on the

dipstick with the fluid at 68-86°F / 20-30°C. Only

use the COLD region of the dipstick as a rough

reference when setting the fluid level after a trans -

mission service or fluid change. Re-check the fluid

level, and adjust as required, once the trans -

mission reaches normal operating temperature.

Fluid And Filter Changes — 8-Speed

Transmission

Under normal operating conditions, the fluid

installed at the factory will provide satisfactory

lubrication for the life of the vehicle.

Routine fluid and filter changes are not required.

However, change the fluid and filter if the fluid

becomes contaminated (with water, etc.), or if the

transmission is disassembled for any reason.

Fluid And Filter Changes — 6-Speed

Transmission

For the proper maintenance intervals Úpage 329.

In addition, change the fluid and filters if the fluid

becomes contaminated (with water, etc.), or if the

transmission is disassembled for any reason.

Selection Of Lubricant

It is important to use the proper transmission fluid

to ensure optimum transmission performance and

life. Use only the manufacturer’s specified

transmission fluid Ú page 407. It is important to

maintain the transmission fluid at the correct level

using the recommended fluid. No chemical flushes

should be used in any transmission; only the

approved lubricant should be used.

REAR AXLE AND 4X4 FRONT DRIVING

A

XLE FLUID LEVEL

For normal service, periodic fluid level checks are

not required. When the vehicle is serviced for other

reasons the exterior surfaces of the axle assembly

should be inspected. If gear oil leakage is

suspected inspect the fluid level. This inspection

should be made with the vehicle in a level position.

When checking the fluid level, the vehicle should

be in a level position. The fluid level at room

temperature should be as follows:

3500 Front Axle: ¼ inch ± ¼ inch (6.4 mm ±

6.4 mm) below the bottom of the fill hole.

3500 Rear Axle: ¼ inch ± ¼ inch (6.4 mm ±

6.4 mm) below the bottom of the fill hole.

4500/5500 Front Axle: ¼ inch +/- ¼ inch (6.4 mm

± 6.4 mm) below the bottom of the fill hole.

4500/5500 Rear Axle: 1/8 inch +/- 1/8 inch

(3.2 mm +/- 3.2 mm) below the bottom of the fill

hole.

CAUTION!

If the fluid temperature is below 50°F (10°C) it

may not register on the dipstick. Do not add fluid

until the temperature is elevated enough to

produce an accurate reading. Run the engine at

idle, in PARK, to warm the fluid.

CAUTION!

Using a transmission fluid other than the

manufacturer’s recommended fluid may cause

deterioration in transmission shift quality and/or

torque converter shudder, and (for 6-speed

transmissions) will require more frequent fluid

and filter changes Ú page 407.

22_DPF_OM_EN_USC_t.book Page 360

Page 364 of 428

362SERVICING AND MAINTENANCE

Exhaust System

Inspect the entire exhaust system for leaks and

damaged parts. Devices such as hangers, clamps,

and U-bolts should be tight and in good condition.

Damaged components, burned or blown out

mufflers, burned or rusted out exhaust pipes

should be replaced according to the procedures

and specifications outlined in the appropriate

service manual.

Air Cleaner Assembly

Inspect air cleaner housing for proper assembly

and fit. Make certain that the air cleaner is properly

positioned and that the cover is tight. Check all

hoses leading to the air cleaner for tightness. The

air filter element must also be clean and serviced

according to the instructions outlined in the

Scheduled Maintenance section of this manual.

Tampering With Noise Control System

Prohibited

Federal law prohibits the following acts or the

causing thereof: (1) the removal or rendering

inoperative by any person, other than for purposes

of maintenance, repair, or replacement, of any

device or element of design incorporated into any

new vehicle for the purpose of noise control prior to

its sale or delivery to the ultimate purchaser or

while it is in use, or (2) the use of the vehicle after

such device or element of design has been

removed or rendered inoperative by any person.

Among those acts presumed to constitute

tampering are the acts listed below.

AIR CLEANER

Removal of the air cleaner.

Removal of the air cleaner filter element from

the air cleaner housing.

Removal of the air ducting.

EXHAUST SYSTEM

Removal or rendering inoperative exhaust

system components including the muffler or tail -

pipe. ENGINE COOLING SYSTEM

Removal or rendering inoperative the fan clutch.

Removal of the fan shroud.

Noise Emission Warranty

The manufacturer warrants that this vehicle as

manufactured by the manufacturer, was designed,

built and equipped to conform at the time it left the

manufacturer's control with all applicable US EPA

Noise Control Regulations.

This warranty covers this vehicle as designed, built

and equipped by the manufacturer, and is not

limited to any particular part, component or system

of the vehicle manufactured by the manufacturer.

Defects in design, assembly or in any part,

component or system of the vehicle as

manufactured by the manufacturer, which, at the

time it left the manufacturer's control, caused

noise emissions to exceed Federal standards, are

covered by this warranty for the life of the vehicle.

22_DPF_OM_EN_USC_t.book Page 362

Page 365 of 428

SERVICING AND MAINTENANCE363

Maintenance Log and Service Chart (Diesel Engines)

Noise Systems Maintenance Chart and Service Log — Insert Month, Day, Year under column mileage closest to the mileage at which service was

performed.

MILES 7,500 15,000 22,500 30,000 37,500 45,000 52,500 60,000

KILOMETERS 12,000 24,000 36,000 48,000 60,000 72,000 84,000 96,000

Exhaust system-inspect

Air cleaner assembly-inspect

ODOMETER READING

PERFORMED BY

PERFORMED AT

MILES 67,500 75,000 82,500 90,000 97,500 105,000 112,500 120,000

KILOMETERS 108,000 120,000 132,000 144,000 156,000 168,000 180,000 192,000

Exhaust system-inspect

Air cleaner assembly-inspect

ODOMETER READING

PERFORMED BY

PERFORMED AT

8

22_DPF_OM_EN_USC_t.book Page 363

Page 366 of 428

364SERVICING AND MAINTENANCE

FUSES

General Information

The fuses protect electrical systems against

excessive current.

When a device does not work, you must check the

fuse element inside the blade fuse for a break/

melt.

Also, please be aware that using power outlets for

extended periods of time with the engine off may

result in vehicle battery discharge.

Blade Fuses

Power Distribution Center

The Power Distribution Center is located in the

engine compartment near the battery. This center

contains cartridge fuses, micro fuses, relays, and

circuit breakers. A description of each fuse and

component may be stamped on the inside cover,

otherwise the cavity number of each fuse is

stamped on the inside cover that corresponds to

the following chart.

WARNING!

When replacing a blown fuse, always use an

appropriate replacement fuse with the same

amp rating as the original fuse. Never replace

a fuse with another fuse of higher amp rating.

The use of a fuse with a rating other than indi -

cated may result in a dangerous electrical

system overload. If a properly rated fuse

continues to blow, it indicates a problem in the

circuit that must be corrected. Never replace a

blown fuse with metal wires or any other mate -

rial. Do not place a fuse inside a circuit

breaker cavity or vice versa. Failure to use

proper fuses may result in serious personal

injury, fire and/or property damage.

Before replacing a fuse, make sure that the

ignition is off and that all the other services

are switched off and/or disengaged.

If the replaced fuse blows again, contact an

authorized dealer.

If a general protection fuse for safety systems

(air bag system, braking system), power unit

systems (engine system, transmission

system) or steering system blows, contact an

authorized dealer.

1 — Fuse Element

2 — Blade Fuse with a good/functional fuse

element

3 — Blade fuse with a bad/not functional fuse

element (blown fuse)

CAUTION!

When installing the power distribution center

cover, it is important to ensure the cover is

properly positioned and fully latched. Failure to

do so may allow water to get into the power

distribution center and possibly result in an

electrical system failure.

CAUTION!

If it is necessary to wash the engine

compartment, take care not to directly hit the

fuse box or the windshield wiper motors with

water.

22_DPF_OM_EN_USC_t.book Page 364

Page 399 of 428

397

TECHNICAL SPECIFICATIONS

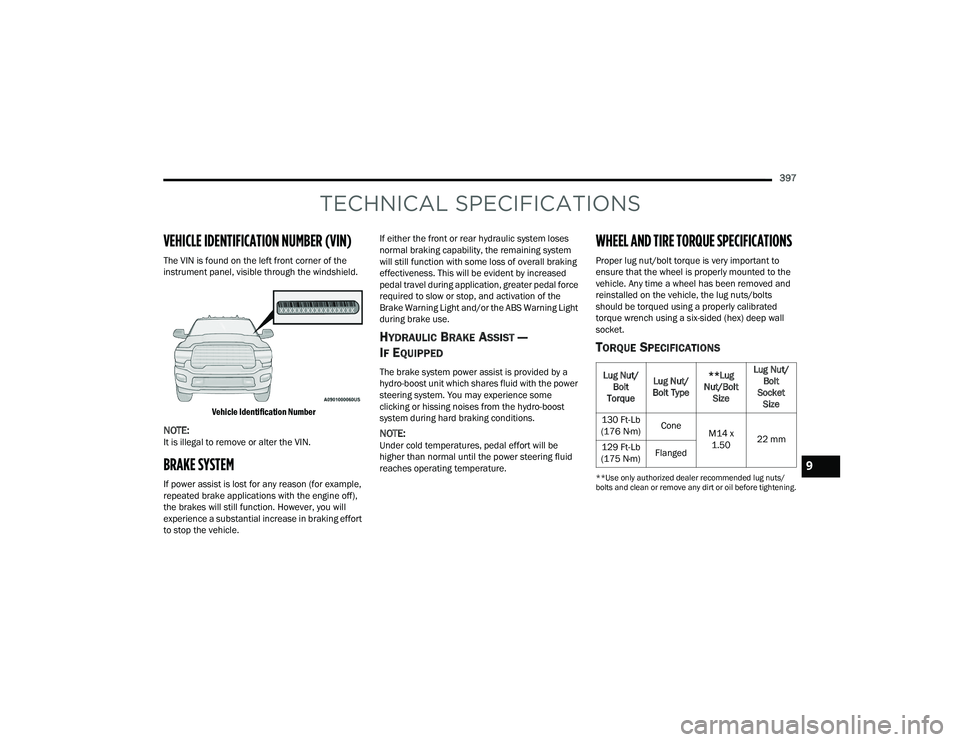

VEHICLE IDENTIFICATION NUMBER (VIN)

The VIN is found on the left front corner of the

instrument panel, visible through the windshield.

Vehicle Identification Number

NOTE:It is illegal to remove or alter the VIN.

BRAKE SYSTEM

If power assist is lost for any reason (for example,

repeated brake applications with the engine off),

the brakes will still function. However, you will

experience a substantial increase in braking effort

to stop the vehicle. If either the front or rear hydraulic system loses

normal braking capability, the remaining system

will still function with some loss of overall braking

effectiveness. This will be evident by increased

pedal travel during application, greater pedal force

required to slow or stop, and activation of the

Brake Warning Light and/or the ABS Warning Light

during brake use.

HYDRAULIC BRAKE ASSIST —

I

F EQUIPPED

The brake system power assist is provided by a

hydro-boost unit which shares fluid with the power

steering system. You may experience some

clicking or hissing noises from the hydro-boost

system during hard braking conditions.

NOTE:Under cold temperatures, pedal effort will be

higher than normal until the power steering fluid

reaches operating temperature.

WHEEL AND TIRE TORQUE SPECIFICATIONS

Proper lug nut/bolt torque is very important to

ensure that the wheel is properly mounted to the

vehicle. Any time a wheel has been removed and

reinstalled on the vehicle, the lug nuts/bolts

should be torqued using a properly calibrated

torque wrench using a six-sided (hex) deep wall

socket.

TORQUE SPECIFICATIONS

**Use only authorized dealer recommended lug nuts/

bolts and clean or remove any dirt or oil before tightening.

Lug Nut/

Bolt

Torque Lug Nut/

Bolt Type **Lug

Nut/Bolt Size Lug Nut/

Bolt

Socket Size

130 Ft-Lb

(176 N·m) Cone

M14 x

1.50 22 mm

129 Ft-Lb

(175 N·m) Flanged

9

22_DPF_OM_EN_USC_t.book Page 397

Page 401 of 428

TECHNICAL SPECIFICATIONS399

final torque in increments. Progress around the

bolt circle, tightening the wheel nut opposite to the

wheel nut just previously tightened until final

torque is achieved.

FUEL REQUIREMENTS— GASOLINE ENGINE

While operating on gasoline with the required

octane number, hearing a light knocking sound

from the engine is not a cause for concern.

However, if the engine is heard making a heavy

knocking sound, see a dealer immediately. Use of

gasoline with a lower than recommended octane

number can cause engine failure and may void or

not be covered by the New Vehicle Limited

Warranty.

Poor quality gasoline can cause problems such as

hard starting, stalling, and hesitations. If you

experience these symptoms, try another brand of

gasoline before considering service for the vehicle.

6.4L ENGINE

Do not use E-85 flex fuel or ethanol blends greater

than 15% in this engine. This engine is designed to meet all

emissions regulations and provide

satisfactory fuel economy and

performance when using high quality

unleaded gasoline having a posted octane number

of 87 as specified by the (R+M)/2 method.

REFORMULATED GASOLINE

Many areas of the country require the use of

cleaner-burning gasoline referred to as

“reformulated gasoline”. Reformulated gasoline

contains oxygenates and are specifically blended

to reduce vehicle emissions and improve air

quality.

The use of reformulated gasoline is recommended.

Properly blended reformulated gasoline will

provide improved performance and durability of

engine and fuel system components.

MATERIALS ADDED TO FUEL

Besides using unleaded gasoline with the proper

octane rating, gasolines that contain detergents,

corrosion and stability additives are

recommended. Using gasolines that have these

additives will help improve fuel economy, reduce

emissions, and maintain vehicle performance. Designated TOP TIER Detergent Gasoline

contains a higher level of detergents to

further aide in minimizing engine and

fuel system deposits. When available,

the usage of TOP TIER Detergent Gasoline is

recommended. Visit www.toptiergas.com for a list

of TOP TIER Detergent Gasoline Retailers.

Indiscriminate use of fuel system cleaning agents

should be avoided. Many of these materials

intended for gum and varnish removal may contain

active solvents or similar ingredients. These can

harm fuel system gasket and diaphragm materials.

GASOLINE/OXYGENATE BLENDS

Some fuel suppliers blend unleaded gasoline with

oxygenates such as ethanol.

WARNING!

To avoid the risk of forcing the vehicle off the

jack, do not tighten the lug nuts/bolts fully until

the vehicle has been lowered. Failure to follow

this warning may result in personal injury.

CAUTION!

DO NOT use E-85, gasoline containing methanol,

or gasoline containing more than 15% ethanol

(E-15). Use of these blends may result in starting

and drivability problems, damage critical fuel

system components, cause emissions to exceed

the applicable standard, and/or cause the

Malfunction Indicator Light to illuminate. Please

observe pump labels as they should clearly

communicate if a fuel contains greater than

15% ethanol (E-15).

9

22_DPF_OM_EN_USC_t.book Page 399

Page 402 of 428

400TECHNICAL SPECIFICATIONS

(Continued)

Problems that result from using gasoline

containing more than 15% ethanol (E-15) or

gasoline containing methanol are not the

responsibility of the manufacturer and may void or

not be covered under New Vehicle Limited

Warranty.

DO NOT USE E-85 IN NON-FLEX FUEL

V

EHICLES

Non-Flex Fuel Vehicles (FFV) are compatible with

gasoline containing up to 15% ethanol (E-15). Use

of gasoline with higher ethanol content may void

the New Vehicle Limited Warranty.

If a Non-FFV vehicle is inadvertently fueled with

E-85 fuel, the engine will have some or all of these

symptoms:

Operate in a lean mode.

OBD II Malfunction Indicator Light on.

Poor engine performance.

Poor cold start and cold drivability.

Increased risk for fuel system component corro -

sion.

CNG AND LP FUEL SYSTEM

M

ODIFICATIONS

Modifications that allow the engine to run on

Compressed Natural Gas (CNG) or Liquid Propane

(LP) may result in damage to the engine, emissions, and fuel system components. Problems

that result from running CNG or LP are not the

responsibility of the manufacturer and may void or

not be covered under the New Vehicle Limited

Warranty.

METHYLCYCLOPENTADIENYL

M

ANGANESE TRICARBONYL (MMT) IN

G

ASOLINE

MMT is a manganese-containing metallic additive

that is blended into some gasoline to increase

octane. Gasoline blended with MMT provides no

performance advantage beyond gasoline of the

same octane number without MMT. Gasoline

blended with MMT reduces spark plug life and

reduces emissions system performance in some

vehicles. The manufacturer recommends that

gasoline without MMT be used in your vehicle. The

MMT content of gasoline may not be indicated on

the gasoline pump; therefore, you should ask your

gasoline retailer whether the gasoline contains

MMT. MMT is prohibited in Federal and California

reformulated gasoline.

FUEL SYSTEM CAUTIONSNOTE:Intentional tampering with the emissions control

system can result in civil penalties being assessed

against you.

CAUTION!

Follow these guidelines to maintain your

vehicle’s performance:

The use of leaded gasoline is prohibited by

Federal law. Using leaded gasoline can impair

engine performance and damage the emis -

sions control system.

An out-of-tune engine or certain fuel or ignition

malfunctions can cause the catalytic

converter to overheat. If you notice a pungent

burning odor or some light smoke, your engine

may be out of tune or malfunctioning and may

require immediate service. Contact an autho -

rized dealer for service assistance.

The use of fuel additives, which are now being

sold as octane enhancers, is not recom -

mended. Most of these products contain high

concentrations of methanol. Fuel system

damage or vehicle performance problems

resulting from the use of such fuels or addi -

tives is not the responsibility of the manufac-

turer and may void or not be covered under

the New Vehicle Limited Warranty.

CAUTION!

22_DPF_OM_EN_USC_t.book Page 400